Cheesemaker Yoav Perry writes:

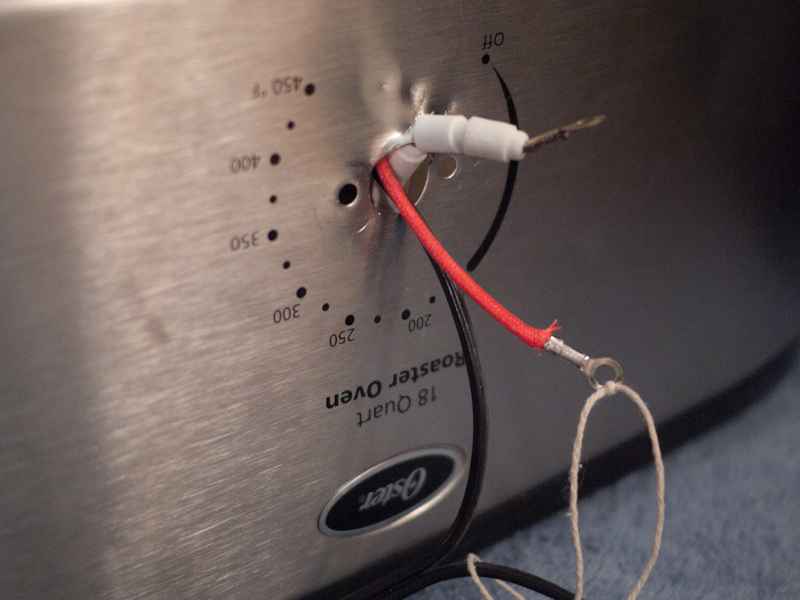

When I began thinking about a sous vide machine that would not cost $400-$5000, I immediately began to understand the enormous potential it has to make a perfect cheese vat. At first, I did sous vide in the cheese vat and that’s where I met Lisa and Abe who inspired me to get a proper digital apparatus of controller and heater in there on the cheap and accurate. I then embarked on finding a form factor that can combine both uses: cheesemaking and sous vide.

See the original post on our blog.