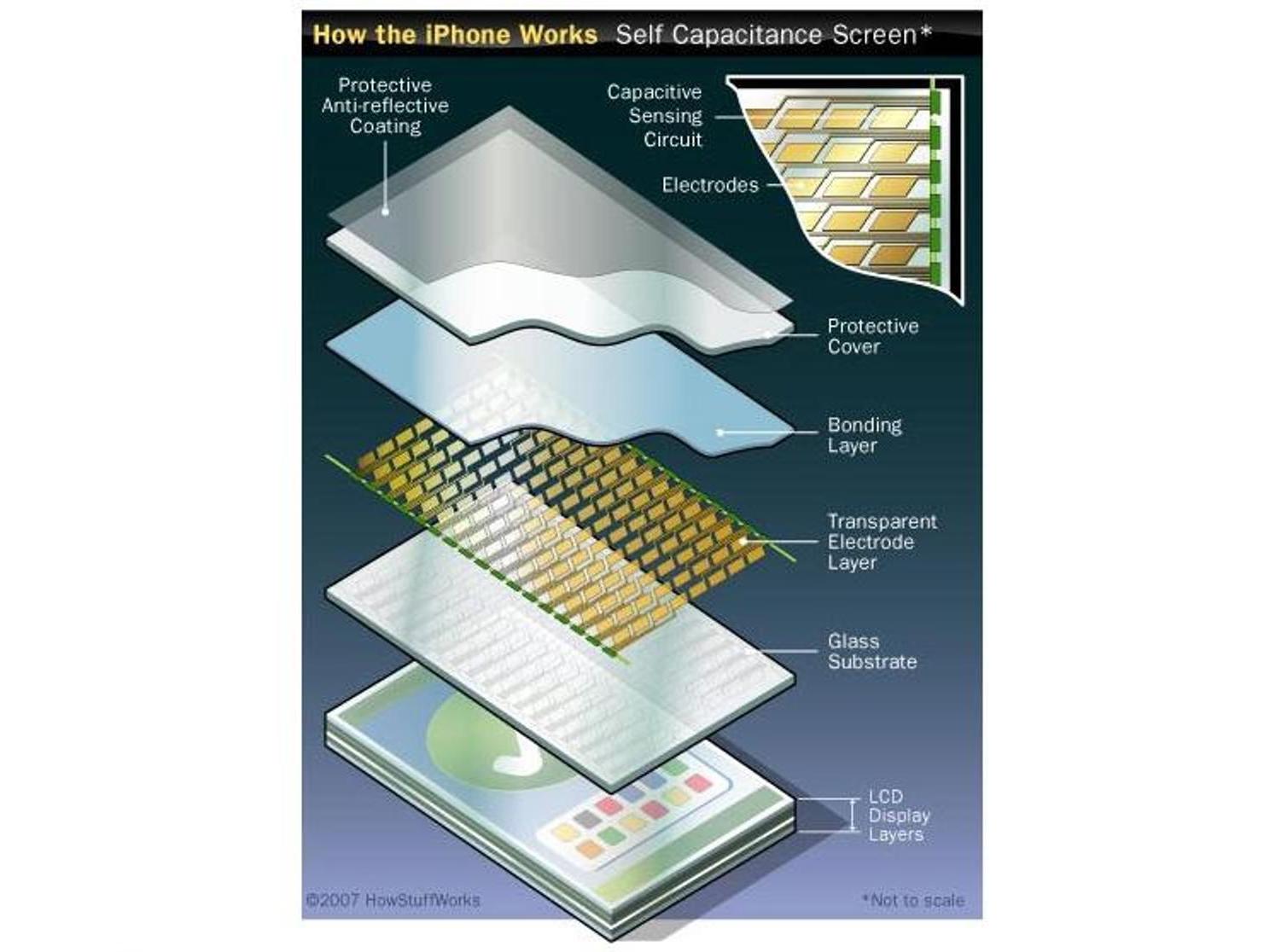

In general, capacitive touch screens work by using an array of sensors to monitor the electrostatic field around the screen. When your finger touches the screen, it changes the electrical capacitance of that portion of the screen. The microprocessor captures, filters, and analyzes the data. Then it calculates where the touch occurred.

When a stylus is used, the same principles apply. The only difference is that the stylus is acting as a conductor to transmit electrical charge between your hand and the phone. In order to function properly, a capacitive stylus must meet several criteria.

1. A conductive surface: It must be able to conduct an electrical charge between your hand and the screen. If the material is too resistive or if the distance between your hand and the screen is too great, the signal reaching the screen may be too weak to be detected.

2. At least 1/4 inch wide: When filtering data, the processor ignores areas that are significantly smaller than a human finger tip. This helps avoid unintentional activation. Having a stylus that is about 1/4 inch wide will ensure that there is enough surface area to be detected.

3. A relatively flat end: Having a flat tip ensures that the whole face can get close enough to the screen to be detected.

4. A smooth surface: This will ensure that you don’t scratch up your screen

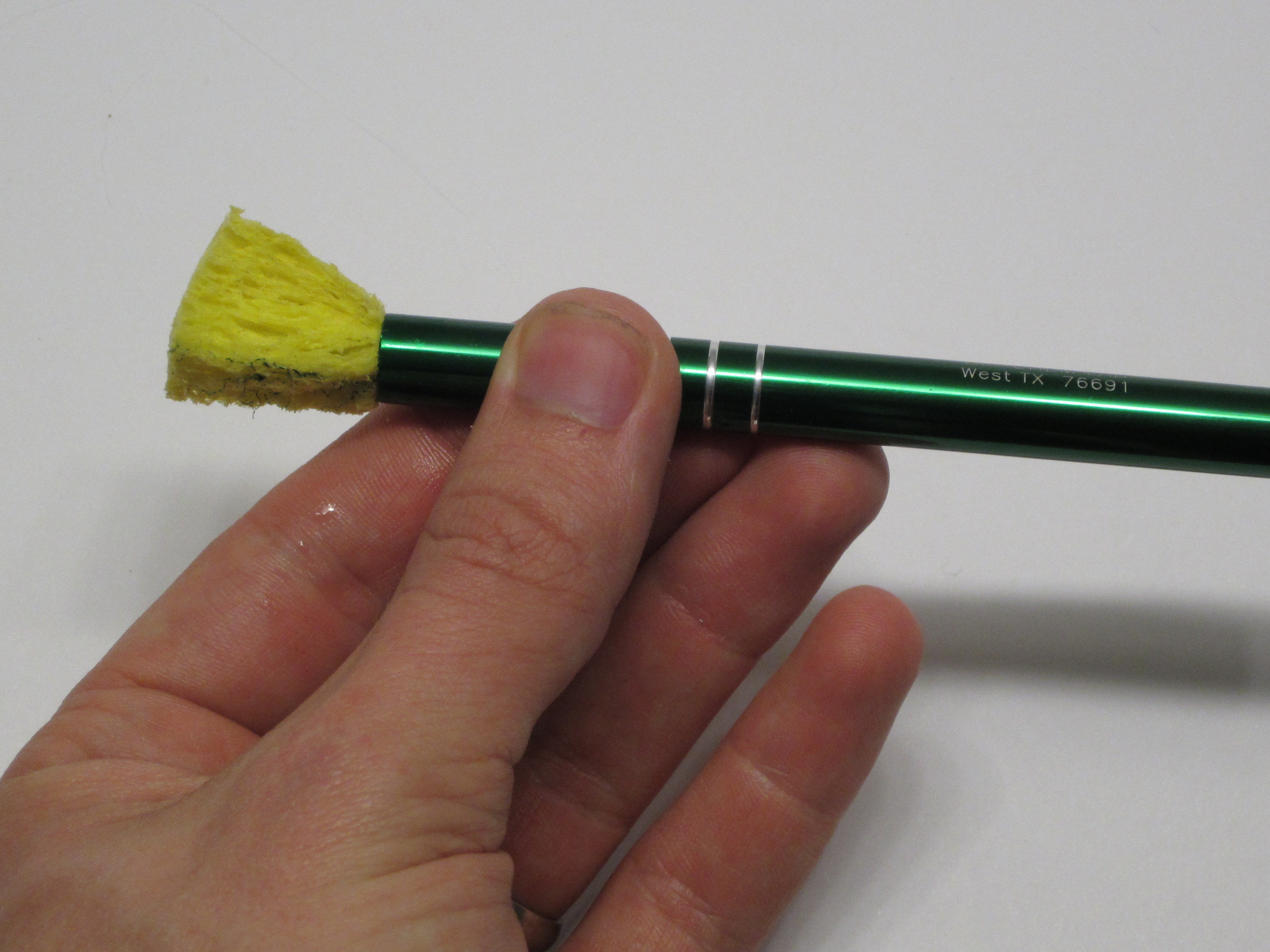

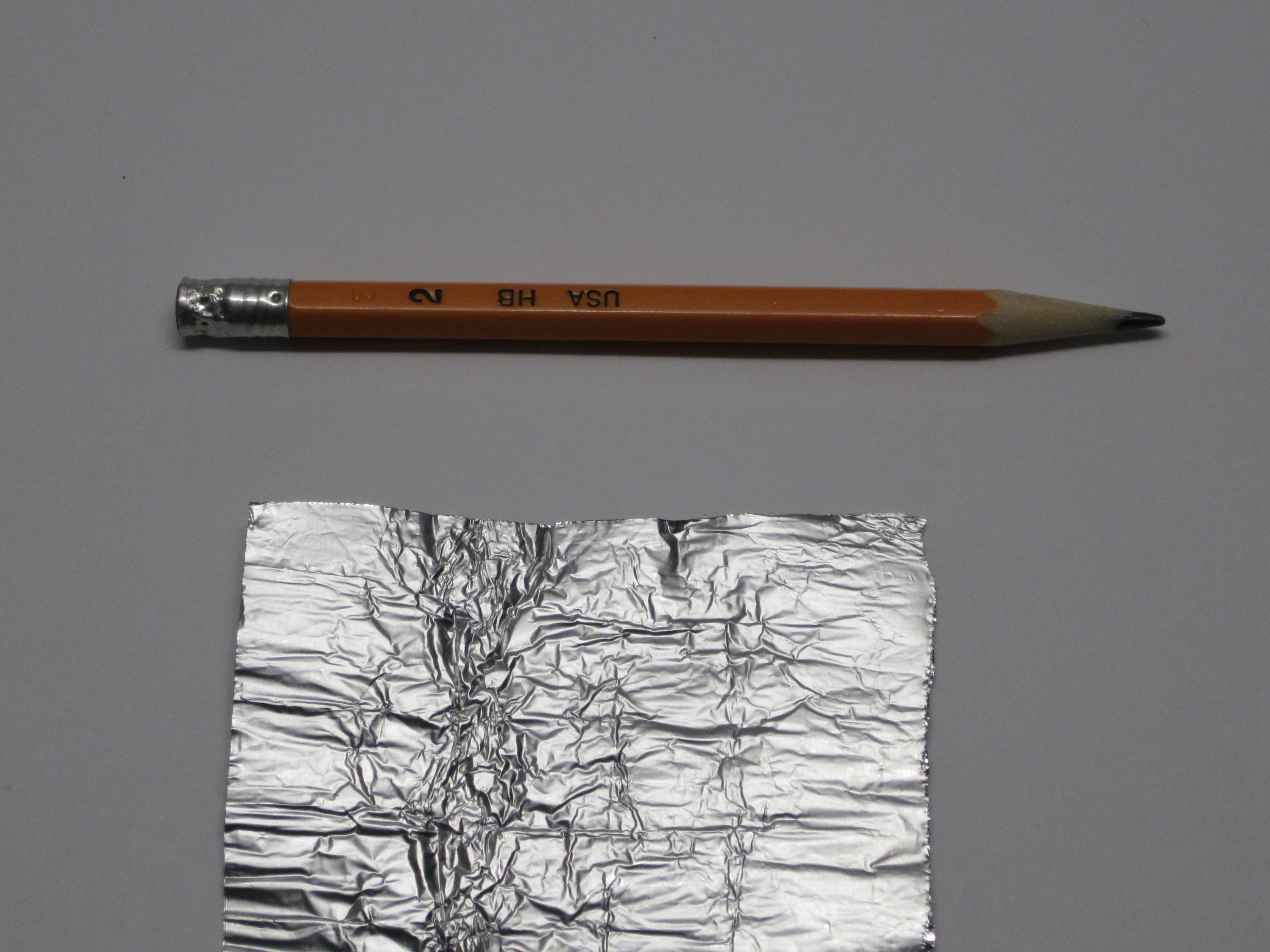

Following these criteria, you can find a wide variety of common items that can be used to activate a capacitive touch screen. Here are five of my favorite designs for a DIY capacitive stylus