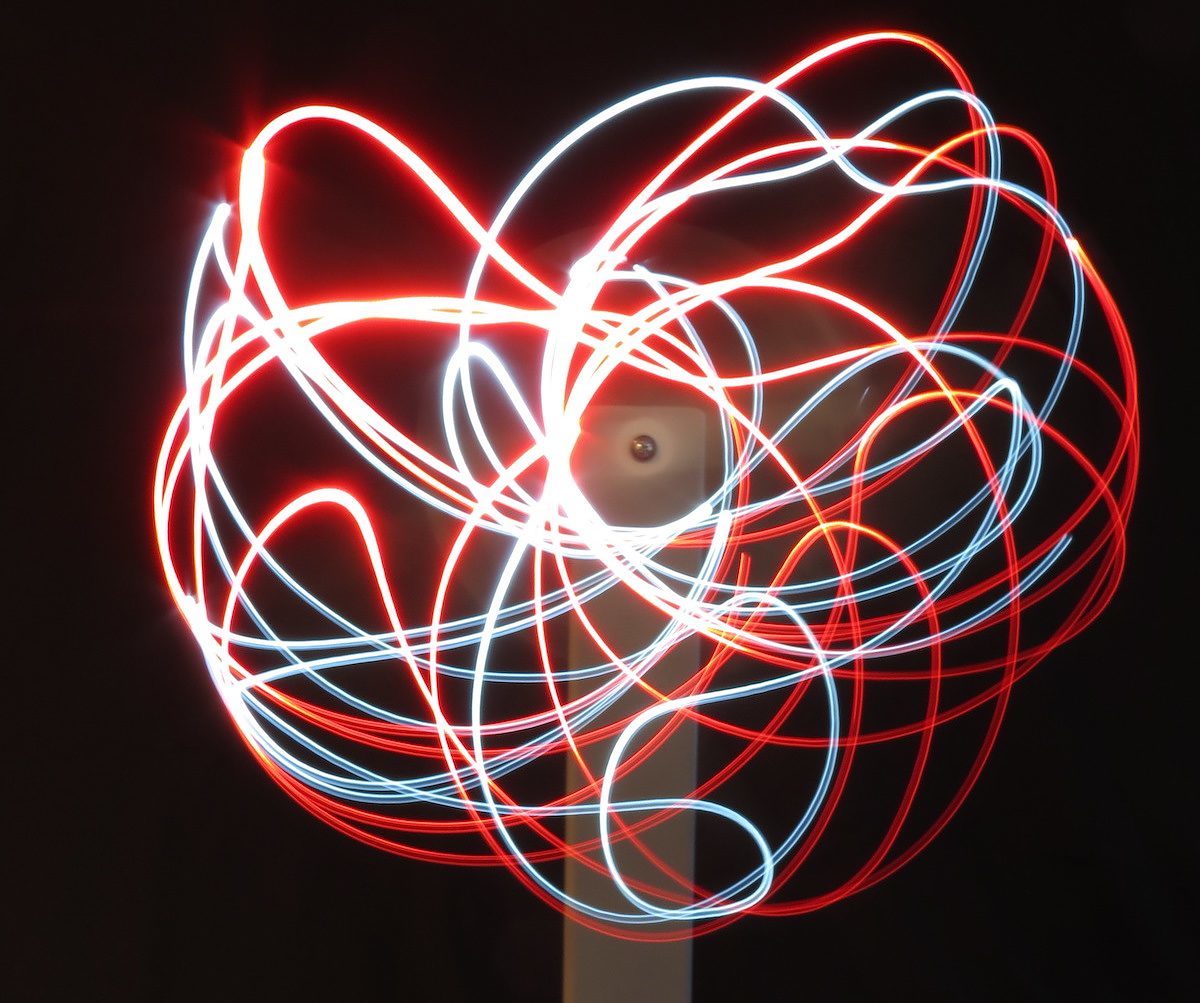

When Dr. Robert Reed, a Ph.D. at North Carolina State University, spotted the fascinating “Double Pendulum” project by William Gurstelle in a 5-year-old copy of Make: (Volume 22, April 2010), he asked us if we’d build two such pendulum rigs to help teach chaos theory to his students. He wanted the rigs to be portable for quick setup anywhere, with red and white LEDs (NC State colors) for creating arty, abstract time exposures.

[youtube https://youtu.be/tlh489Gkw7s]We began by building a sturdy wooden stand (Figure A) capable of handling the sometimes-violent slinging forces generated by the crazily gyrating pendulum arms. We fastened the parts with wood glue and 2½” screws. The 2×4s at the bottom cross with a half-lap joint. We added four rubber feet for stability and painted the stand flat gray to minimize reflections during photography.

Otherwise we pretty much followed Bill Gurstelle’s specs for the components. We used precision U.S.-sized bearings (¾” OD × ¼” ID × 9/32″ thick) so a U.S.-standard ¾” spade bit and assembly hardware would work. We super-glued them into acrylic arms, which we painted white for good visibility in motion. We added red stripes on the short arms to indicate placement of the LED pods. We also used standard ½” diameter plastic spacers, and chose ¼” thick foam for the Rott spacer.