We are surrounded by electromagnetic forces, which go largely undetected but are vital to modern technology. Electromagnetic field (EMF) radiation comes from natural phenomena like the planets in our solar system, the heat of a burning fire, the lightning from a storm, and even the beating of a heart. It also emanates from human-made inventions like cellphones, Wi-Fi and other radio signals, lightbulbs, X-rays, microwaves, and much more.

Anything that produces an electric current will emit EMF radiation, creating invisible electronic fields all around us. The EMF Explorer project offers a unique opportunity to tune in and listen, by transforming electromagnetic activity into audible sound. It’s like giving a voice to the silent but constant companions of our electronic era.

The EMF Explorer Project

While this circuit amplifies the majority of EMF signals it picks up, we will only be able to hear those that fall within the frequency range of human hearing, about 20Hz–20kHz. This also happens to be the frequency range that most of our electronic appliances operate within!

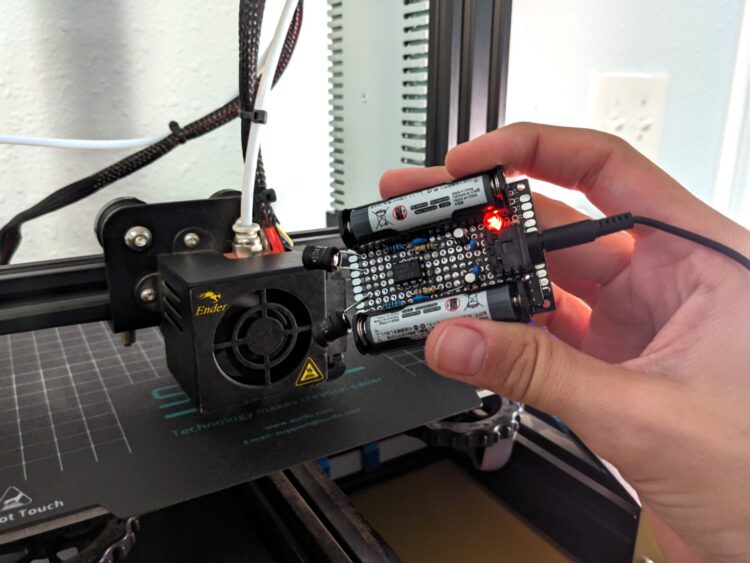

Imagine hearing the electronic operations of your cellphone, the rhythmic patterns emitted by Bluetooth headphones, or the electronic harmonies of countless devices whirring along in our lives. This article will guide you through creating your own EMF amplifier at home with minimal parts.

The Project at a Glance

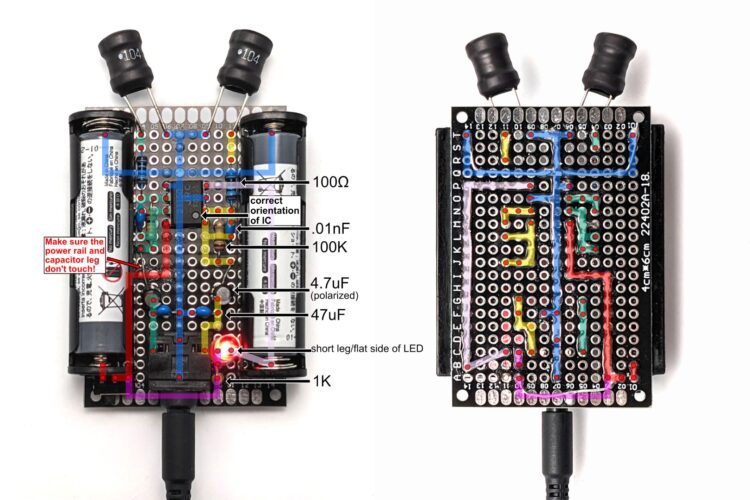

Originally used in an exploratory electronics soldering workshop, this project allows participants to assemble their own EMF Explorer PCB. Inspired by Jonas Gruska’s Elektrosluch circuit and DIY Circuits’ Electromagnetic Field Detector, the circuit was modified to use a smaller battery source, simplified voltage divider, different amplifier and low-pass filter, and optimized to be worn as a wearable PCB badge.

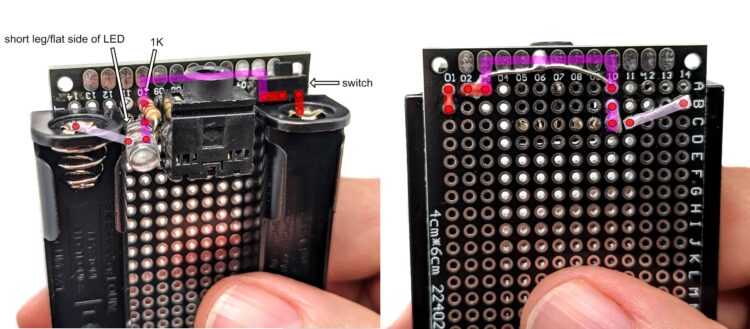

This badge encourages participants to explore the electronics world around them and opens up opportunities for learning about physics, electronic theory, audio applications, and more. It requires only basic electronics know-how and just a handful of components.

Deep Dive Into the Components

- Protoboard lets you solder the connections in a durable configuration that should last years.

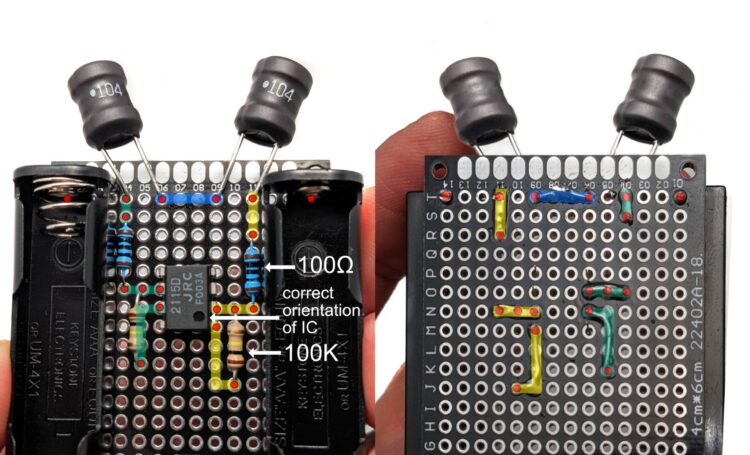

- Inductors are the “sensors” that pick up EMF frequencies and translate them into a measurable signal. Inside are tightly wound coils of wire which, when exposed to an EMF signal, will react and generate a current from the electromagnetic waves in the air.

- Op-amp and resistors amplify the inductors’ signal to be loud enough to drive a speaker. We wire up the operational amplifier to create an inverting amplifier, whose gain is determined by the two resistor values connected to the op-amp.

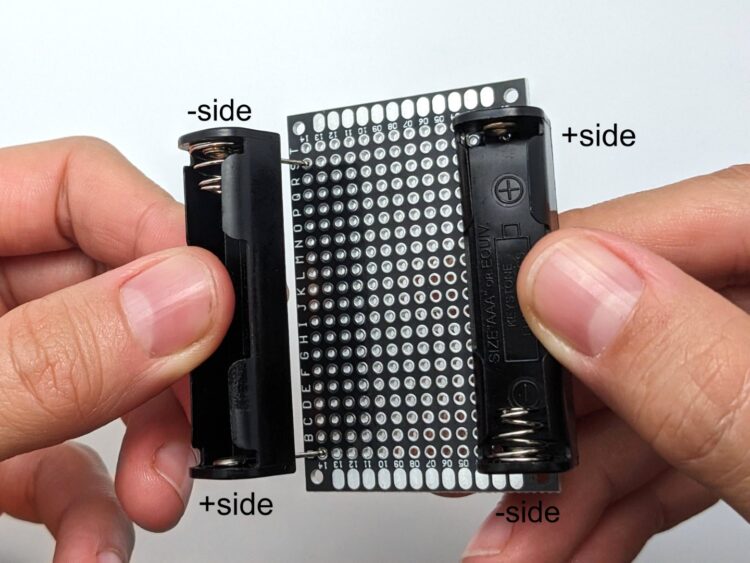

- AAA batteries and holders provide the necessary dual-voltage supply for the op-amp.

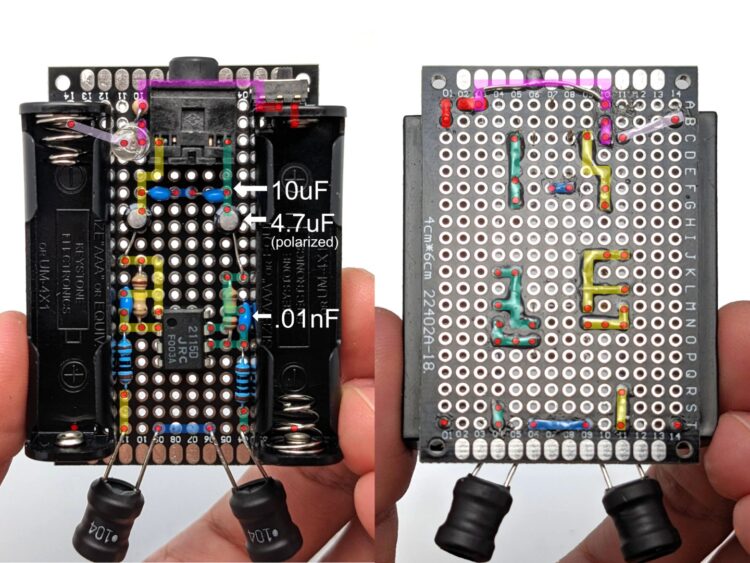

- Capacitors sculpt the signal, shaping and filtering the electromagnetic waveforms. The .01nF capacitors help to stabilize the output of the op-amp from the massive gains we are pulling from it. Optional 10µF capacitors act as a low pass filter, cutting out some of the high frequencies for easier listening. Experiment and decide which sounds you prefer.