Joe Bowers is sneaky, resourceful, and rotten to the core. Whatever you do, don’t get in a prank war with him.

Returning to my desk from a coffee break, I sat down, grabbed my mouse, and … nothing. The cursor was stuck to the left wall of my monitor. I shook my mouse wildly. The cursor moved up and down just fine. But when I jerked my mouse viciously to the right, the cursor nudged a little, then slammed back to its new favorite position, clinging maddeningly to the leftmost pixel.

Blowing on the mouse’s nether regions didn’t help, so my officemate, Hide Yosumi, took pity on me. “Do you hear something?” he asked knowingly. There was a high-pitched whine coming from behind my workstation. I looked and saw that a strange mouse was plugged in. Not just any mouse. A prank mouse.

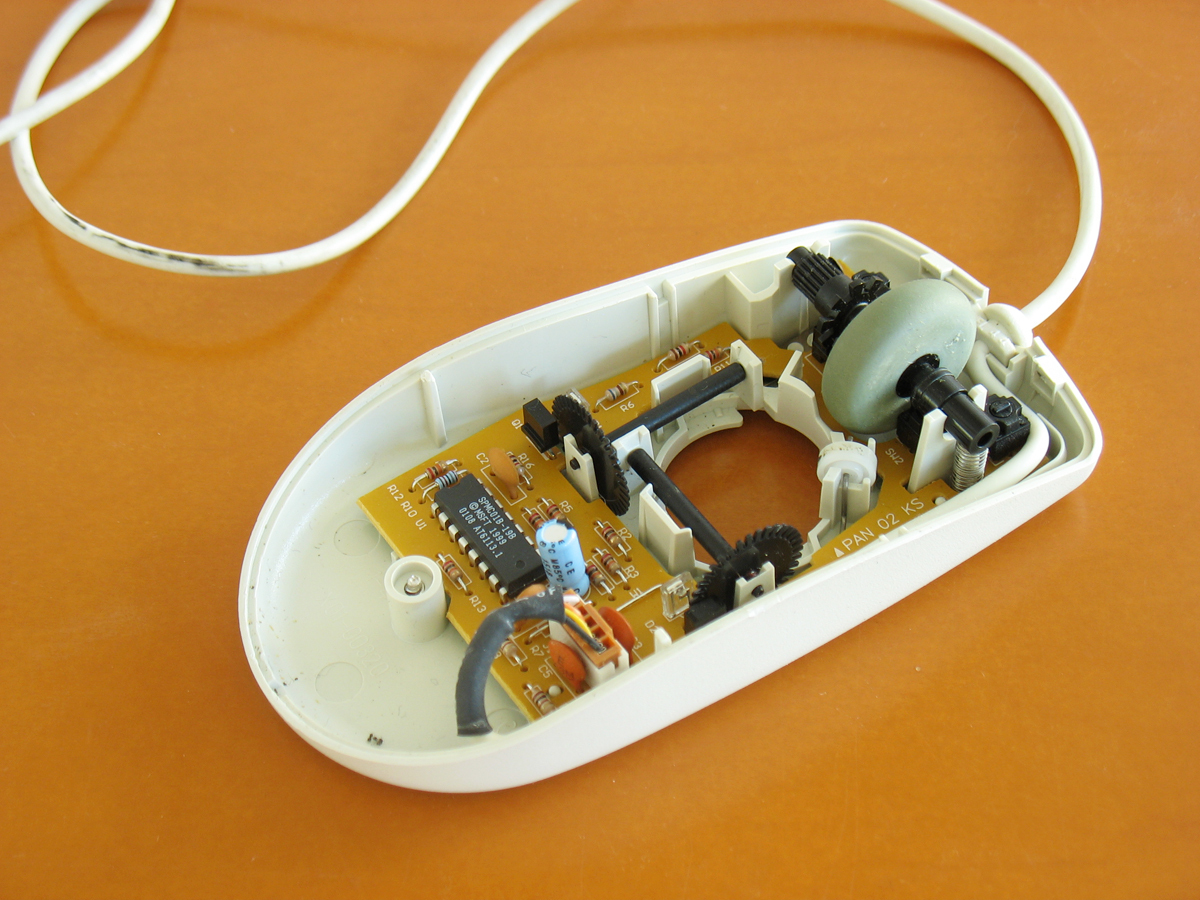

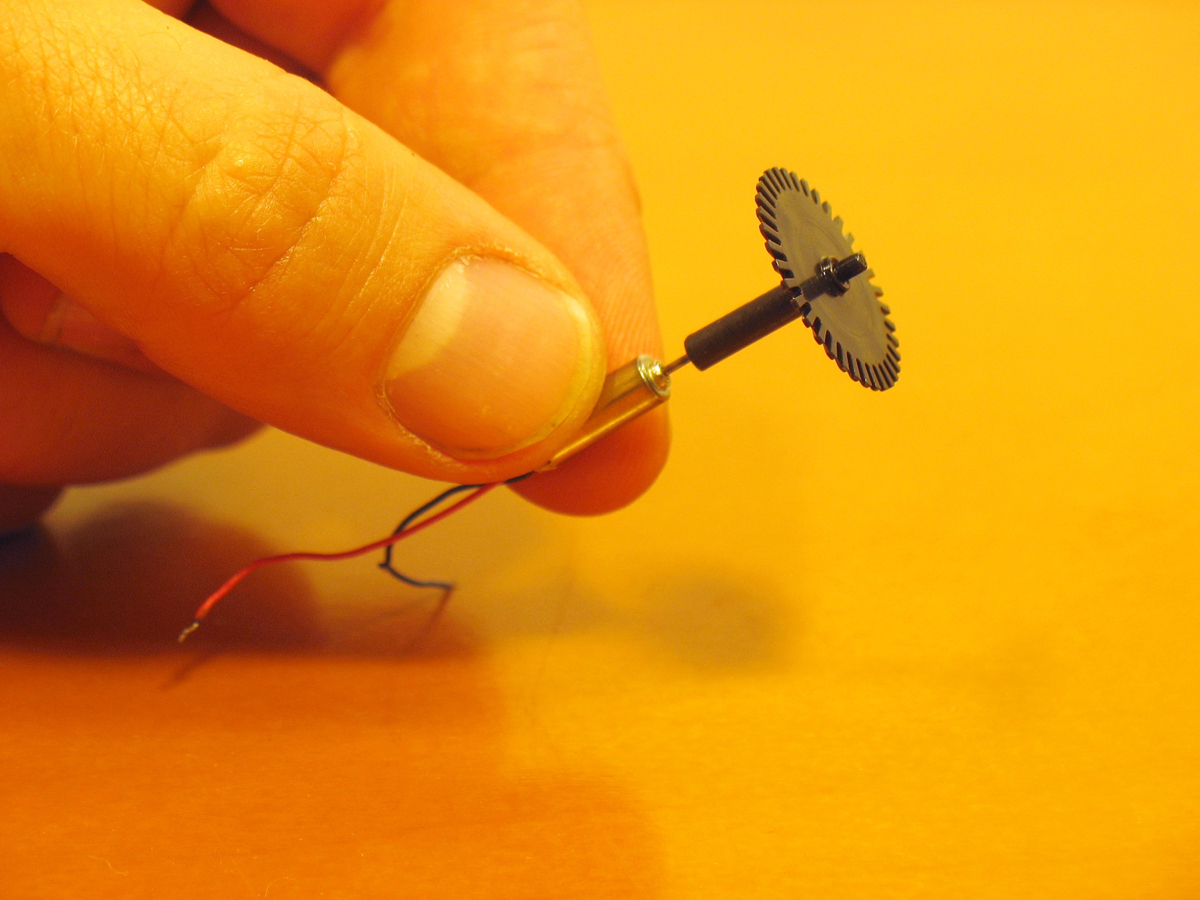

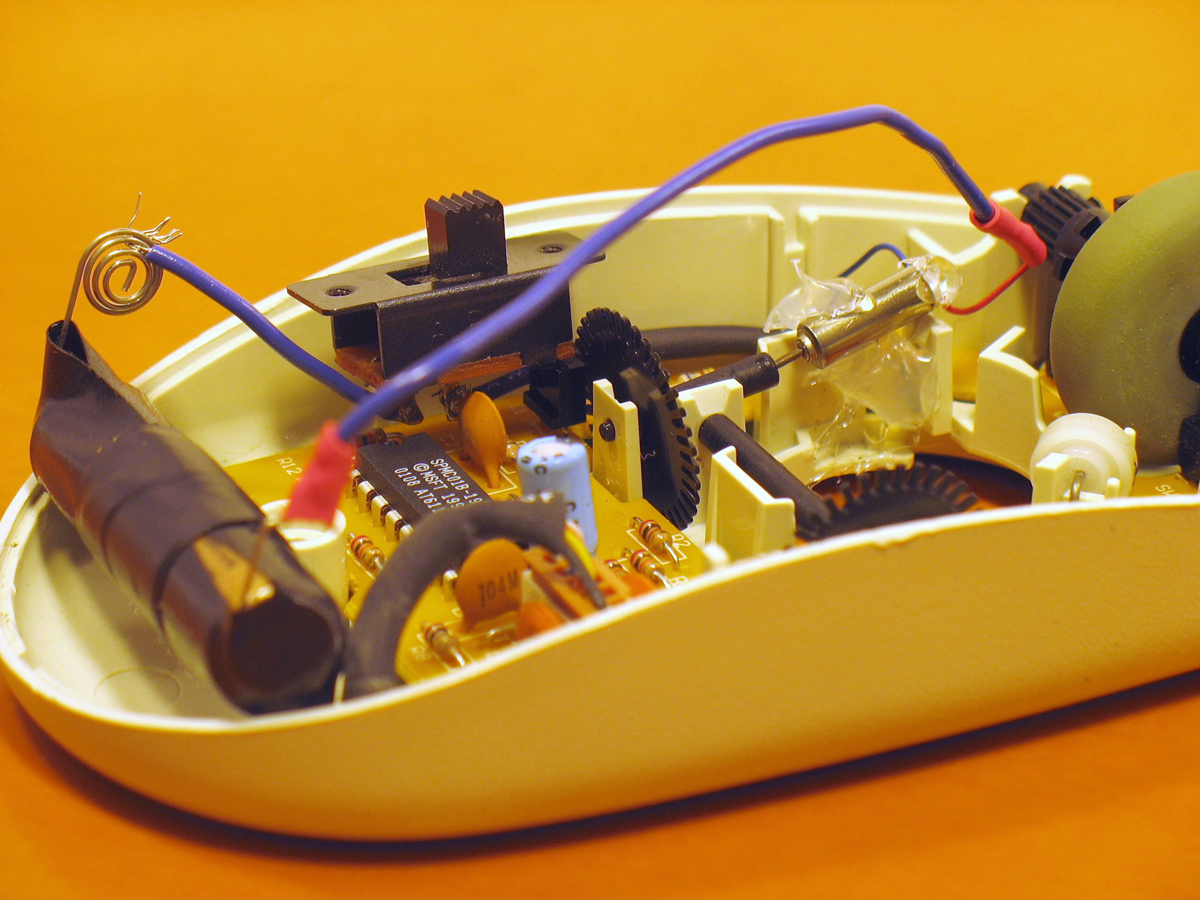

Like most analog mice, it once used a ball to drive the shafts of a pair of rotary encoders (disks with notches cut into their edges). Spinning an encoder breaks an IR beam, which drives cursor movement.

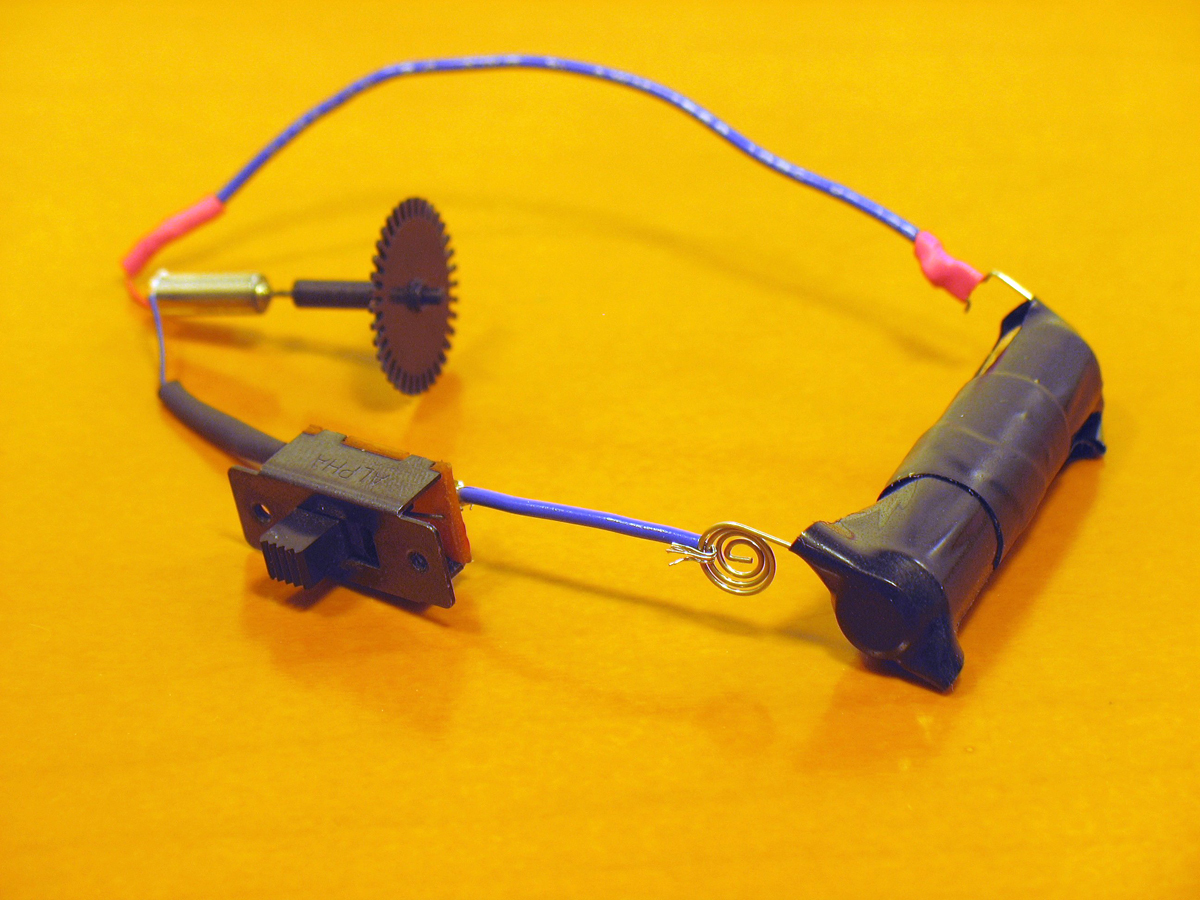

Joe had attached a DC motor to the x-axis encoder disk (hence the noise). My confused computer thought someone was sprinting the mouse down an infinitely long table. My attempts to budge the cursor were overwhelmed by this much-harder-working prank mouse. I’m honored to have been so cleverly pranked, Joe.