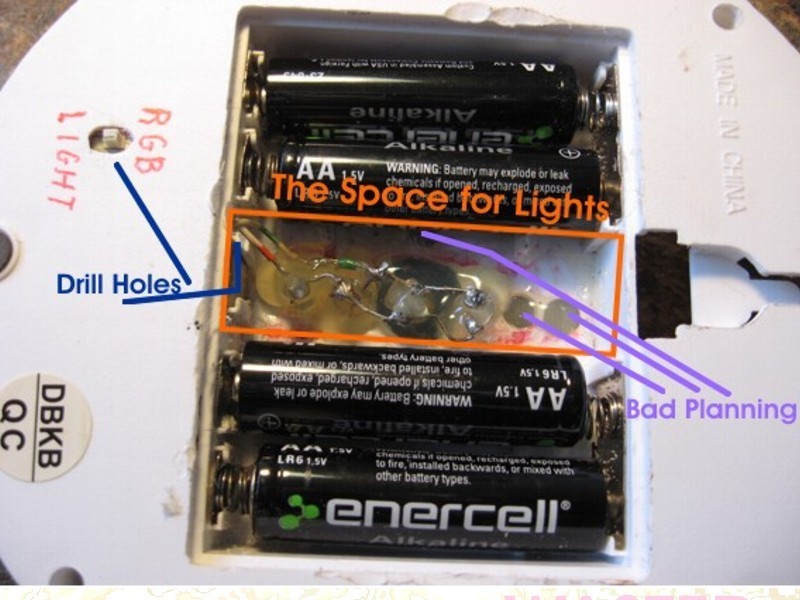

We have all used something like these battery-operated stick-up lights for closets and dark places. And we forget about them. Note: You should check all of your battery-powered devices at least once a year. When batteries leak they can damage everything and rust metal contacts.

Most of the older stick-up lights use light bulbs, not LEDs. This is a good thing for us. Why? You can do more with more voltage. Four AA batteries equal six volts. That will run electronics like 555 timers and microprocessors (Basic Stamps and Arduinos, for example) and that makes for much more fun projects.

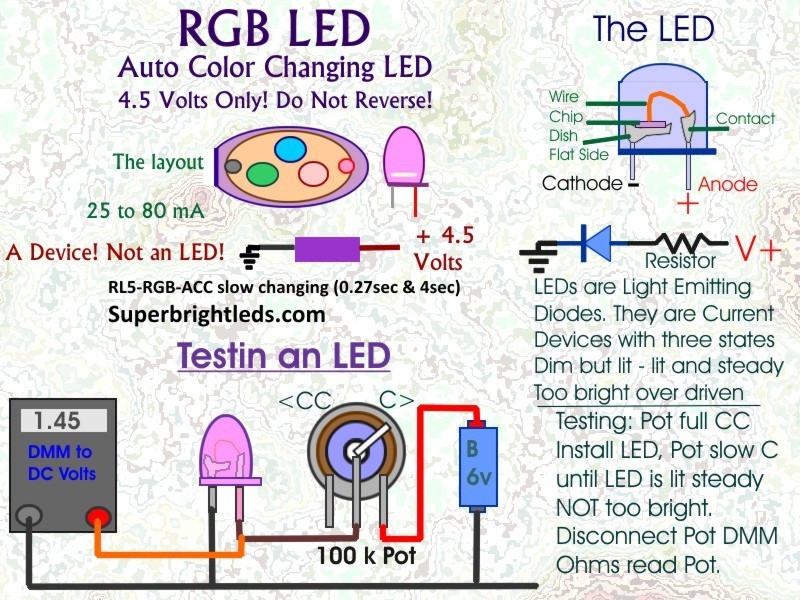

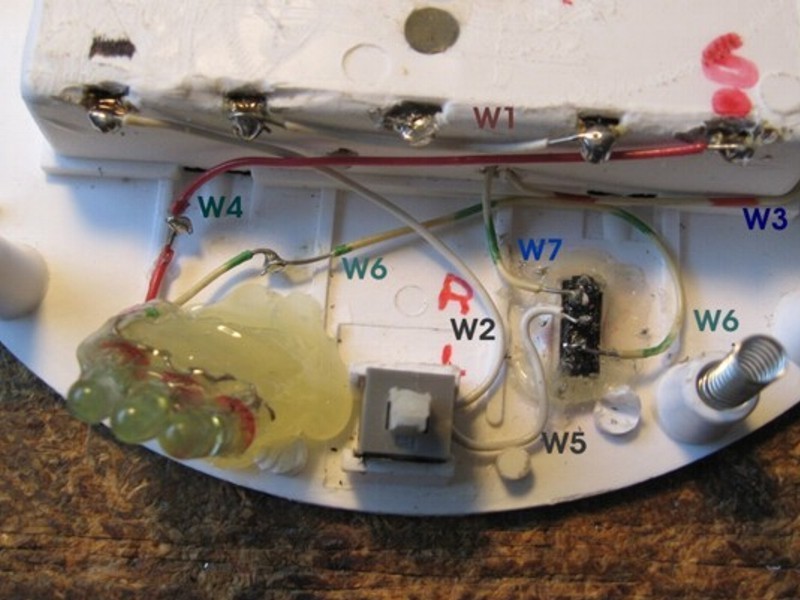

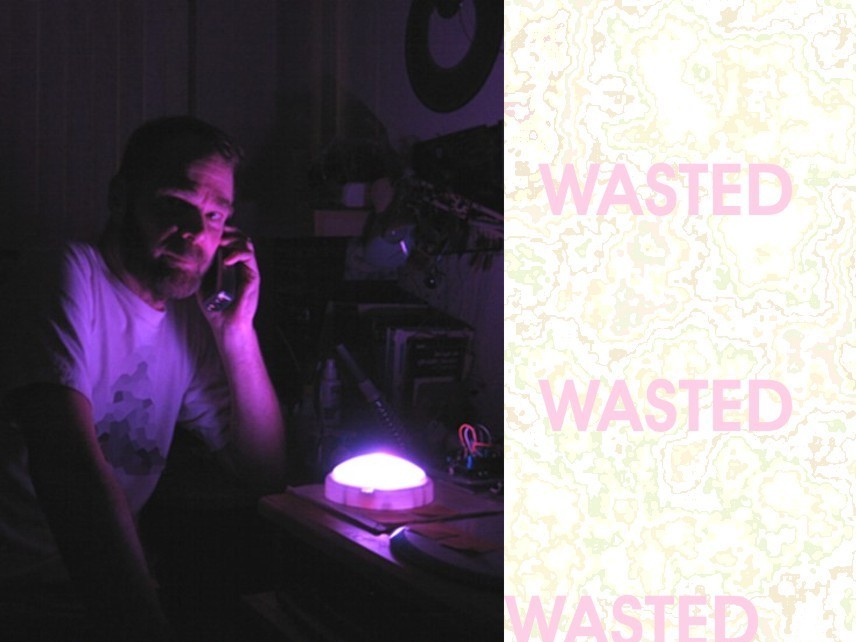

This is a simple modification of a battery-operated light to use LEDs instead of a light bulb. LEDs use different voltages than a light bulb does in most cases. You need to wire in the LEDs to the right voltage to get them to work right. The RGB LEDs need 4.5 volts and the work LEDs can run on 6 volts.