Steel is such an important industrial metal because it is strong yet malleable. Further, steel can be heat-treated to make it harder or softer, flexible or stiff, ductile or brittle, depending on the application.

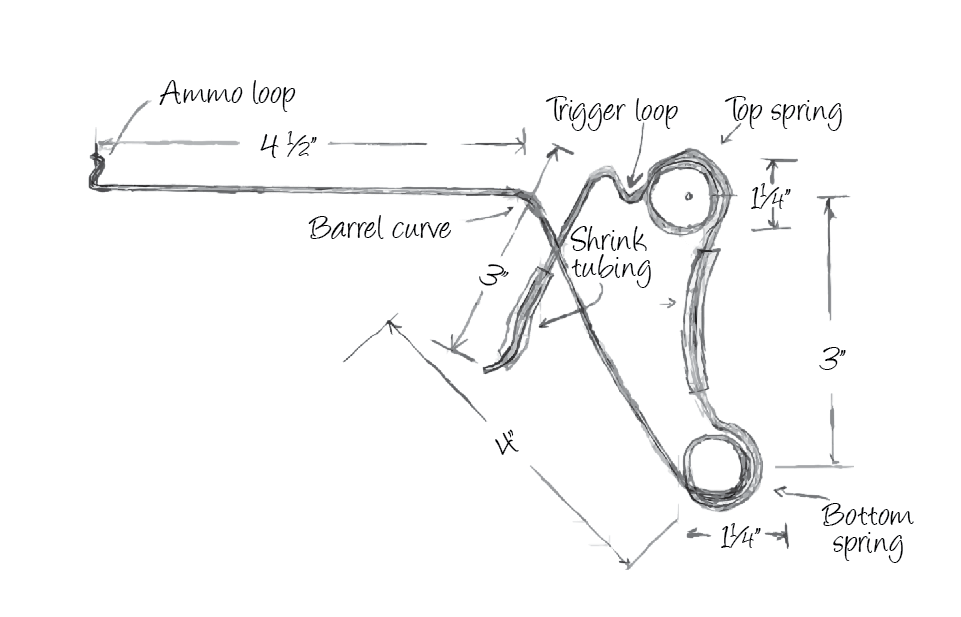

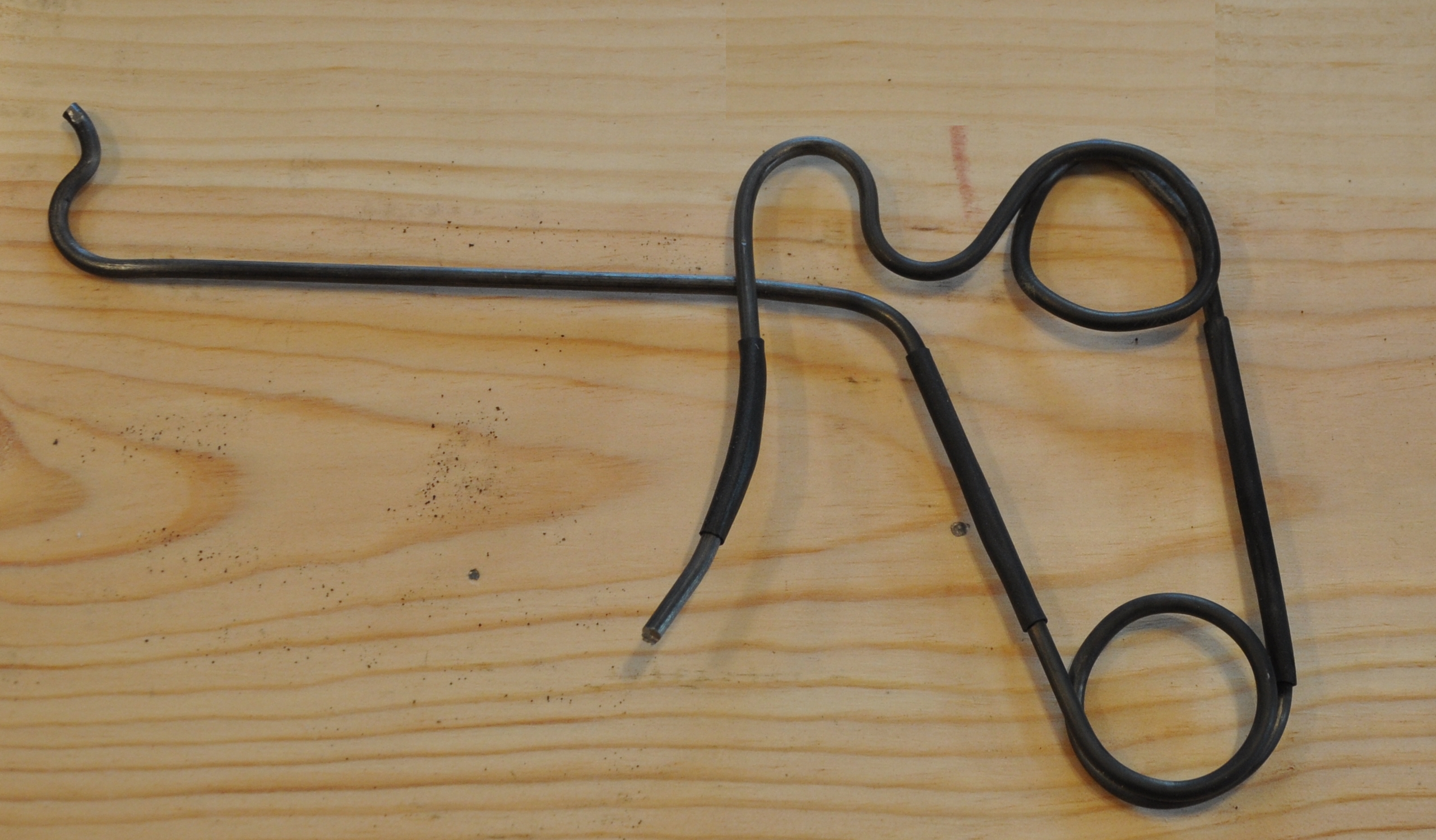

In this project, you’ll heat-treat steel to make a rubber band shooter. First you’ll anneal it to make it soft and malleable, then cut and form it to shape, quench it to harden it, and finally temper it to give it the tough, springy characteristics your gun requires.

SAFETY NOTES

Use extreme care when handling the hot oil and wire. The smoke point of soybean oil is very high, around 450°F, and even then doesn’t ignite readily. Still, take care to:

- Use an electric hot plate, not an open flame

- Not let the oil heat up past the flash point

- Have a lid handy to cover your pot in the unlikely event of a problem

- Keep a grease-fire capable extinguisher close by.