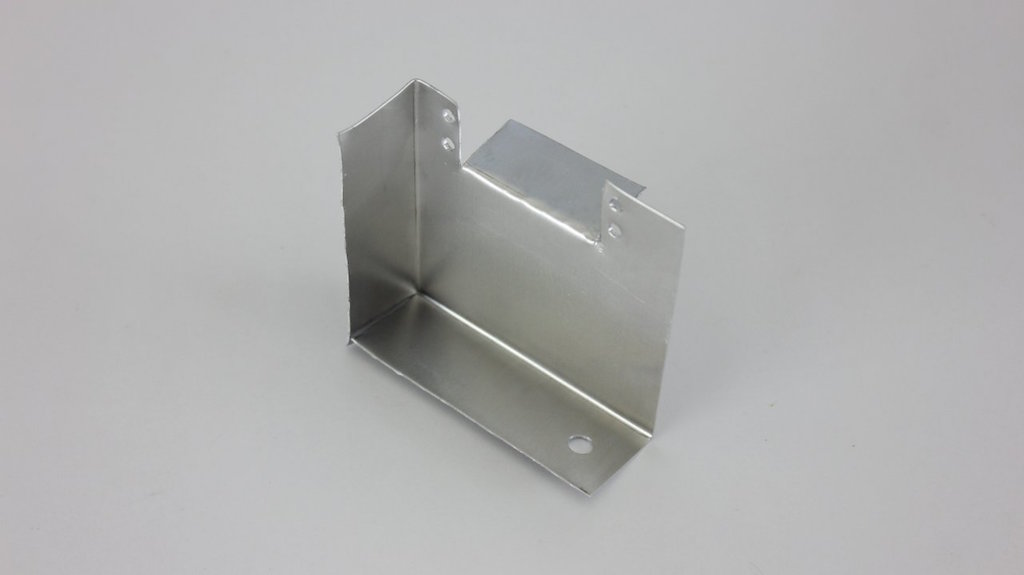

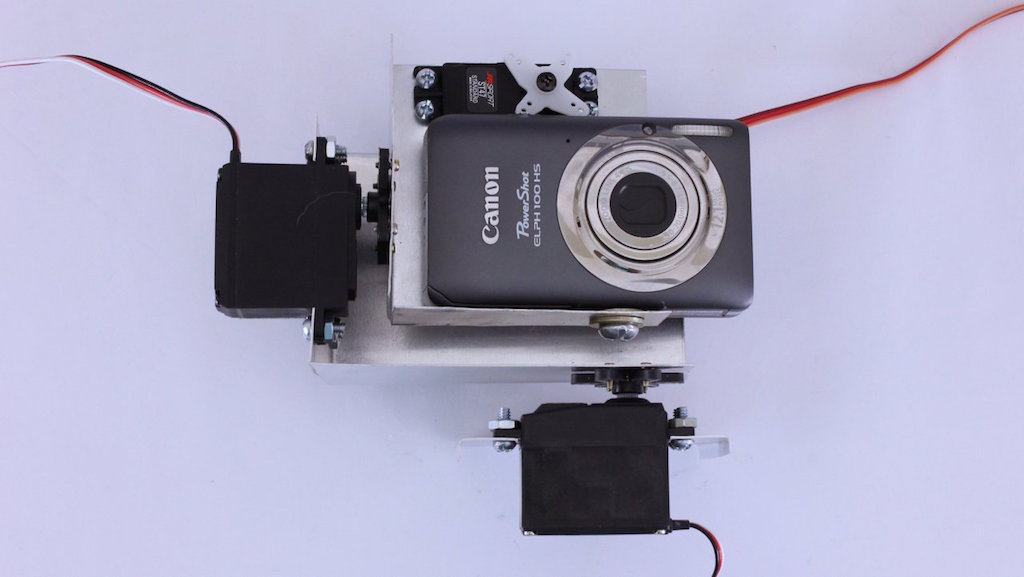

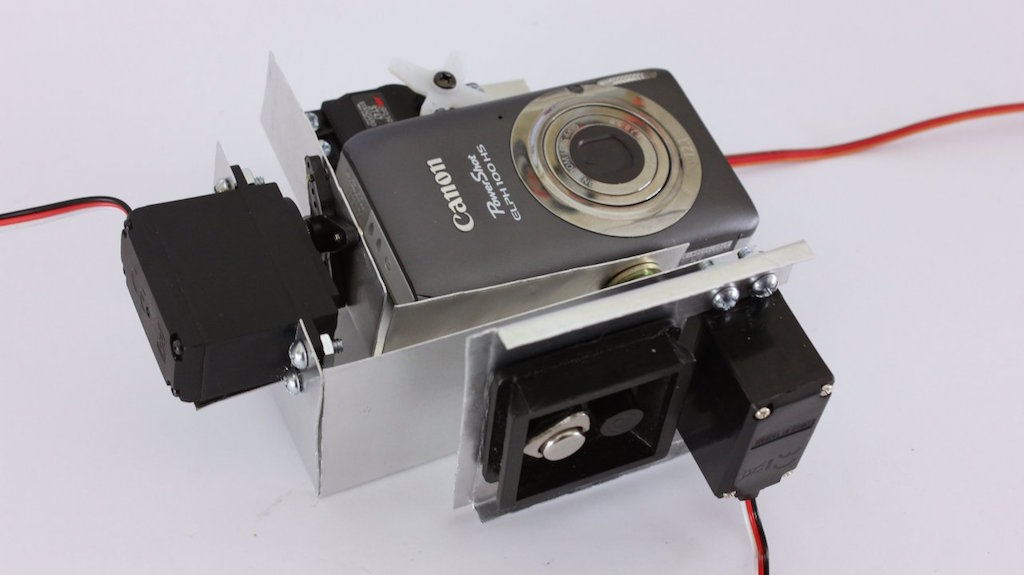

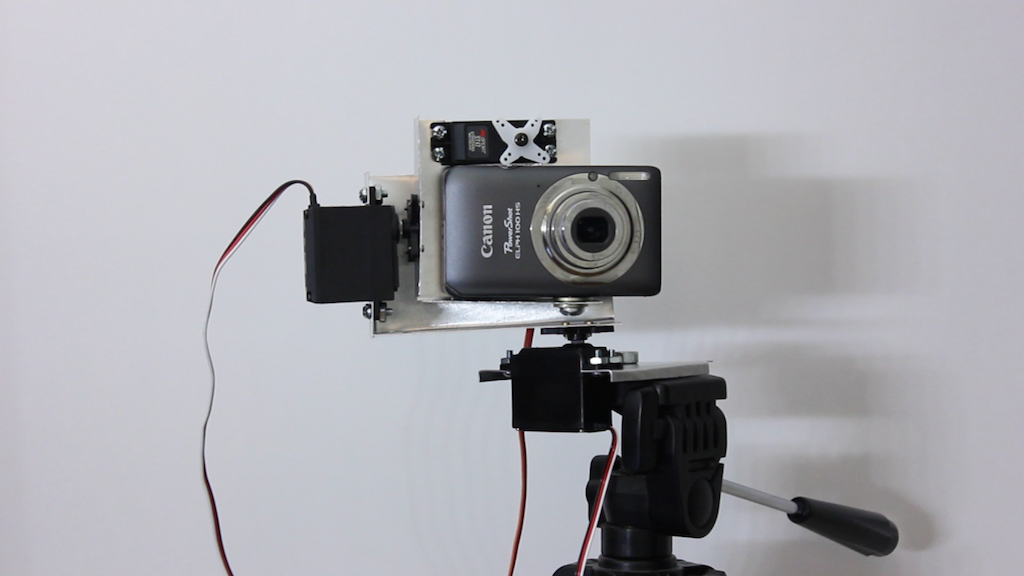

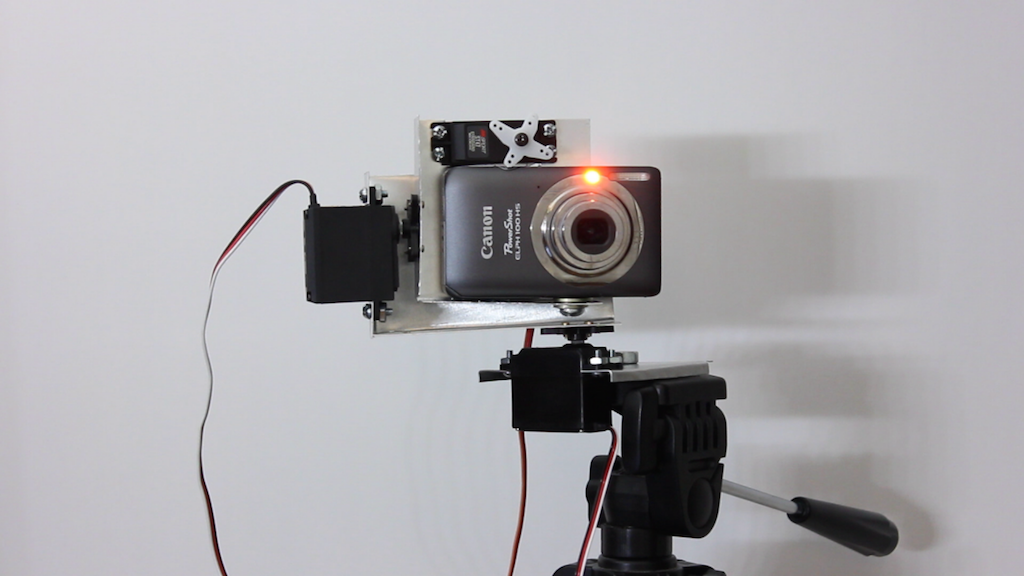

The first plate that you need to cut out is the camera mounting plate. This plate will be used to mount the camera and the shutter servo motor. It also attaches to the rotor of the tilt servo.

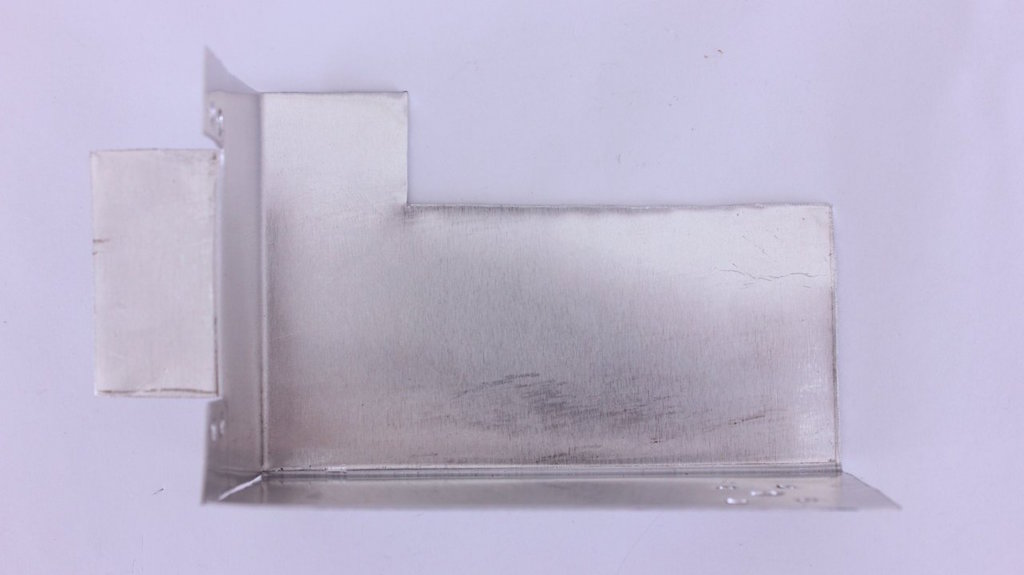

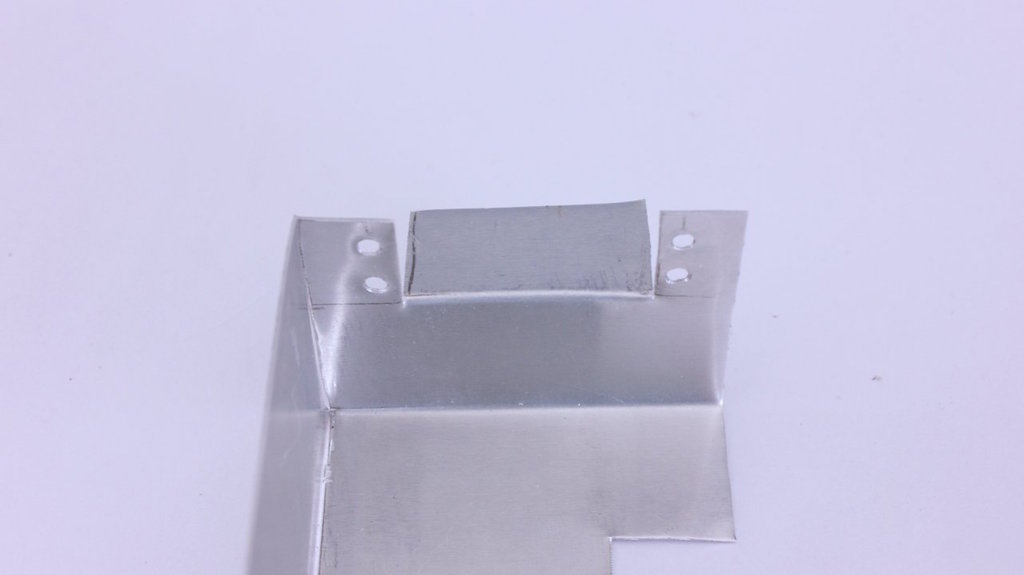

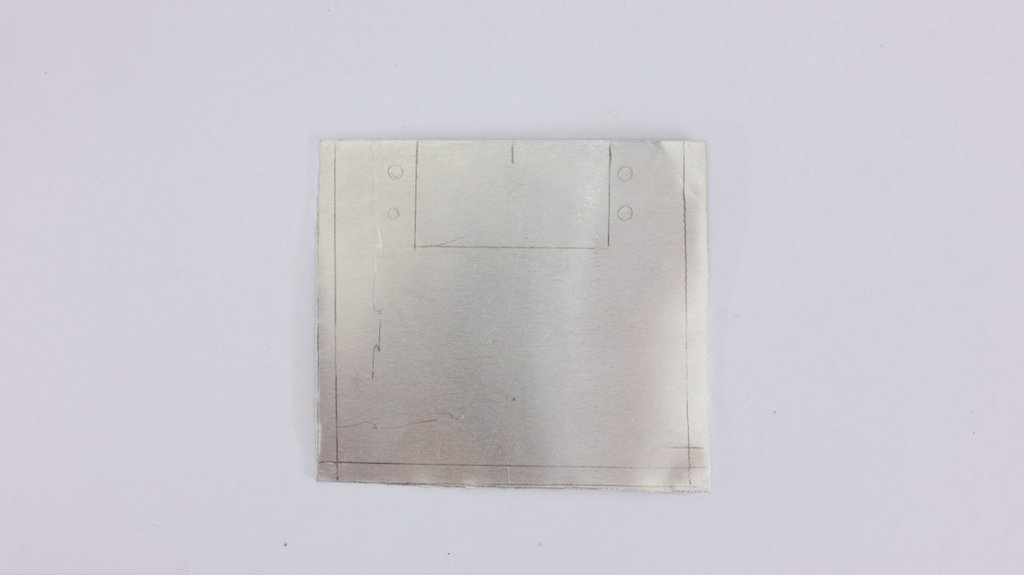

Start by positioning the camera where it will be mounted and mark the location where the mounting hole will be. Next figure out where the shutter servo needs to be so that it can activate the shutter button. I was fortunate in that my shutter button was right next to the power button, so I was able to use one servo to activate both the power button and the shutter button on my camera. Mark the locations of the mounting holes for the servo and the section of metal that needs to be cut to make room for the body of the servo. Also mark where the metal needs to be cut so that you can bend the bottom and left sides up. It may also help to mark the bend lines.

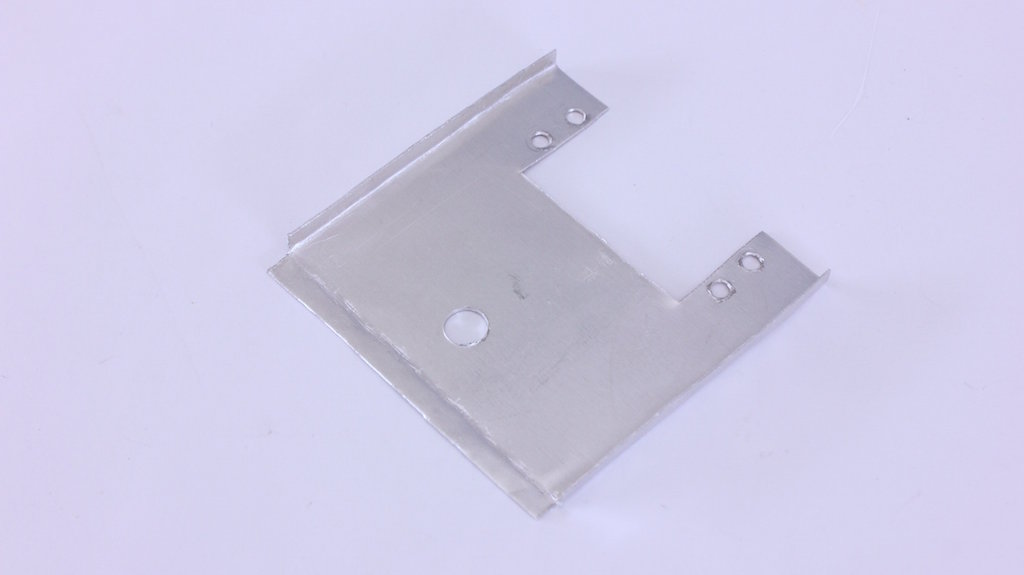

Using a small drill bit, drill a hole in each of the hole locations. When drilling sheet metal by hand, I prefer to start with small holes and gradually widen them by re-drilling the holes with larger and larger bits until the hole is the right size. If you have trouble getting the holes started, it can help to first dent the metal with a nail.

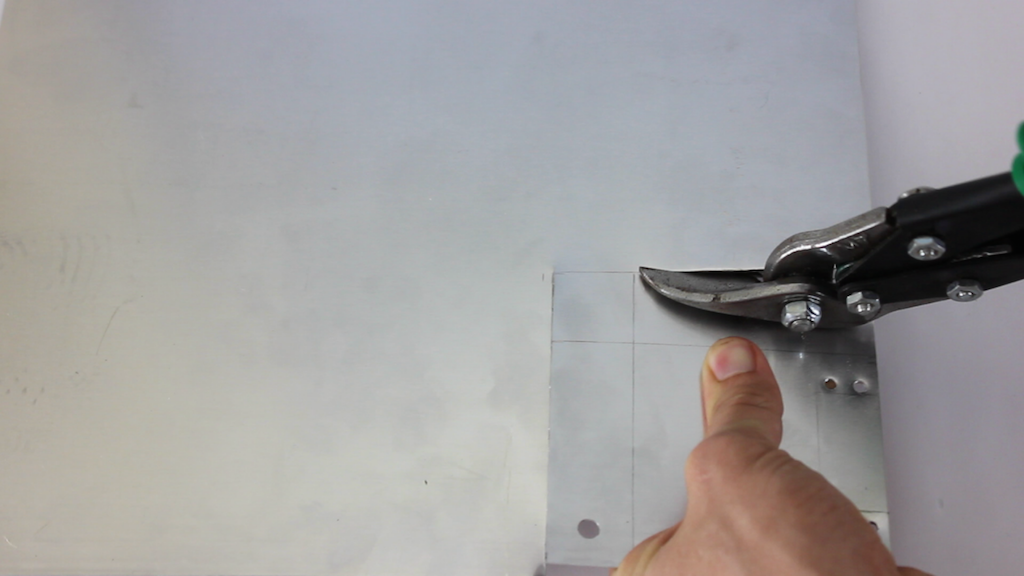

Using a pair of tin snips, cut out each section of metal that needs to be removed. The section cutout for the body of the shutter servo can either be bent over so that it is out of the way, or you can repeatedly bend the flap back and forth until it breaks off.

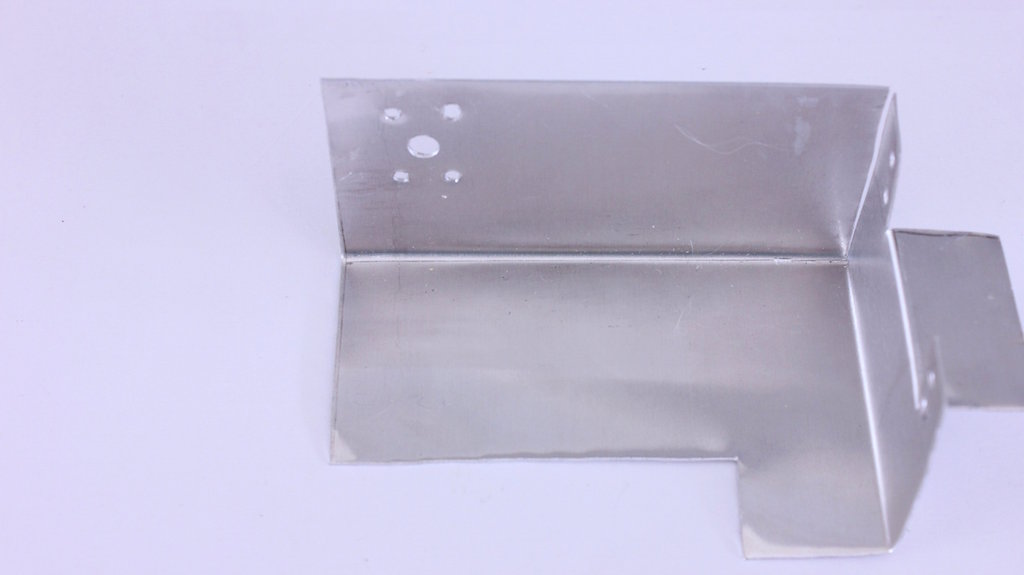

Finally, bend the bottom and left sides up to make the final shape of the bracket.