Optical fibers are ultra-clear strands of plastic, glass, or silica consisting of a central core surrounded by a cladding and a protective coating. Light injected into the core of a fiber remains trapped until emerging from the opposite end. This lets you transmit light point-to-point with very little loss, and even bend it around corners. The light stays in the core because the cladding has a slightly higher index of refraction than the core.

Silica optical fibers are primarily used to transmit high-bandwidth data over long distances. Inexpensive plastic fibers are widely used in sensors, illuminators, and toys. They’re also used to couple light to photodiodes in environments that require electrical isolation or protection from the elements or a corrosive environment. Plastic fibers are also used to illuminate displays and to send light through openings too small for a flashlight.

Connecting Fibers to LEDs and Sensors

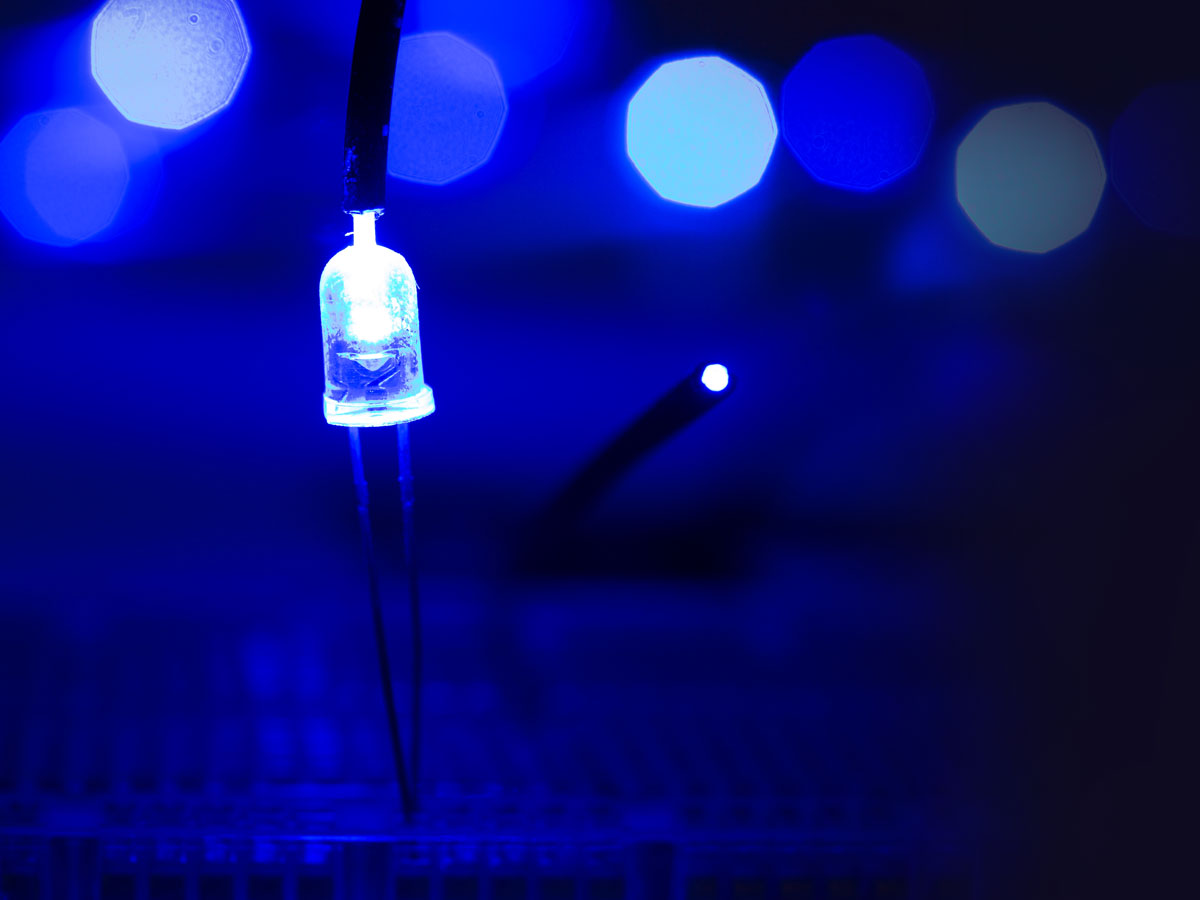

Optical fiber couplers for various LEDs and light sensors are commercially available, but you can skip the connector and simply connect silica and plastic fibers directly to LEDs and sensors. For the examples described here, I used LEDs encapsulated in standard 5mm clear epoxy packages, and 2.2mm-diameter plastic fiber having a 1mm core and a black polyethylene jacket. I used fiber from Jameco Electronics (jameco.com) but many kinds of fiber are available from other online sources, including eBay, and the methods described here can be adapted for use with most of these fibers.