By Larry Cotton and Phil Bowie

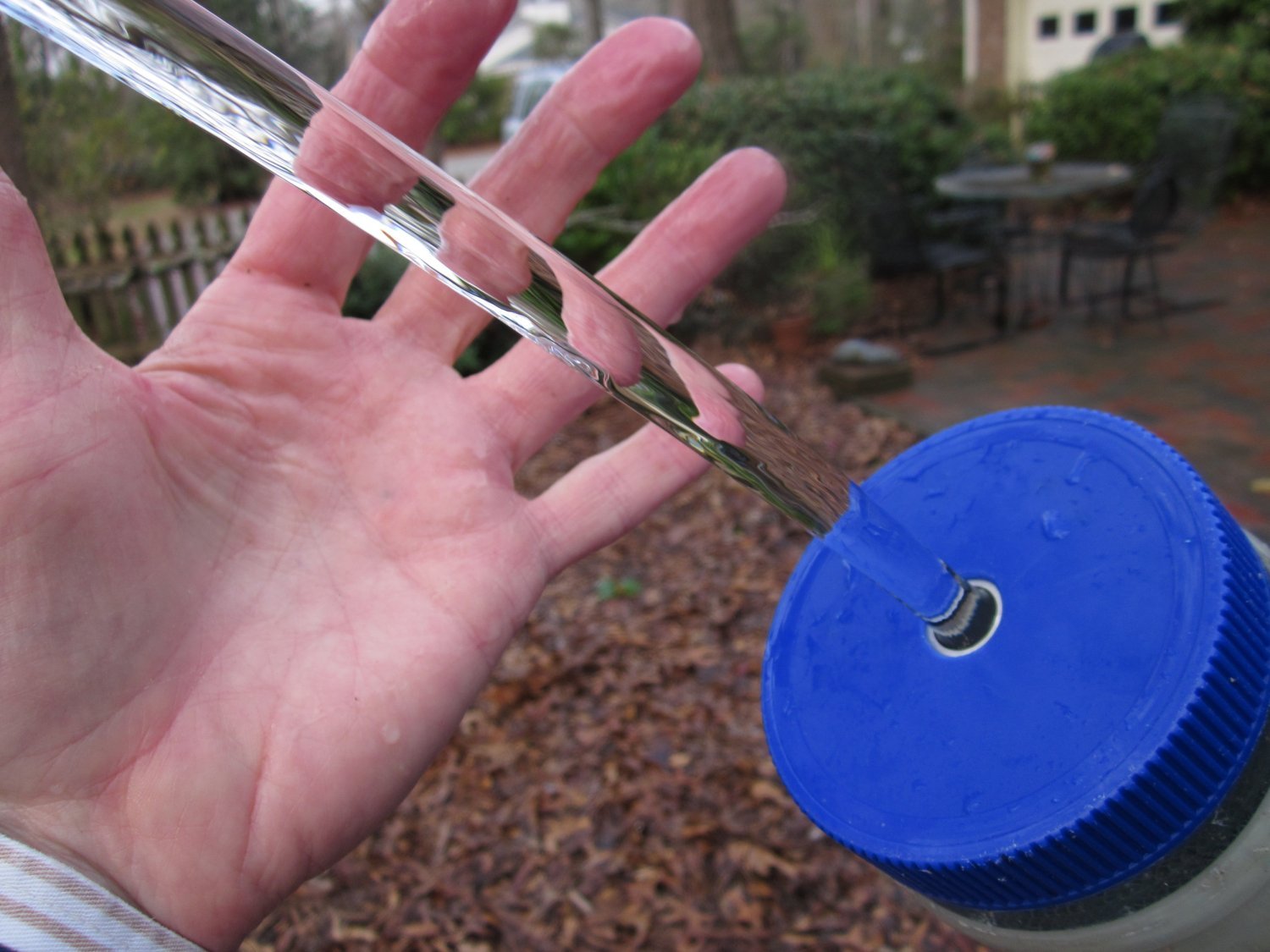

Laminar-flow water charms and fascinates. It behaves quite differently from ordinary turbulent water, such as the flow from a faucet or garden hose. A laminar stream is so perfect it could pass for a glass rod. It doesn’t splash upon hitting a surface, it will conduct light like a fiber-optic cable, and it’s so cohesive, it will enwrap and levitate a smooth sphere, even at a surprising angle to the vertical.

In 2011, we drove 600 miles from our North Carolina homes to Disney’s Epcot theme park to study the “Leap Frog” fountain, which chops a laminar stream into arcs, creating impish, cavorting water creatures. We’ve been obsessed with laminar flow phenomena ever since, joining an online cult of experimenters.

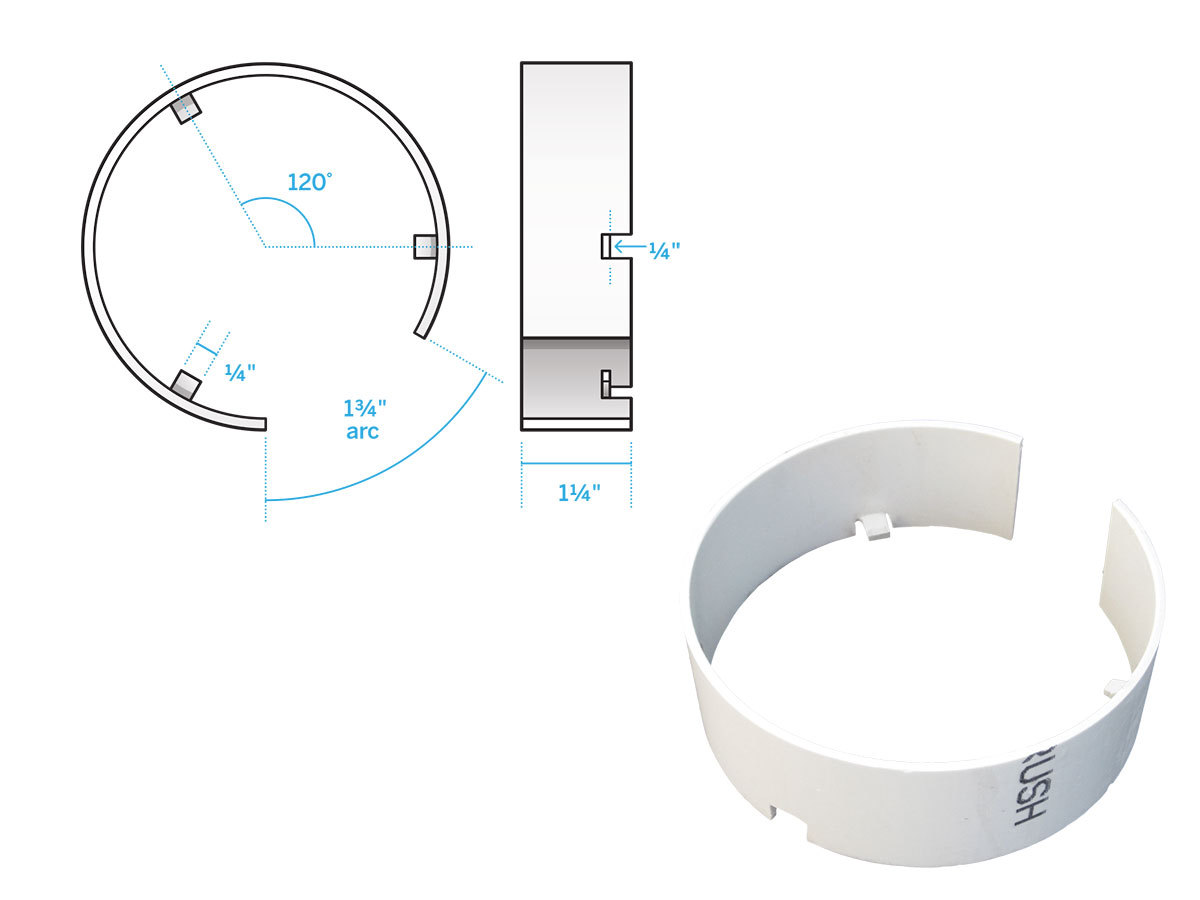

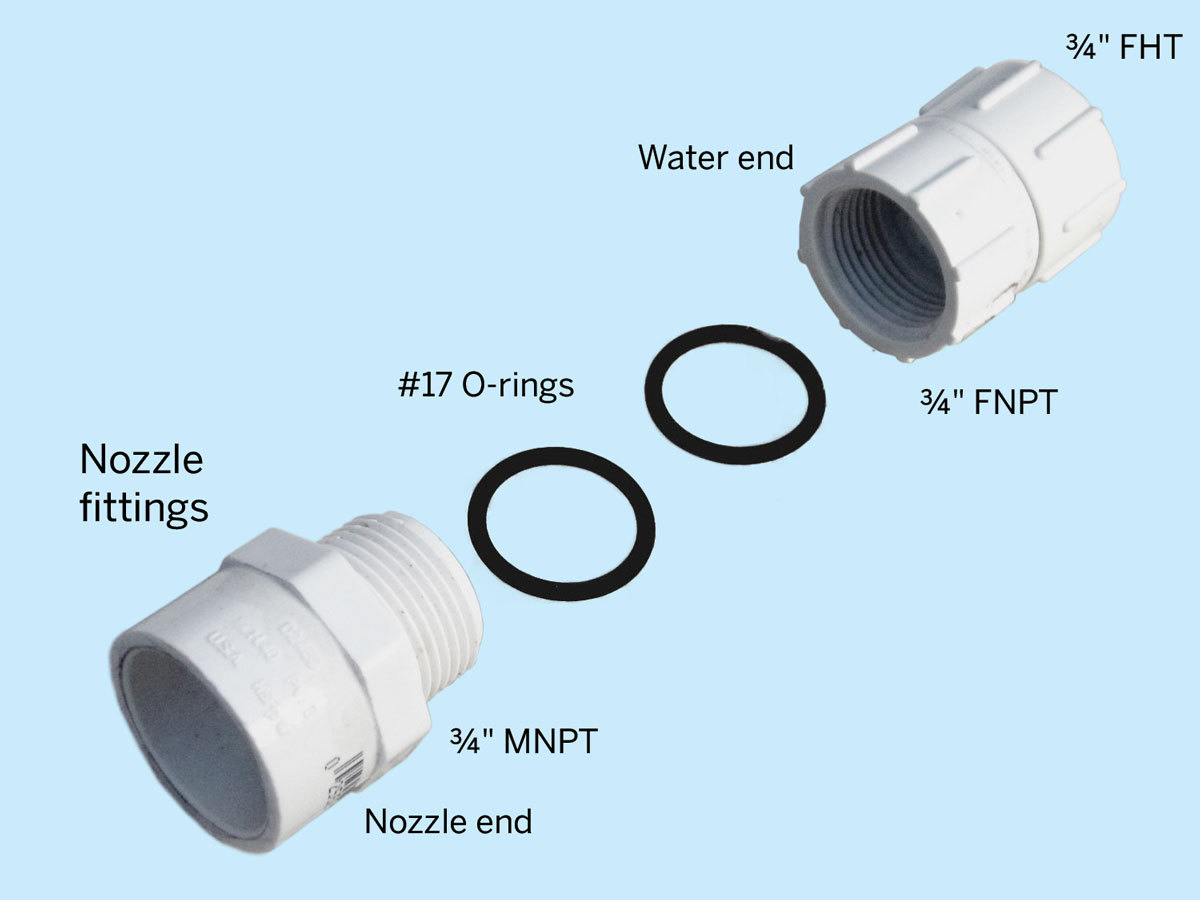

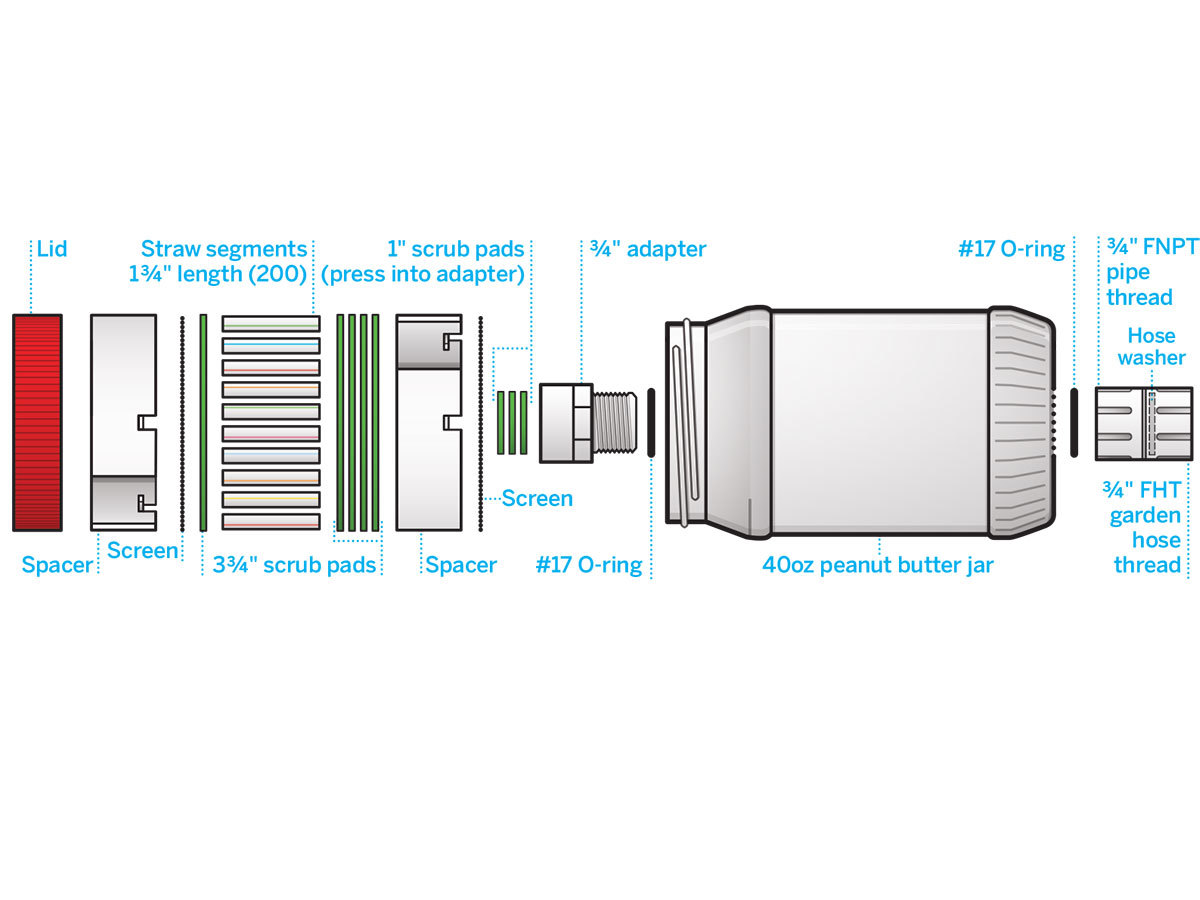

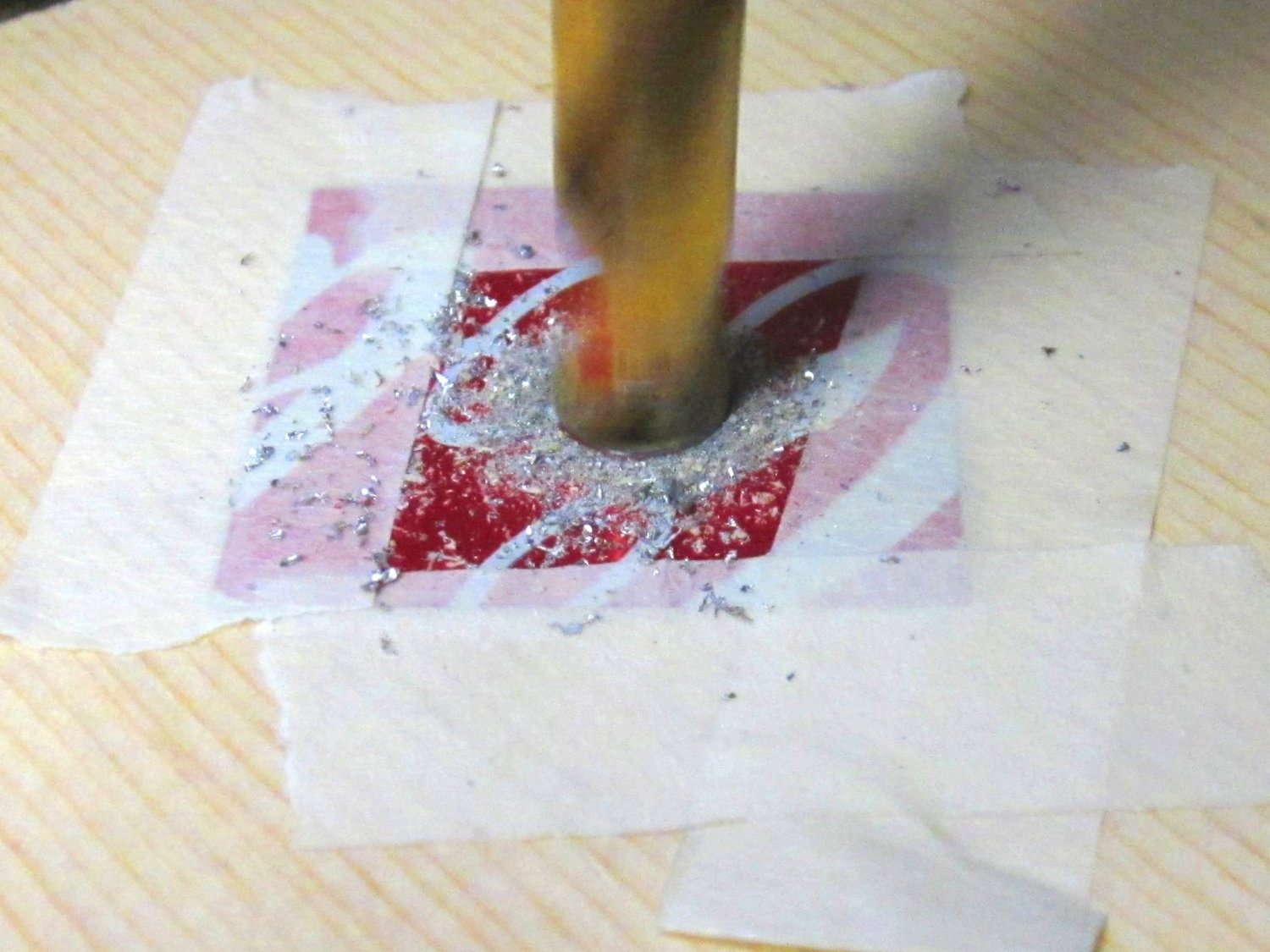

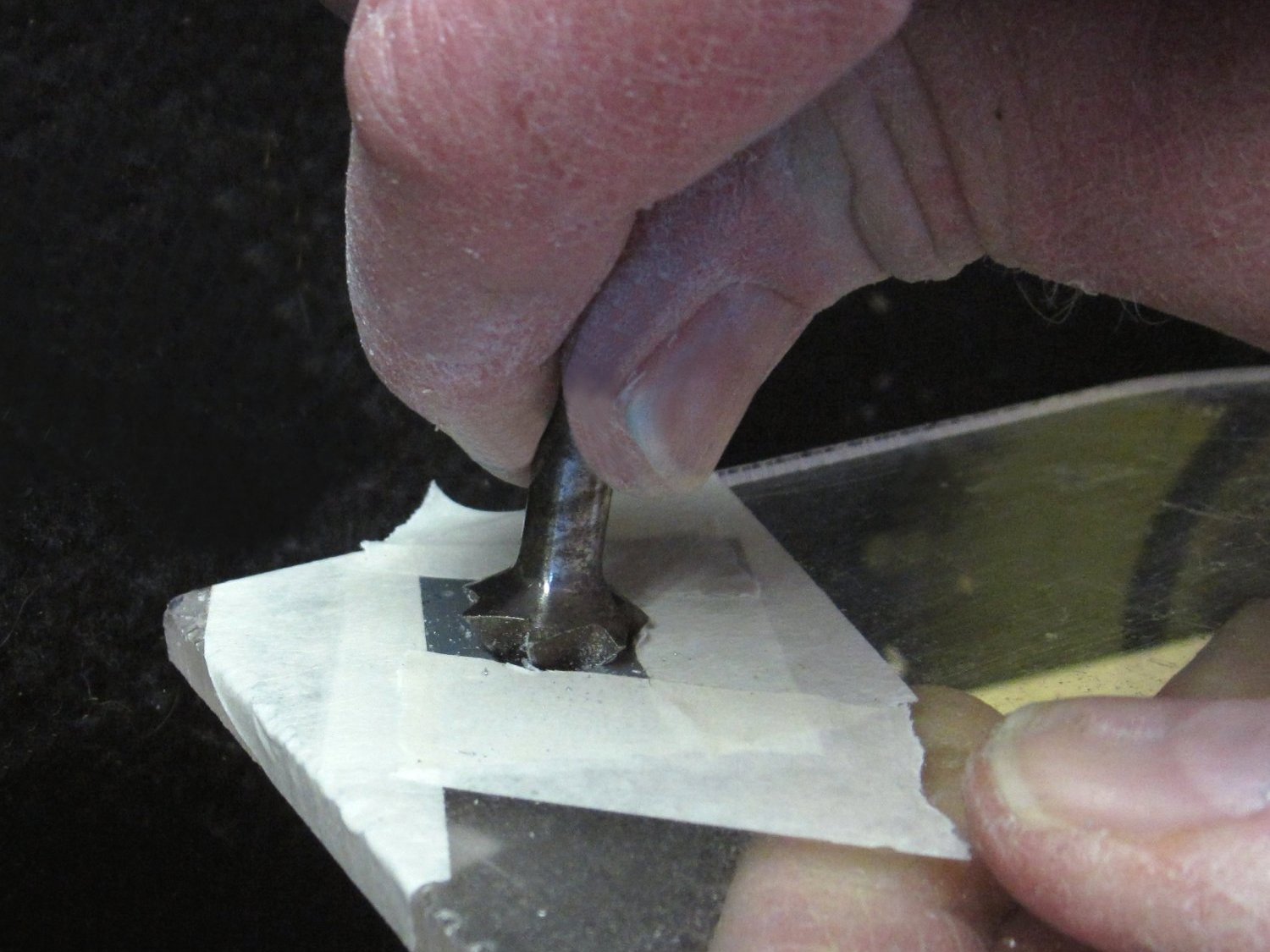

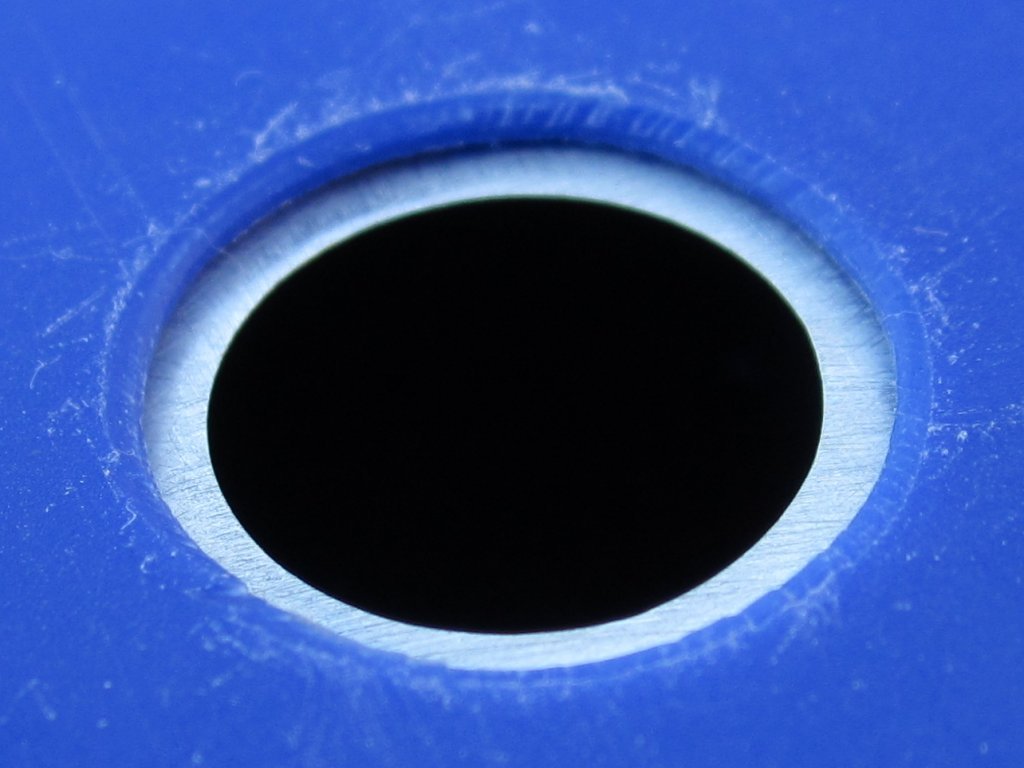

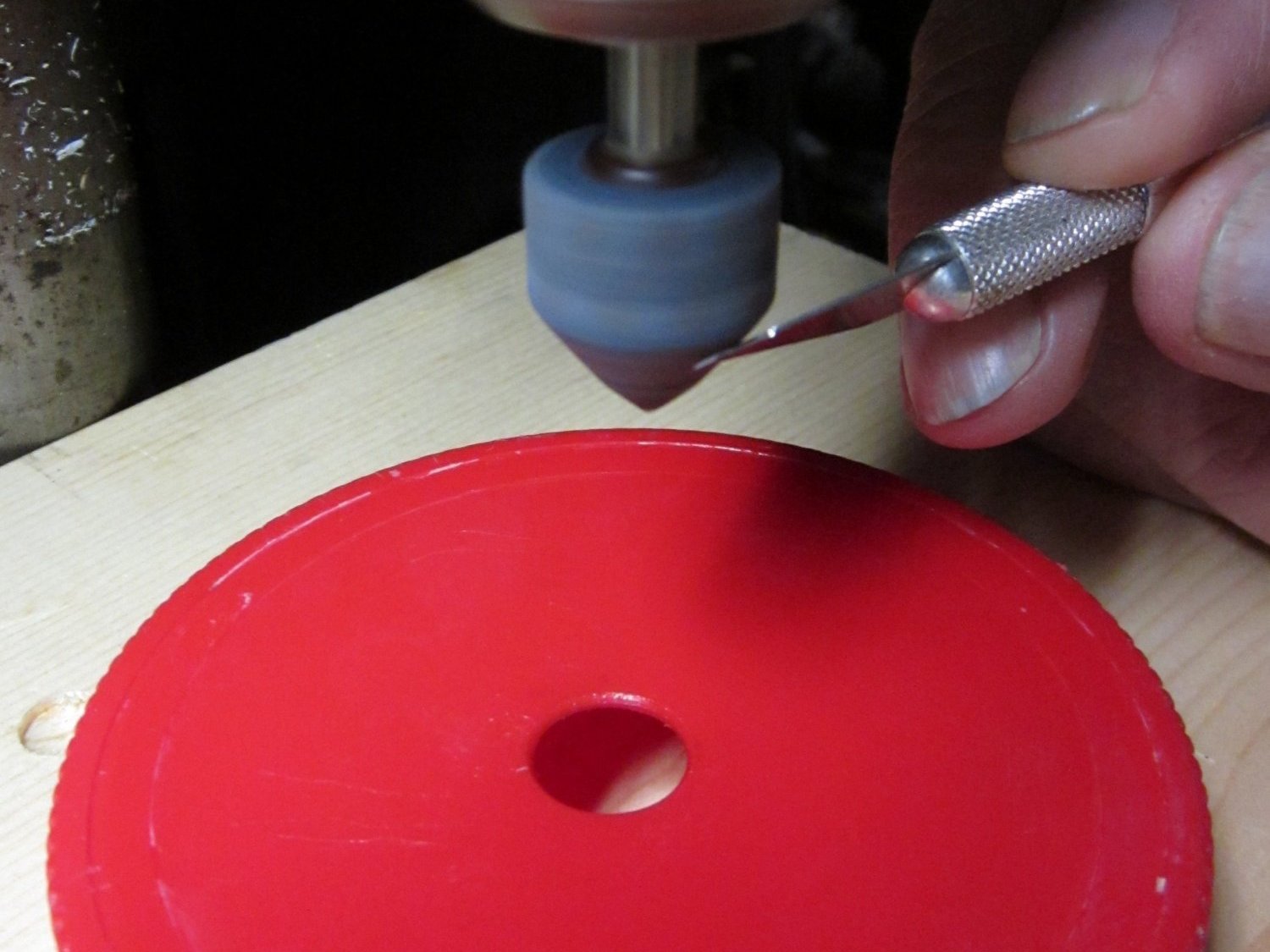

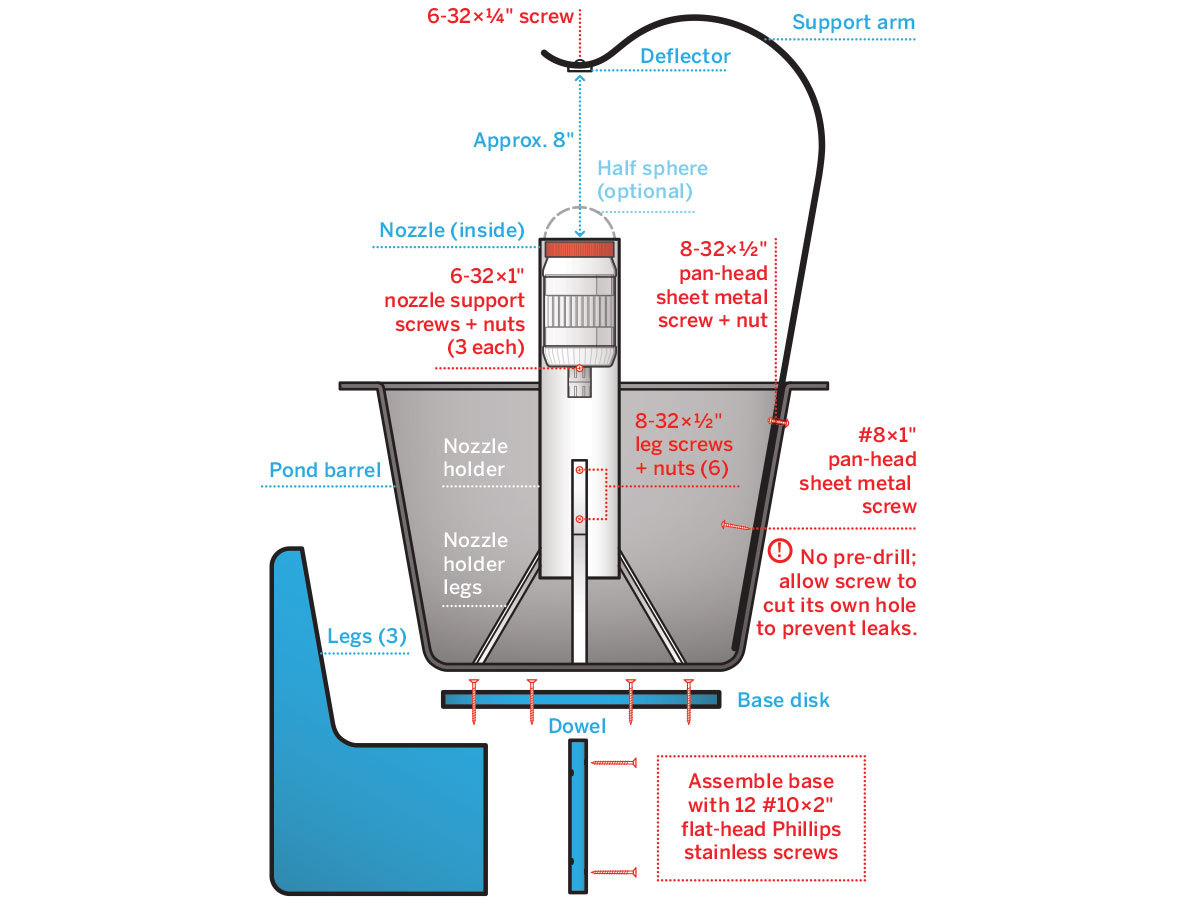

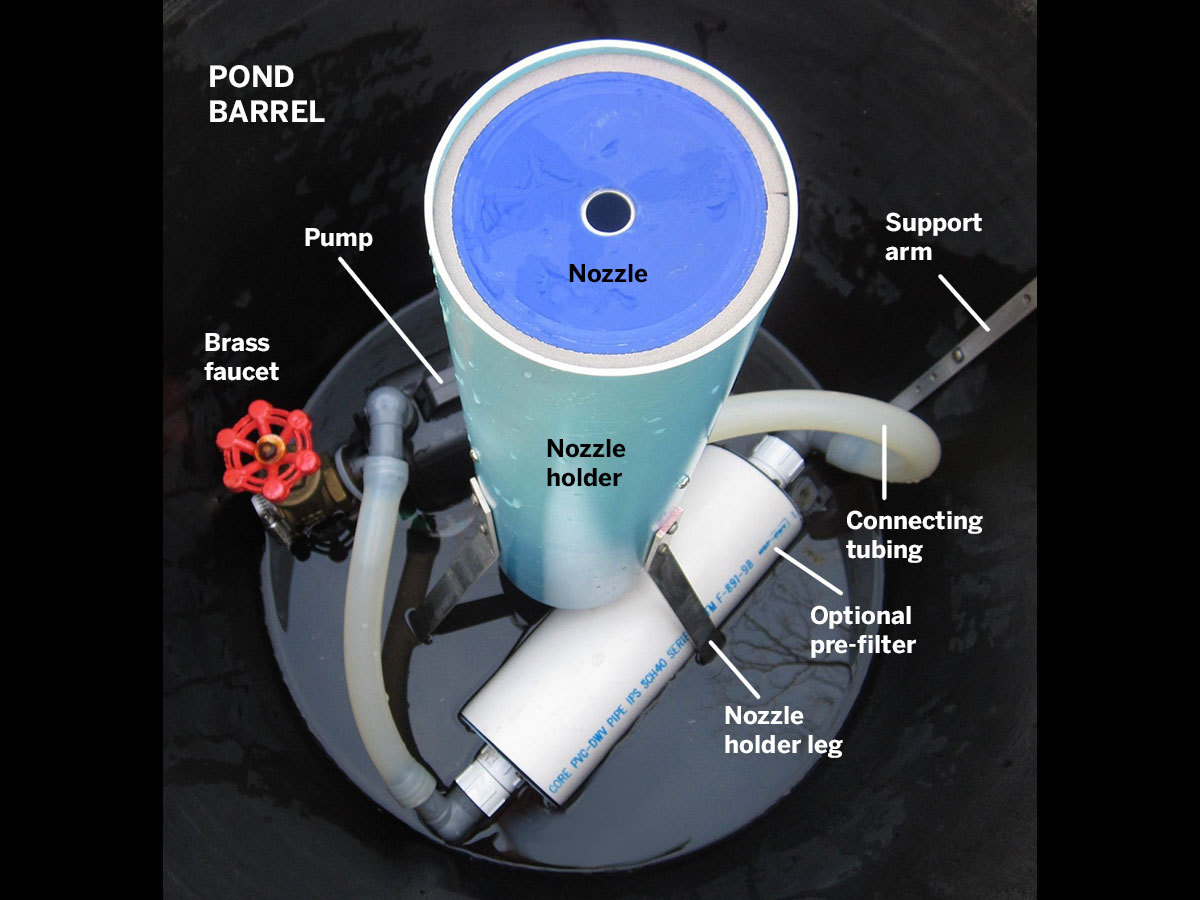

We have achieved laminar flow simply and inexpensively by making a nozzle from a big plastic peanut butter jar, scrub pads, drinking straws, and standard PVC pipe and hose fittings. A fine way to show off its elegant stream is to build a fountain using this nozzle as its heart. It’s easy to make, and can produce captivating shapes or even levitate lightweight spheres.