Working in a very, very, very well-ventilated area over newspaper, give each plaster section 2 coats of Kilz spray primer (they don’t call it Kilz for nothing), allowing the first coat to dry before applying the second. If the dried plaster didn’t end up looking white and fresh, you may want to paint the forms before the next step.

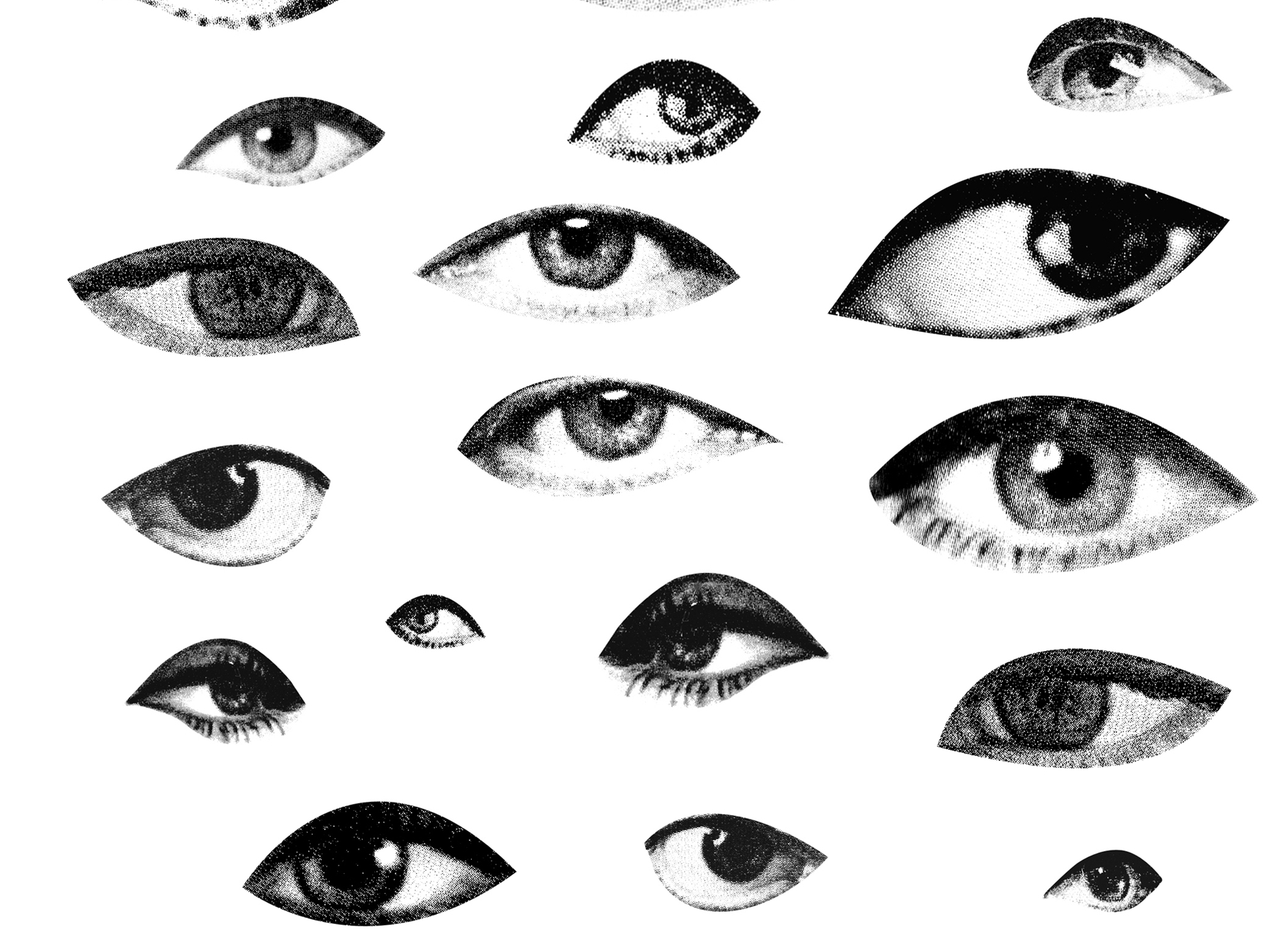

The eyes shown here were scanned from the pages of my vast vintage magazine collection (download them at http://craftzine.com/03/lamp). However, eyes are pretty easy to come by. Look for magazines with lots of makeup and hair product advertising, and you’ll find some good clear eye images.

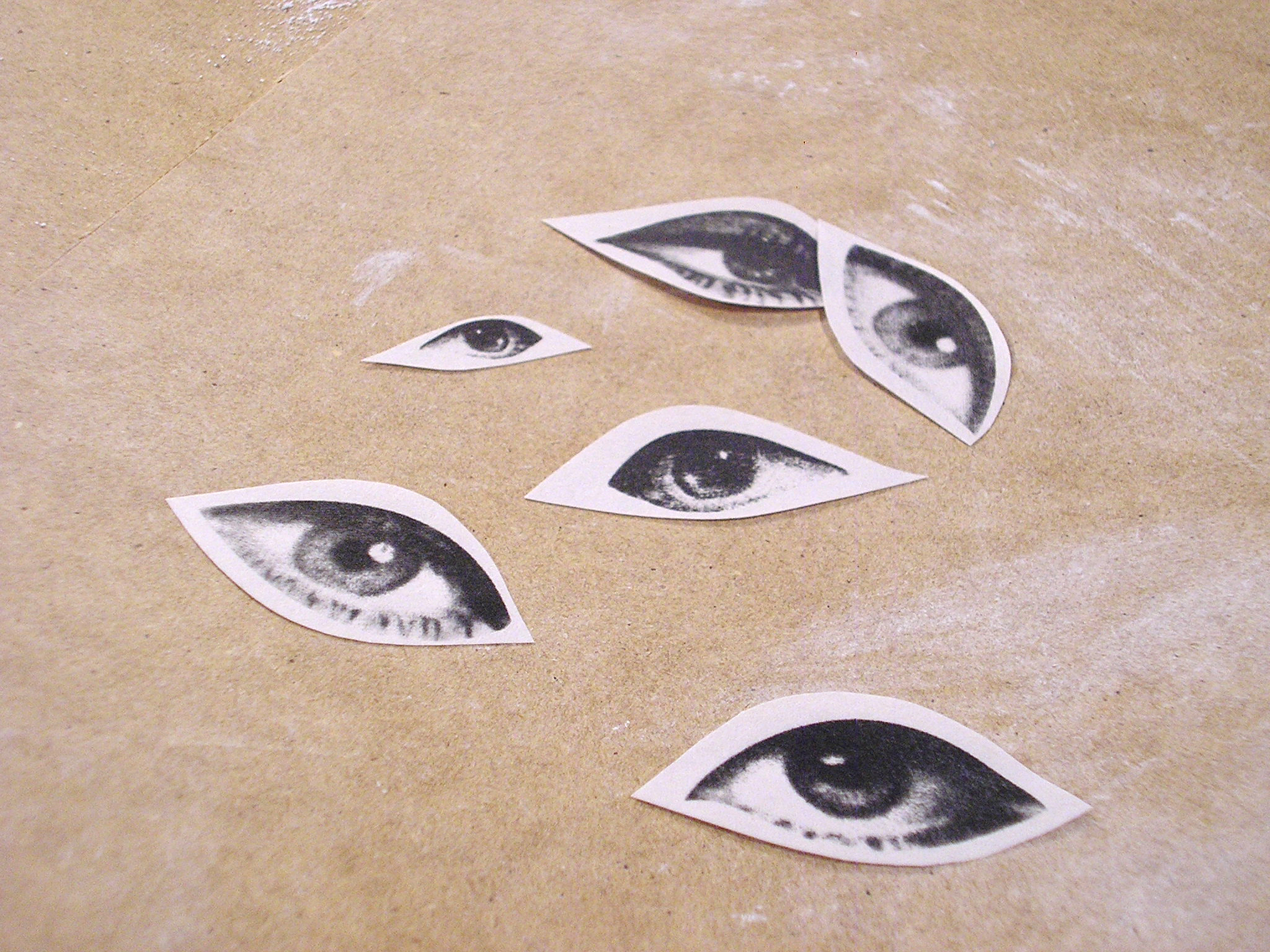

Once you’ve found a good assortment of high-contrast images of eyes, scan them (grayscale). Then flip, enlarge, or reduce to varying sizes, and print on newsprint sketch paper cut to 8 1⁄2″×11″. Cut each of the eyes just outside the actual image area.

Combine 1 cup of Elmer’s glue, 1⁄4 cup of flour, and 1 cup of hot water. Mix with a fork or a wire whisk until the glue and flour have completely dissolved. Dip each eye into the glue mixture, completely submerging each one. Then remove, shake off the excess liquid, and apply the eyes to the lamp forms.

If your plaster forms have curved walls, allow the printed eyes to soak in the glue for a few seconds to really saturate the paper — this will help make the paper mold to a curved surface. After applying an eye, gently press it into place with a dry dishtowel. If you are working on a curved surface, press firmly and hold for a few seconds. Wipe any excess glue from the plaster. Allow the eyes to dry completely.