If you like LEGO, and have plastic working facilities then you will be able to make a life size LEGO helmet.

Projects from Make: Magazine

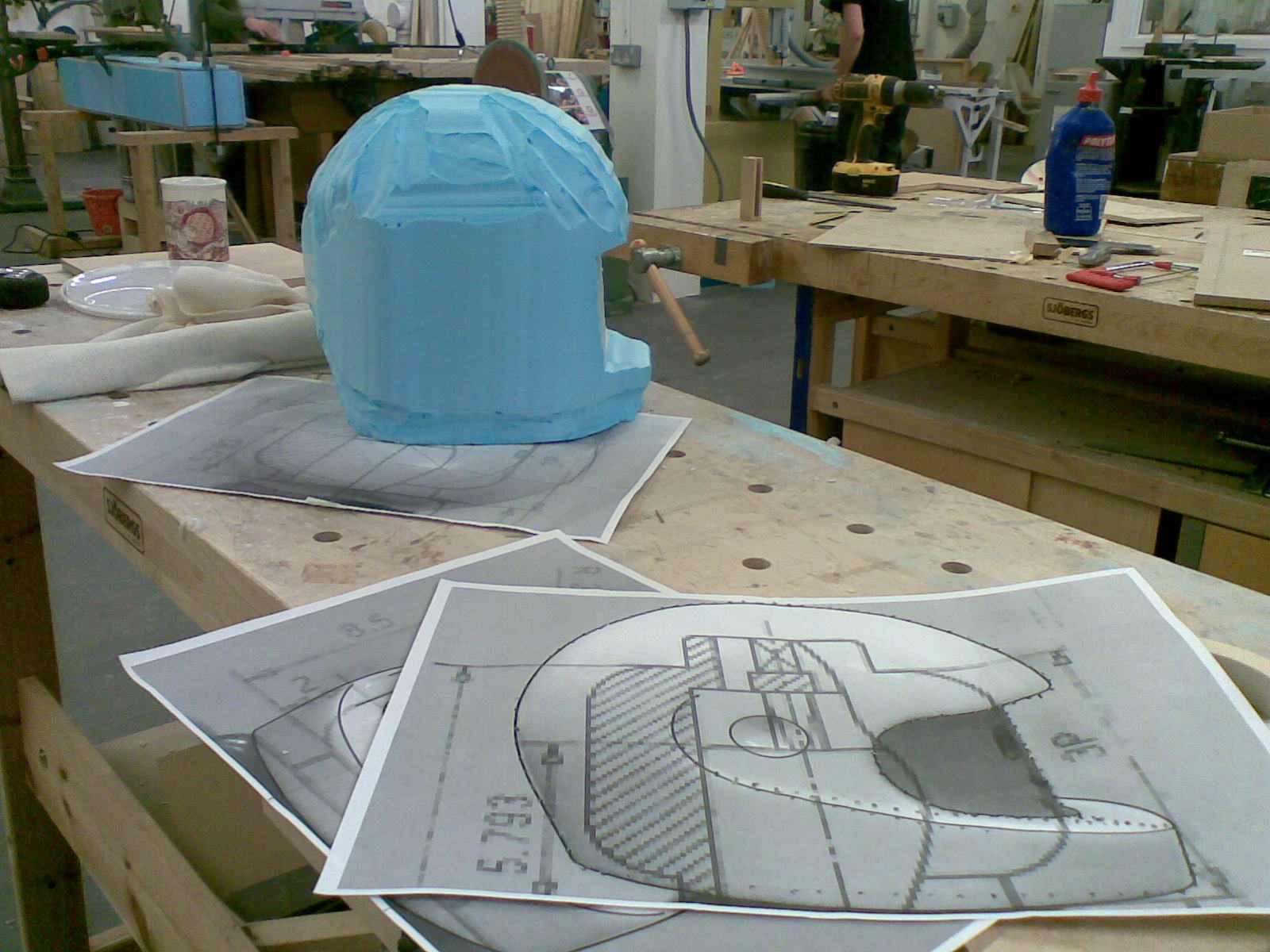

Life size LEGO helmet

Audio ComicA life-size LEGO Space Helmet made to play downloadable audio tracks for LEGO comics.This is for a University project but I had to share it!