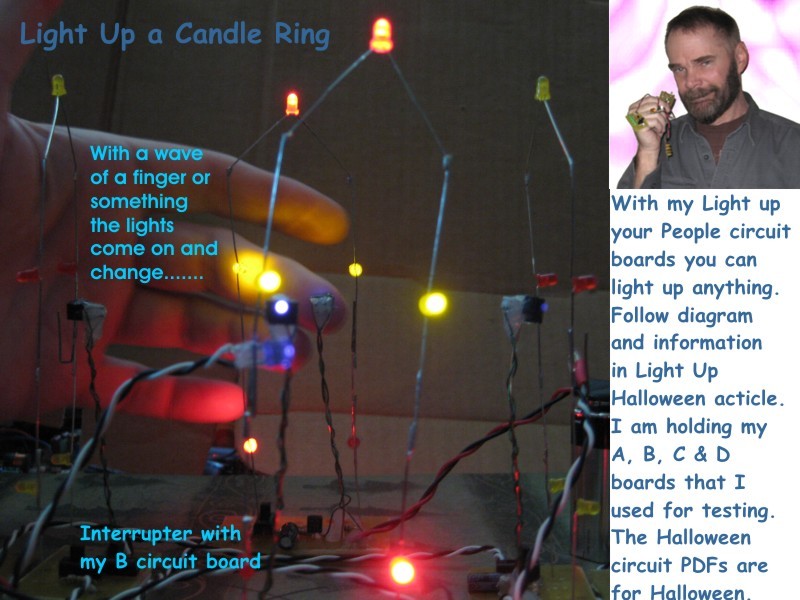

Infrared diodes and detectors make things fun and magical. We are used to touching or flipping a switch to turn on lights. A simple transistor circuit with an infrared detector and the lights change with a wave of your finger. My circuit boards are simple and all of the parts to run the detector, transistor and lights are on the board. Once you have my circuit boards you just aim the transmitter at the detectors and your lights move and change. The switch is optional and just there to control your lights. Just remember to put a jumper across the two contacts if you do not install the switch. One switch can control everything. The capacitor slows down both the turn-on and turn-off of the lights. Use 22 to 100 microfarads (mf) cap if you want to.

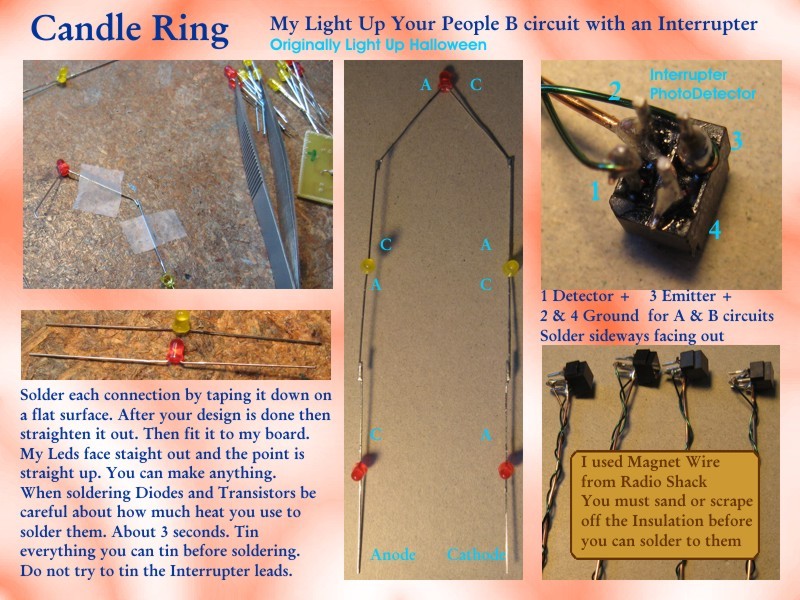

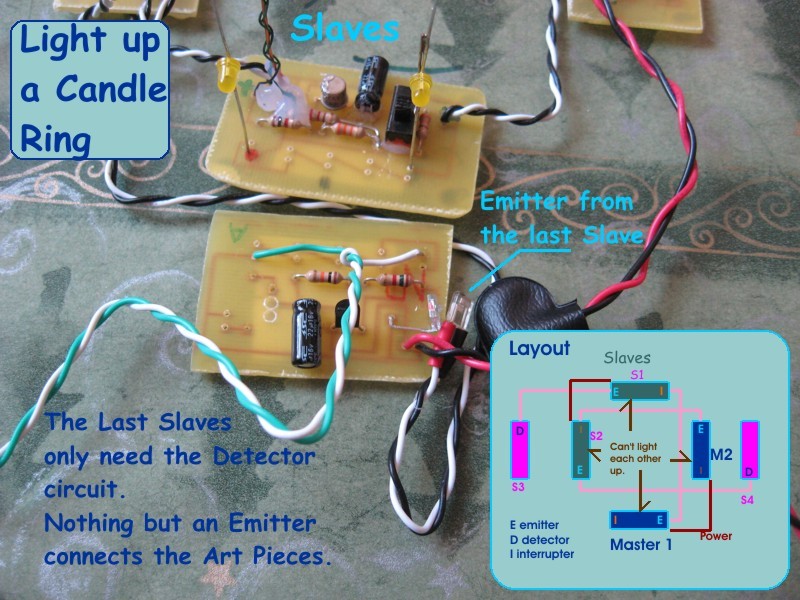

You can use my Light Up Your People (Light Up Halloween) B circuit board to light up a candle ring or anything. In this circuit I am using what I call an interrupter. It has both the infrared detector and emitter in one package. This one faces straight up and has four leads. See the pictures. In this B circuit board I needed to change R3 from 10K to 33K to handle the interrupter’s detector. I haven’t modified the C & D circuits to use the interrupter yet. Also, because the interrupter has its own emitter I just put a 220-ohm resistor on the board next to R3 to power it. The right side of R3 is V+ (9v). You just solder the 220-ohm resistor to R3 on top of my board.

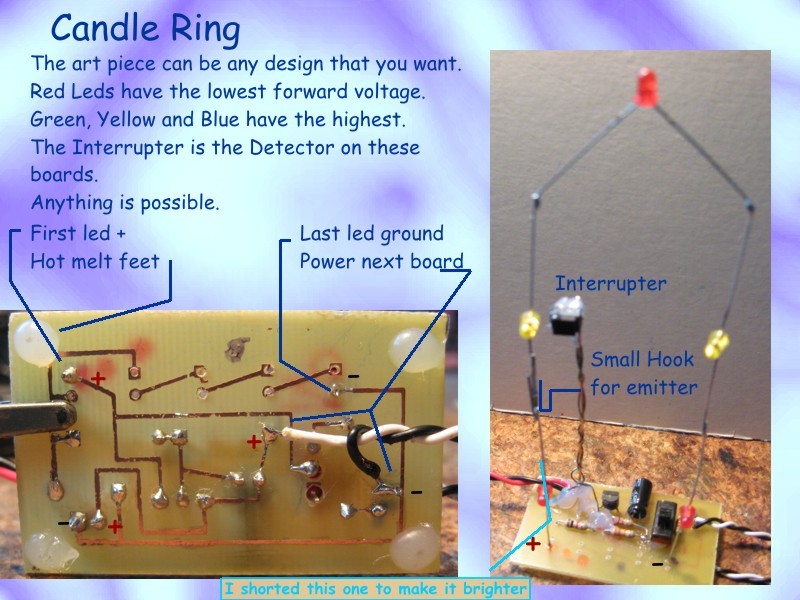

The interrupter has four leads so just solder wires to the outside corners of each lead. The emitter and the detector can share the ground in the A & B circuits. The detector is reversed on the C & D circuits. One small wire or lead trimming can be used to connect pins 2 & 4 on the interrupter. Interrupter Pin 1 is Detector Collector (+), 2 is Detector Emitter (-), 3 is Emitter Anode (+), 4 is Emitter Cathode (-). Just three wires are required for the A & B circuit boards. Ground (2&4) to detector (-) on my board. Interrupter Collector (+) to detector (+) on my board. Interrupter emitter (+) to the 220 resistor to V+ next to R3.

Infrared emitters can vary in forward voltage because of power output differences. To check your emitter use a 470-ohm resistor connected to emitter + and to 9 volts, and connect the emitter’s ground to ground. Measure the emitter + and – to get the forward voltage of your emitter. Then try the 220-ohm resistor and see what the forward voltage is. Most digital volt/ohm meters have a diode checker. Clip the positive probe to the emitter’s + and negative probe to the emitter’s -. You should get the diode’s forward voltage. Some digital meters’ top range for a diode is 3 volts. This still means your diode is OK so just check your diode manually as described above. My interrupter has a better range with a 220-ohm resistor.

The interrupters, sometimes called photoreflectors or photodetectors, come clear or tinted to help with operation in ambient light. Here are some current parts and where to get them.

- Jameco.com OPB606A (same as mine) Part no. 1872628

- Solarbotics.com Line Sensor QRD1114 clear square

- OPB730F IR Darlington Photoreflector tinted red round

They all work about the same. The reason I call them interrupters is where you find them being used. Your printer has one that tells the printer where the paper is. That is why clear printer sheets have a white stripe label on the top edge. In hobby robots they are used for line tracking and object sensing.

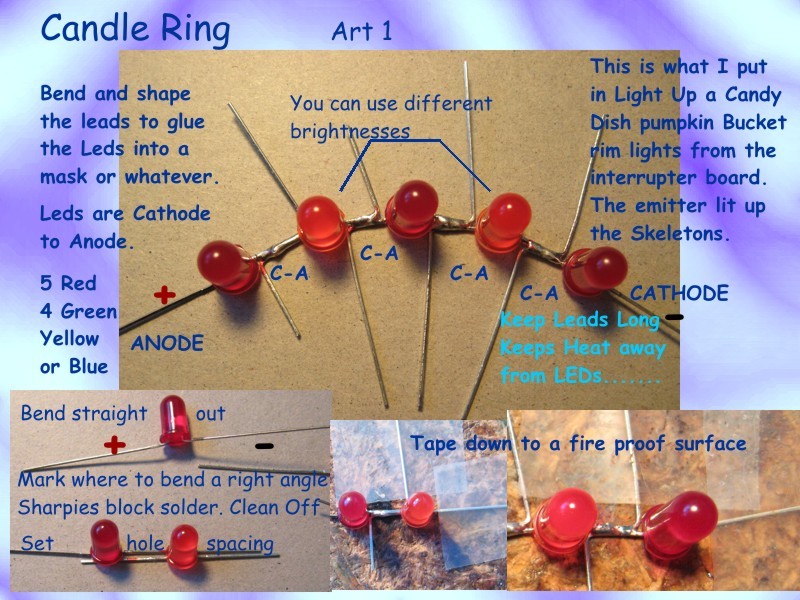

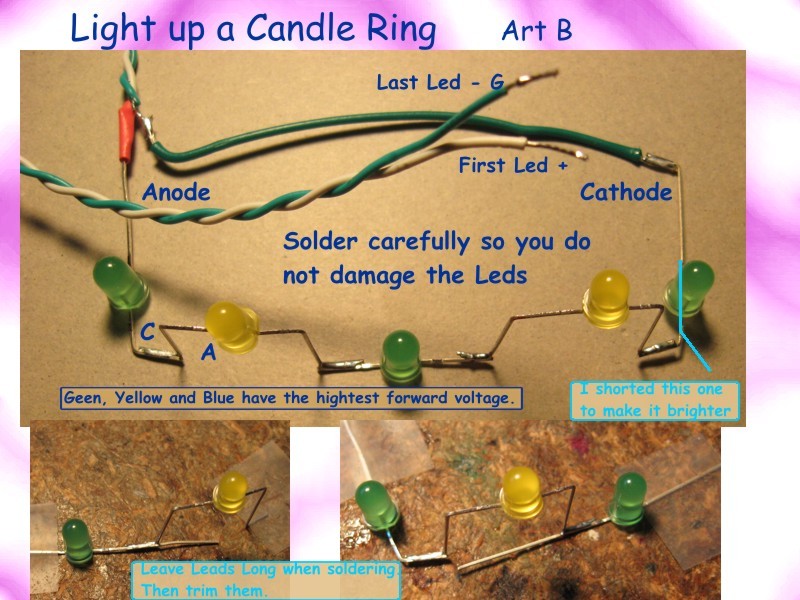

Each Candle LED art has my B circuit board with an emitter, interrupter and up to 5 LEDs. The interrupter’s detector is the detector in these circuits. I made them look like a window. You can make anything. Keep the LED leads long while making your art piece. This keeps the heat away from the LED. Trim the leads as needed after you solder them. I taped them down to my desk and soldered each joint. After the art piece is done then straighten it and then fit it to my board. The LEDs are in series, cathode to anode. The first LED’s anode goes to my board’s first LED positive lead. The last LED’s cathode goes to my board’s last LED ground lead.

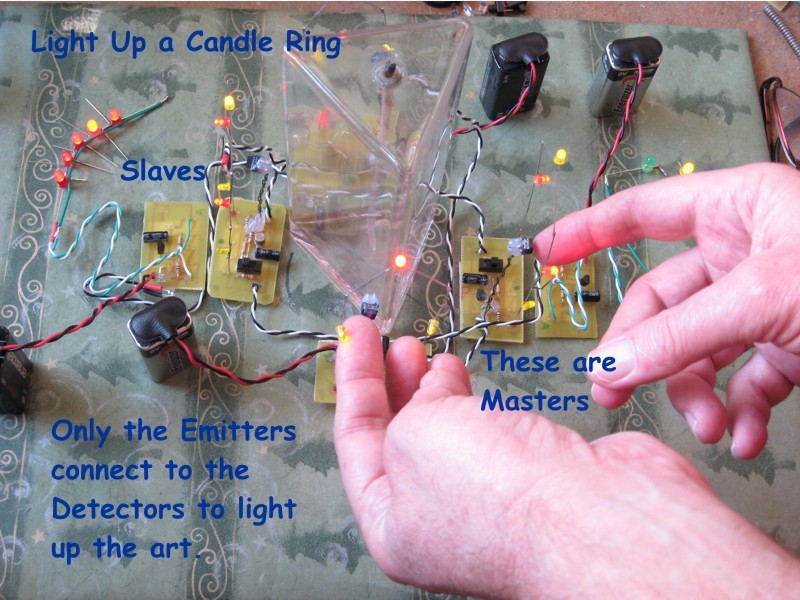

In this project the interrupter lights the LED art and its transmitter by wires and a hook lights the interrupter of the LED art across from it. By combining other circuits you can create motion art. Just aim the emitters at the detectors and the lights move. If it is the last board in a group then you can leave out the switch, the emitter resistor (R5) and the emitter. Normal-size LED emitters can light up a big area and many of my circuits at one time. The side-shooter two-lead type has a very narrow beam and only goes about three inches. Shielding stray infrared is a good idea, but stray infrared can also be fun.

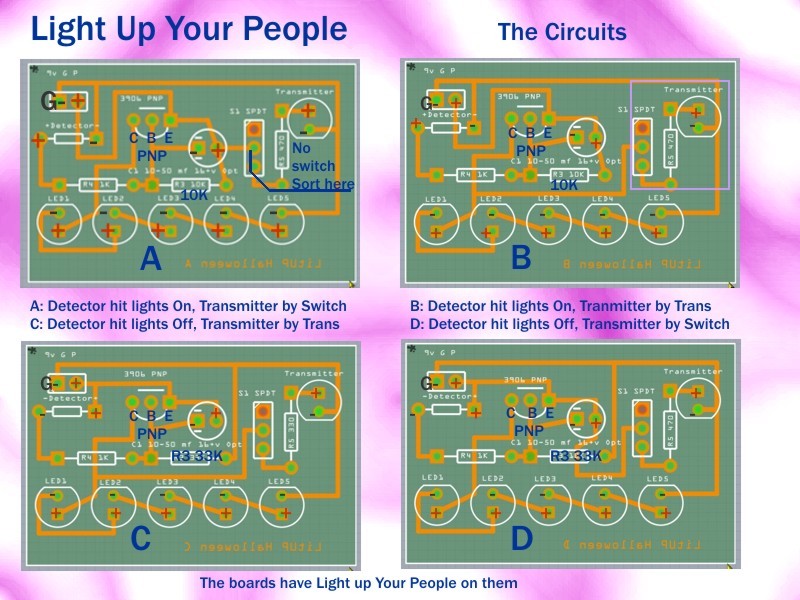

In the A & B circuits the lights come on when the detector is lit up by an emitter. In C & D the lights go out when the detector is lit up. In the A & D circuits the switch is connected to V+ to turn on the emitter. In the B & C circuits the switch is connected to the transistor so the emitter only turns on if the detector is lit. Many wonderful things can be made with my circuits.

With my circuits you can use a switch to short the detector to turn on the transistor. Connect one wire to the detector + and the other to the detector -. The switch turns on that art piece is on and the rest of the art pieces connected to it by the transmitter.

Making PC (Printed Circuit) boards is easy in this day and age. Jameco.com has everything to make a PCB at home. One positive resist 4×6 board will make 10 of my circuits. Look for 10 in the name of the PDF file. Print the PDF file at 100%. For laser printers print on the smooth side of the transparency sheet. Cut out the circuit on the board’s outline. My exposure is about 10 minutes for a small board and about 16-20 minutes for a 4×6 board. I have to rotate my 4×6 board halfway through because I have a single 17” fluorescent tube exposer frame. Mine is about 5 ½” high. I got it at Fry’s in Burbank. I think it is the same one in Jameco.com under prototyping supplies. Read the instructions that come with the boards. A good exposure makes a good PCB.

When installing the parts, start with the switch if you use it and then the resistors, cap, transistor and LEDs. For transistors, diodes and LEDs wait at least 30 seconds after soldering each lead for it to cool down before you solder the next lead. Heat can damage these parts. Soldering should only take about 3 seconds. 5 seconds is too much. Clean and tin your soldering tip. The brown stuff on your soldering tip is oxidized flux and can be scraped off with the back side of an X-Acto knife blade.

Checking parts on my boards: With a digital volt/ohm meter on the diode setting the diodes check with their normal forward voltage. The detector is about what is when checked with the diode setting and should fluctuate as normal. For each LED you can use a sharp probe, like a pin, to get to the Anode + and Cathode – to test it. Ground does not work. The transistor can be checked with the diode setting too. Place the black probe on the base and the red probe on the emitter and then the collector should show about .6 volts each.