This project first appeared in MAKE Volume 38, on pages 82–83.

Controversy swirls about who most deserves credit for inventing motion pictures. Thomas Edison, Eadweard Muybridge, and Étienne-Jules Marey all have their advocates, but a pretty good case can be made that French brothers Auguste and Louis Lumière were the fathers of the modern movie. Moving picture cameras and display systems existed prior to the Lumières’ creations, but the experience we get at the local multiplex is due, in large part, to this brilliant pair.

The Lumières were born in Besancon, France, in the 1860s. Their father, Antoine, was a well-known portrait painter who, seeing an opportunity in the nascent photography industry, started a photographic equipment manufacturing business. Both boys worked for their father, the younger brother Louis in a technical role and the older Auguste as a manager. The business became largest manufacturer of photographic plates in Europe.

In 1894, Antoine saw a demonstration of Edison’s kinetoscope, an early motion picture player. He was impressed; not so much by the technology, but by the potential for an entirely new entertainment-based business. Excited by their father’s vision, the brothers took up the challenge of building something that would provide a better, more immersive motion picture experience than the peephole that Edison’s kinetoscope used. If moving pictures were to become popular, they believed, the image had to be projected on a large screen. Not only could many people watch (and pay for) the movie at one time, but the experience would be bigger, grander, and more exciting. Besides that, the kinetoscope was a gigantic piece of equipment, heavy, bulky, and breathtakingly expensive.

They moved forward with astounding speed, designing and patenting their device in 1895. Unlike Edison’s heavy and expensive machine, the Lumières’ cinématographe was compact and lightweight, weighing a mere 16 pounds. It used a simple hand-cranked mechanism instead of the kinetoscope’s heavy, noisy, and expensive DC electric motor. But certainly the most important advance was that their machine was a bona-fide projector, able to throw a moving image onto a large screen, making it possible for a group of people to watch a movie at the same time. In March 1895, the brothers screened a short film called La Sortie de l’Usine Lumière a Lyon for a Parisian audience. The 47-second long movie is a bit short on plot and character development — it consists mainly of female workers walking out of the gates of the Lumière factory in Lyon, France. The highlight is when a man almost rides a bicycle but then doesn’t. The Godfather it isn’t, but in terms of movie technology, it was a world changer.

The cinematograph did a lot of things much better than did the praxinoscope, the kinetoscope, the mutoscope, or any other of the motion picture machines that preceded it. The patent drawings detail, among other innovations, its most important technological advance: the incorporation of a sophisticated mechanism called an eccentric cam to position a single frame of the film stock in front of the projector lens, hold it there for one-sixteenth of a second, and then quickly advance the film to the next frame.

If you were to visit a movie theater in 1985, you would doubtlessly notice a projectionist in the back of the room, carefully cranking the cinematograph at a speed of 2 revolutions per second. By maintaining this cranking speed, he moved the film past the projecting lens at a feed rate of 16 frames per second, providing a smooth, realistic depiction of motion, perfect for films of factory employees leaving work, passengers getting on and off trains, babies eating crackers, and other popular turn-of-the-19th-century storylines. (You can see the entire selection of the films the Lumière Brothers exhibited at the 1895 Paris debut at http://www.institut-Lumière.org/english/films/1seance/accueil.html.)

More than a century ago, the Lumières brought the motion picture into world focus when they created the modern movie theater experience. They were the pioneers whose cam-controlled movie projector provided the means not only to tell stories but to permanently preserve and depict nearly all aspects of life.

The Cam Controlled Movie Projector

Rotary cams are among the most important mechanical mechanisms. Every car and truck has a bunch. They’re in sewing machines, weight training machines, machine tools, assembly lines, and myriad other common technologies. Their main purpose is to translate rotating motion into linear motion. To do this, a spring is often used to keep a part called a follower in sliding contact with a rotating disk called a cam. As the cam turns, the follower traces out a programmable up-and-down pattern that can used to control the speeds, accelerations, and directions of machine parts.

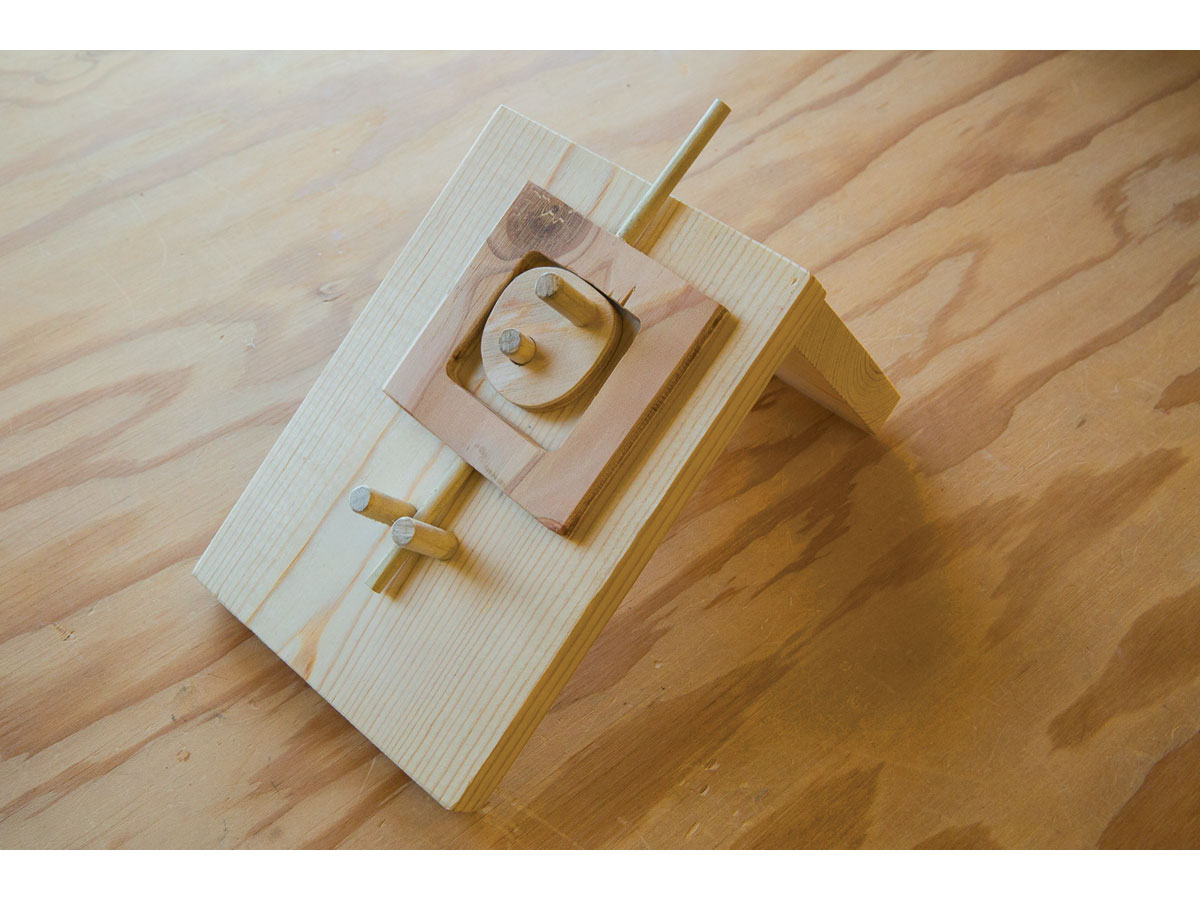

In their movie projector, the Lumière brothers designed the cam follower to completely enclose the cam. In this design, neither a spring nor gravity is necessary to maintain sliding contact; the mechanism works flawlessly in any direction or orientation. The follower is connected to claws or pins that grab the movie film by its perforations, hold it stationary in front of the lens for a one-sixteenth of a second, and then advance the film through the projector and release the perforations. This method provides a smooth, relatively simple, and above all, dependable method of moving, pausing, and advancing film. To see it in action, visit makezine.com/go/lumierecam.

Make a Lumière Cam and Follower Mechanism

This project is fun to make, and you’ll get a really interesting desk toy out of it. When you turn the crank, the claw moves with a peculiar motion that you can adjust by making small changes in the profile of the cam with a file or saw blade. You can perform endless experiments with the shape of the cam to make the follower move in a variety of interesting ways.