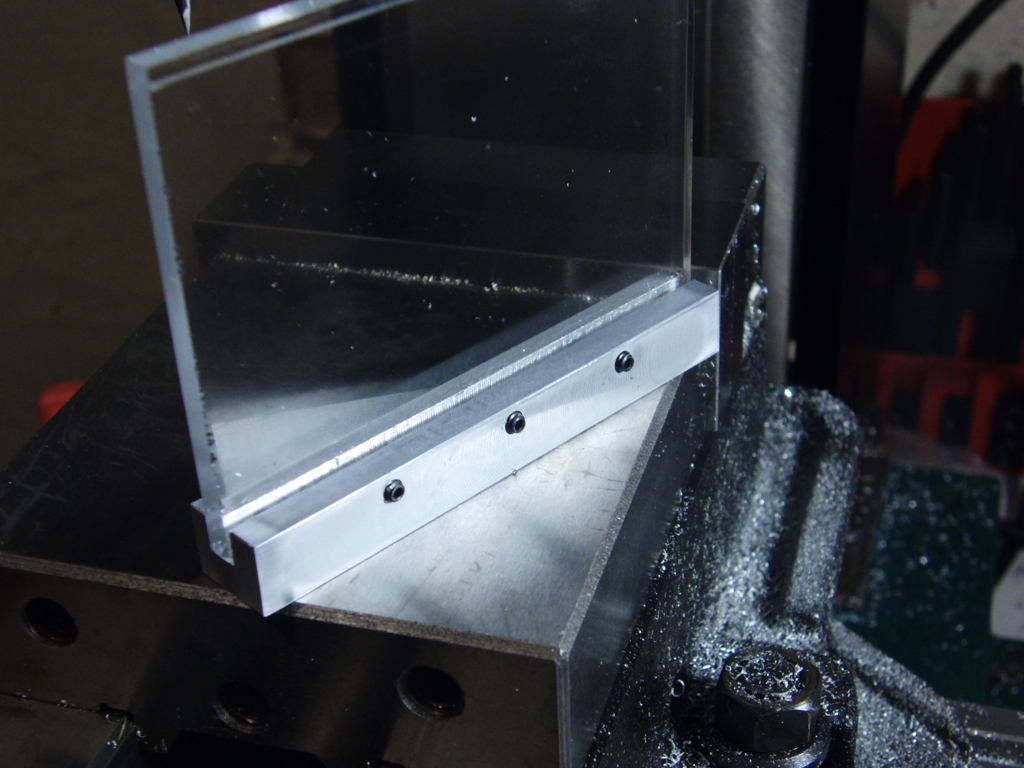

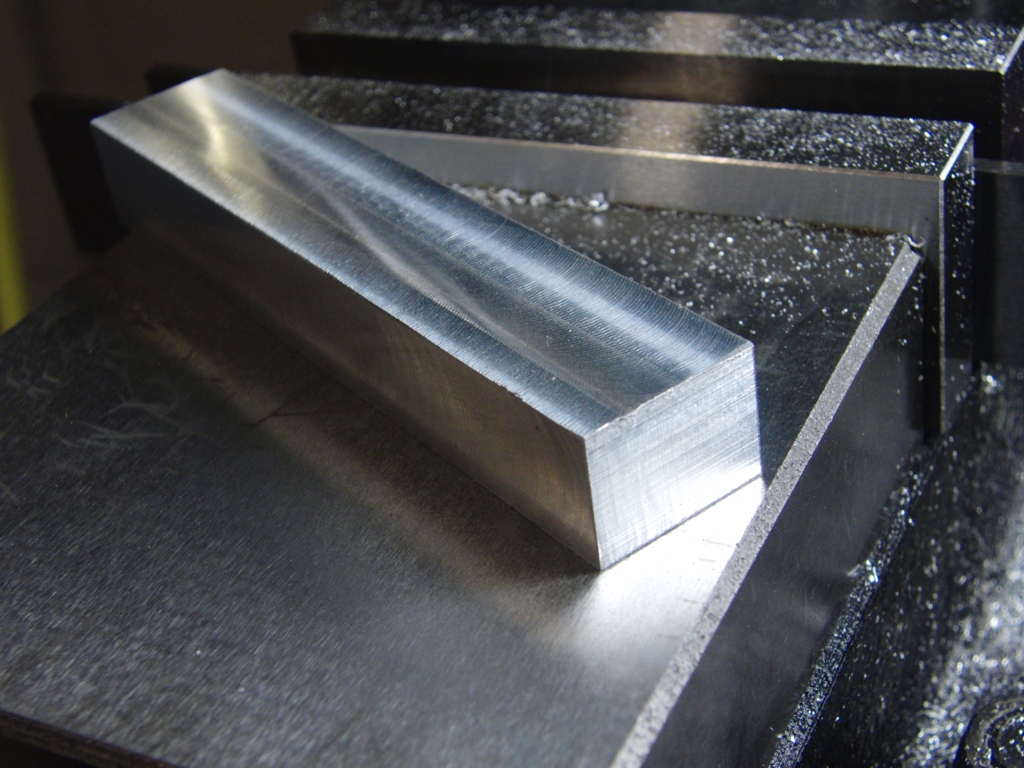

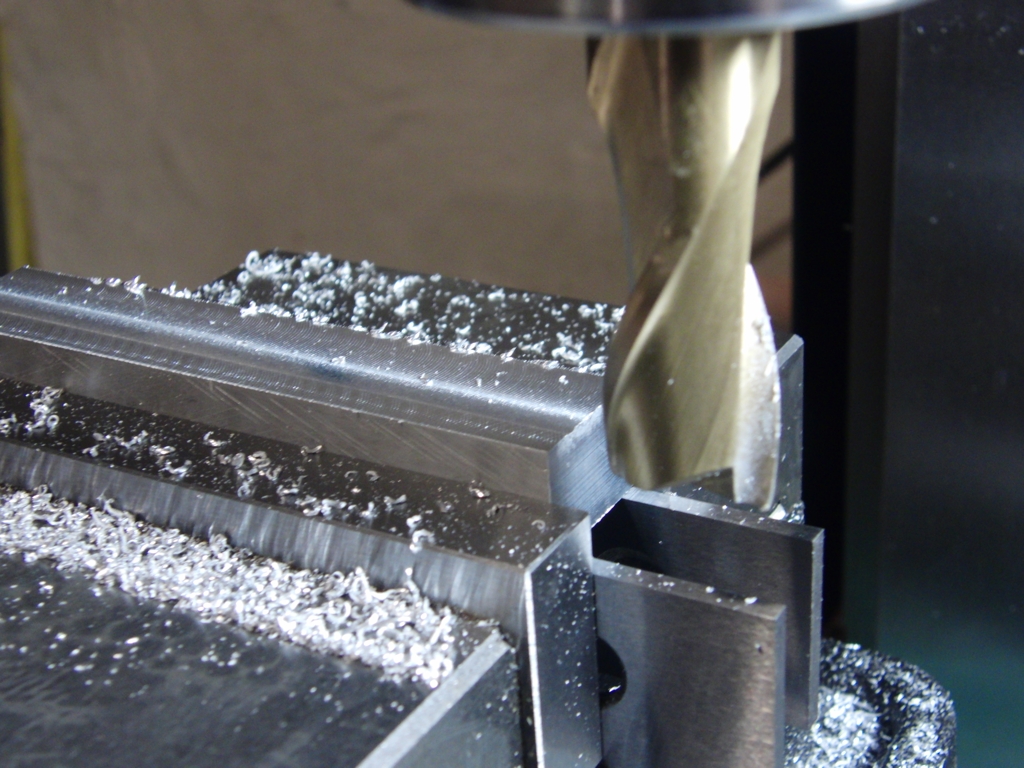

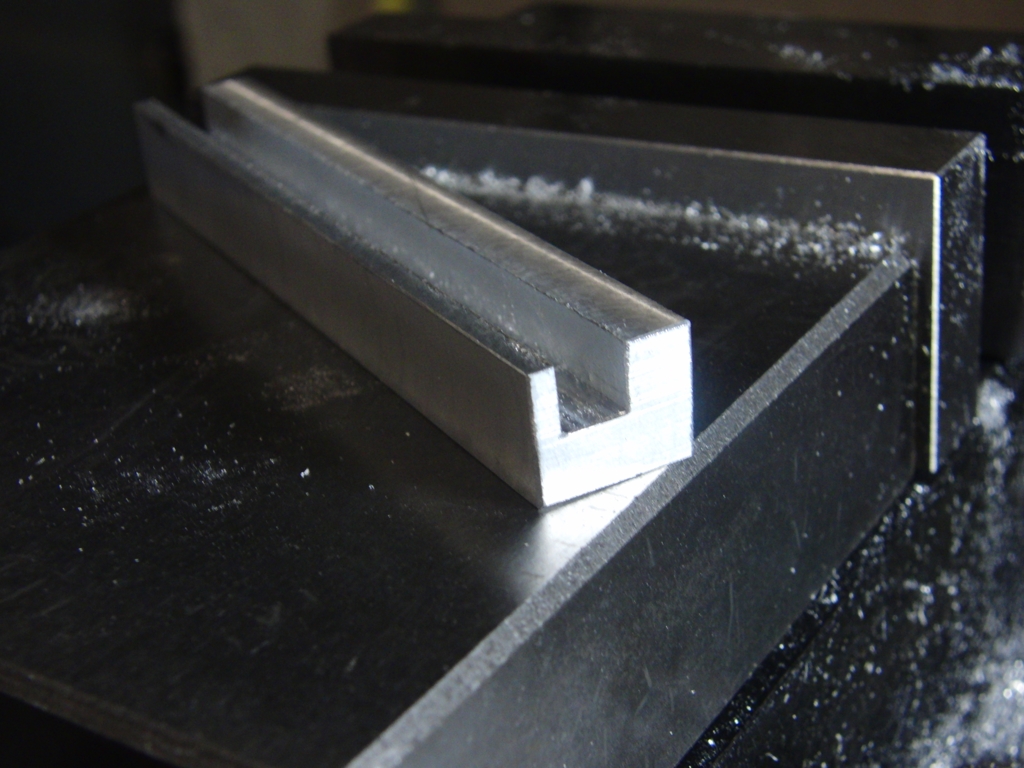

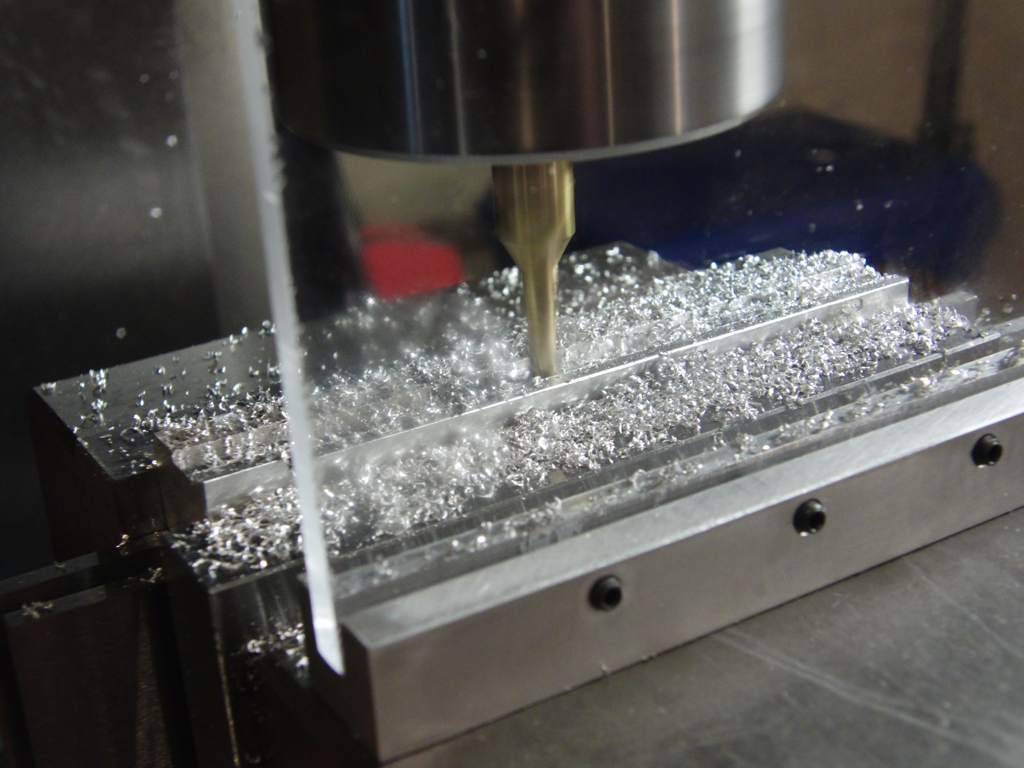

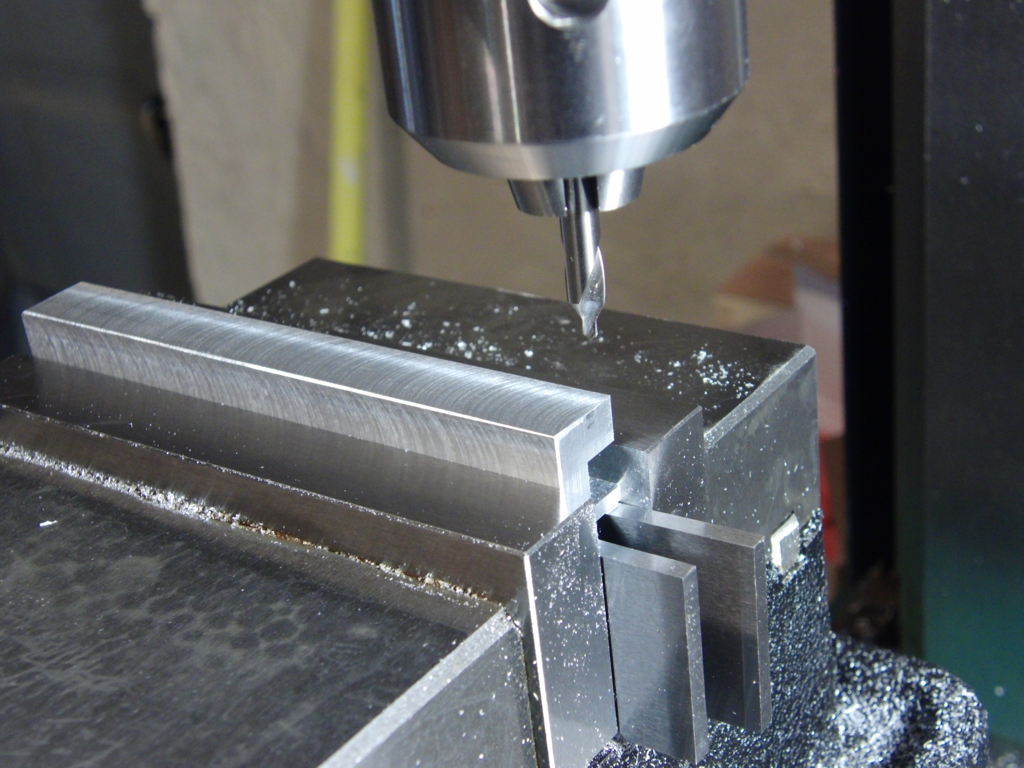

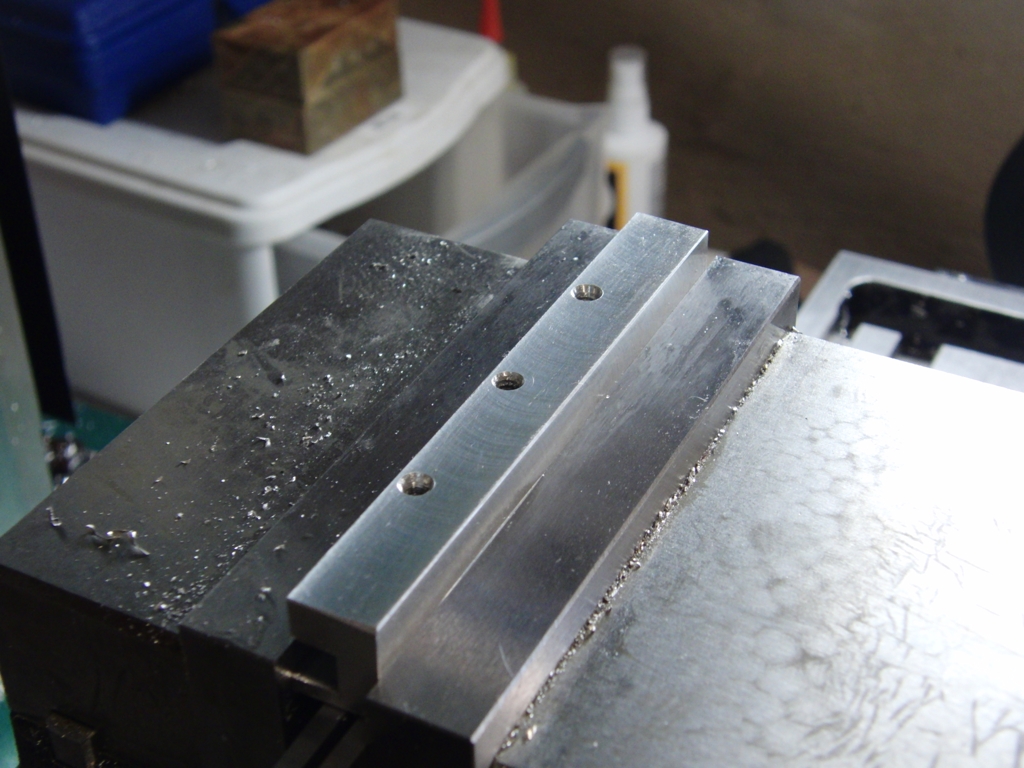

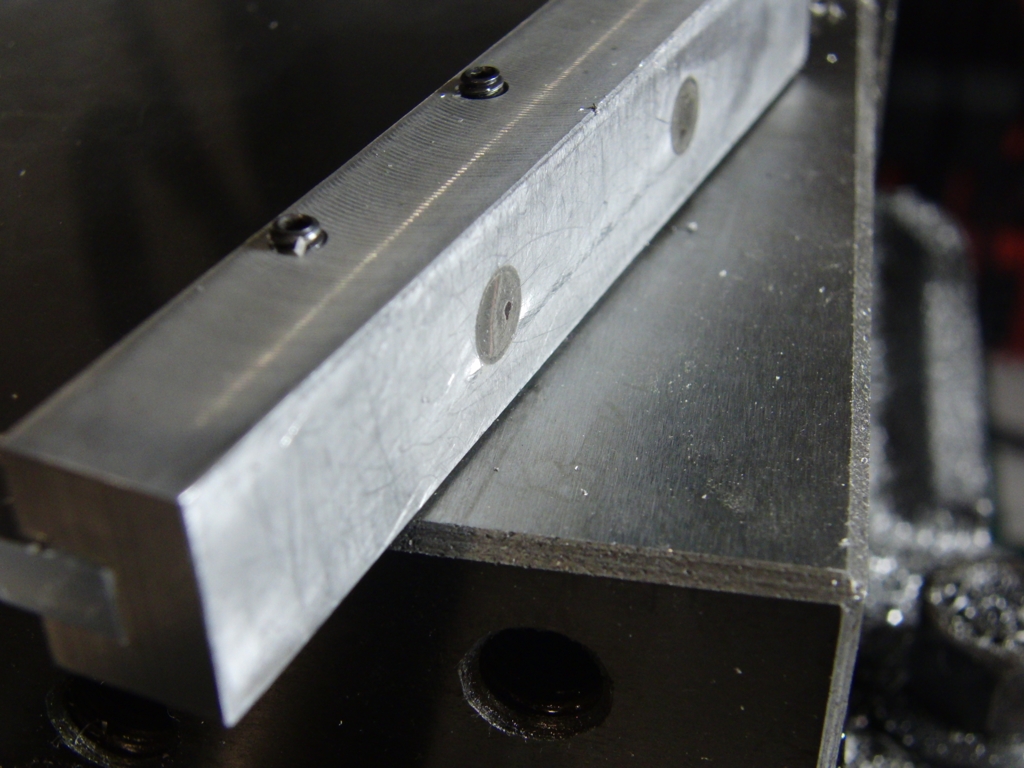

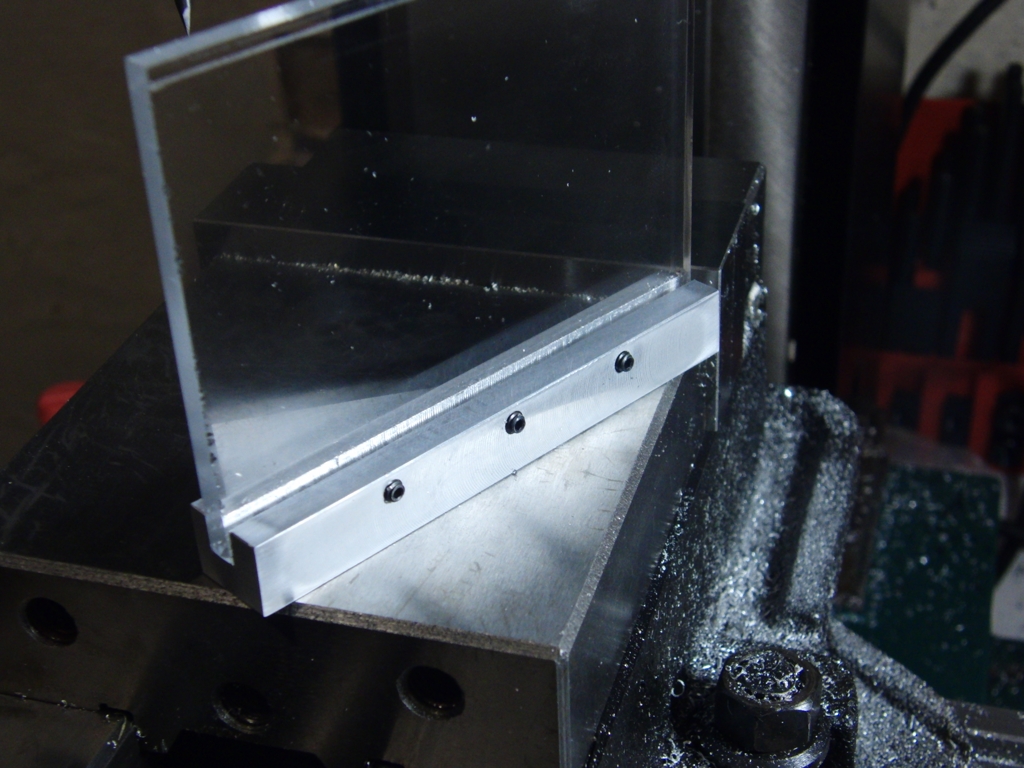

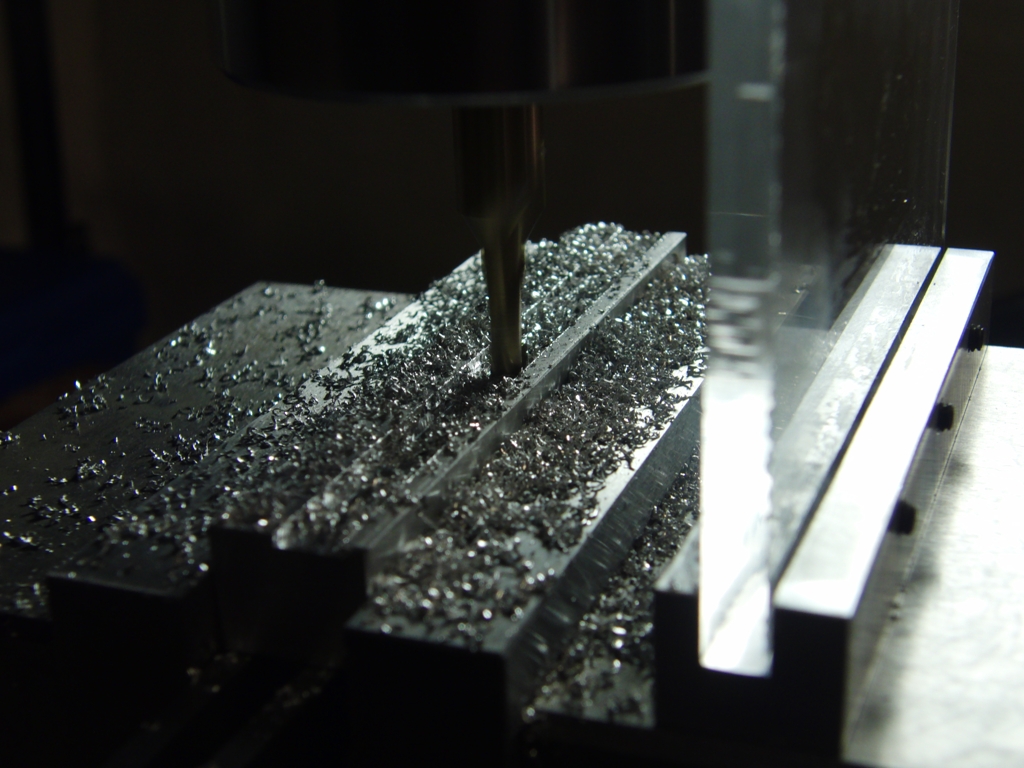

For too long I’ve been standing in the stream of chips flying off my milling machine. This small shield sticks to my milling vise magnetically, and takes less than an hour to make. It does a good job of helping keep chips contained, especially when using cutting fluid or fly cutters. I’ve also found it to be useful on my drill press.

Projects from Make: Magazine

Magnetic Chip Shield

In under an hour, build a small shield to shelter you from flying chips.