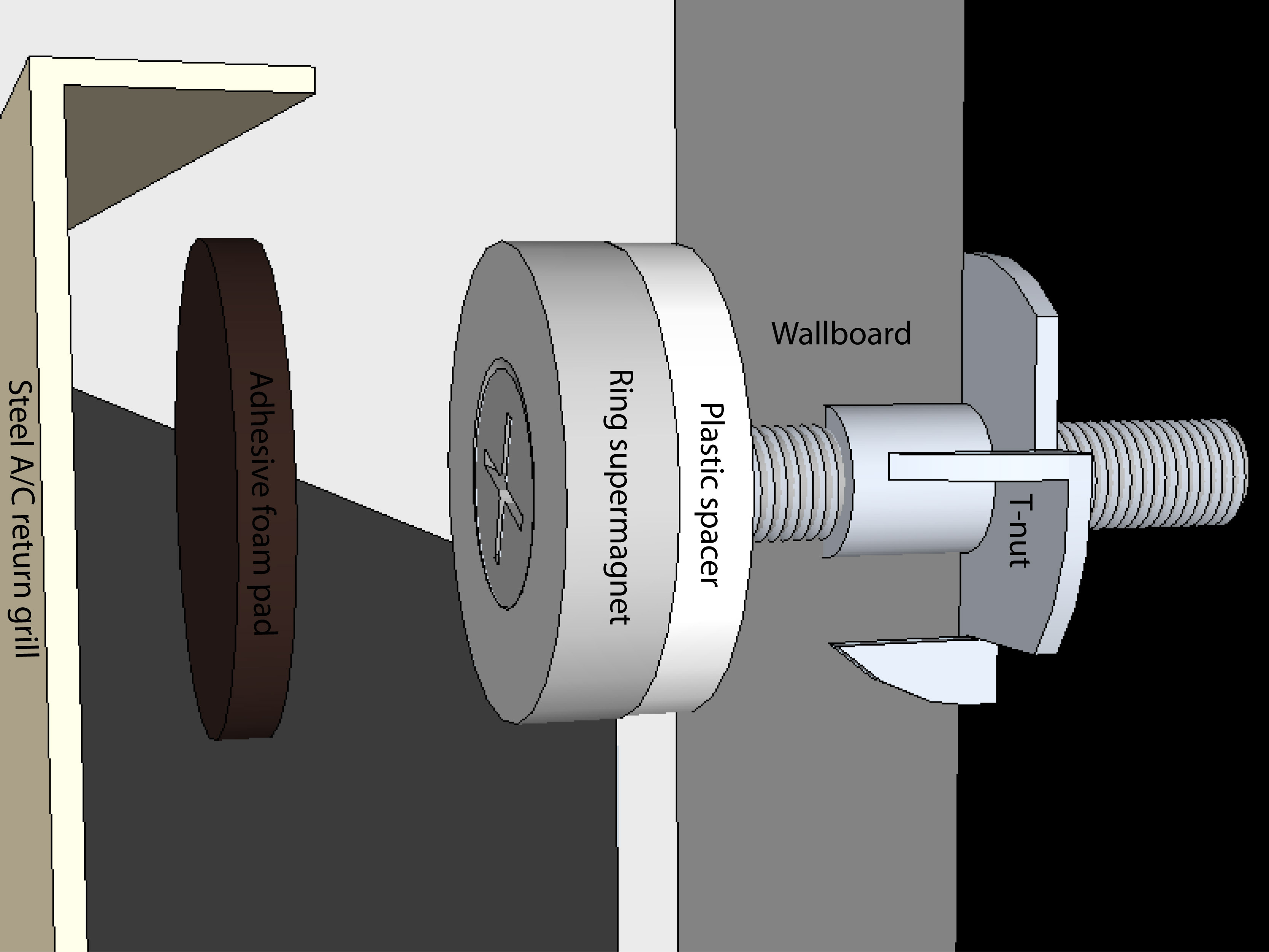

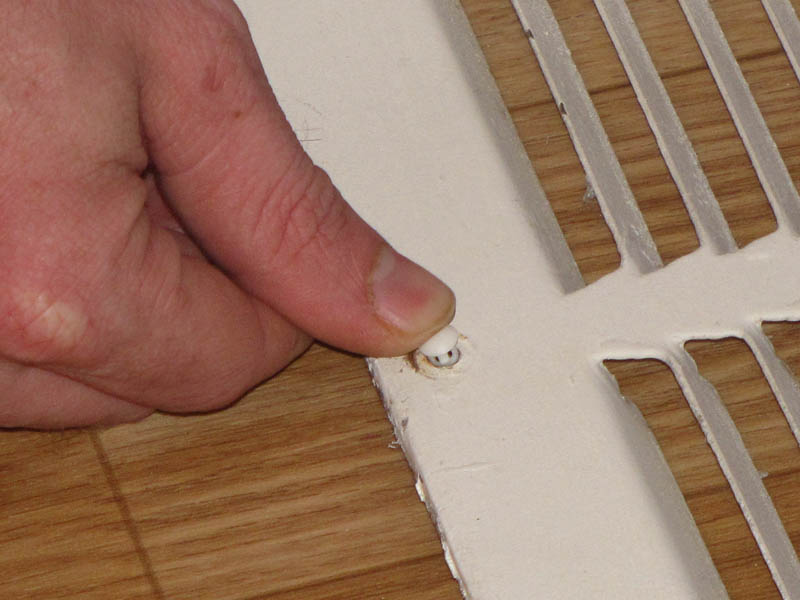

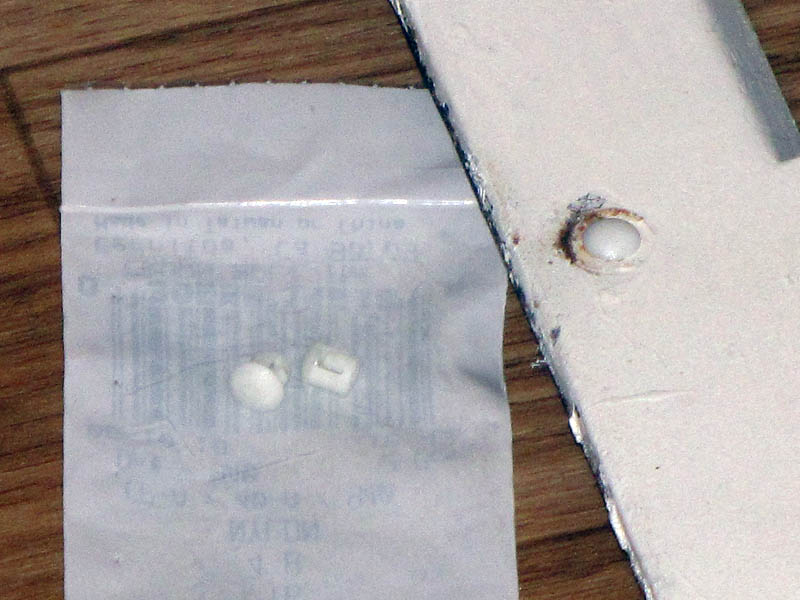

The return grille mounting in my new house was very sloppy, with a mixture of Molly bolts, toggle bolts, and bare screws in drywall. The sloppy workmanship annoyed me, and made swapping the filter way more work than it needed to be, so I came up with this no-tools fix. It could easily be adapted to any steel maintenance panel.

Projects from Make: Magazine

Magnetic HVAC Return Grille Mount

Replace screws with magnets for tool-free maintenance.