I like to pick things out of trash cans and reuse castaway items. Here, I repurpose the trash can itself to facilitate recycling organic waste into beneficial compost.

Commercial composting canisters can be costly, but they’re simply a place to allow natural microbial processes to convert waste matter into a dark, fresh-smelling soil. Commercial versions allow air and some water to get in, and sometimes a way to mix.

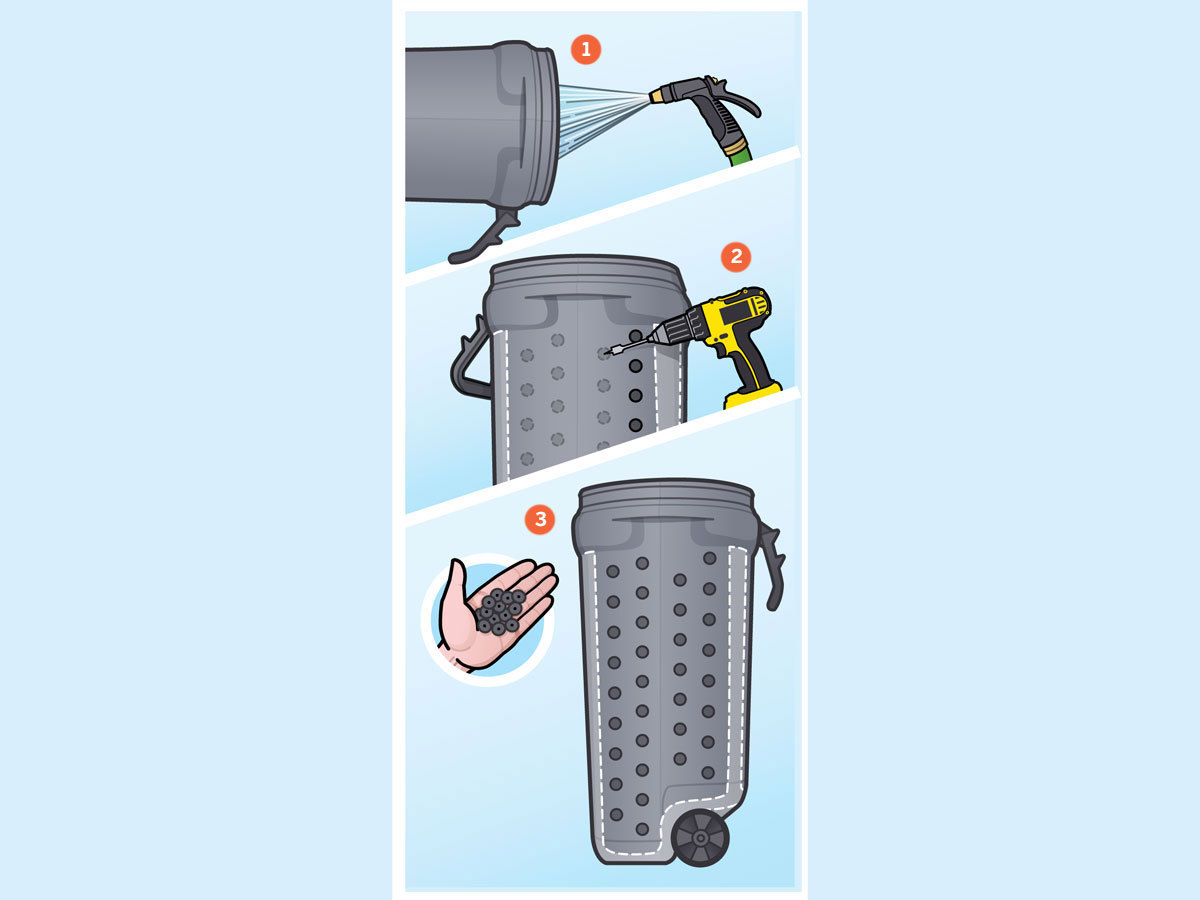

Most home trash cans fail when part of the bottom wears away, leaving a hole. Such a trash can is perfect for this project, since we’re just going to add more holes anyway.