For many years, the U.S. military has enjoyed playing with “toys.”

Today that includes unmanned drone aircraft, but in the past, it was toy balsa wood airplanes. Thousands of folding-wing balsa gliders were shot out of the sky in the early 1940s for World War II artillery practice. High in the air, these toy airplanes had the scale effect of a full-sized plane. Developed and patented in 1939 by Jim Walker, founder of the American Junior Aircraft Company, the folding-wing Army Interceptor glider bore the brunt of the action.

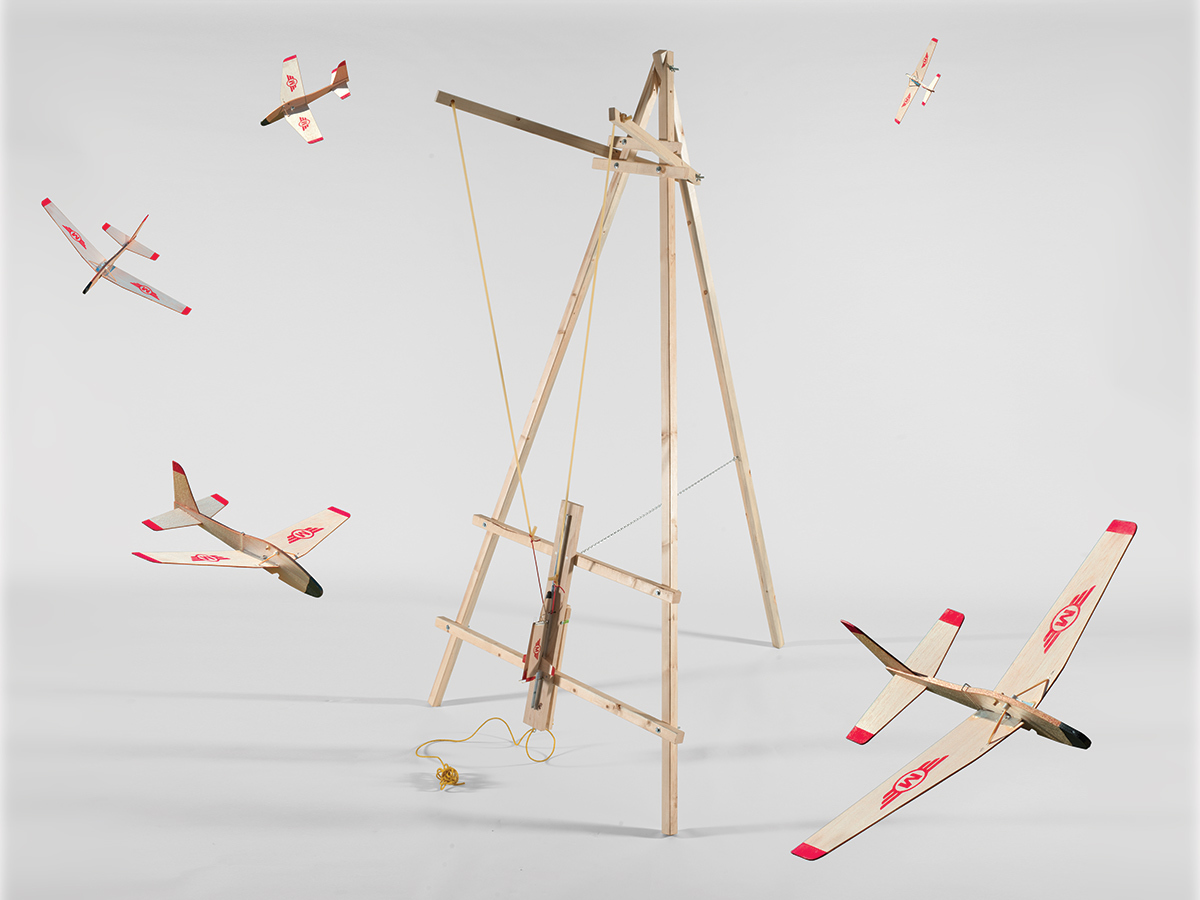

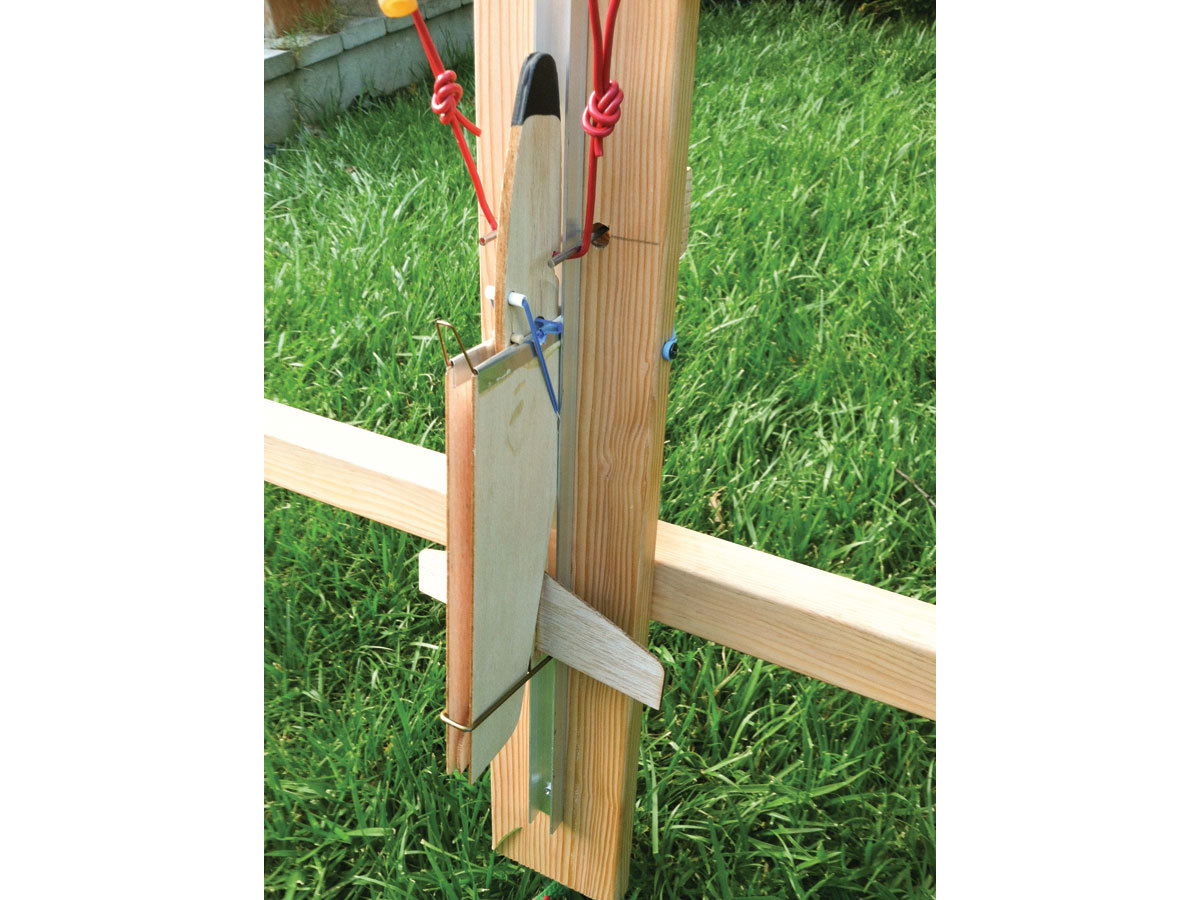

My folding-wing Rocket Glider, based on the Interceptor, was featured as a how-to project in MAKE Volume 31 and is available as a kit from Maker Shed. While the Interceptor originally used a handheld rubber-band catapult, the military designed a launcher to hurl the gliders nearly 300 feet high. In 2004, Frank Macy designed the first reproduction of this launcher, on which this project is based.

With nearly 20 pounds of pulling force, this simple catapult remarkably flings the tiny glider (weighing less than an ounce) 150 feet into the air. Stand clear, pull the rope trigger, and watch a piece of history rocket into the sky!