It’s easy to build up a “junk box” of items you can use to build projects seen in MAKE — or just about anything you can imagine.

Many of my articles for MAKE take advantage of found components, often picked out of trash bins. Just because an electronic device has failed at its original task doesn’t mean it can’t perform other tasks. Castoffs can be recovered and the parts repurposed in countless ways.

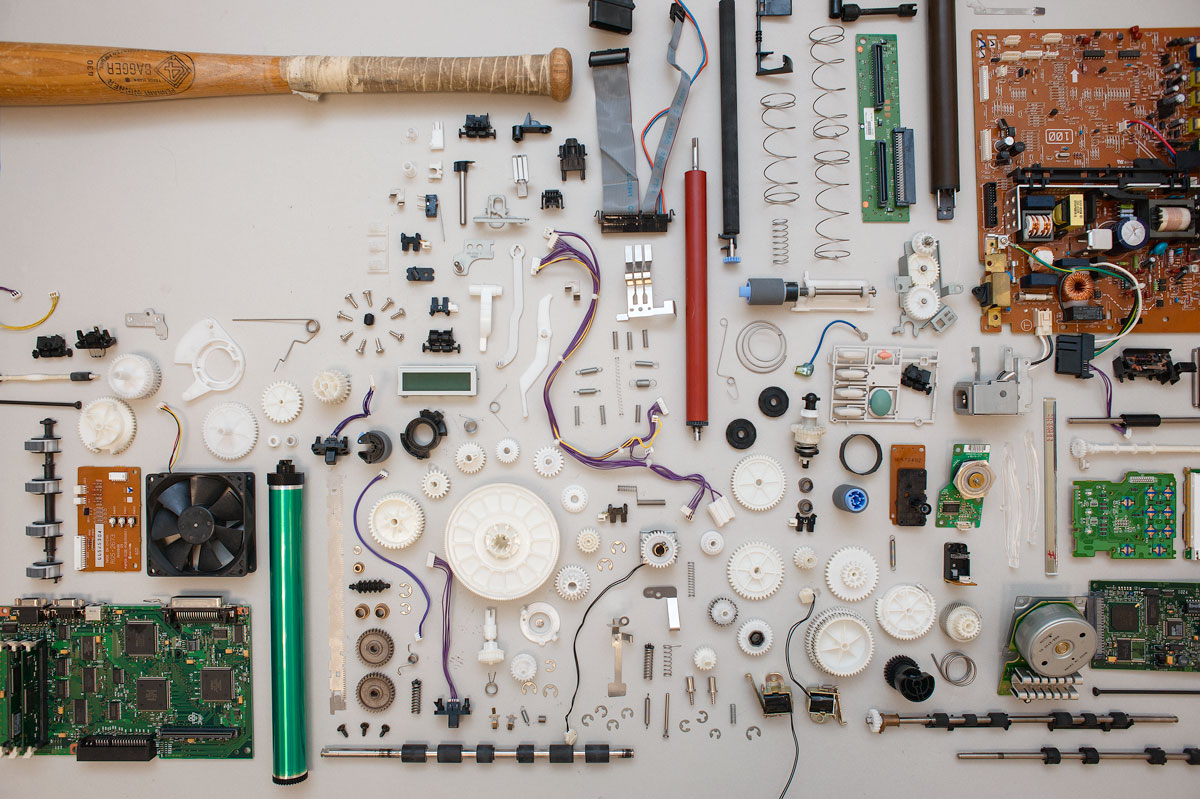

Recently, my trash-picking adventures turned up a discarded laser printer. I set about finding what wonders were waiting beneath the plastic covers.

Jackpot of Parts

My first discovery was the main circuit board. Once I stripped the heat shields off, I found over 50 nonproprietary electronic parts, including capacitors, resistors, voltage regulators, transistors, transformers, coils, and integrated circuits. Jackpot! A couple of boards like this, and you’re on your way to building a backup supply of parts for future projects. A second, smaller PC board also yielded numerous useful components.

There are 2 strategies for keeping these components in stock: take the time to desolder the parts and store them separately, or leave them on the boards and inventory them on a sheet of paper attached to the board for future reference.

Digging deeper into the printer, I uncovered the paper transport mechanism. Gears, gears, and more gears! I harvested 2 gear mechanisms for turning rotating movement into linear movement. Anyone interested in robotics projects would find these useful.

The rest of the teardown revealed the laser tube and lenses, various rollers, wires, springs, and hardware, micro switches, relays, and of course a motor. I scored over 200 free, useful parts found for future use.

And don’t forget the plastic or metal case and chassis parts. I keep a couple boxes of these allegedly useless scraps to cut and shape when developing design ideas.

WARNING: Capacitors can hold a charge for months after they’ve been disconnected. Always bleed off the charge to ground, to prevent any shock hazard.

Inventory and Storage

So now that we’ve begun the process of pre-owned parts procurement, let’s give some thought to keeping track of what we’ve found. I’ve tried many strategies over the years, and I’ve discovered that one of the easiest (and cheapest) ways to store most electronic components for future use is in common mailing envelopes. For example, you’ve amassed a quantity of resistors of various values. Sort them by ohm rating (and perhaps by wattage and tolerance), and place them in envelopes marked with the relevant values. When you need a 100-ohm, 2-watt, 5% resistor to complete the circuit you’re playing with, you know right where to find it. This strategy works great for any components that are not potentially damaged by static discharge in handling. Complementary metal-oxide semiconductors (CMOS) and field-effect transistors (FET), as well as many integrated circuits, can be damaged by even the slightest static electric discharge. Such parts should be handled while taking anti-static precautions and need to be stored in static-free bags or containers.

Larger parts require larger containers. Pill bottles, as well as juice and coffee cans, are great found storage containers for the bigger items in your junk box. Again, clear marking with a felt tip pen or label maker makes quick location of any desired part a snap.

Sometimes it’s useful to have a container to gather all the parts you might want for a specific project. Let’s say I want to keep all the mechanical parts I found in the castoff printer for a specific robotics project. Head to your local discount or sporting goods store and find the aisle devoted to fishing. You’ll find dozens of small, partitioned containers designed to hold fishing lures and hooks. These are perfect for project parts management.

Fair Warning: There is an addictive quality to parts gathering. Once, my personal junk box was simply a box. Now, it’s more like a junk room. But I know that I have all I need to make just about anything that comes to mind, and most of it was found and free. That’s the maker way!