Assembling a single electronic board using SMD parts is doable using simple tools with tweezers and a fine tip soldering iron. However, it can become tedious after a few boards or simply if you start an actual production yourself.

Also, some parts are really hard to solder by classic means, and I ended up building a reflow oven to “bake” my boards.

If you’re not familiar with reflow soldering, I suggest you have a look to this wikipedia article for details.

For large boards, placing the SMD parts on the solder paste can really be an issue since your hands must travel above the board to reach the part location, with risks to drop the part and mess all your solder paste stencil work.

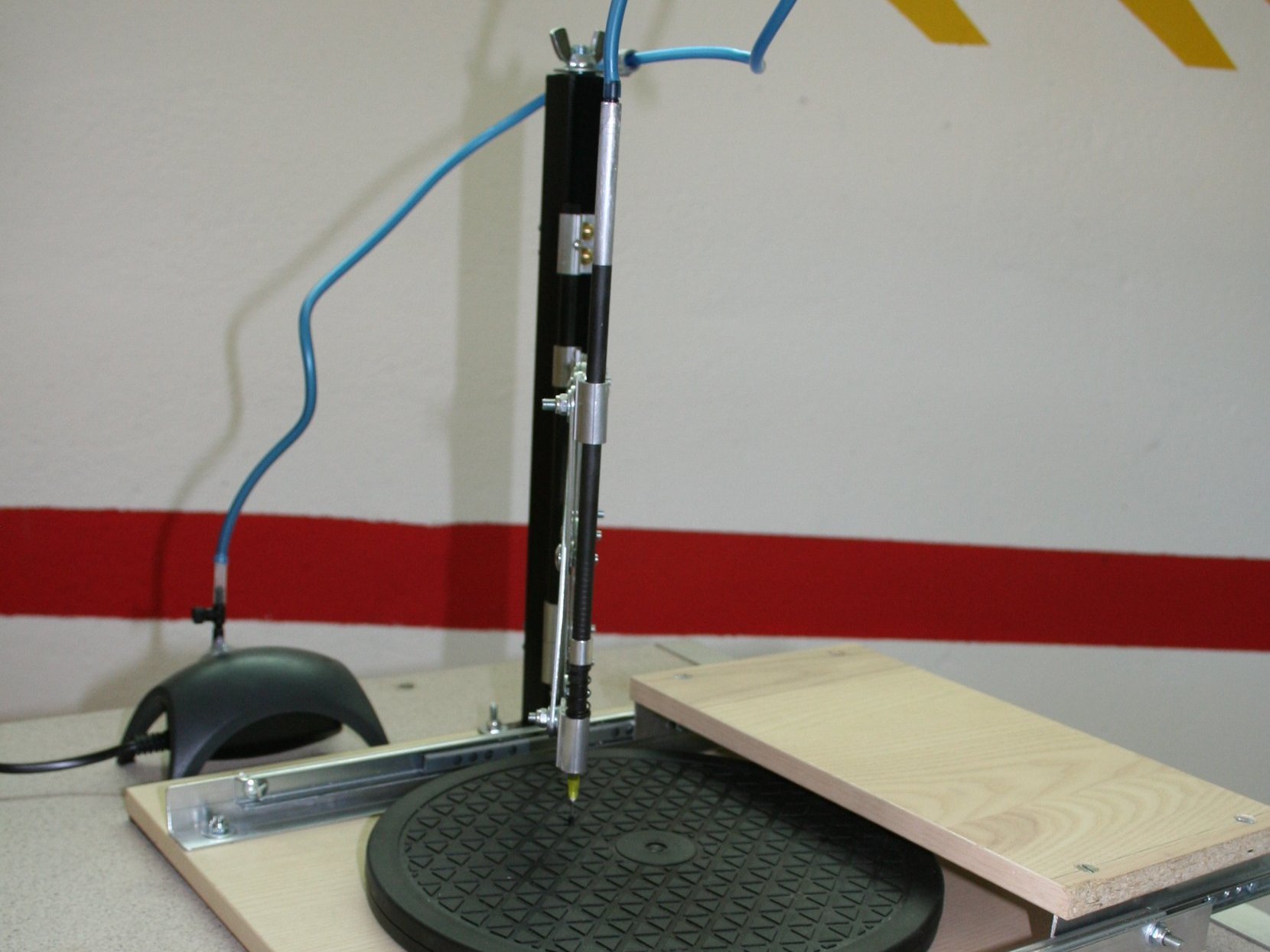

The SMD pick and place station is meant to help the operator traveling above the PCB, pick parts using vacuum, and place them with a straight, smooth and accurate vertical movement to the exact spot where it’s suppose to land.

Surprisingly enough, that station can be assembled with many classic hardware parts available for cheap.