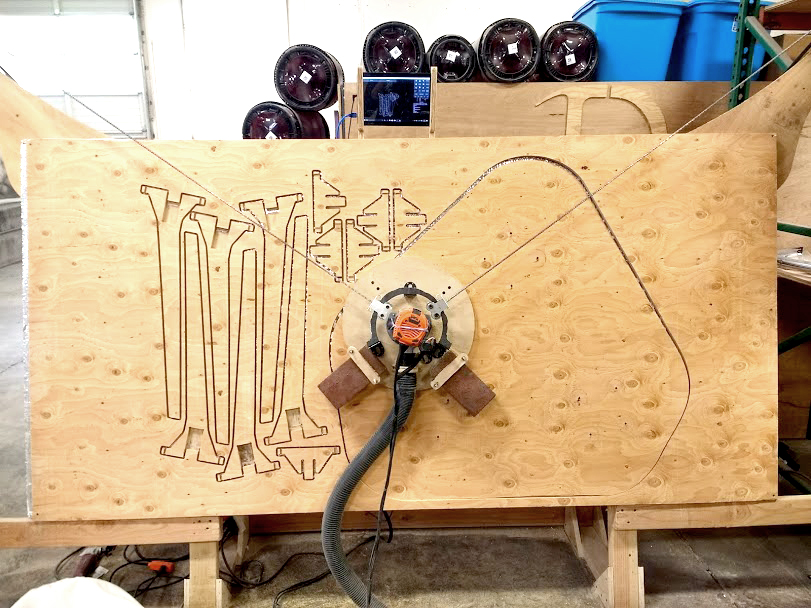

The Maslow is a large format CNC router capable of cutting wood and other materials with precision and repeatability, based on a digital file. A CNC (computer numerical control) machine allows makers to automate the cutting process in woodworking and other manufacturing operations. When the Maslow kit is built and software is installed, makers will have a fully functional CNC machine able to cut a surface of 4×8 feet, with adjustable cut depth. The design is open source so anyone can build it, from scratch or from a kit.

The application for this tool is enormous. Cabinet makers, hobbyists, sign makers, woodworkers, furniture makers, and more have all seen the value in automated cutting that can multiply their productivity and produce extremely intricate designs. Whether for personal use, side hustle, or full-time day job, the Maslow CNC is an incredibly versatile tool. You can build it for about $600 if you’ve already got an ordinary fixed-base router, and unlike traditional flatbed CNCs, its upright design takes up very little floor space in your shop or garage.

Maslow began as a hobby project of Bar Smith in 2015. In 2016 Hannah Teagle joined to help run a Kickstarter campaign to build an open source community around the project. In 2017 they showed the machine at Maker Faire Bay Area, shipped four batches of kits sending thousands of vertical CNC machines around the world, and watched the community take off.

Soon the logistics of packing and shipping kits became too much, and Bar and Hannah asked the Maslow community for help. They publicly posted the design files and made the factory tooling available to anyone who was willing to take on the task of continuing to make kits.

Maker Made CNC stepped forward and made kits available again only a few months after the last kit from Maslow shipped. Their mission is to continue the work of Bar and others by investing in updates to make the kit accessible to a wider audience of makers, and introduce products and accessories that will further enhance its functionality and capabilities.

BUILDING YOUR MASLOW CNC

Building the Maslow is a true DIY project. You can follow the complete, user-editable assembly guide here.

Scratch builders can also get schematics, blueprints, and CAD files for the custom parts on the Maslow website, so a local shop with a waterjet cutter and a press brake could easily make them.

Here’s an overview of how it all goes together.

Materials

ROUTER

Router, fixed base, with depth adjustment We recommend the Ridgid R22002 for U.S. customers. International users have been successful with Bosch routers.

FRAME

¾” plywood, 4’×8′ sheet

2×4 lumber: 10′ lengths (6) and 8′ lengths (2)

Bricks (2)

Wood glue

You can build your Maslow from a kit by Maker Made CNC ($499, makermadecnc.com), and they’re offering free shipping to Make: readers (use coupon code MakeMag2019). Or you can build it from scratch by sourcing the parts yourself. Key components include:

ELECTRONICS

Arduino Mega 2560 microcontroller board Maker Made (MM) part #810 or Amazon #B01H4ZLZLQ

CNC motor controller shield for Arduino MM #800, or maslowsurplusparts.com/products/arduino-shield-v1-2. Or make your own, using the design files and components list at github.com/MaslowCNC/Electronics.

Heat sinks (2) included in MM #800, or try Digi-Key #345-1102-ND

Gearmotors, worm drive, 191:1 reduction, 7ppr encoder (2) MM #880, or maslowsurplusparts.com/products/maslow-cnc-motor-single. The key is that the encoder is on the back side of the gearbox so the 7ppr encoder gets scaled up 191x, then quadrature encoding gives us 4 steps per pulse, so at the output shaft you have 7*191*4 = 5,348 steps per rotation.

Motor cables, custom (2) MM #900

Power supply, 12V 5A, 2.5mm × 5.5mm plug MM #850 or Amazon #B07D3TCXVK

Z-axis gearmotor kit with cable, mounting brackets, and shaft coupler MM #910

BRACKETS

Motor mounts (2) for the X-Y motors;

MM #890 or Amazon #B073NZ81M9

Router sled ring, custom included in the Maker Made ring kit, #860. The CAD files for these parts are at github.com/MaslowCNC, so your local laser cutting or waterjet company could fabricate them easily.

Sled ring bearing carriage brackets (2) included in MM #860

L-brackets (5) included in MM #910 and 860, or try maslowsurplusparts.com/products/l-bracket

OTHER

Sled ring bearings (4) included in MM #860, or maslowsurplusparts.com/products/sled-ring-bearings

Roller chains, #25 (2) MM# 830 or Amazon #B018H9ZAD2

Motor sprockets for #25 chain, 10 tooth, 8mm bore (2) included in MM hardware kit #840; or the 9-tooth #SPR-2509P from electricscooterparts.com. There’s software setting for the number of teeth.

Slack sprockets for #25 chain, 16 tooth (2) included in MM #840, or robotshop.com #RB-Sct-228 looks like a good alternative.

Pulleys, 4mm × 13mm × 7mm (2) included in MM #840, or use Amazon #B017691AJW

Elastic cords (2) MM #820 or Amazon #B06W5279YL

Assorted bolts, nuts, washers, screws, and fasteners included in MM #840; see complete bill of materials at maslowcommunitygarden.org/Maslow-CNC-Kit.html?buy=true.

Tools

Screwdriver or drill/driver

Wood saw

Pliers

Wood glue

Computer with Arduino IDE and Ground Control software free downloads at arduino.cc/downloads and github.com/MaslowCNC/GroundControl

Your Maslow CNC can cut anything that can be cut with a hand router. Maximum thickness is only restricted by your bit size and router travel. The recommended Ridgid R22002 router has 1½” of travel, and the machine will make multiple shallow passes to cut through thicker materials. The most popular materials are:

» Hardwoods

» Plywood

» MDF

» Laminate

» Hard plastics: acrylic, nylon, uPVC, hard PVC

» Soft plastics: polycarbonate, polyethylene, soft PVC

,