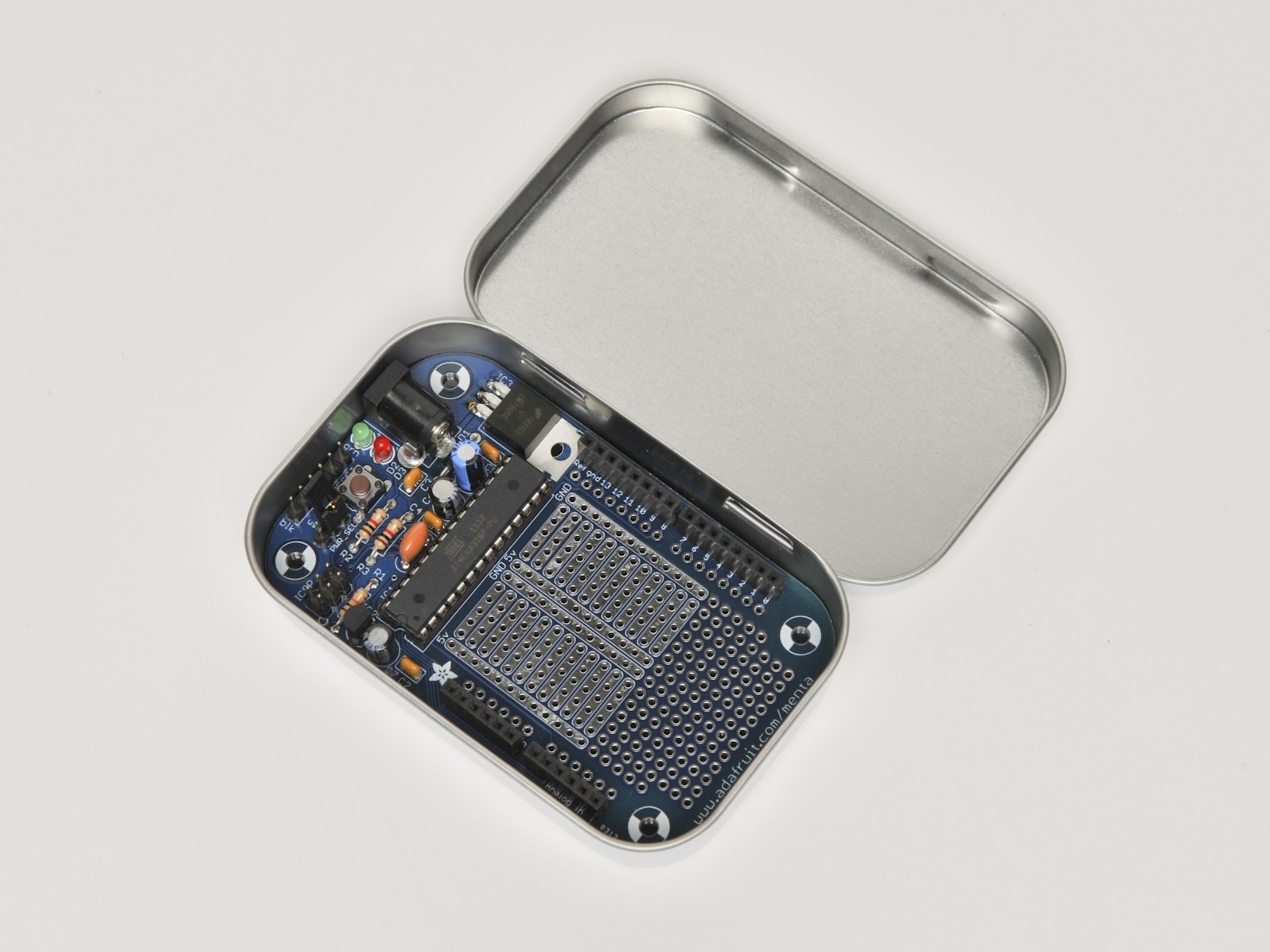

The Mintronics: Menta is a unique Arduino-compatible microcontroller kit. It features a handy, on-board prototyping space and is specifically designed to use the included mint tin as an enclosure! This makes it perfect for logging applications and on-the-go development. The prototyping area is perfectly sized for one of our mini breadboards (not included) so you can wire circuits without soldering. Ready for some expansion? The Menta can be used with all Arduino-compatible shields.

The Mintronics: Menta kit was designed in NYC by open source hardware pioneer Adafruit Industries, in partnership with MAKE and Maker Shed.

Note: Requires FTDI programmer (like the FTDI Friend) and soldering.

(Assembly photos and text are used with permission from Adafruit Industries)