If you’re familiar with tabletop product photography and video, you know what a pain it can be to shoot those overhead shots while working on something at the same time. Setting up a tripod so you get the right shot without it getting in the way can be unnerving at best. The remedy for this is usually to bring in a document camera.

The modern equivalent of the overhead projector, a document camera lets you display close-up shots when used with an LCD projector or external monitor. They usually cost between $500 and $1500 and are perfectly suited to the task of capturing images of document-sized objects. A thousand dollars for a glorified webcam? OK, it’s got a tight focus, clean lighting, and hooks directly up to a projector, but come on, srsly, a grand?

We’ve all got streaming video on our smartphone now, right? Couldn’t we just use that instead? But how do we get it held over the project we’re working on without having to work around a tripod? Well, it just so happens that Hollywood grips figured this problem out long ago. Known loosely as a gobo arm and sold commercially under many names, including “Magic Arm”, this lightweight mount will help you place your smartphone (webcam, etc.) right down where the action is, without getting in the way. But a commercial unit usually runs between $100-$150. And that doesn’t include the $30 clamp you attach it to.

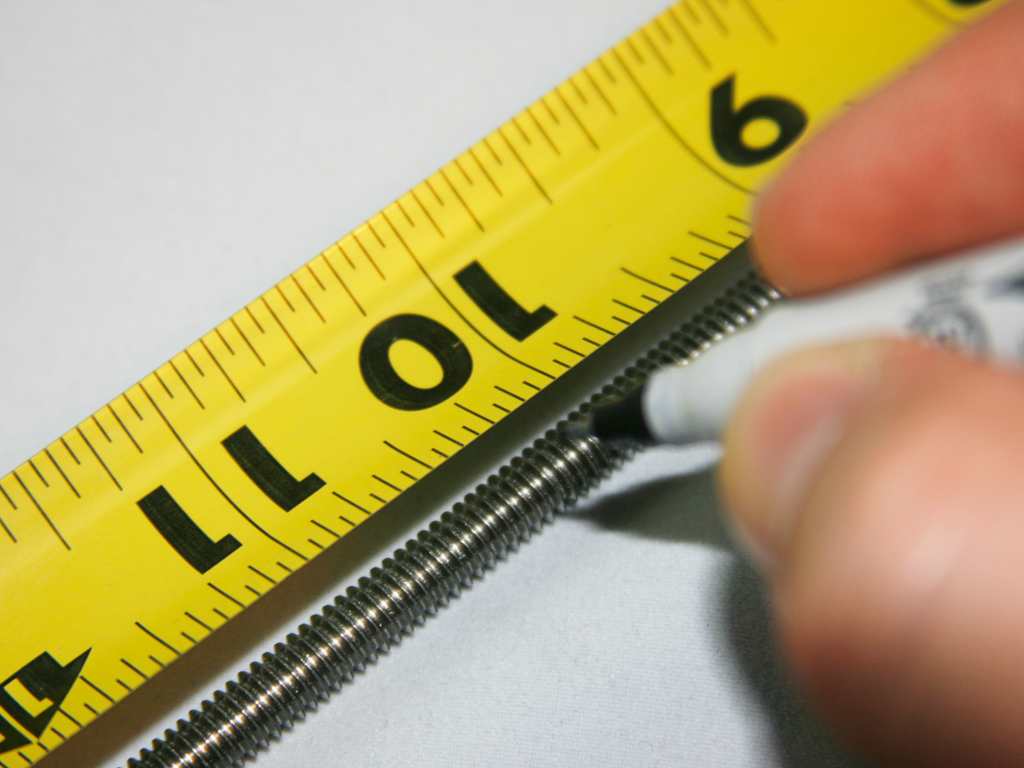

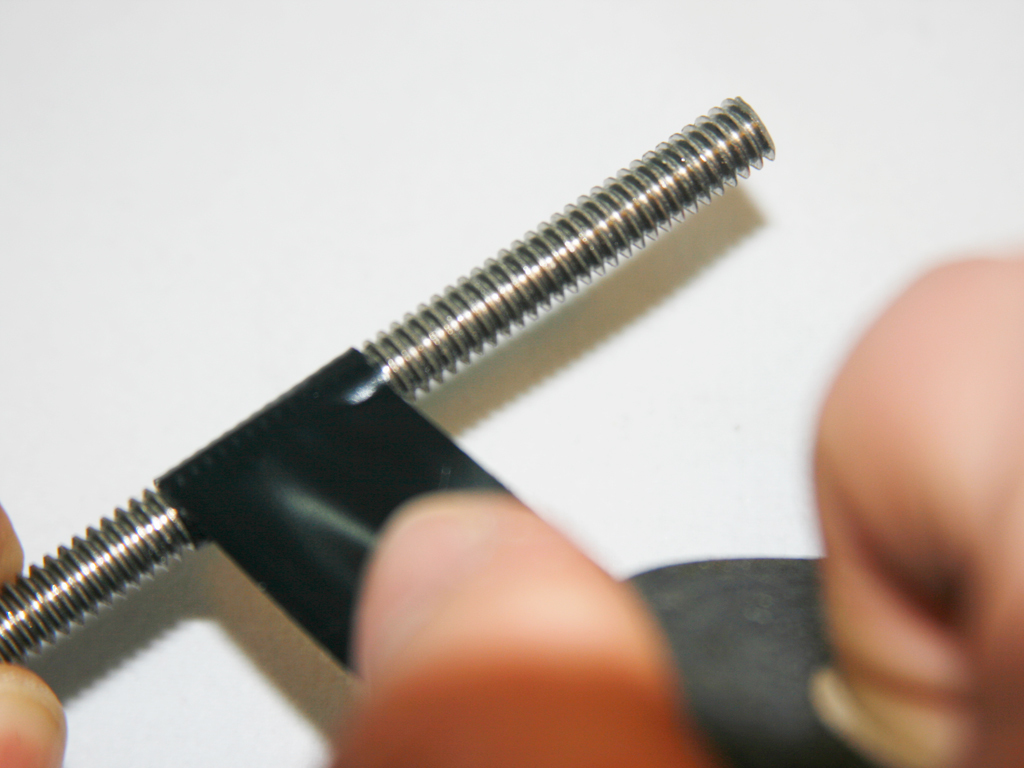

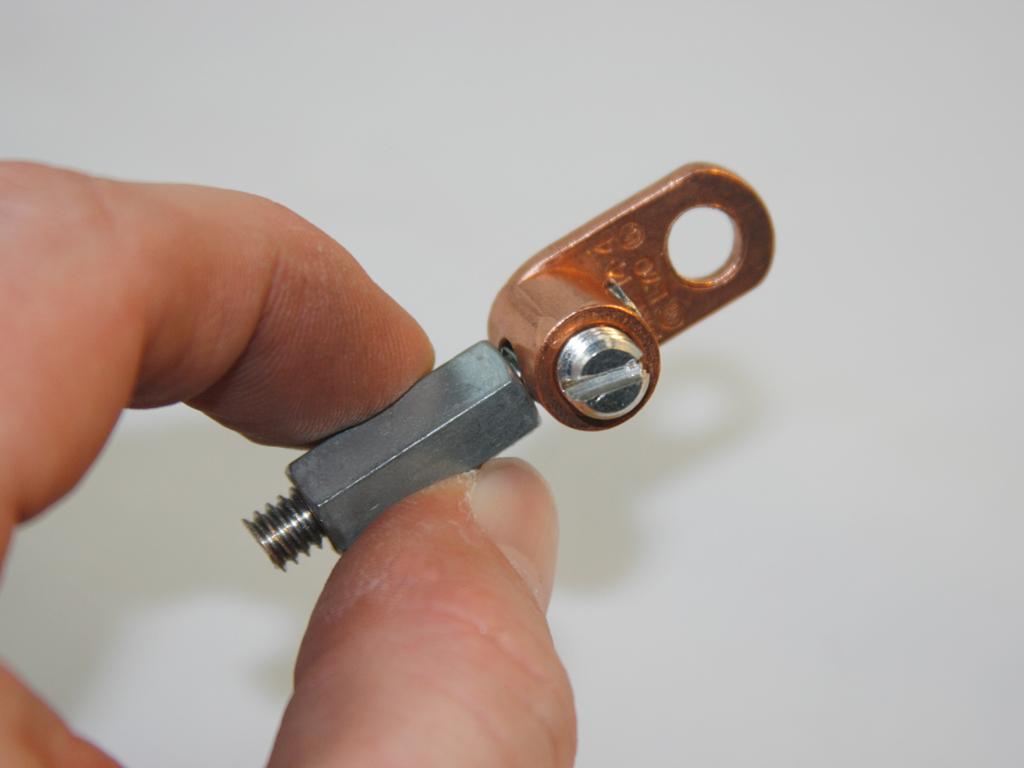

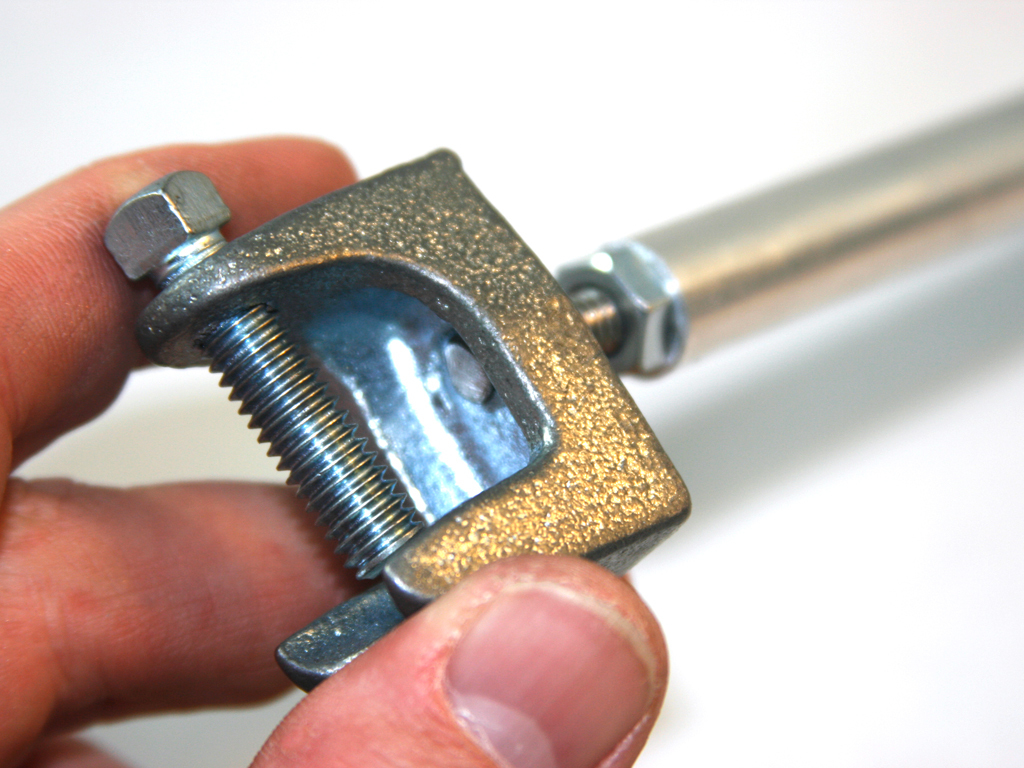

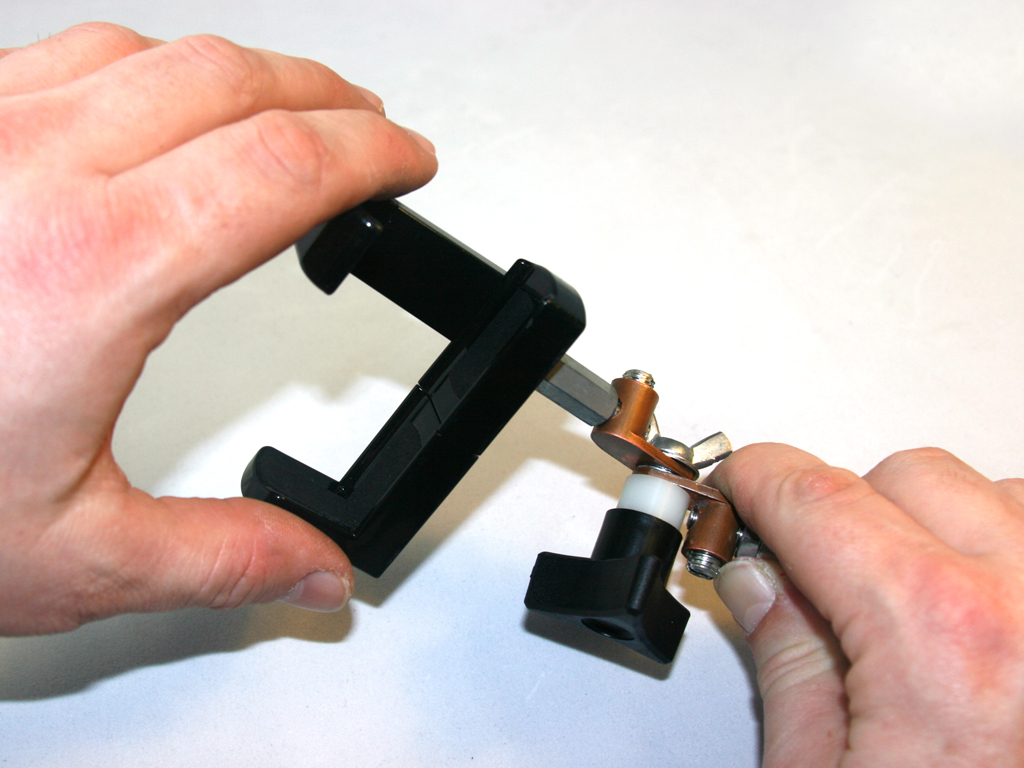

So, for the price of one of those fancy clamps you can piece together your own Mobile Document Camera Stand using easily sourced parts from the local hardware store and online. It’s not as fancy as an Elmo Document Camera or Manfrotto “Magic Arm”, but it gets the job done, and you can always repurpose the parts for other projects if need arises.

This project is easier than it looks. If you can make small cuts with a hacksaw, you can build this. There’s also plenty of room for improvement. Need an extra length or another span? Add it! As a matter of fact, just after I shot these photos, Make Engineering Intern Eric Chu suggested that I use o-rings instead of lock washers. Turns out, they hold the same and act as a variable friction joint. Cool, huh? Now go make one for yourself and see what you can improve.