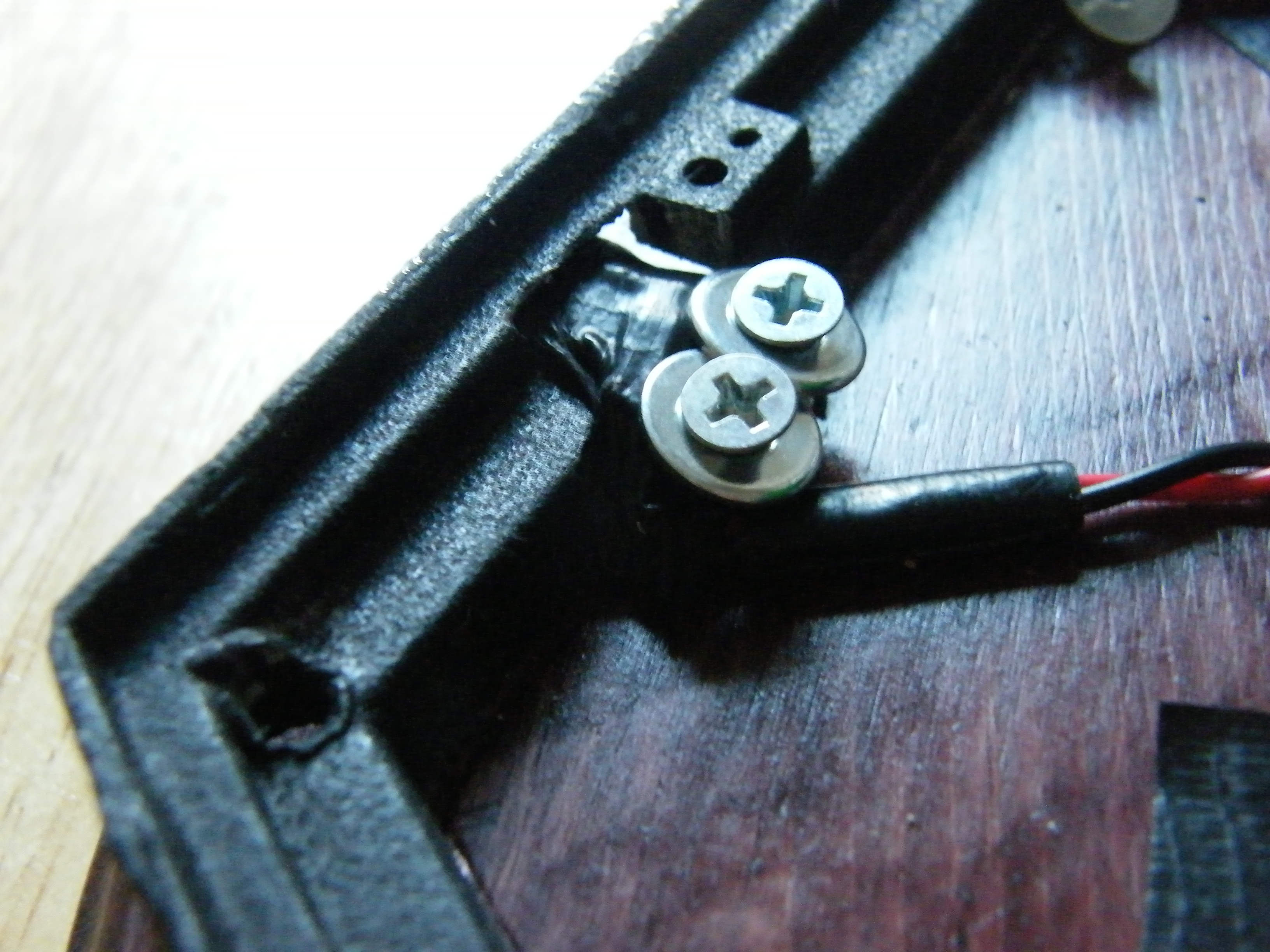

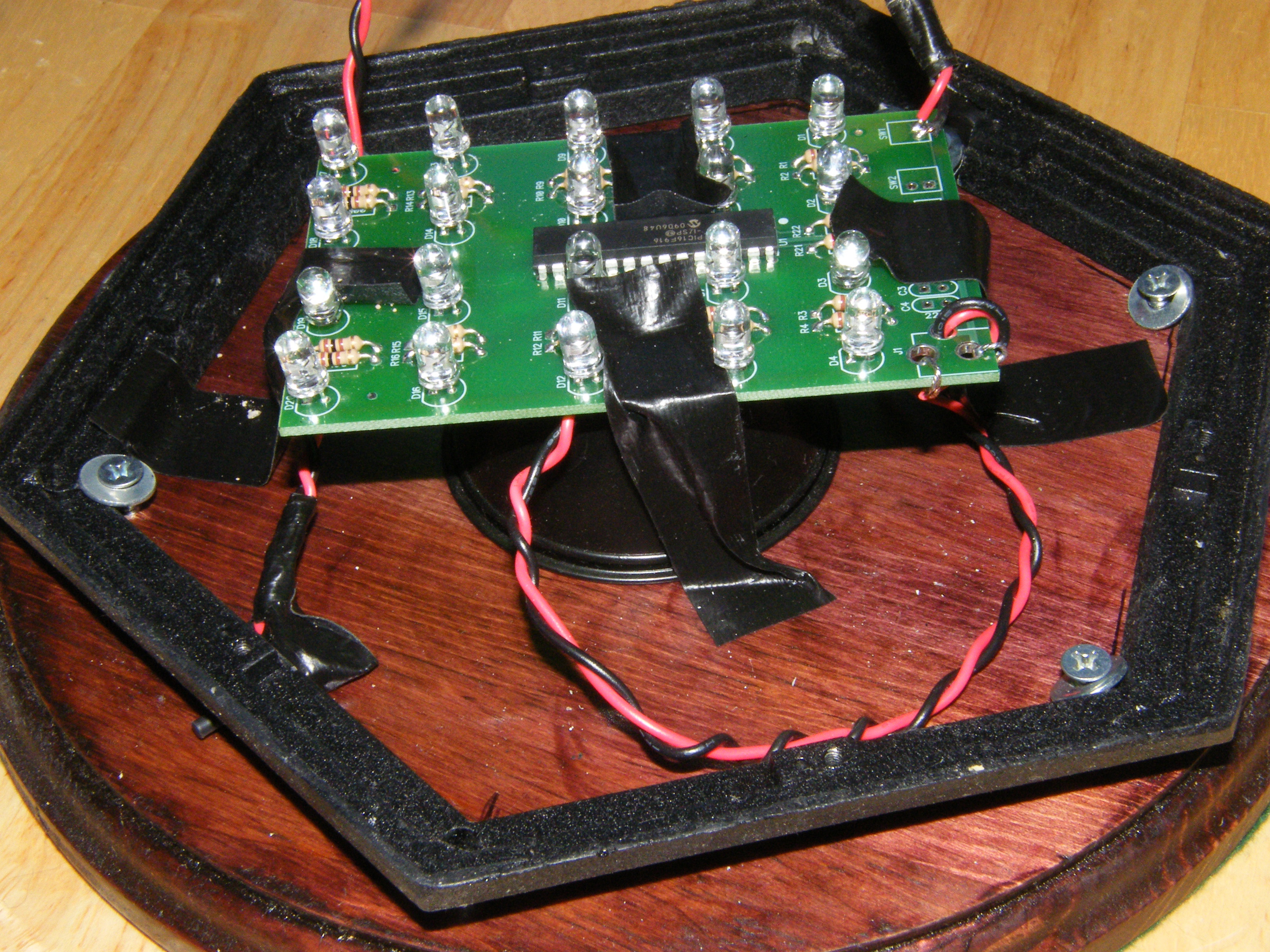

Last year I assembled a “Light Brick” kit (MAKE Magazine #18, https://makezine.com/18/lightbrick/). Well, I actually just completed the circuit board. I had trouble finding the materials for the cast plastic “brick” locally. Then I found, in the trash, a “tea candle” lantern with frosted panels. The light brick panel, placed inside, produced a very pleasing display.

Recently, I found another sort of lamp in the trash; one of the pole-mounted lanterns that illuminate the paths of my apartment complex.

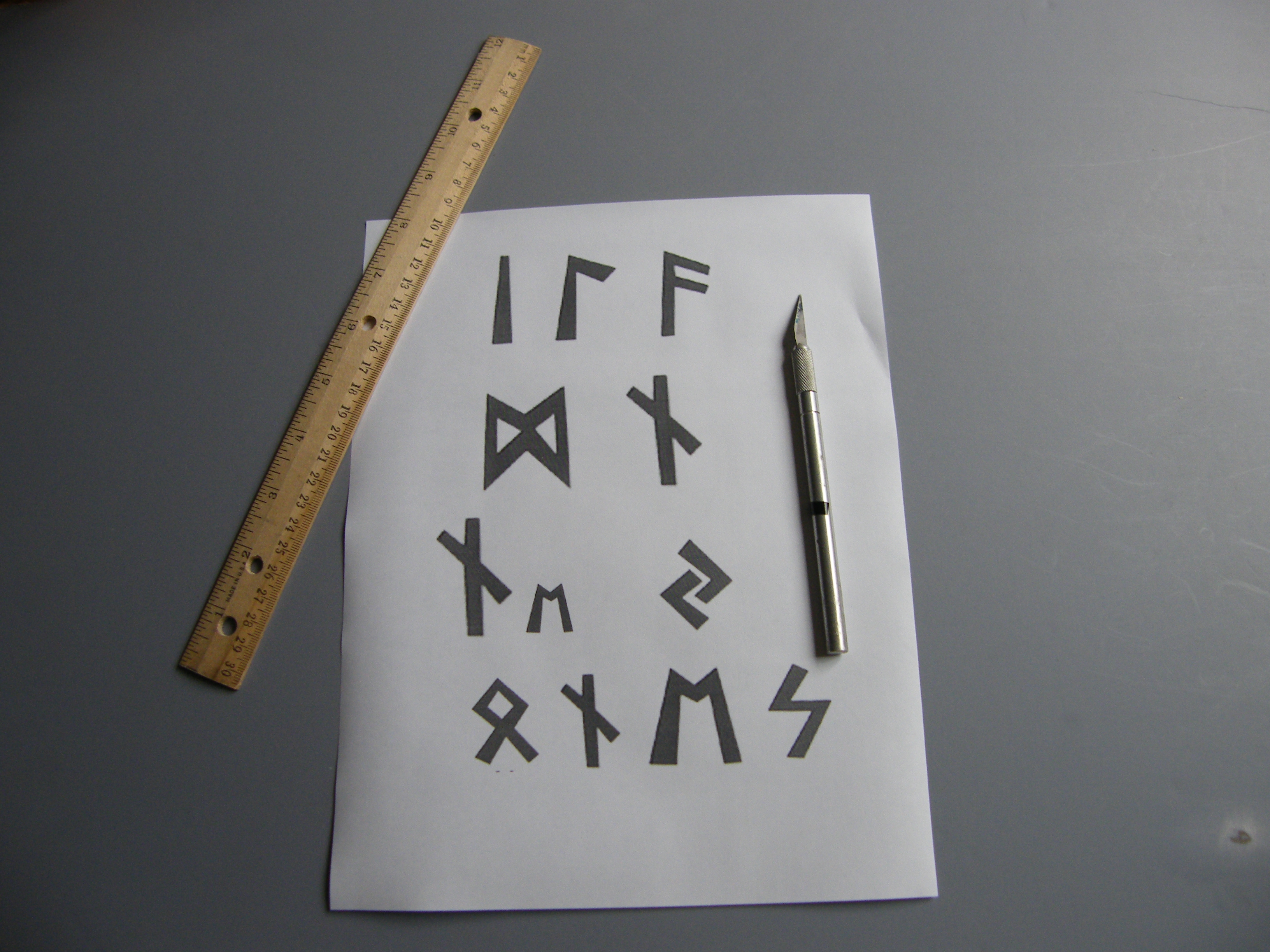

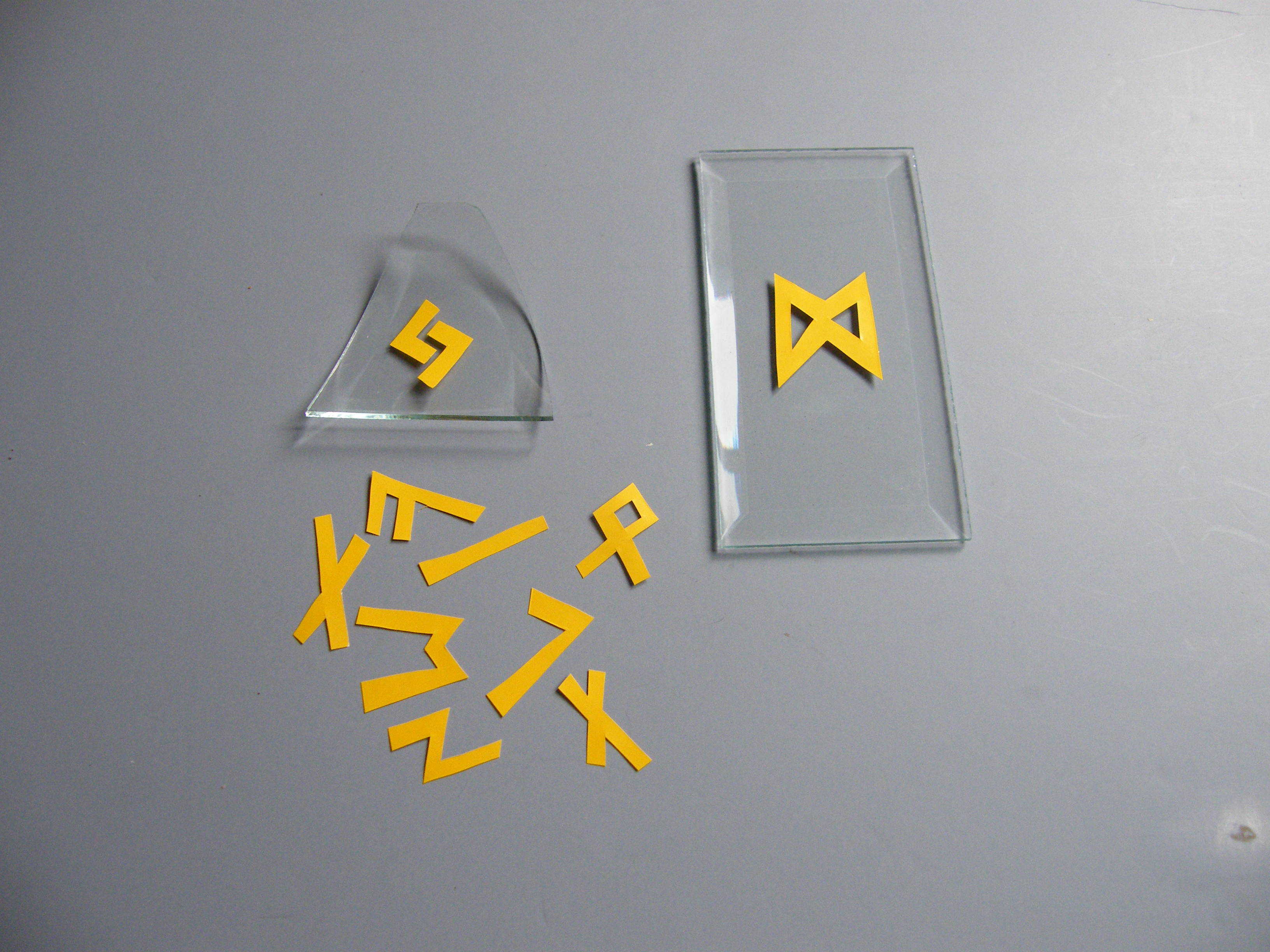

I decided to make it into a custom holder for another light brick panel . . . a belated housewarming gift for my brother. It would have, etched into the glass panels, ancient runes spelling out my brother’s name.

Here goes!