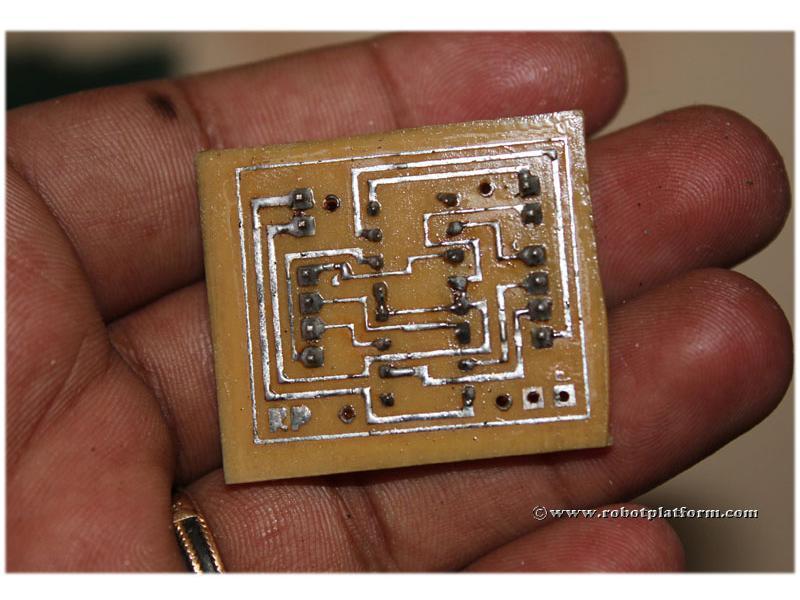

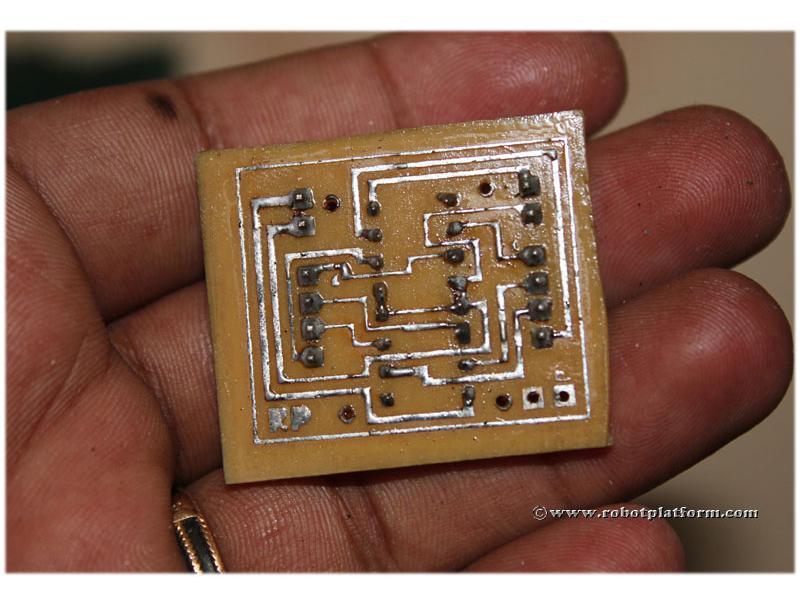

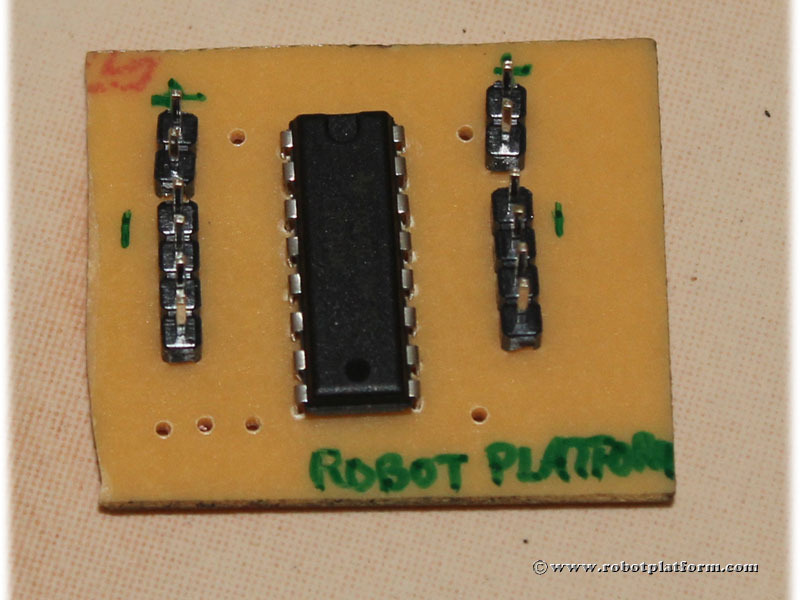

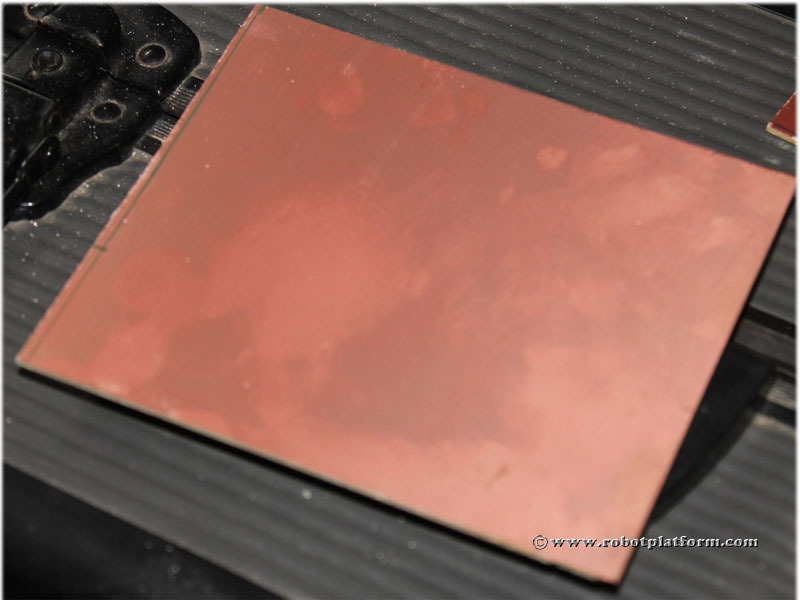

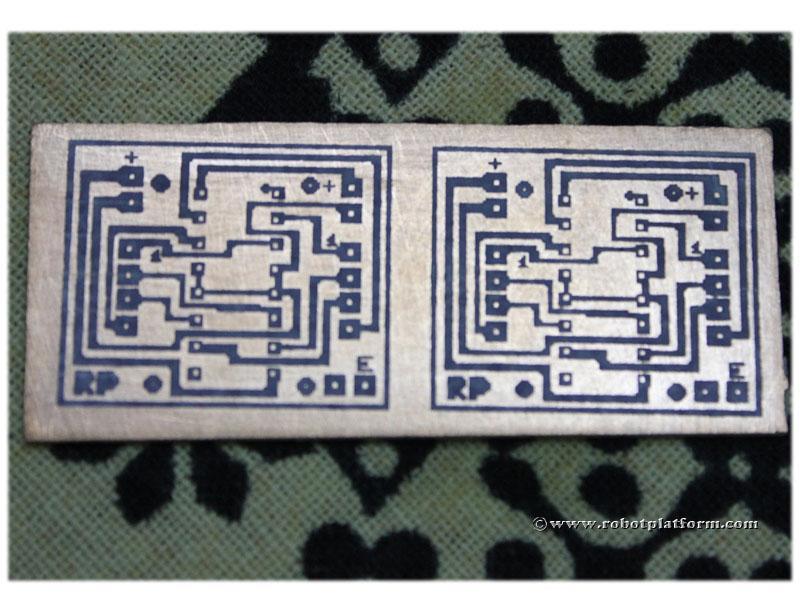

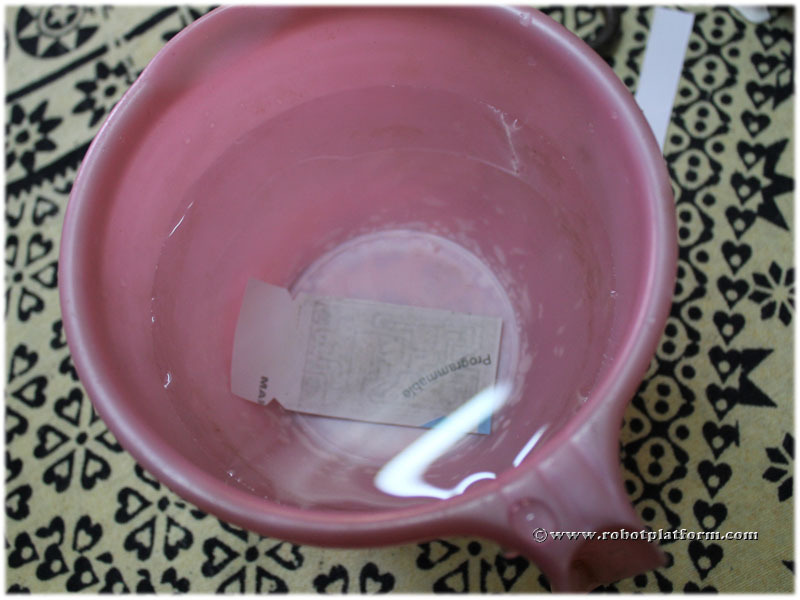

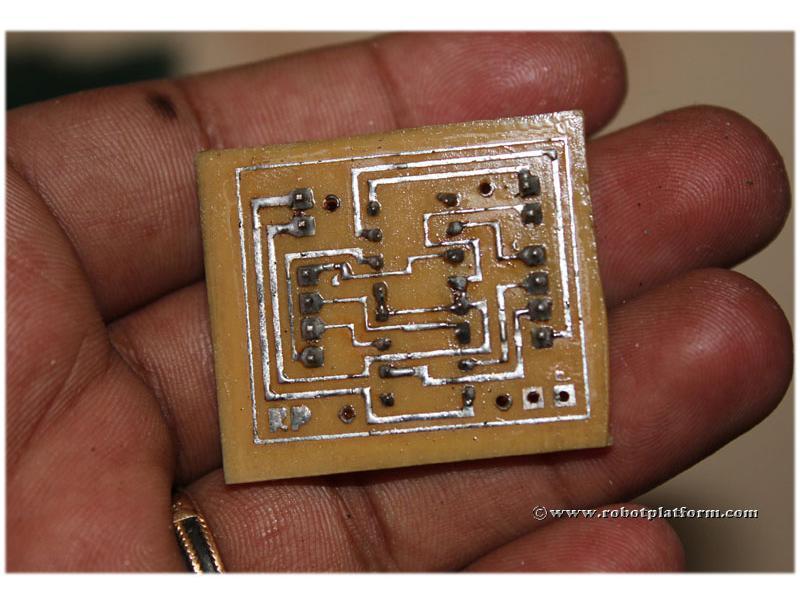

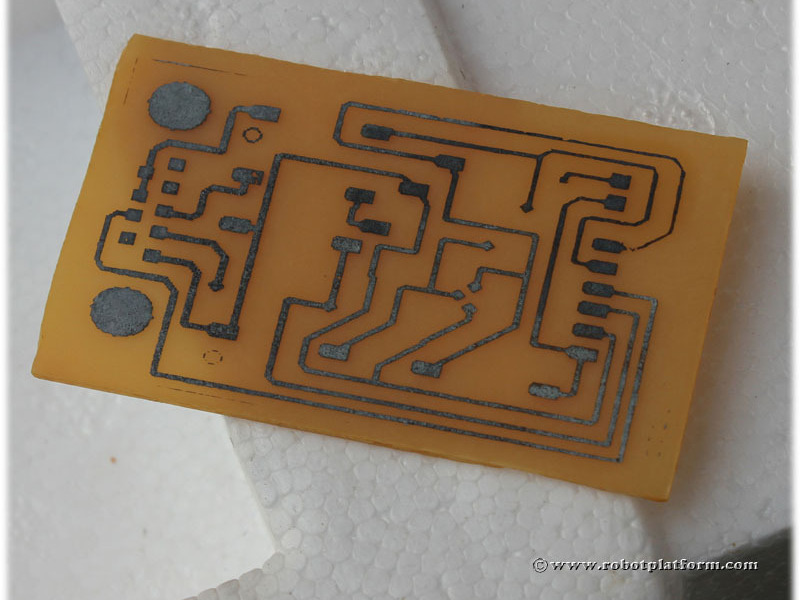

What is the fun in making robots if you can’t make your own circuit boards? This PCB etching tutorial describes a step-by-step process to MAKE your own circuit board. There are many tutorials already available on etching. Each method uses different materials and I have used hydrochloric acid and hydrogen peroxide. Did you read acid? Be careful. If you are cautious, you can expect great results. If you abuse these chemicals, they might turn dangerous.

For a detailed tutorial with more pictures including a video tutorial, go here.