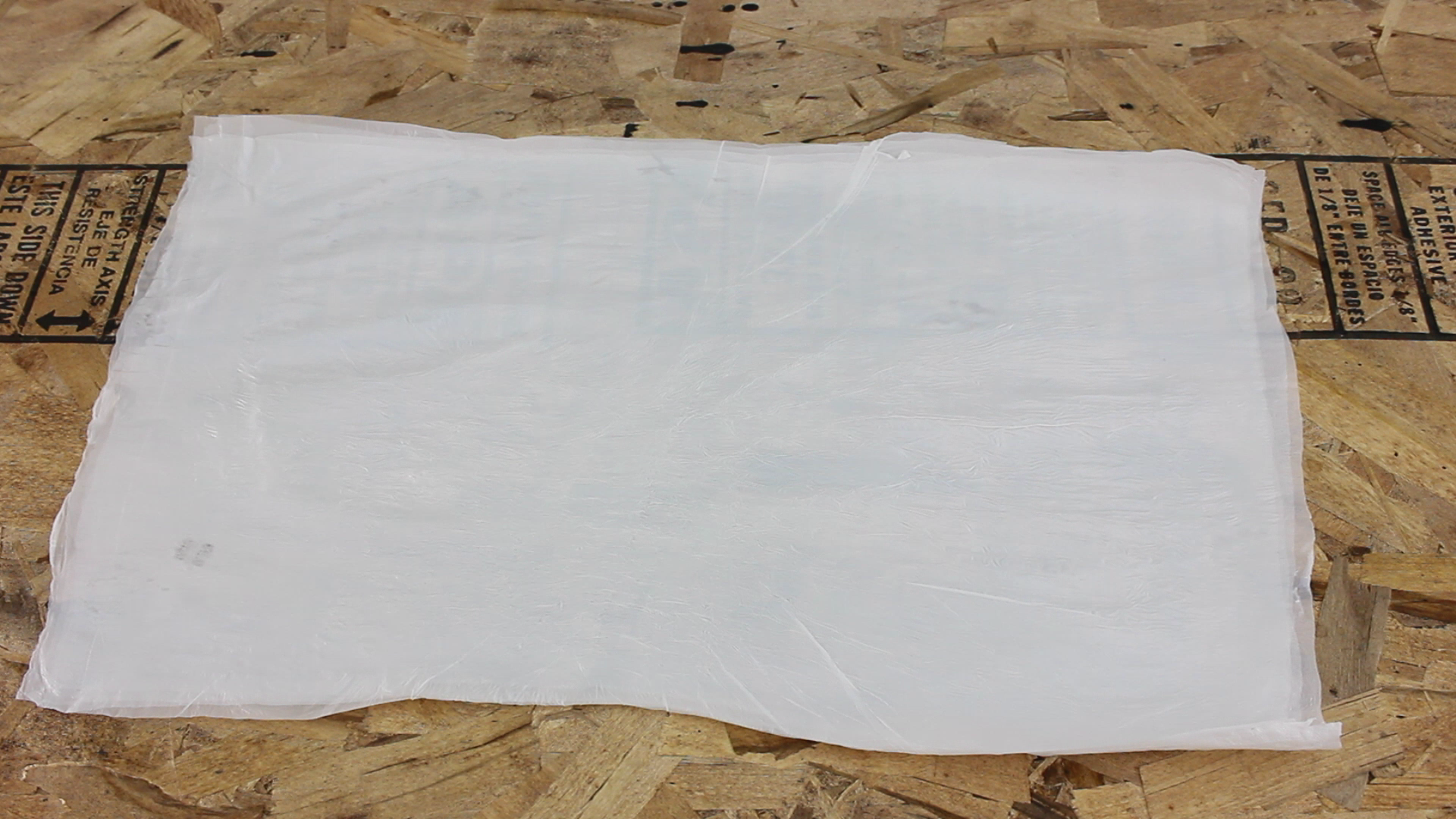

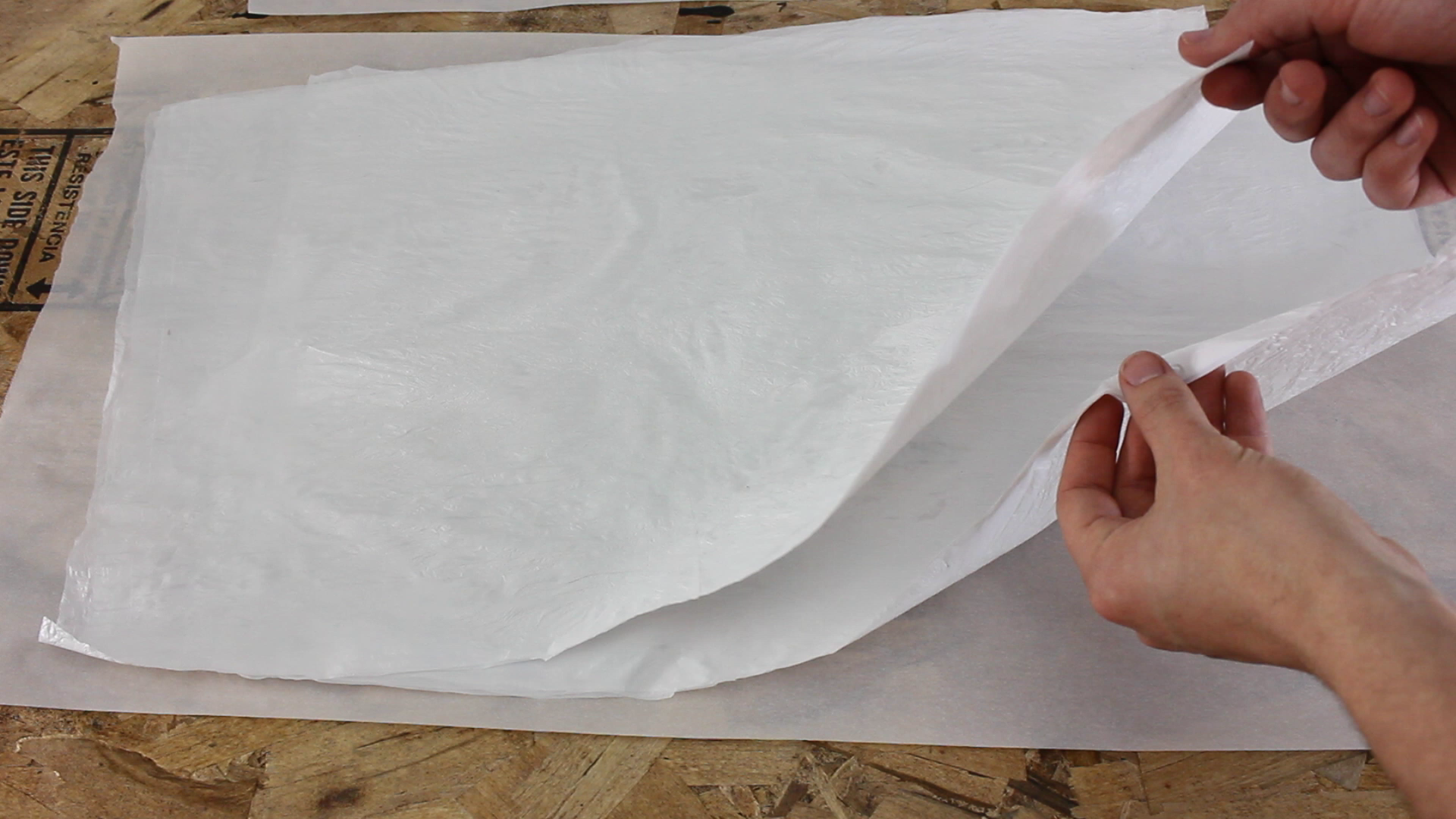

Now you are ready to start combining the plastic sheets. Start by tearing off a large piece of baking parchment. Then lay it on top of a heat resistant surface. My normal work table has a plastic finish on top, so I decided to work on a scrap piece of wooden construction board.

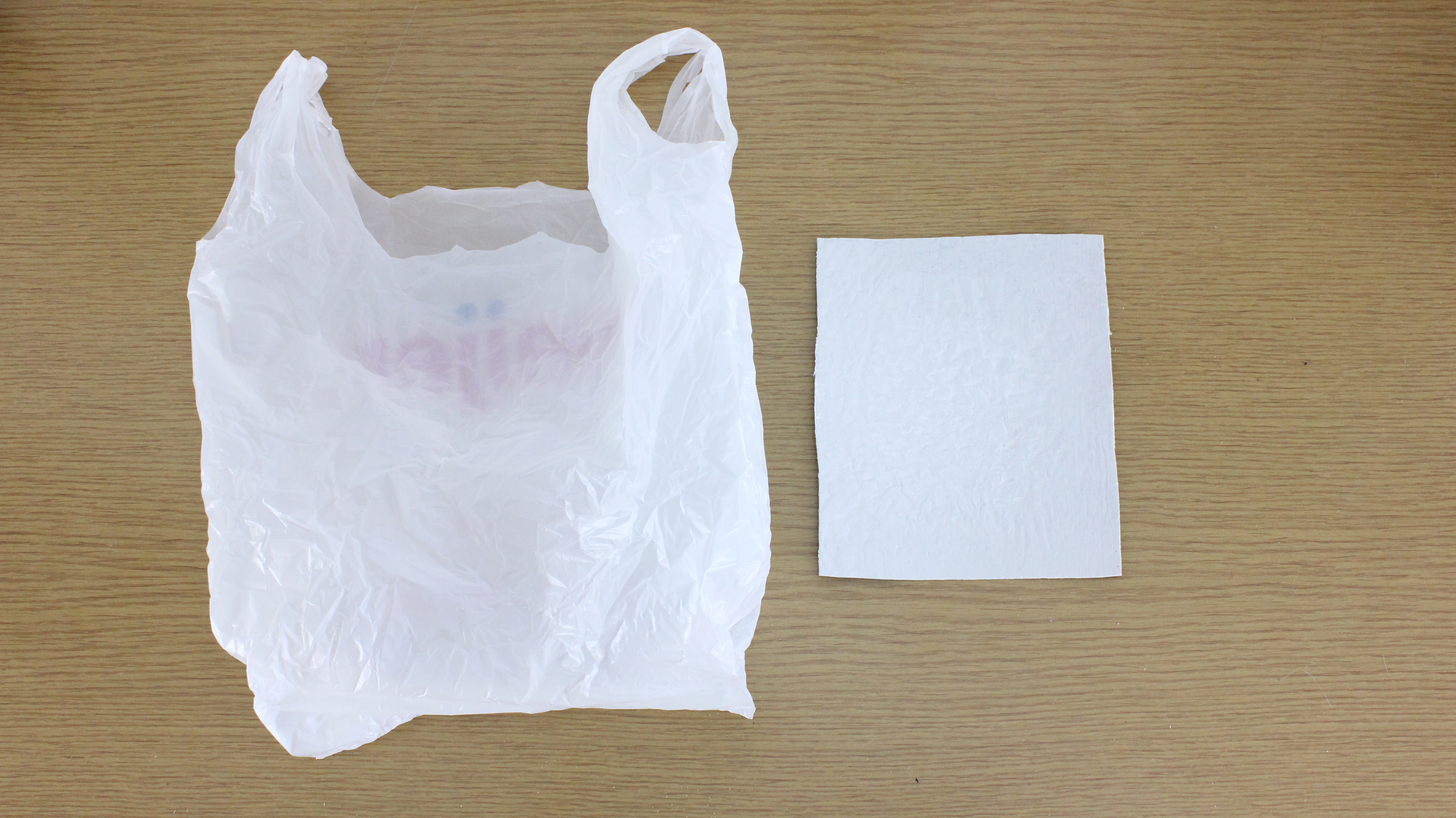

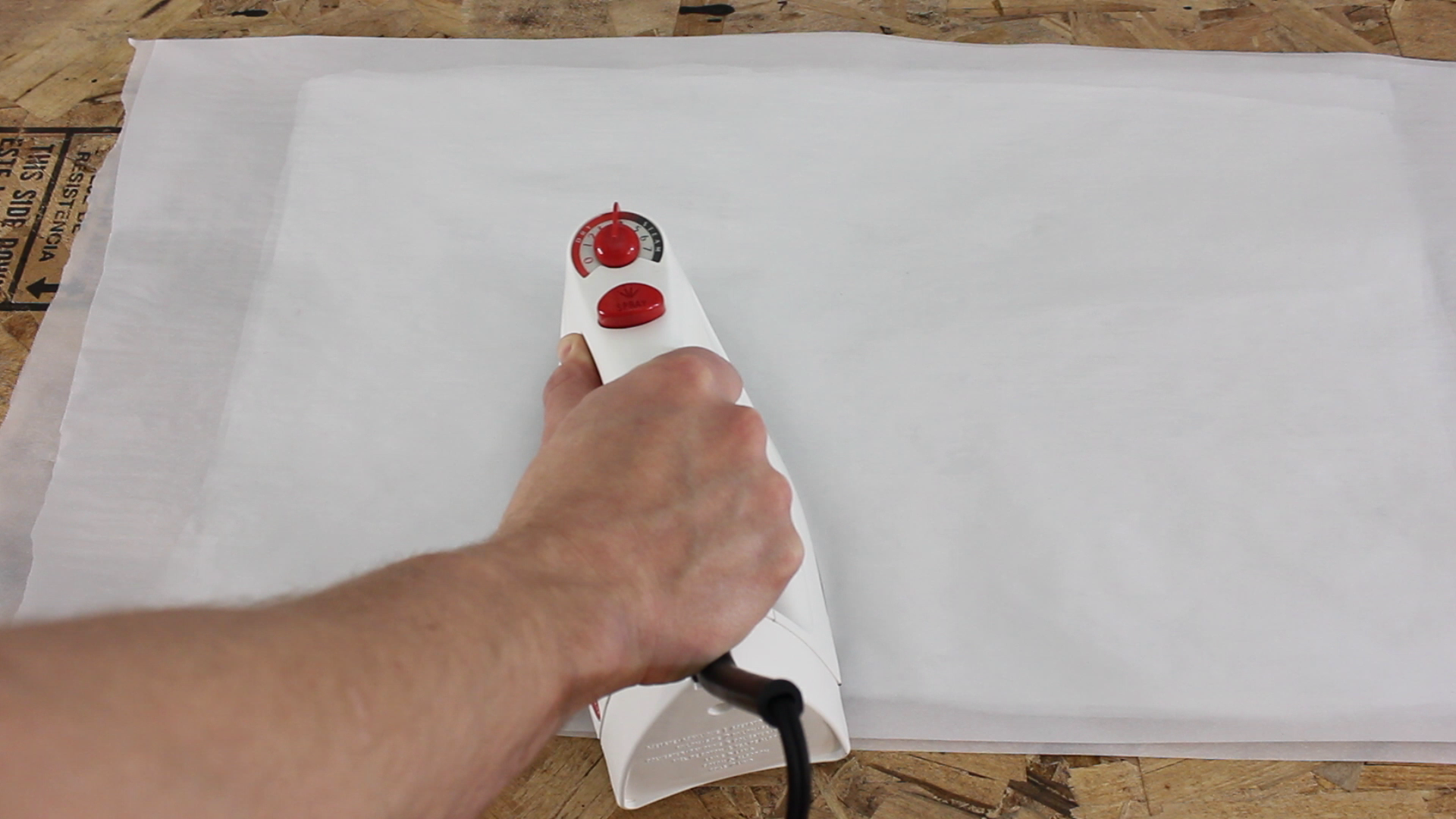

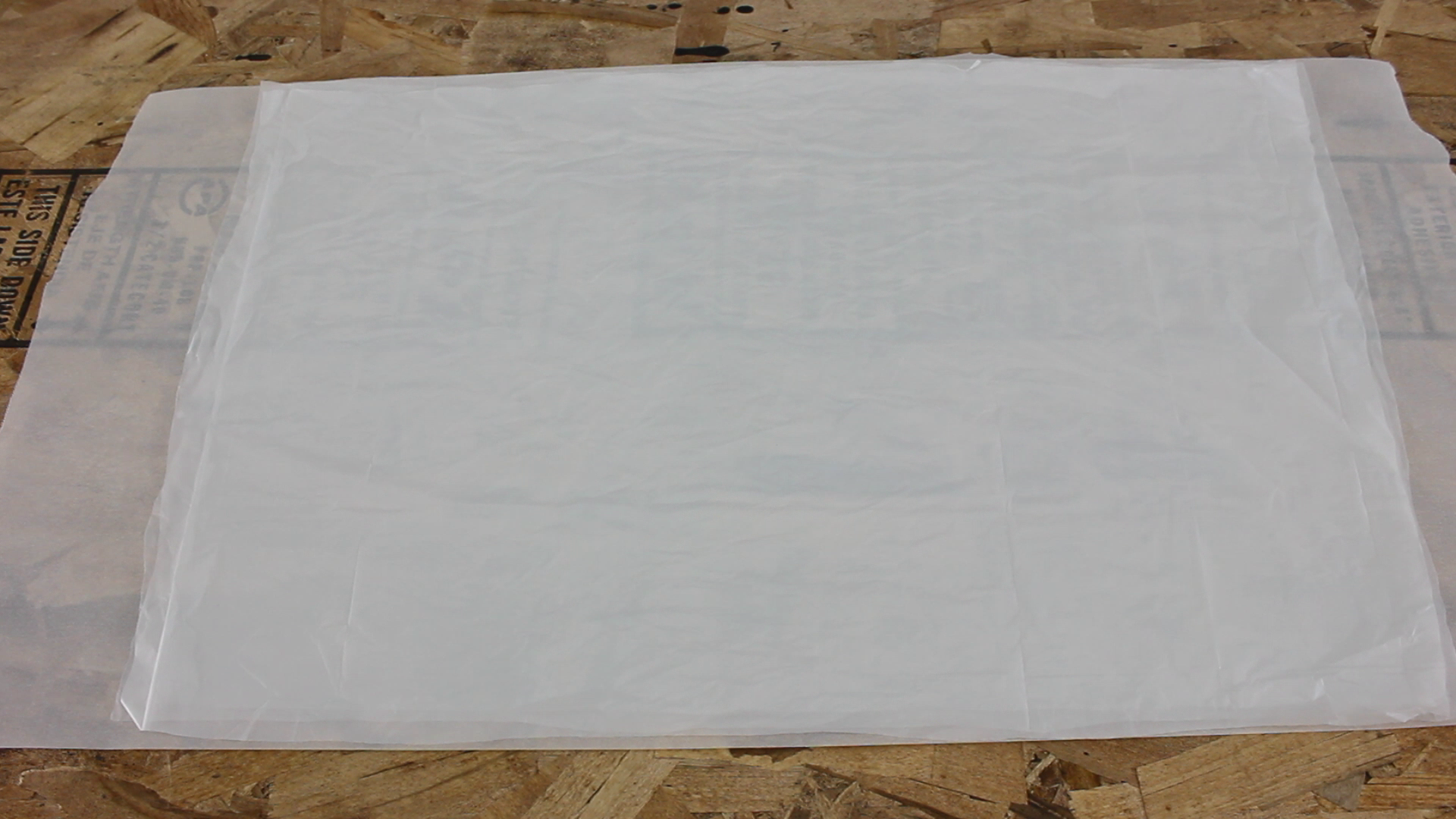

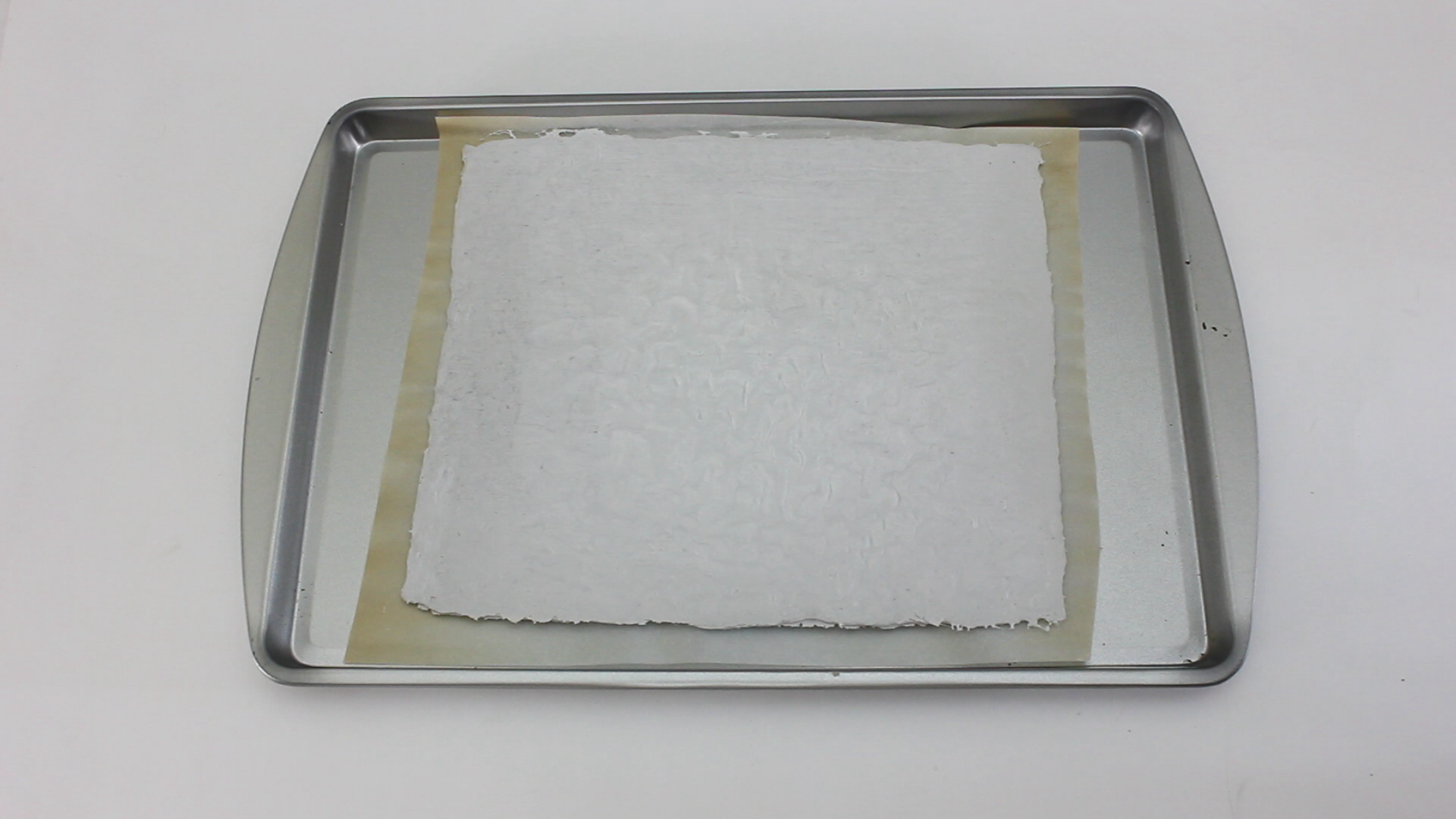

Next lay the plastic sheets on top of one another. Try to line them up as well as you can. Then place another large piece of baking parchment on top of the plastic sheets.

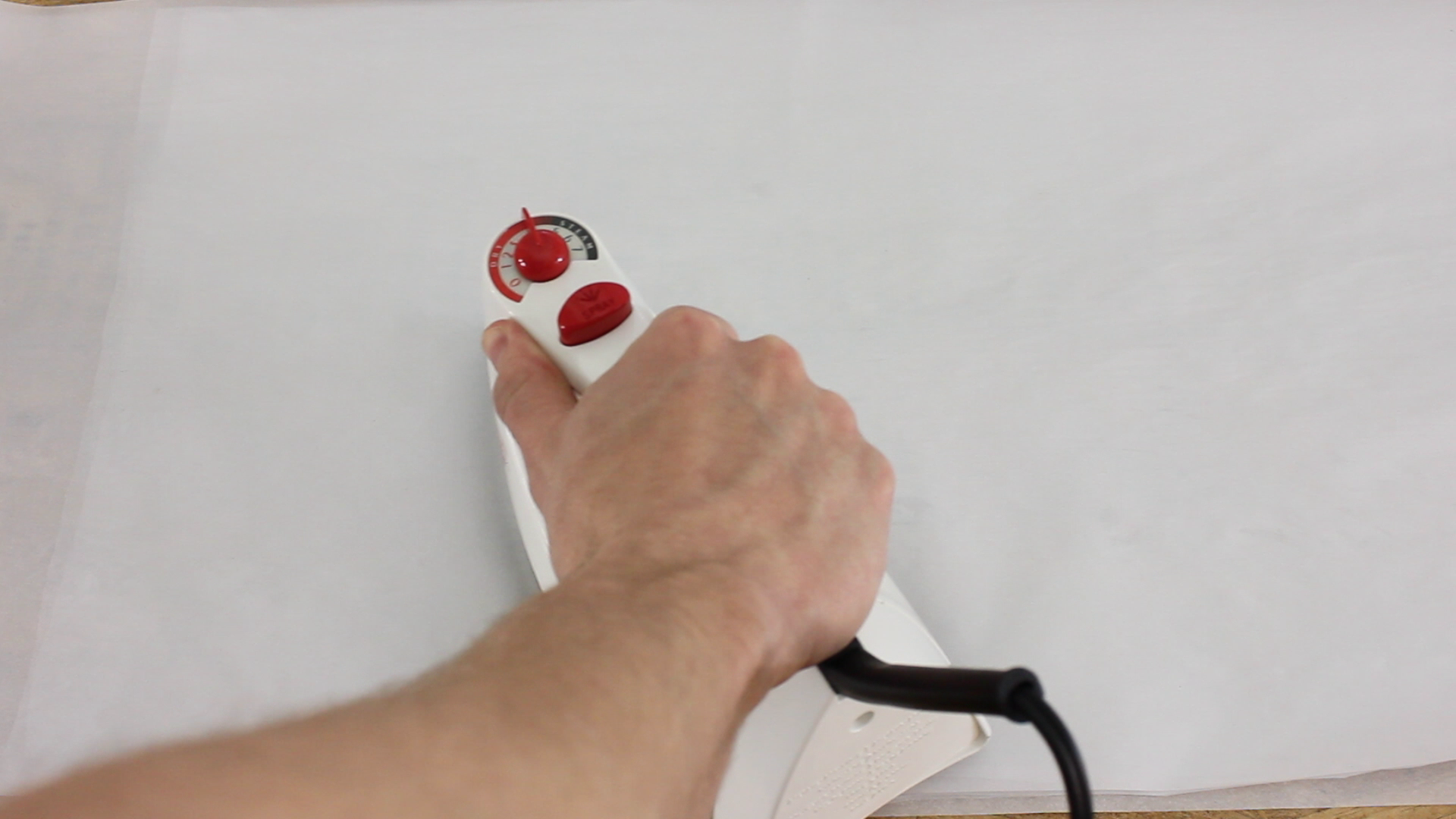

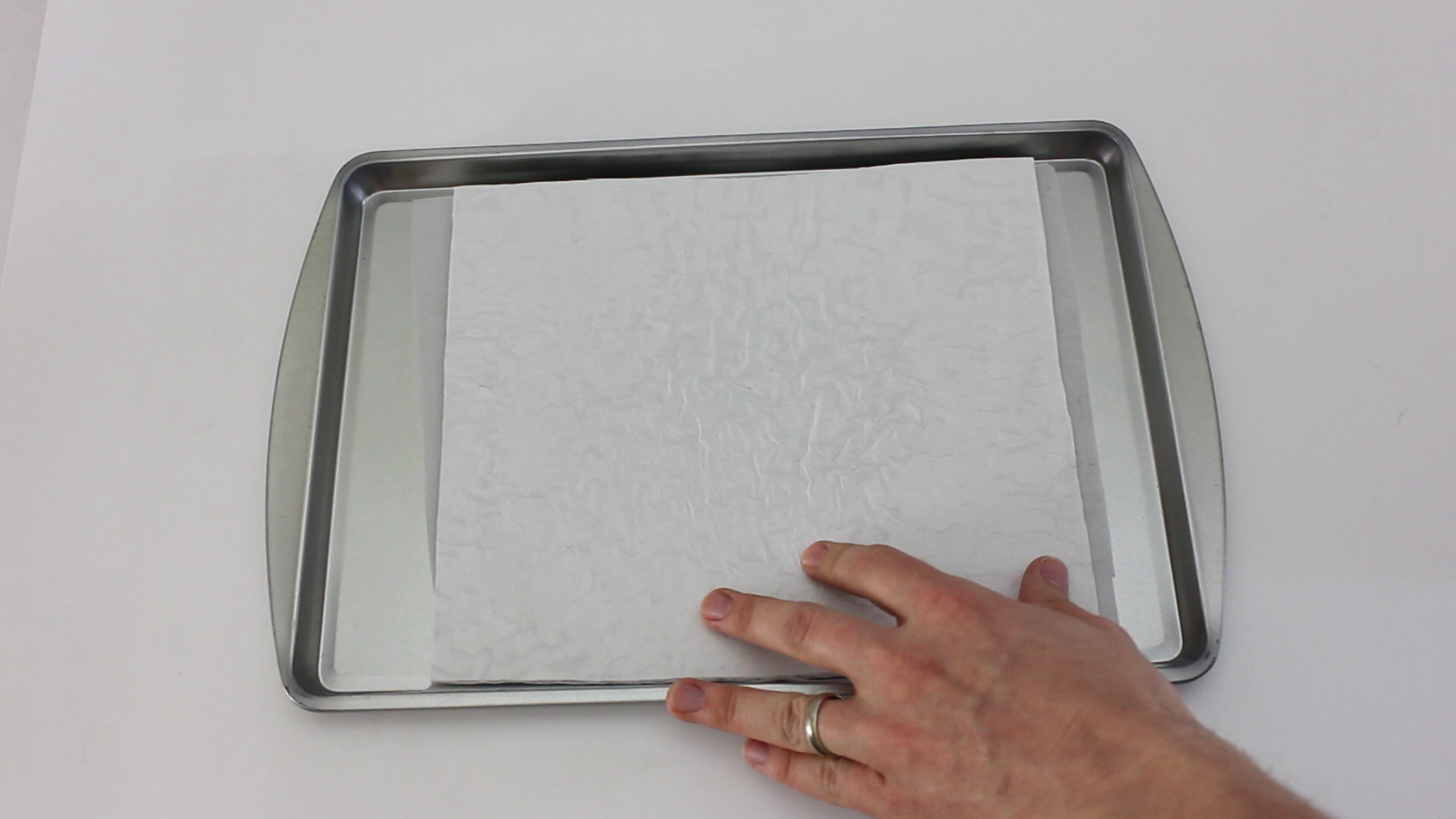

Turn on your iron and set it to the medium temperature setting. Press the iron down firmly over the center of the plastic sheets. Slowly slide the iron across the paper toward the edge. Press down firmly as you go. Iron over the whole sheet.

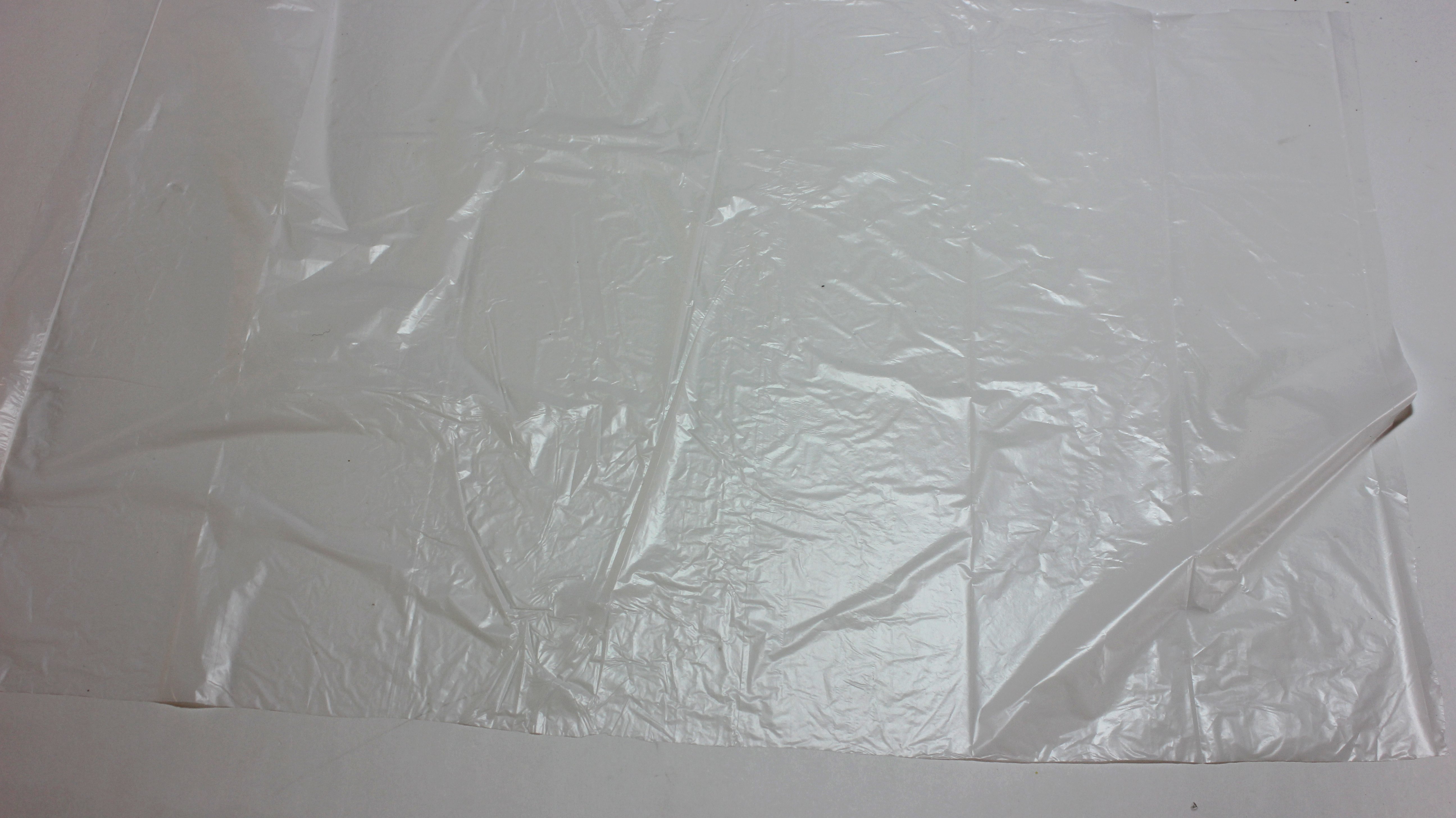

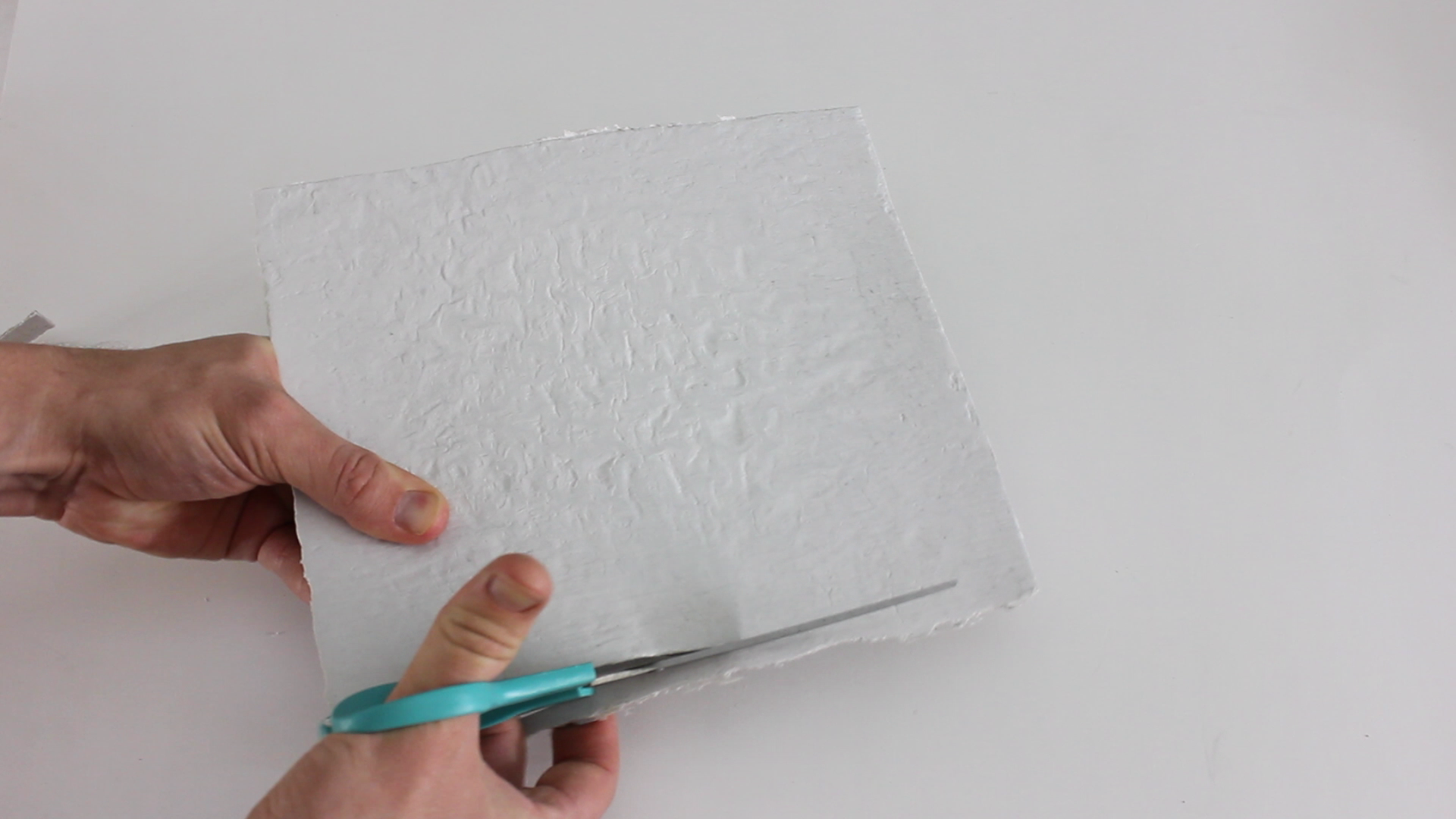

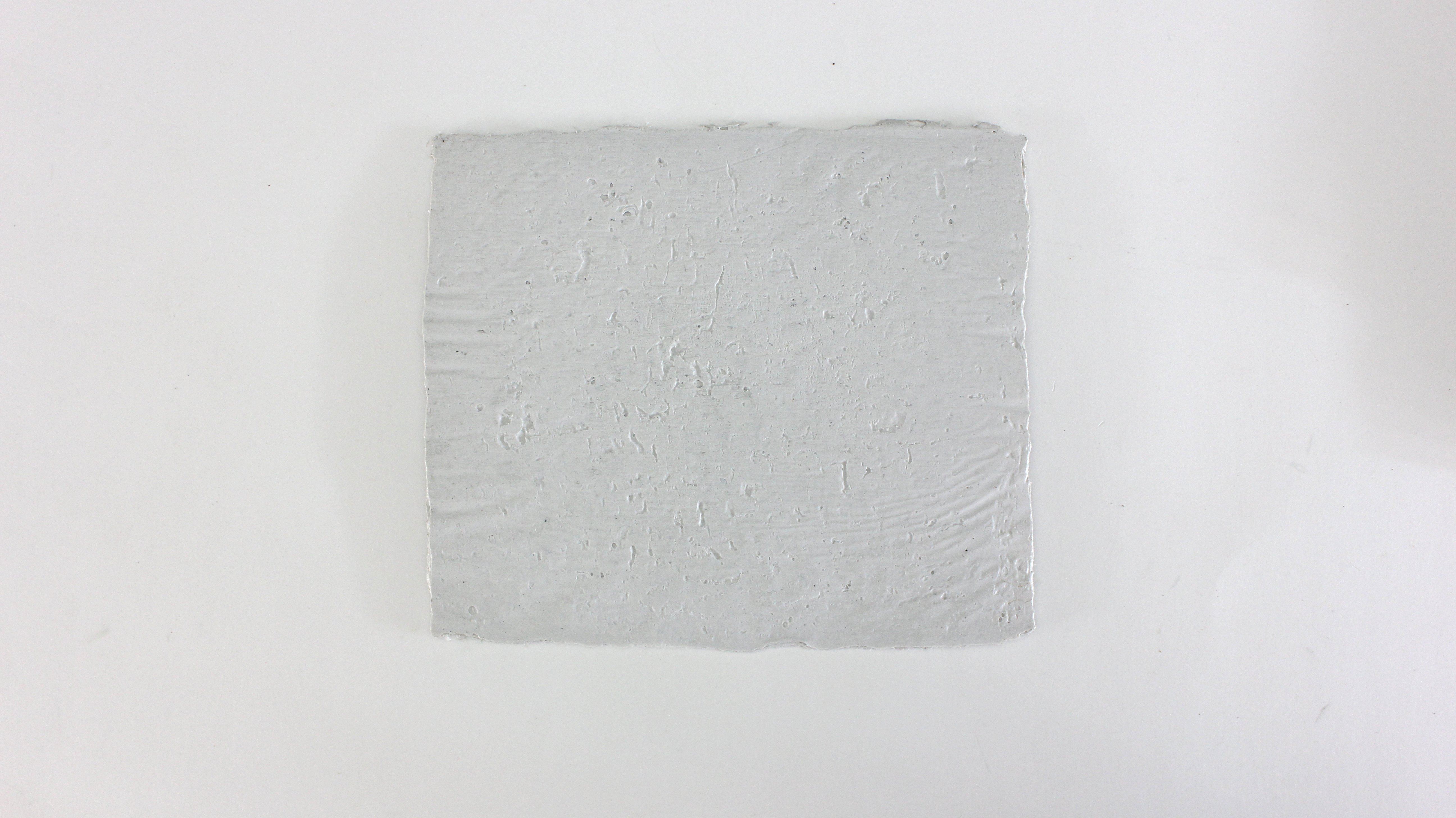

After you have ironed the whole sheet a few times, lift up the top piece of parchment and check to see if the plastic sheets are fused together. If the sheets can still be easily separated, your iron may be set too low. Turn up the temperature a little and iron over the sheets again. If, however, you see holes melted in the plastic, then your iron is too hot and you should turn it down a little. You want to use the minimum heat required to fuse the bags together.

Once you have done this, you should have a single four-ply sheet of plastic. Repeat this process with the rest of your bags, making as many four-ply sheets as you can. We will combine these later into thicker sheets.