Da Vinci used wooden gears in many of his mechanisms and drawings. I’ve already figured out how to use “cage” or “lantern” gears (Make Magazine, October 2010). For my next project I decided to explore making a wooden worm gear. I’ll show you how I built it.

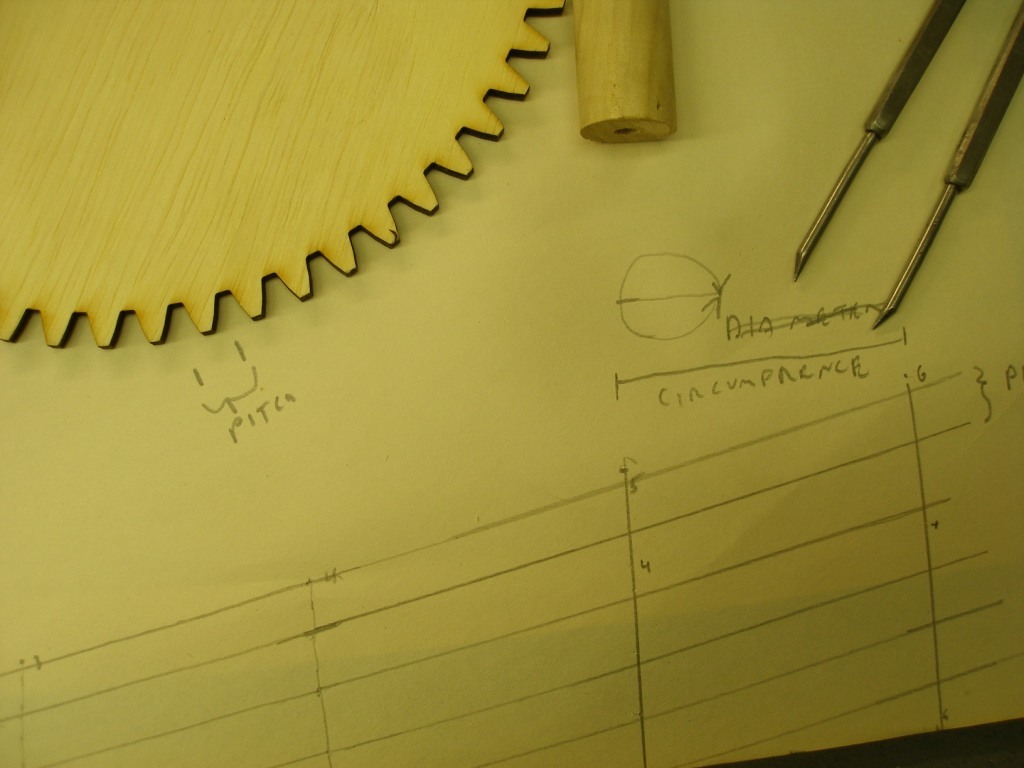

I used a 1″-diameter poplar dowel (a standard item at Home Depot and Furrow). I used SketchUp to draw the gear using an involute-gear program. I used ¼” birch plywood to cut the mating spur gear. It has 60 teeth and is 10″ in diameter. You need two measurements to lay out the worm: 1) the “pitch” is the tooth-to-tooth distance of the spur gear, about ½”. 2) The other measurement is the outside circumference of the cylinder from which the worm gear will be cut (3.14″).

To lay out the worm, draw a right triangle on a 17″ by 11″ piece of paper. For each circumference, go up one pitch. You should end up with a long narrow triangle. Cut this out carefully and wrap it around a 6″ length of the dowel. (Depending on how you wrap the screw, it will be left- or right-handed.) Using tacky glue, hot glue or tape, fasten the paper to the dowel. I used a pencil to mark the edge of the paper.

Next, I used a small fine-tooth Japanese-style pull saw to cut a ¼” groove all along the line.

After getting the first cut done, I carefully expanded the cut by cutting down from each side in a “V” pattern. I finished up with a triangular file and sandpaper. In the old days, large screws for wine- and cider presses were carved entirely using hammer and chisel. Once the screw was cut, a tap was made from it, and that was used to make the nuts. I plan to write another article about making wooden screws and nuts later.

I used dowels and glue to attach all the parts. The supports are recycled oak from a kitchen remodel project and a couple of other scraps.

The Da Vinci worm gear works well. The worm gear offers a large mechanical advantage. Each full turn of the crank moves the gear wheel one tooth; a 60-to-1 advantage. I hope to utilize both worm and lantern gears in my next Da Vinci project.