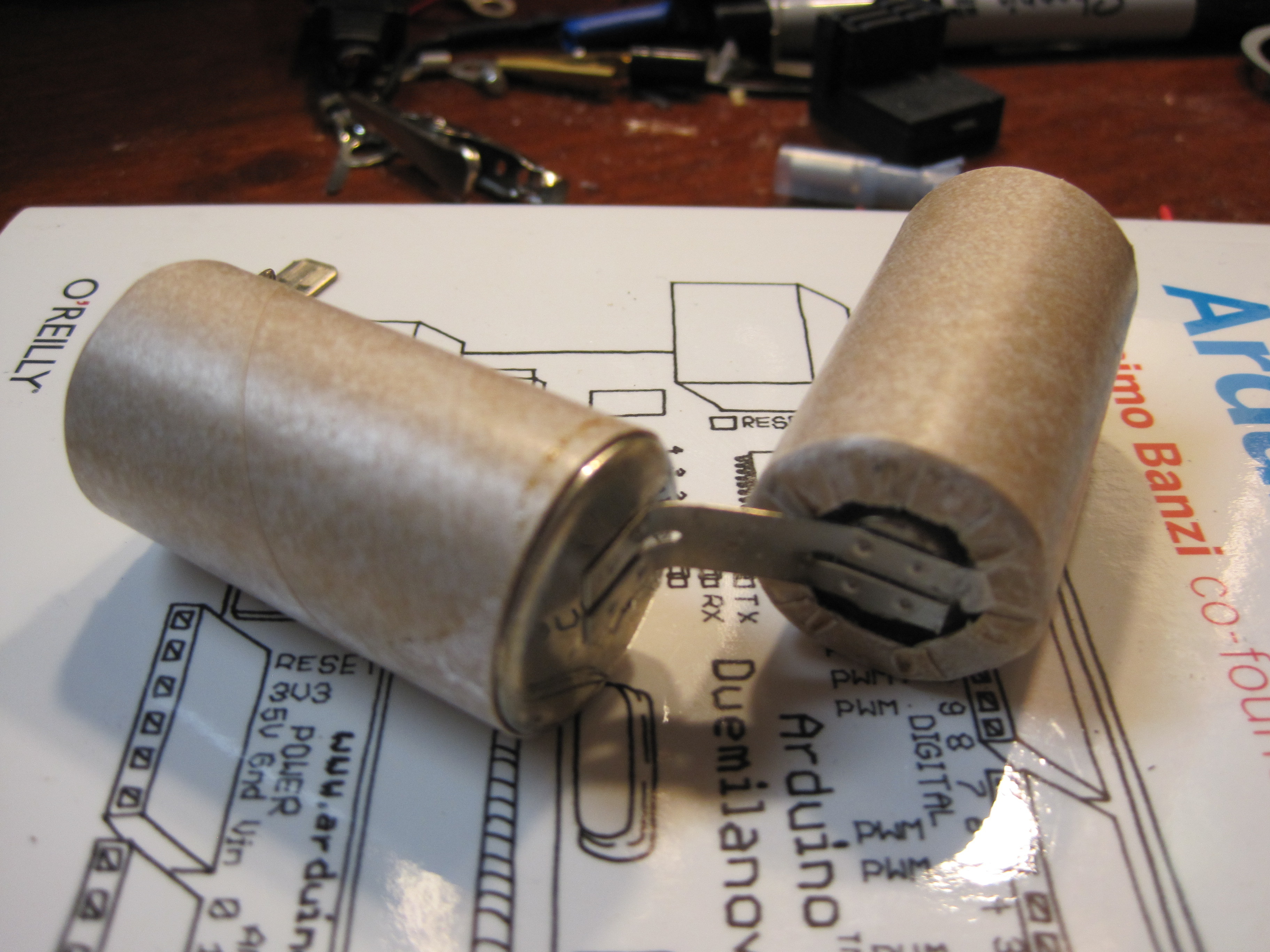

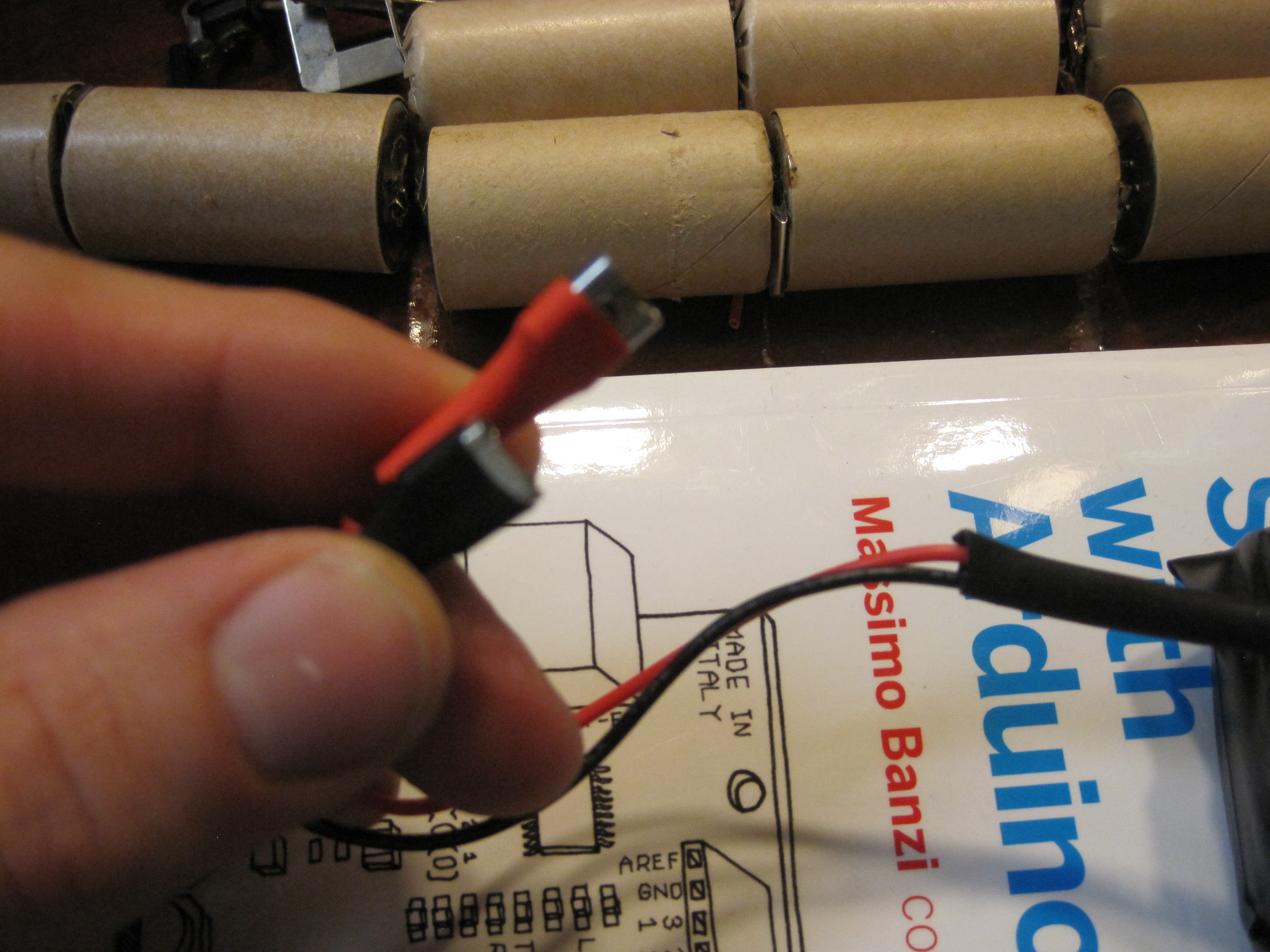

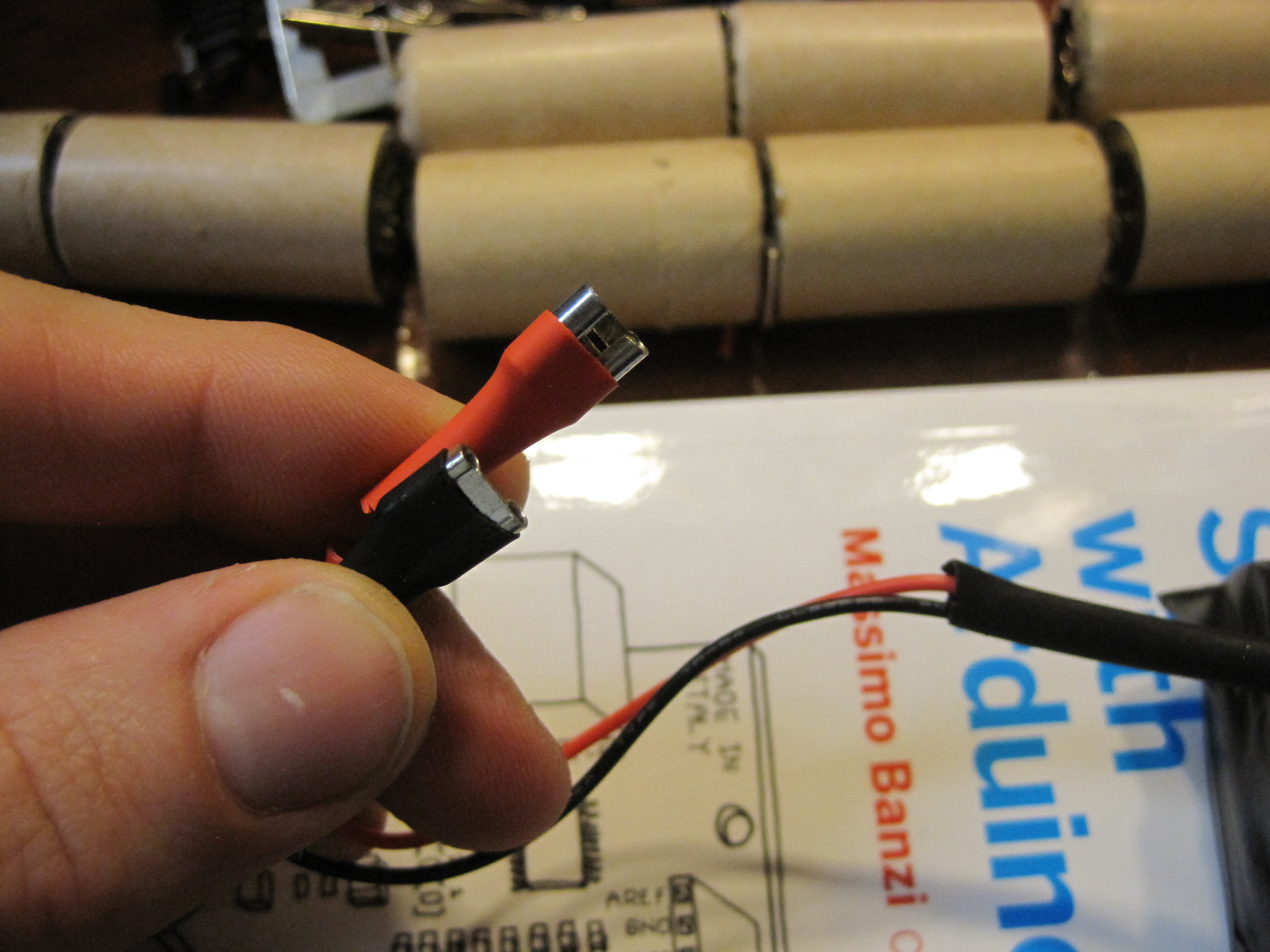

After disassembling the housing that holds the batteries you want to salvage, you should have something similar to what is in the pictures. I didn’t think to take a picture of mine when I disassembled it, but using the leftover cells I can demonstrate how to put them together.

The cells I used were Ni-Cad 1700mAh (milliamp-hours). This means that they can supply 1700mA for one hour, 850mA for two hours, 425mA for four hours, etc.

If you take apart 2 different types of batteries, you will most likely have similiar cells that were manufactured in different locations. In any case, make sure you keep similar cells together.

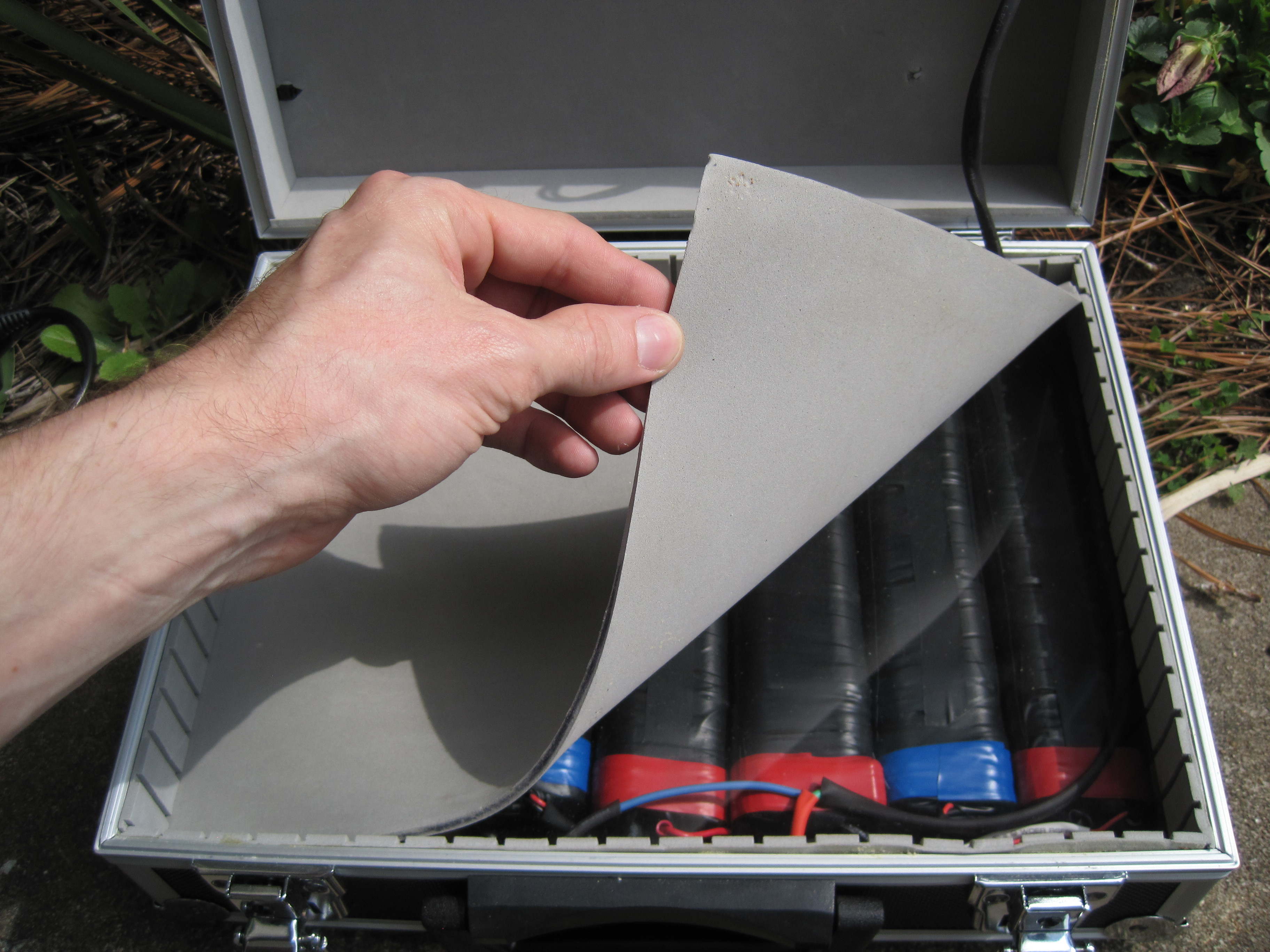

OK; if you took apart an 18V battery pack you should have 15 of the cells all tabbed together. Find the best 10, which for me were the ones starting with the positive lead. Count out 10 cells, then snip off the tab holding them together and put the rest of the cells to the side.

If you have 14.4V packs, it’s the same thing except you’ll have 12 cells to work with. Again, find the best 10.

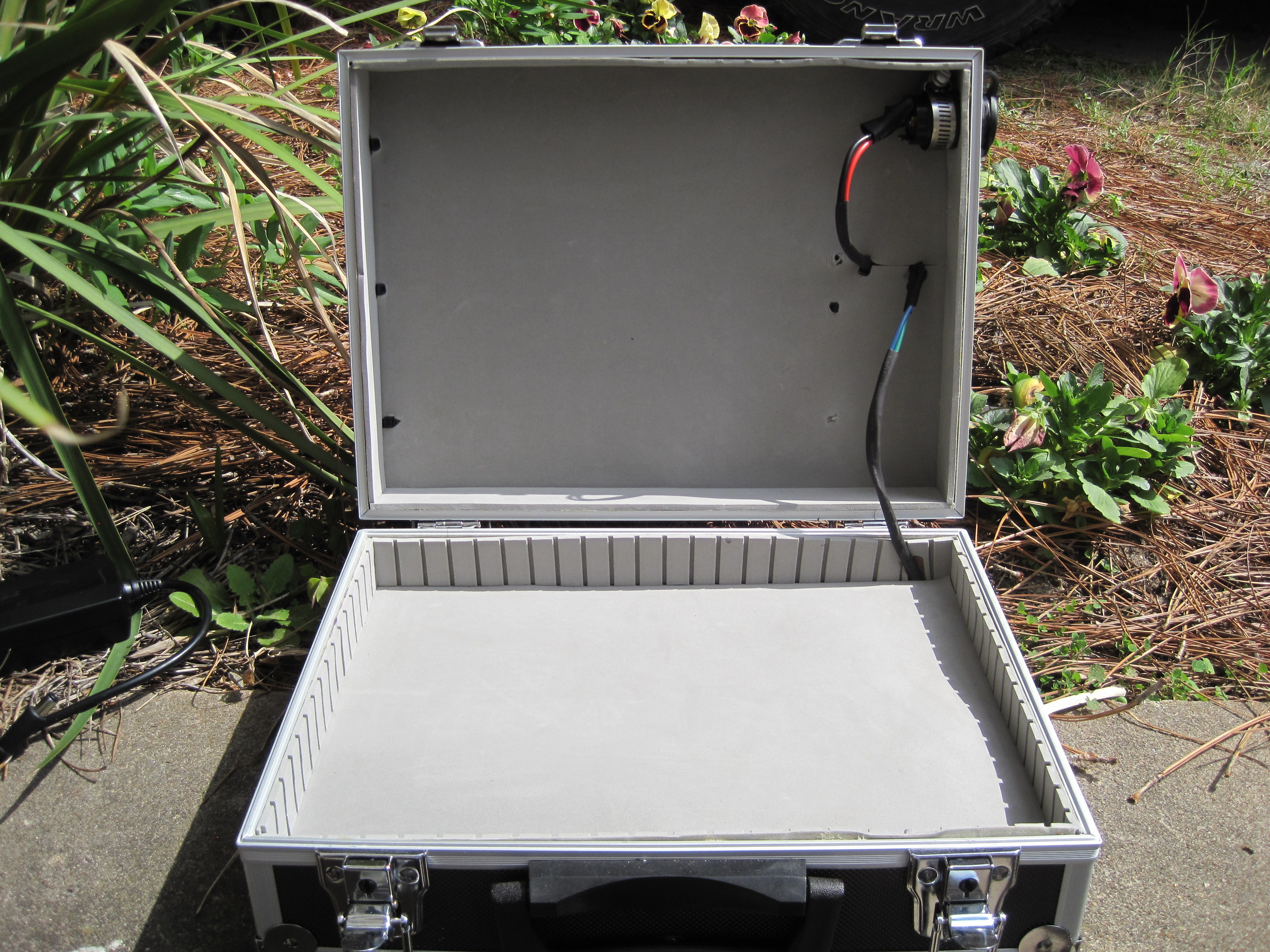

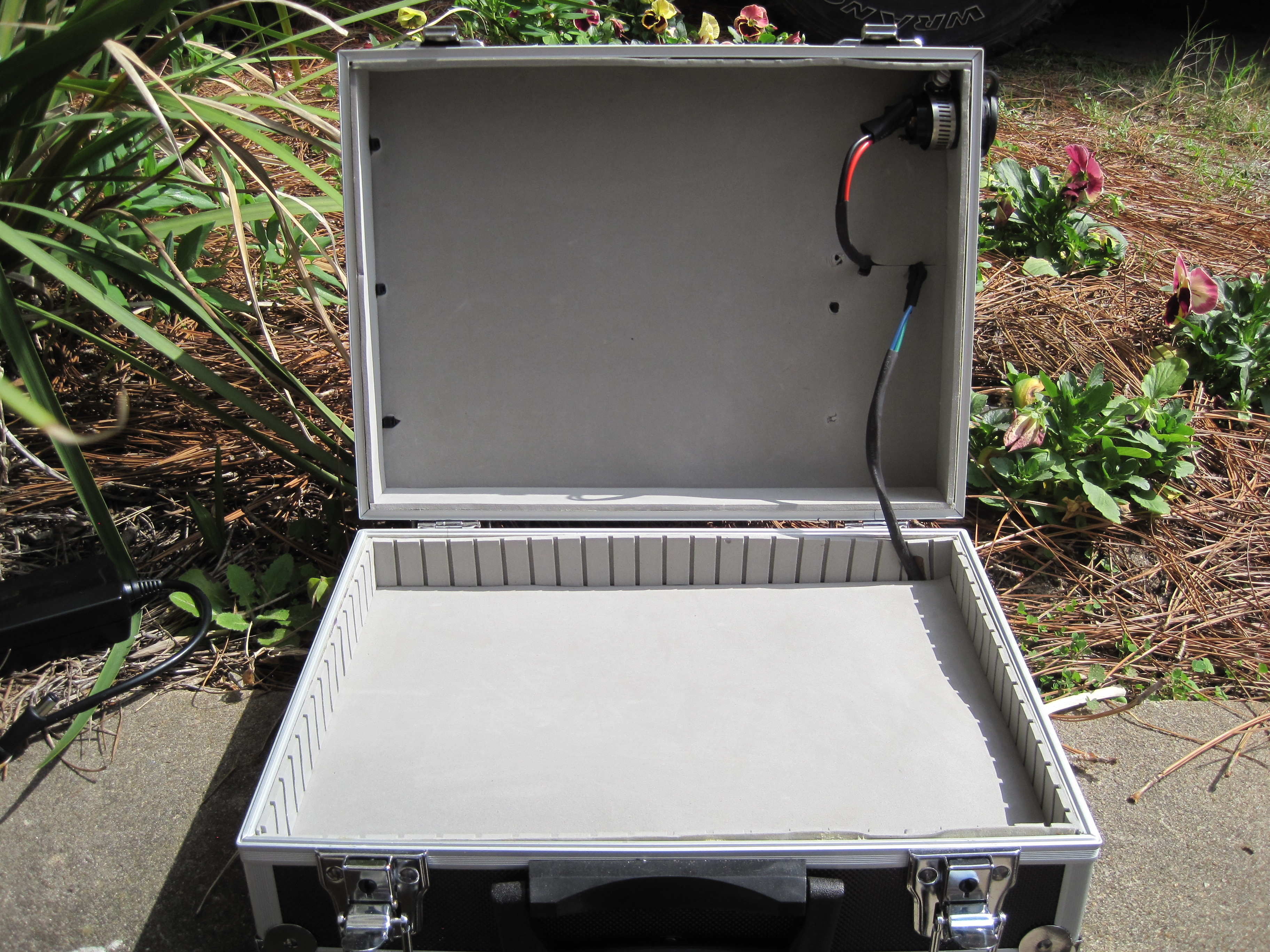

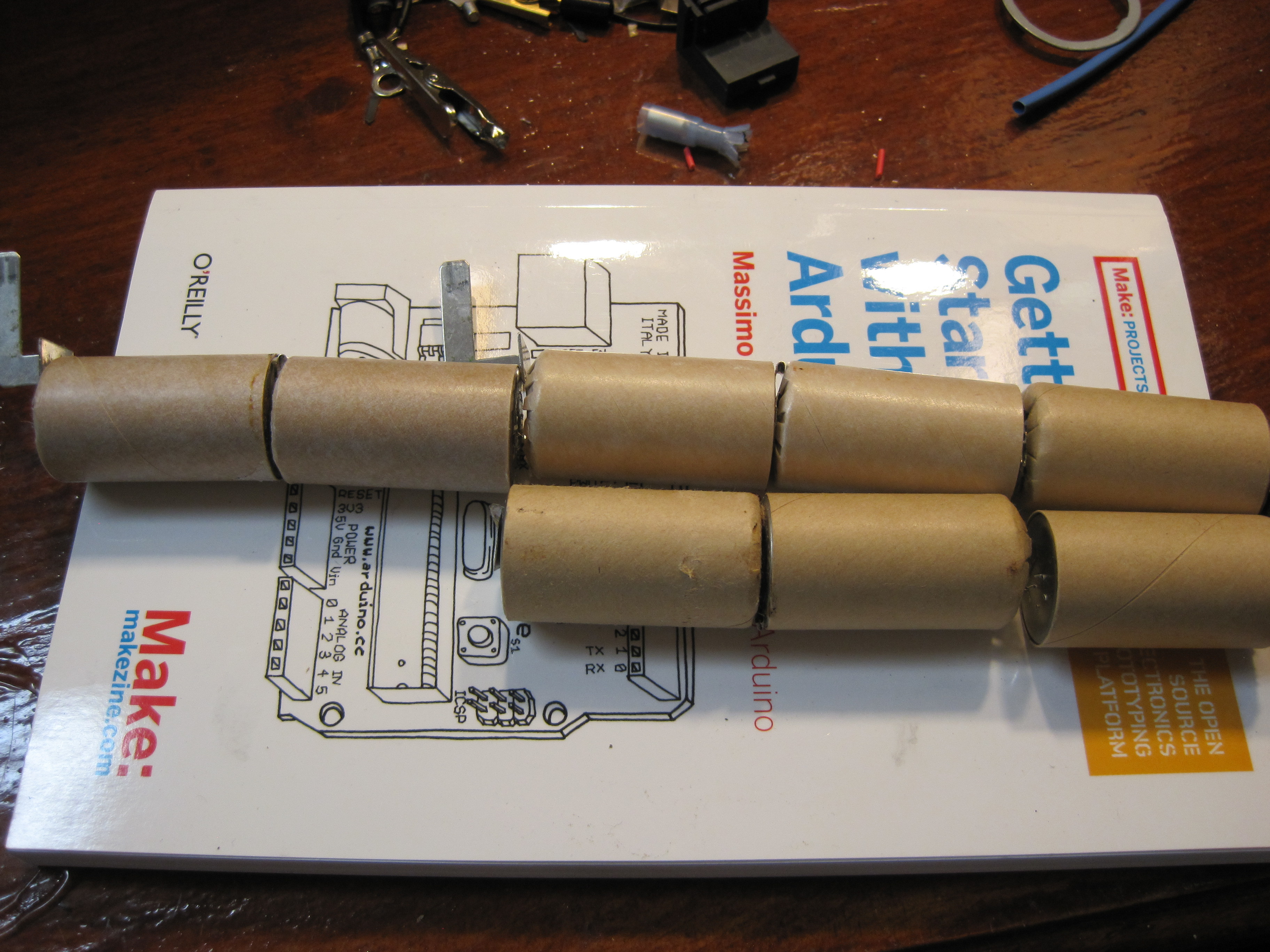

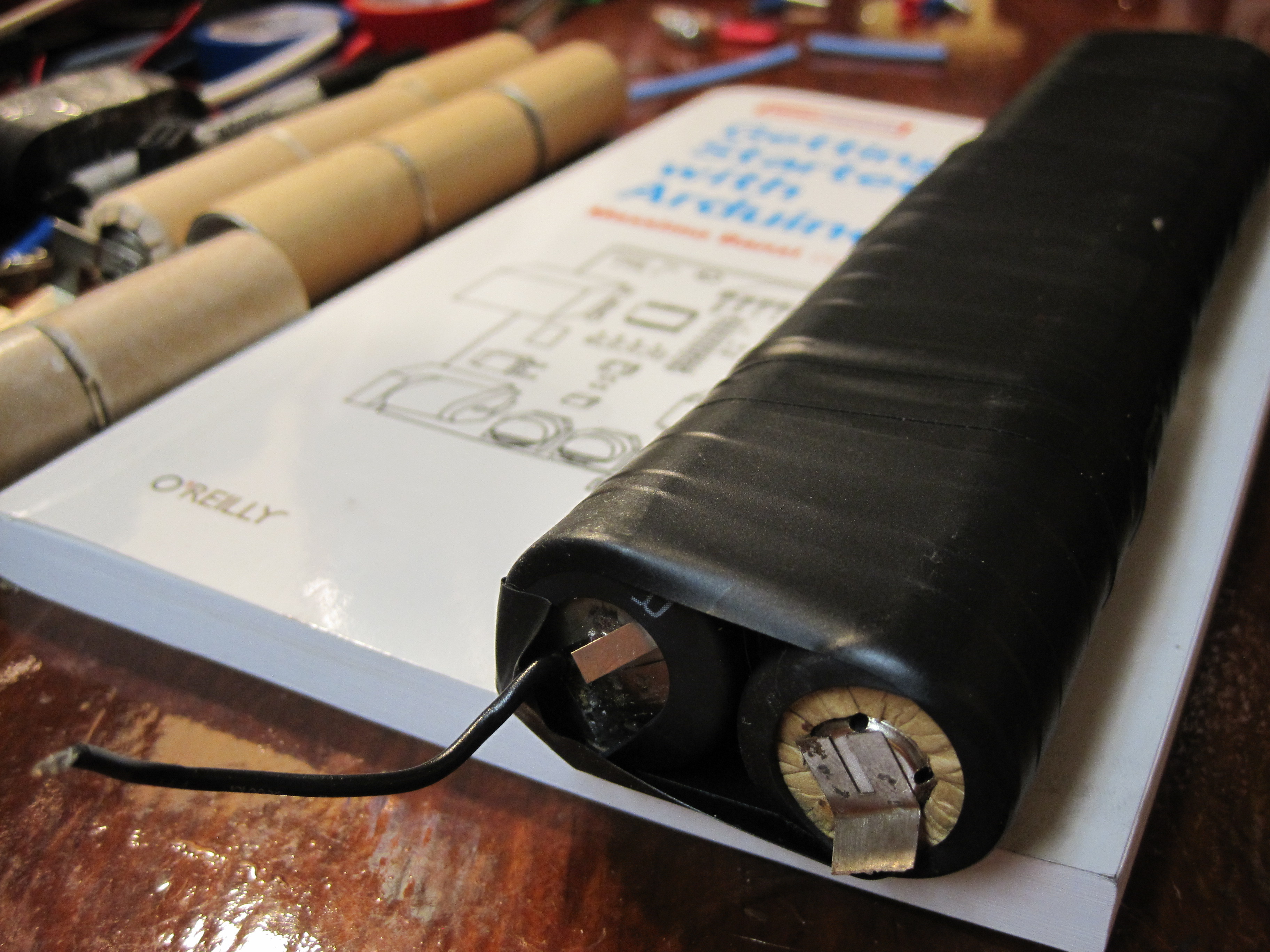

Here comes the difficult part, at least for me. You want to end up with a long flat pack that easily fits within your case, so you need to “fold” the cells and the tabs connecting them so that there are 2 rows of 5 cells each, all held together by their factory tabs.

You dont want to break those tabs. Soldering those batteries is a pain, and heating them up isn’t really a good idea.