It might have been Robots of Saturn that first got my young brain thinking about building a mechanical man. In that obscure 1962 sci-fi adventure novel, Dig Allen and his fellow teenage space explorers transfer their thoughts into the bodies of teleoperated robots to mine Saturn’s dangerous rings for precious Methane-X.

Using some of my stepfather’s “extra” ham radio gear, I tried to build my own telerobot, with plans of world domination swimming through my head. I didn’t get far, but now, with powerful yet inexpensive microcontrollers, maybe this time it’ll work.

Big ideas begin with small steps, so let’s start petite, cheap, and easy. Here’s how to build a super-affordable remote robotic gripper that can pay the pizza delivery guy.

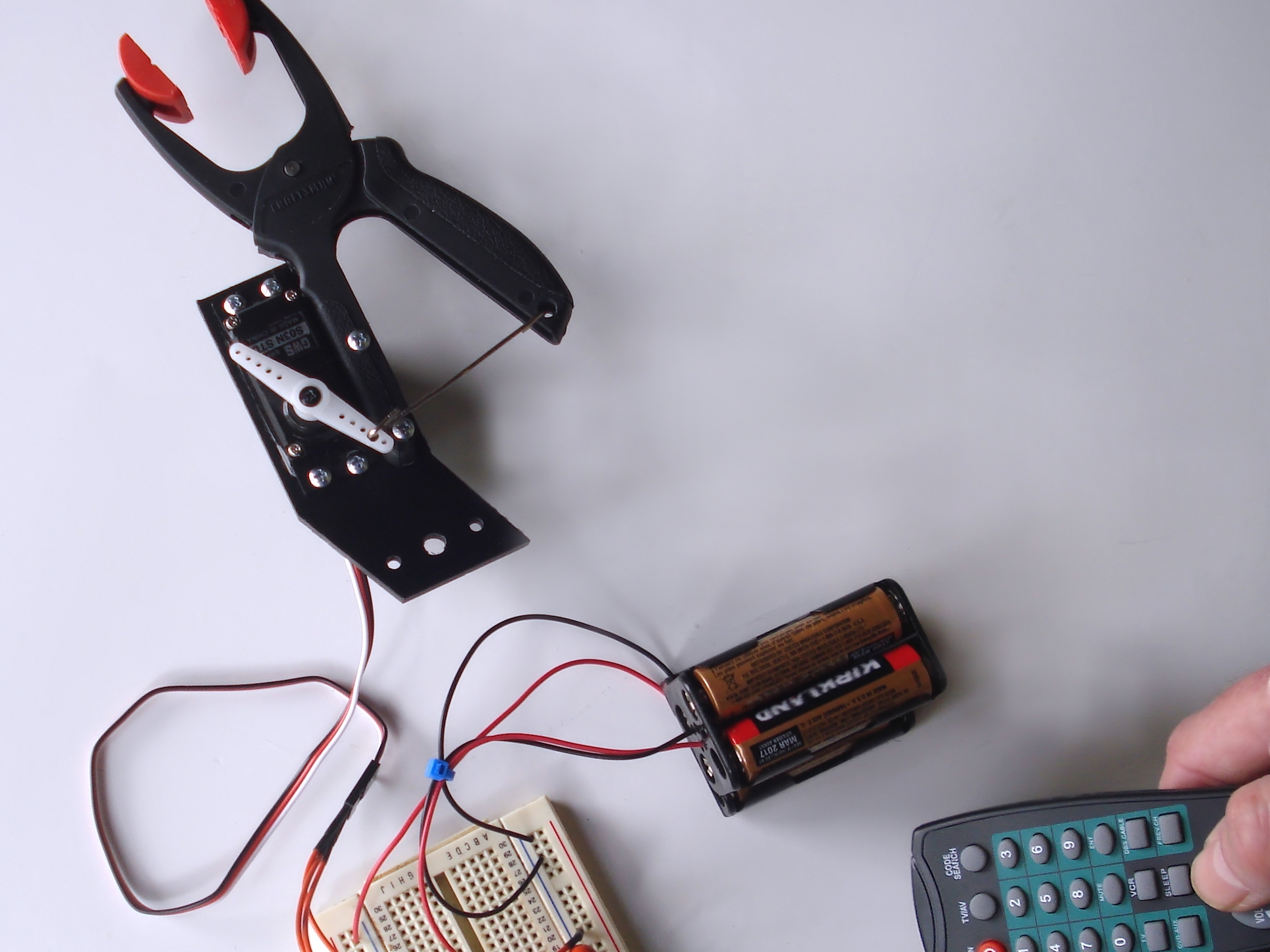

The telerobotic gripper (let’s call it the Teleclaw) has three main parts. The mechanics include a $2 plastic clamp, a radio-controlled (R/C) servomotor, some stiff wire, and a bracket to hold it all together. The electronics are a simple circuit designed around the Picaxe 08M microcontroller and an infrared (IR) receiver/demodulator module.

The remote control unit is an ordinary TV/VCR/DVD remote. You can use a remote you already have or get a cheap one just for this project. I paid 99 cents for the model here, but note that cheaper remotes usually have shorter ranges.

NOTE: Save time and money by picking up the MAKE Telerobotic Gripper Kit (item #MSTGK from the Maker Shed: http://www.makershed.com/teleclaw), which includes all of the project materials.