Fiery devices have always fascinated me. From Jam Jar Jets (MAKE Volume 05) to Fire Pistons (Volume 19) to Faux Flames (Volume 25), I’ve built all sorts of fire-related projects. So when a friend told me about a device that lets you visualize sounds using fire, I knew I had to make one. I found it described in several old physics demonstration manuals, then I adapted those directions to make it less expensive and easier to build.

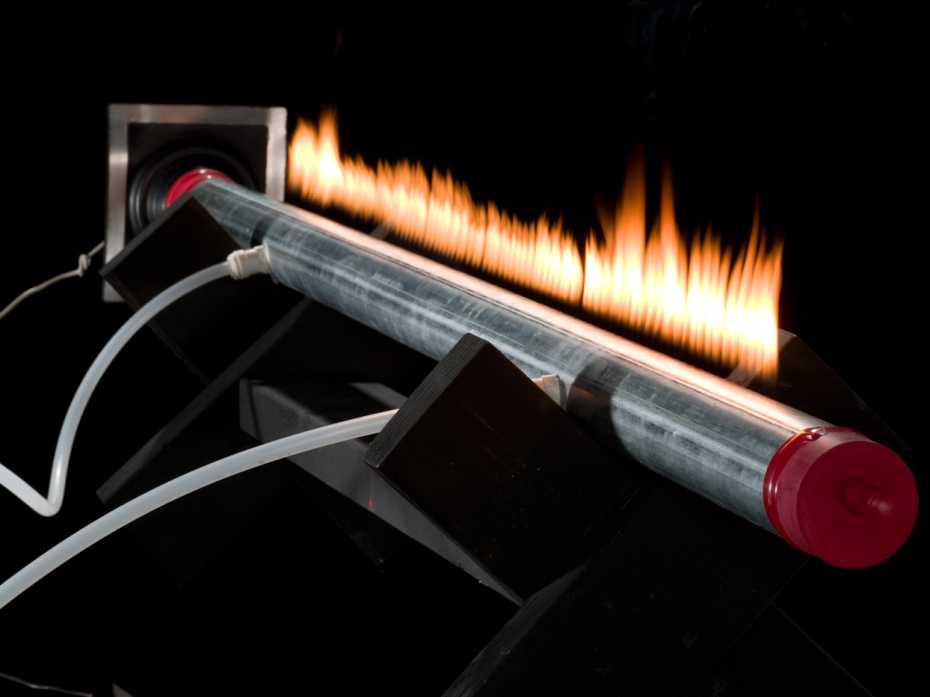

When you play a constant-frequency tone into the Flame Tube, it displays a perfect sine wave of fire. Play music, and the flames make a wild display caused by big, air-moving bass beats, standing waves from resonant frequencies, and other acoustic phenomena. It’s inspiring, fun to watch, and good for heating up your garage or workshop on a cold day.

In 1860, Dutch physics professor Pieter Rijke was investigating the relationship between sounds, gases, and fire. He stuffed a piece of iron mesh inside a large glass tube, then held it over a gas flame until the mesh was red-hot. Suddenly, the contraption emitted a sustained musical tone so loud that workers several rooms away complained.

Intrigued, Rijke’s colleagues set out to discover the reason for “the singing flames.” Some thought it was the periodic evaporation and condensation of water, but later scientists showed that the sound was caused by waves of air, set in recurring motion by the fire’s heat. Hot air, being less dense, moved upward while cool air sank. This vibrating air resonated at the natural frequency of the tube.

Years after Rijke’s work, German scientist Heinrich Rubens turned the idea on its head. He knew fire could produce resonating sound waves. Was it possible to use fire to make sound waves visible for the first time? In his laboratory at the University of Berlin he developed the standing wave flame tube, also called the Rubens tube in his honor.

The flame tube (aka Rubens tube) is a waveform visualizer. It works because sound is a pressure wave. As sound moves through a gas like propane, the wave alternately compresses and expands the gas in different regions. When you use a frequency generator to produce a constant tone of, say, 440Hz (the musical note A), the speaker pushes this sound through the gas, and a stationary wave is set up.

The stationary wave causes areas of high pressure to appear at fixed points along the pipe, spaced half-wavelengths apart. Where the pressure is high, the propane is driven more strongly out of the pipe, resulting in a tall flame. Between these high-pressure points will be low pressure points that create lower flames.

When music is played instead of the frequency generator output, the clean curves of the sine wave are replaced by much more chaotic and perhaps even more intriguing patterns. Strong vibration from drums and low-frequency sounds from bass guitars, tubas, and string basses cause the flame tube to send fire pulses out of the holes nearest the loudspeaker. Overlaying that are sine waves that are visible whenever the musical pitches being played coincide with the tube’s resonant frequencies. This layering of resonant frequencies and bass beats produces a dazzling display of musical pyrotechnics.