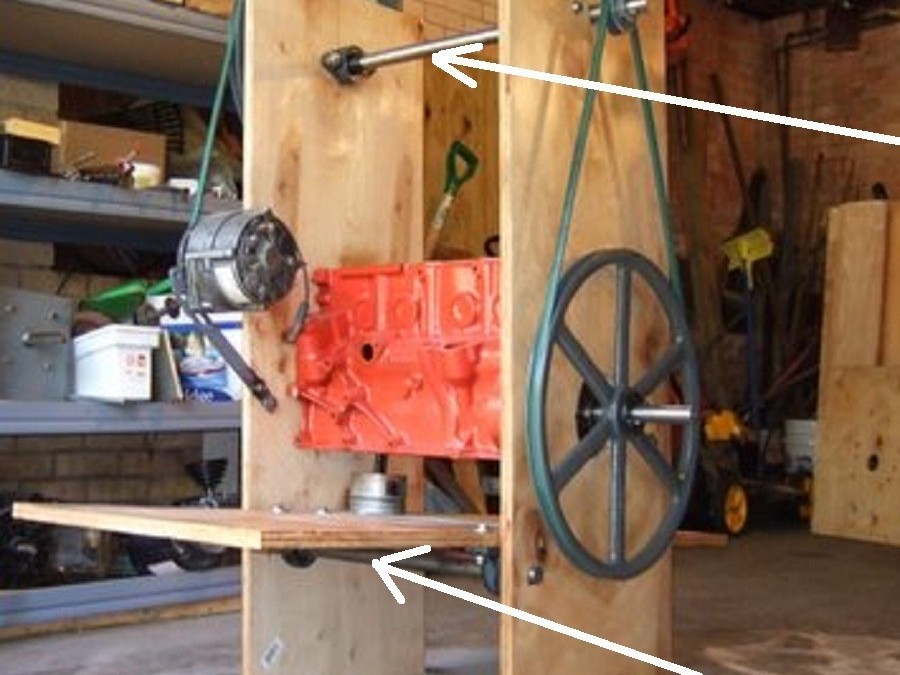

The big Genny secret! The piston and connecting rod come out the bottom of the engine block so that it can be the major part of an almost unbreakable multi-person treadle drive. A vehicle alternator requires much more power than one person can provide.

Using 2 pistons and rods may seem stronger but they are hard to set up and keep in exactly the same plane. If they are not perfectly parallel, most pedaling effort is wasted.

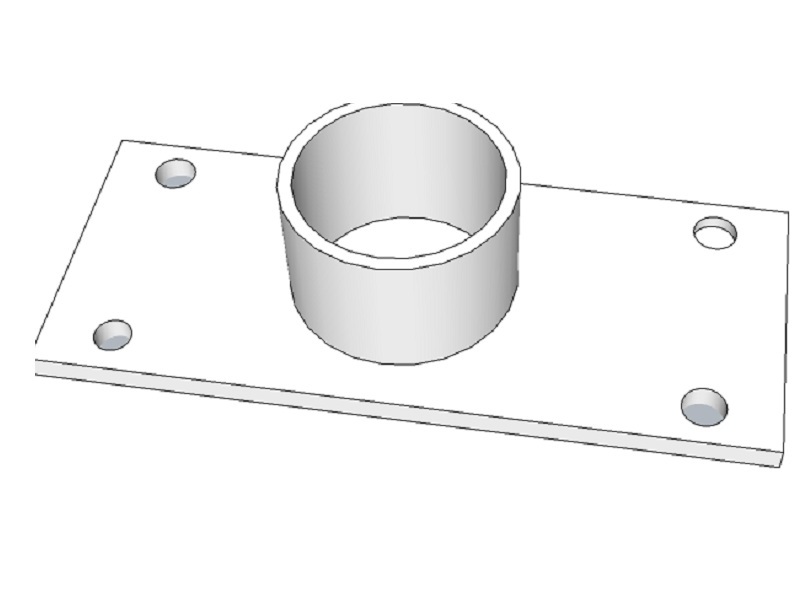

The connecting rod should be extended by cutting and welding a pipe spacer between the 2 pieces. The bores for the crankshaft and the piston pin must be kept EXACTLY parallel. Attaching the piston to the treadle by just threading the top of the piston for hold down bolts is not adequate, this spacer will make room for additional support. A good way to attach the piston is shown in the next step.

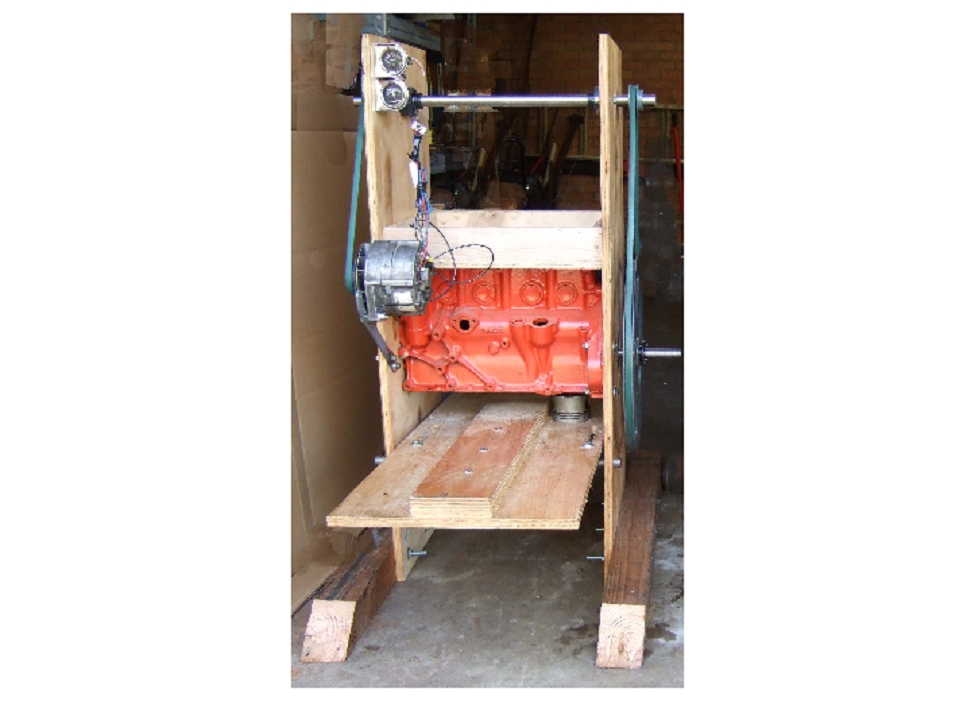

The treadle board and frame should be made from pallet wood or something of similar strength.

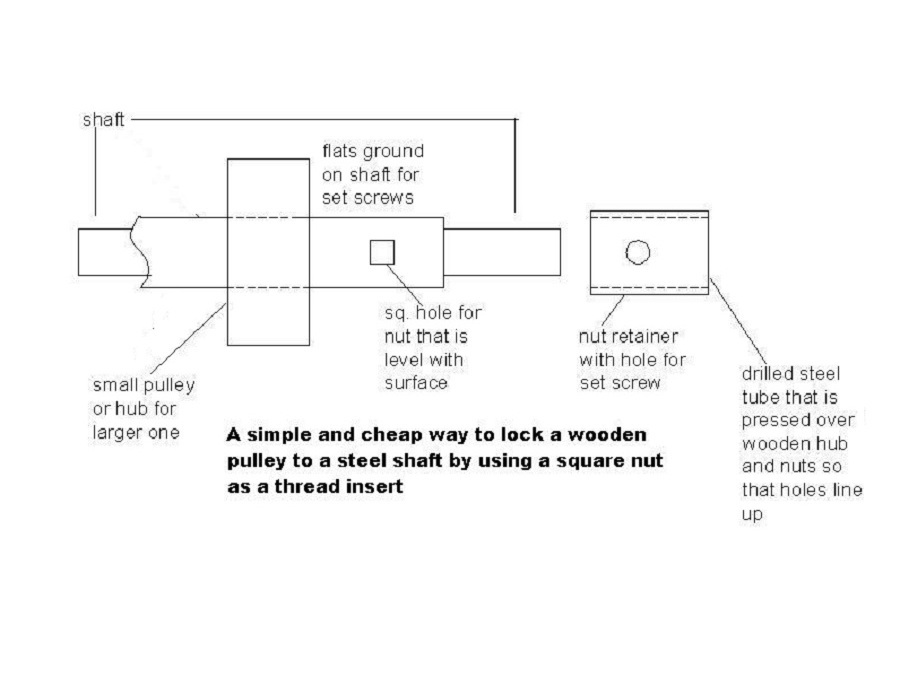

Very carefully drill and tap the main and rod bearing caps for grease fittings and keep well greased. Countersink the inner side of the bearing caps to remove burrs.

Drill matching holes in the bearing inserts and be very careful to remove any burrs. A grinder may be the best way to cut the holes since the thin insert will be less likely to be bent.

In case a part of the block gets in the way of the rod, break the offending part off. Use a narrow, sharp chisel to make a line of sewing like stitch cuts along the desired break line and then use a big hammer and chisel to break it off.