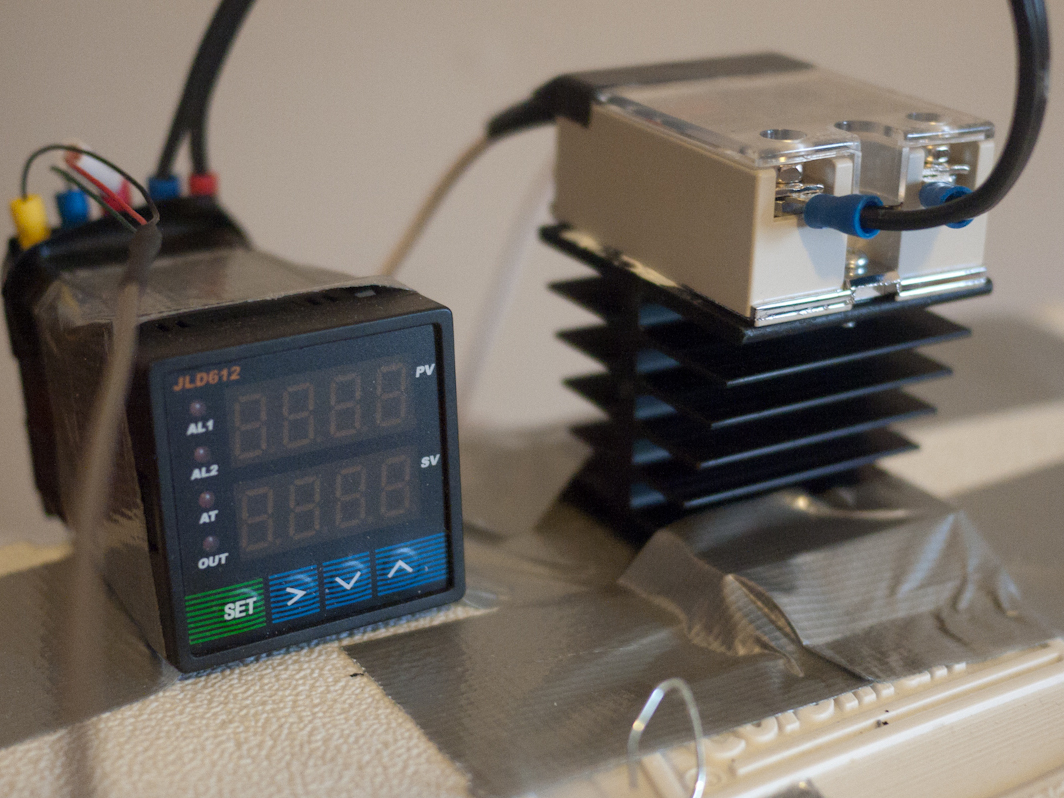

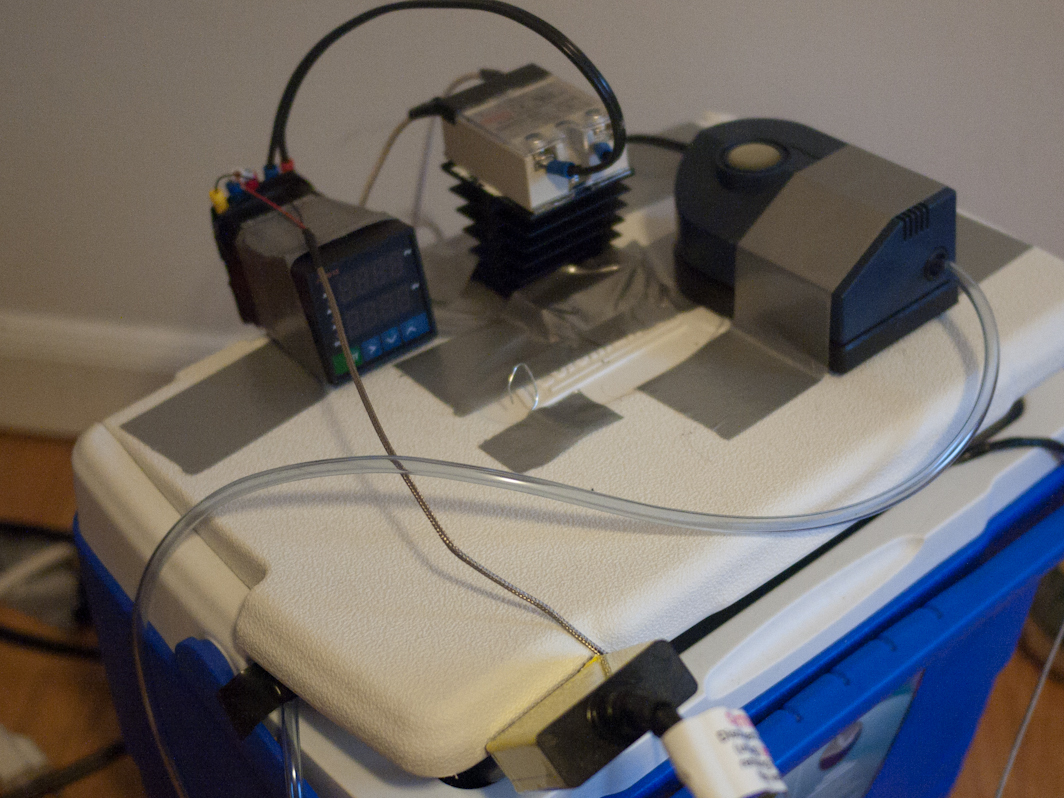

A while ago we built a $50 dollar sous vide machine to start messing around with sous vide cooking. We loved it, and it has been precise and stable over a long period of time.

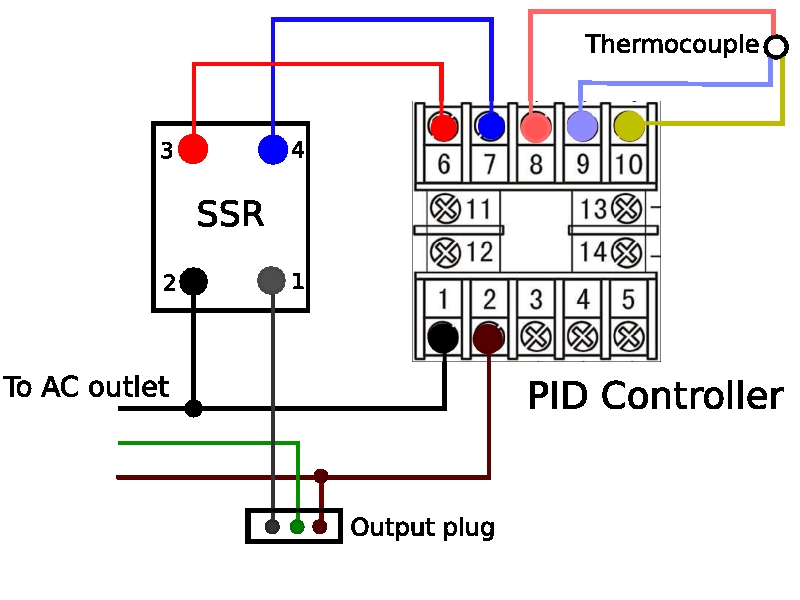

However, we thought it’d be awesome to create a brain that could control anything based on the thermocouple output. Something that would work with a rice cooker, bucket heater, or even a smoker. We could’ve gone out and bought a $160 Sous Vide Magic, but we built our own controller for $70! And now we’ll show you how to DIY.

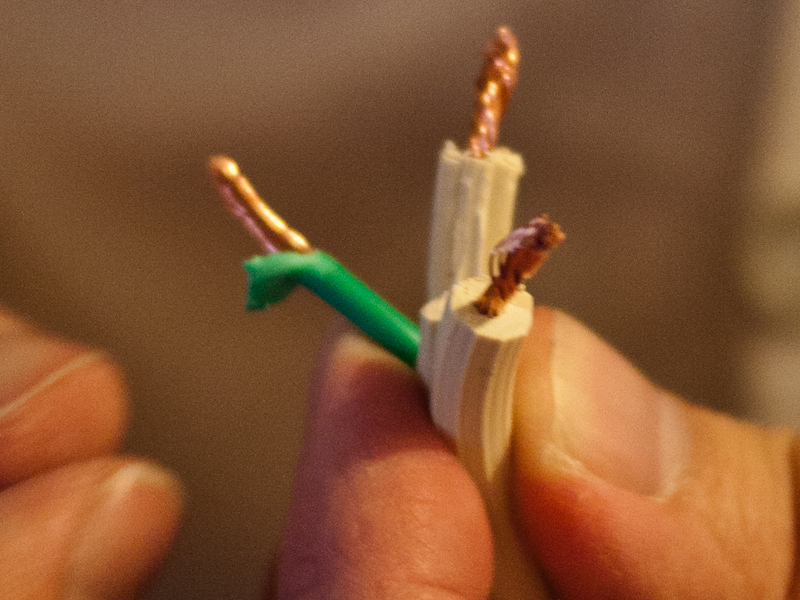

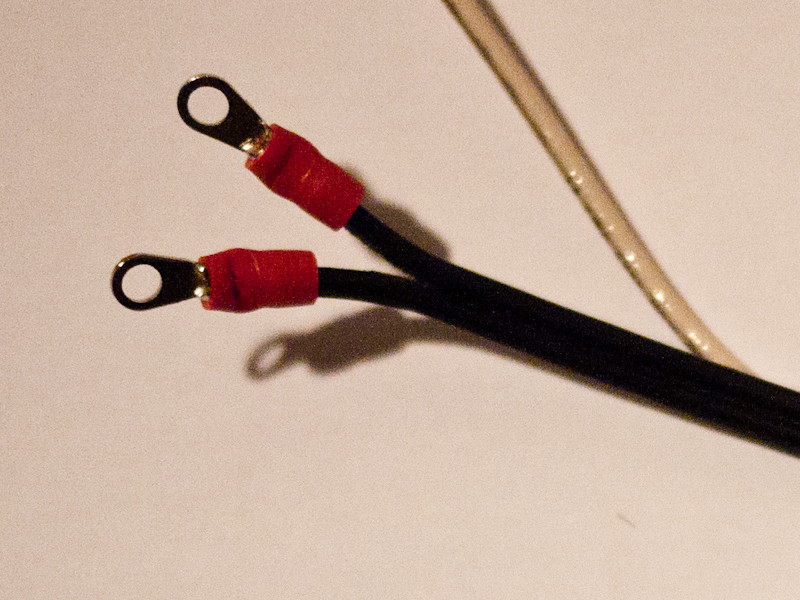

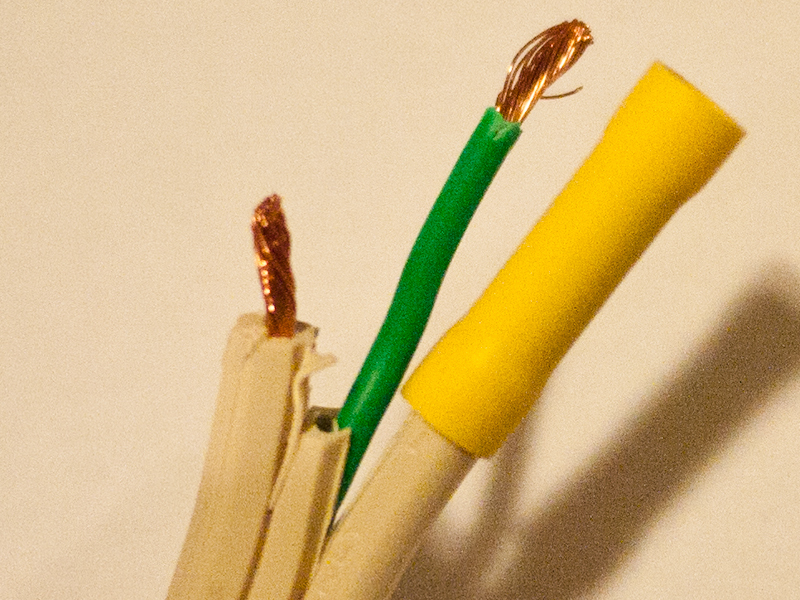

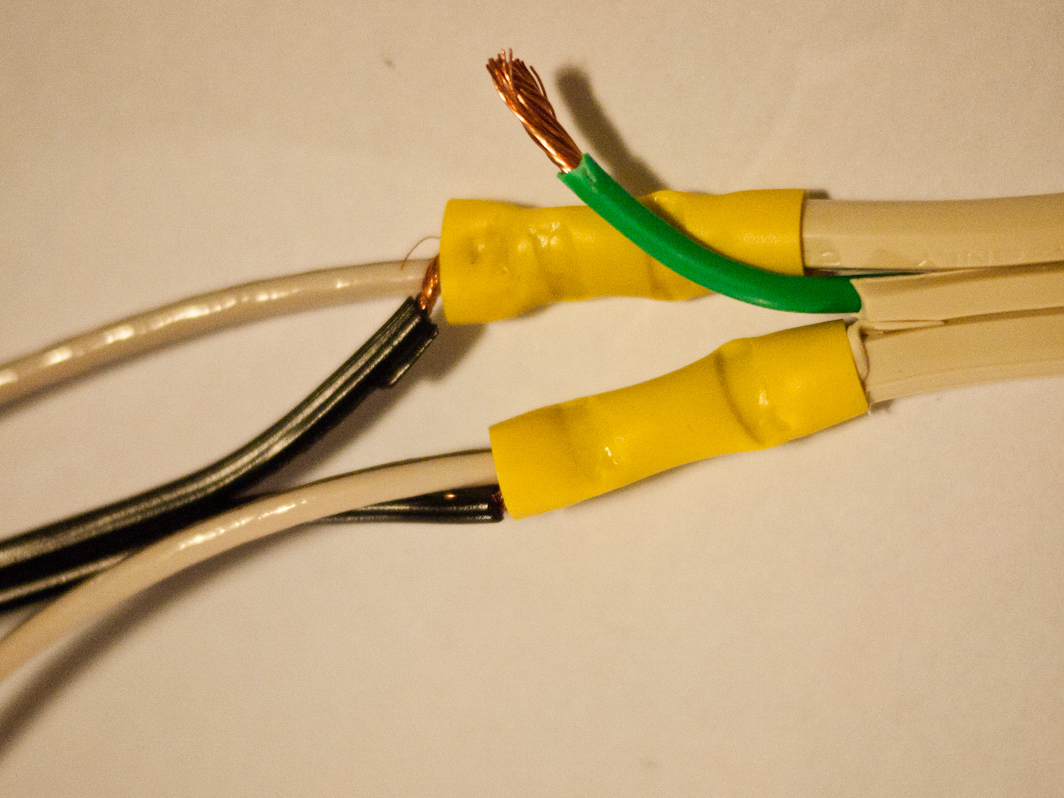

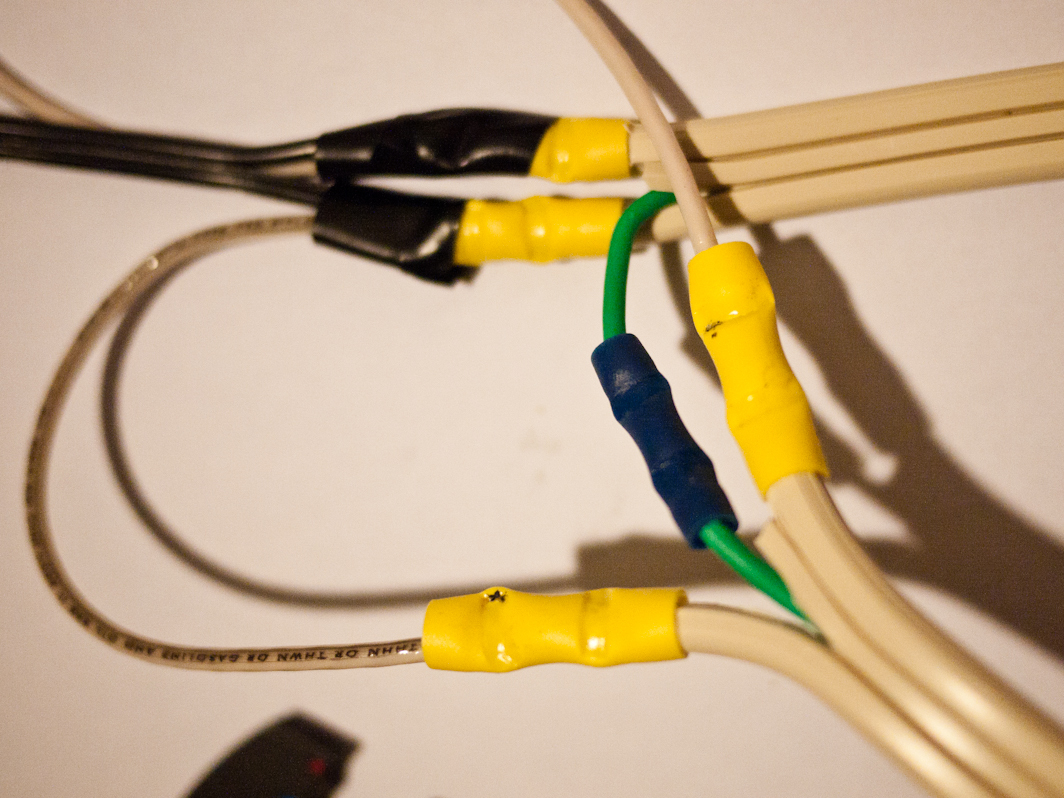

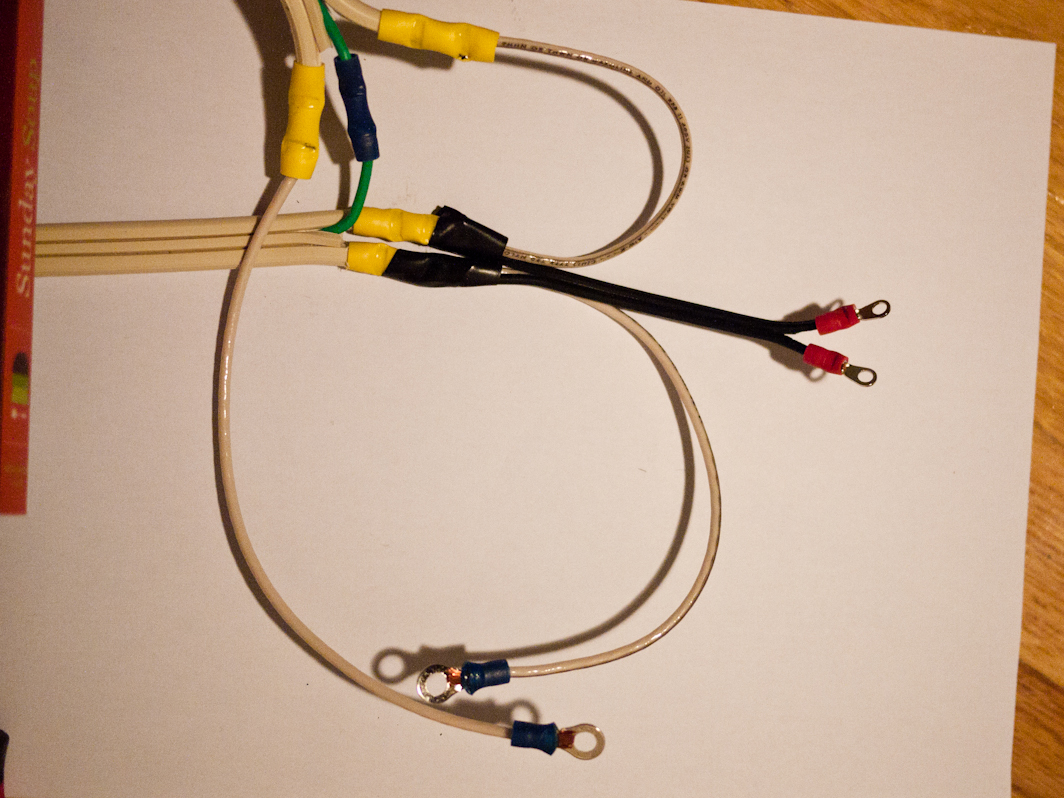

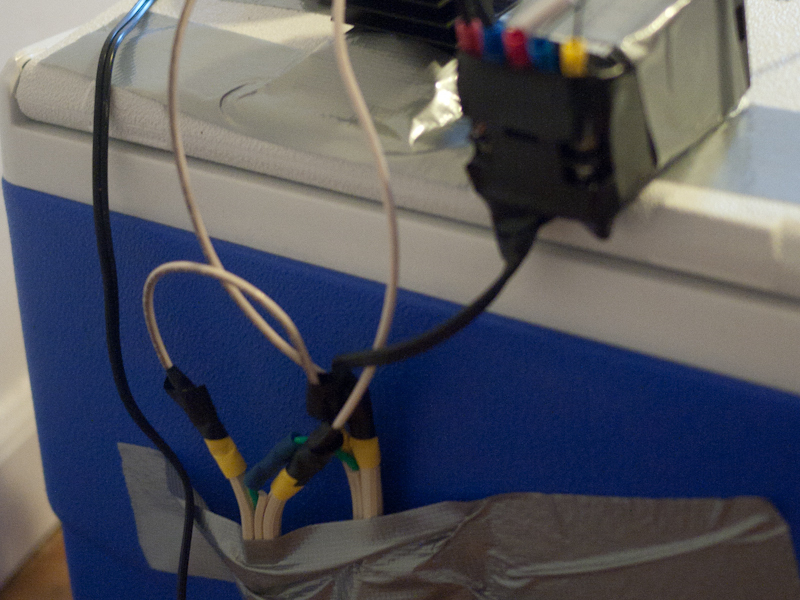

Again we’ve avoided soldering anything, which simplifies the construction considerably.

You can check out some recipes and more DIY sous vide advice at our blog. The details in this guide are posted there as well.

Warning: do not embark on this if you are not comfortable with electronics, including high voltages. Some connections carry AC power direct from the wall outlet which can lead to personal injury or death.