Walkers, a common adaptive aid for the mobility-disabled, are often not accessible or affordable across the global market. Private insurance and even countries with universal health coverage may not cover the cost of a walker, which can cost $100 or more. My colleagues Anita So, Jacob Reeves, and I at the University of Western Ontario were determined to learn if mobility aid costs could be reduced.

Mobile Device Developers

After interviewing people who use walkers and examining commercially available models, our team developed a low-cost static walker, aka walking frame, by using freely available Onshape CAD software, simple hand tools, a 3D printer, and wooden dowels. Though strength will vary depending on the wood type chosen (e.g., basswood, beech, maple, oak, pine, etc.), we built it from relatively lower-strength basswood to assess our design conservatively. We tested several iterations with a constant focus on safety and stability, until finalizing this free and open-source design that’s easy to build, adapt, and customize.

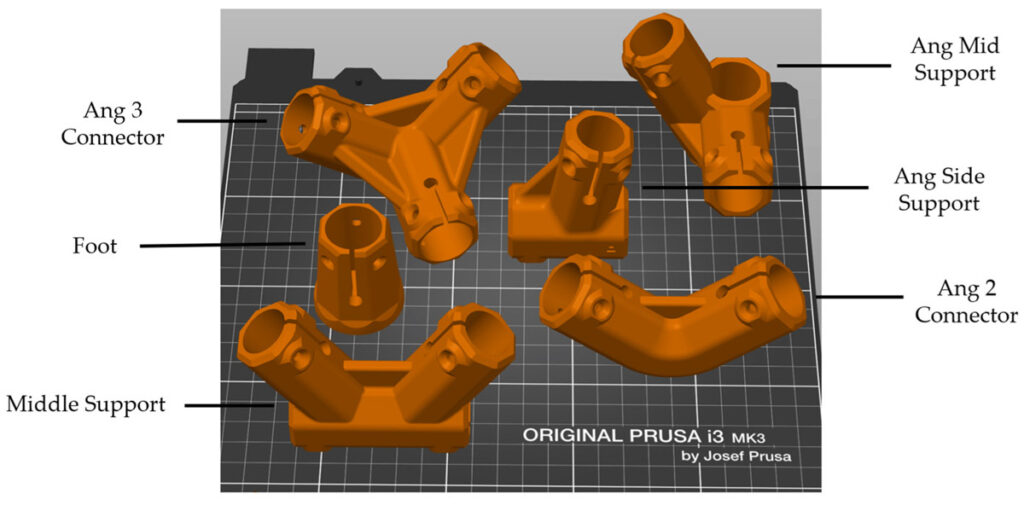

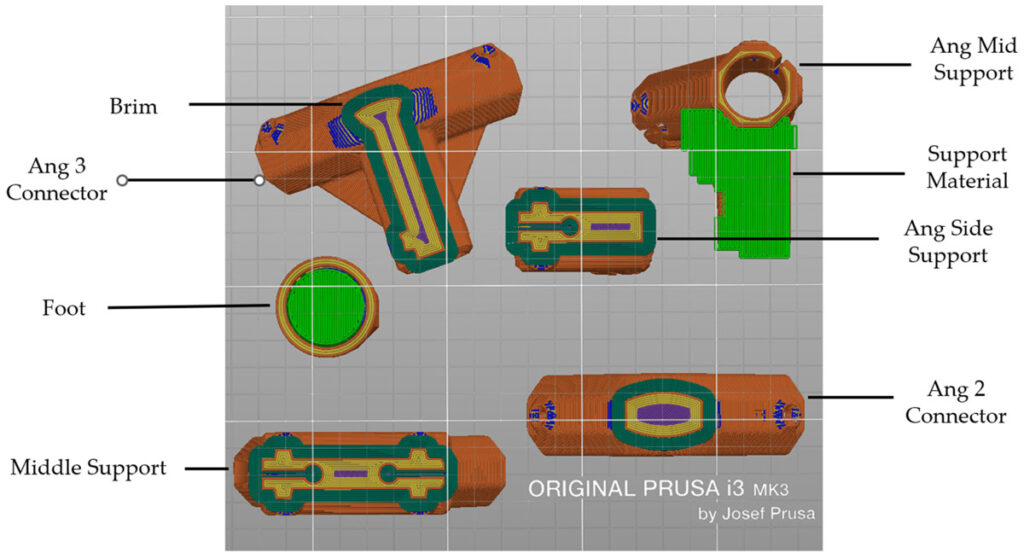

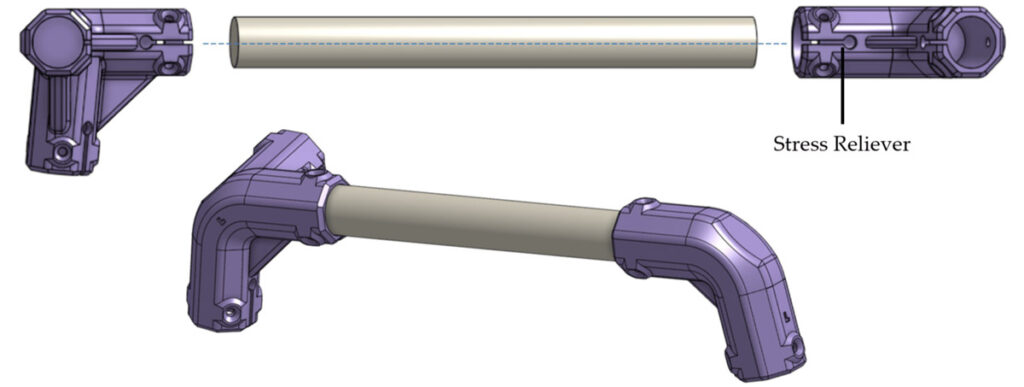

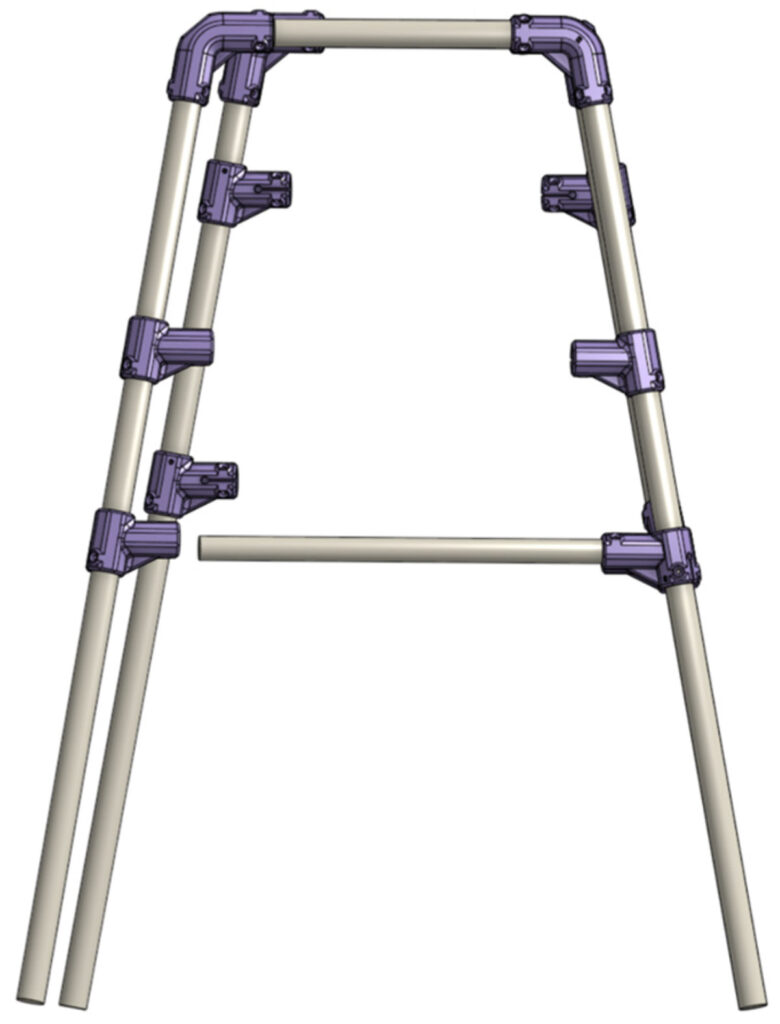

This walker’s stability and rigidity are achieved by three main features: an A-frame design, triangular bracing that angles inward from the front legs and meets centrally on the top bar, and two horizontal braces on each side (Figure A). The wooden dowel frame parts are connected by tough PETG plastic connectors.

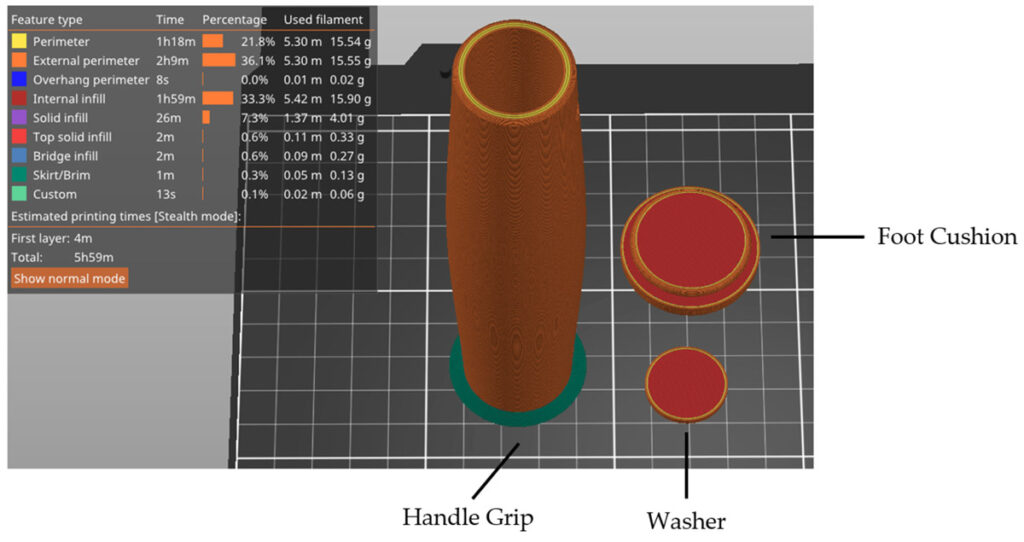

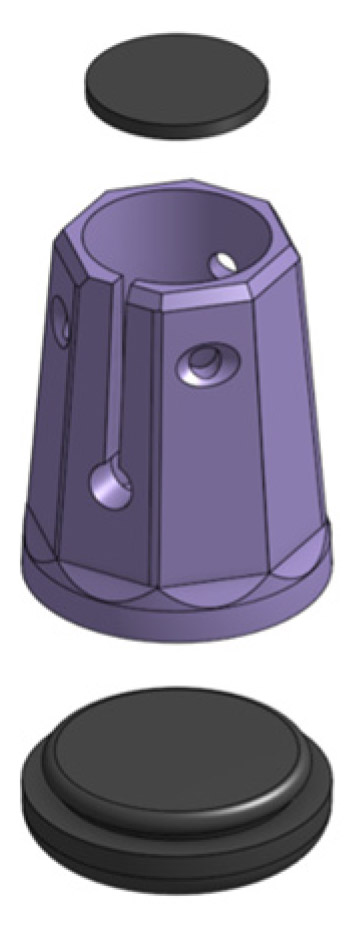

The three-piece foot design connects a rubbery TPU base to the dowels via a press-fit PETG body and #6 flat-head screws. These dual-material feet provide greater friction to improve the walker’s stability on smooth surfaces such as tiled floors. Similarly, a convex cylindrical TPU handle can be press-fit on the walker’s top sides to improve grip and comfort.

To ensure these walkers could safely withstand regular use, the team rigorously tested them to exceed the “static strength of walking frame” described in ISO 11199-1:2021, a standard that requires walkers to bear a purely vertical load of 1,500N — about 337lbs or 153kg — without cracking or breaking for a duration of 2 to 5 seconds. To study failure modes and locations, we exceeded this standard by testing the walkers to failure in a hydraulic press (Figure B).

Lateral loading was also considered. Initially, we played an energetic game of tug-of-war; controlled studies with a second hydraulic pump followed. You can read testing details and data here. Western did all the necessary testing for this design; you won’t need to replicate it as long as you follow the manufacturing instructions.

These walkers are designed to be customized. Not only do you size it for a specific person, but you should also choose the user’s favorite filament color!

We’re honored that our low-cost walker is included in the Project Library at Open Source Medical Supplies, whose Victoria Jaqua and Christina Cole helped prepare this article for Make:.