I used EagleCAD to lay out the circuit and PCB design for this project. Download and install the free version of Eagle CAD here: http://www.cadsoft.de/download.htm

Download the project design files here: (schematic and PCB). To make a board, you can either send the PCB files out to a fabrication house, or (if you’re feeling brave) etch your own board, as follows in this step.

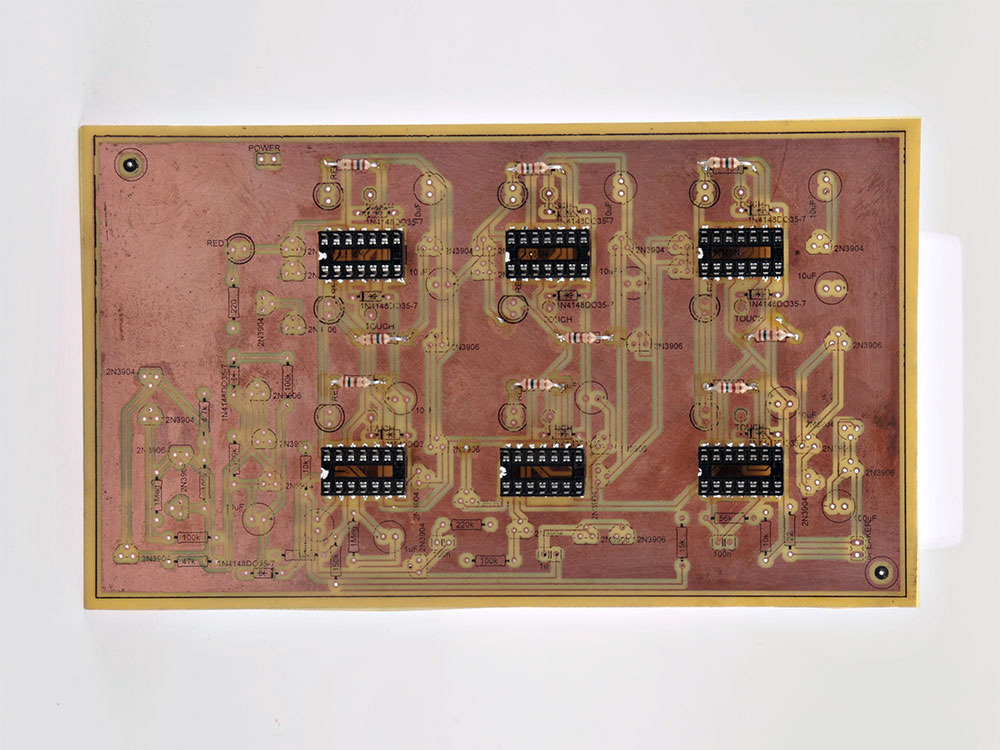

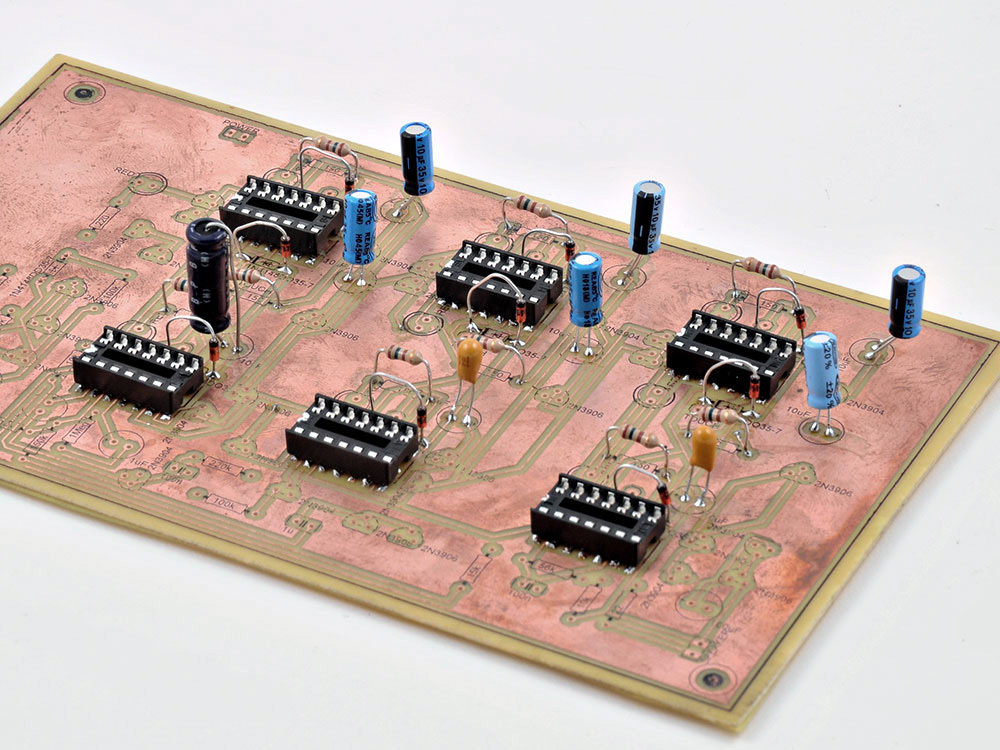

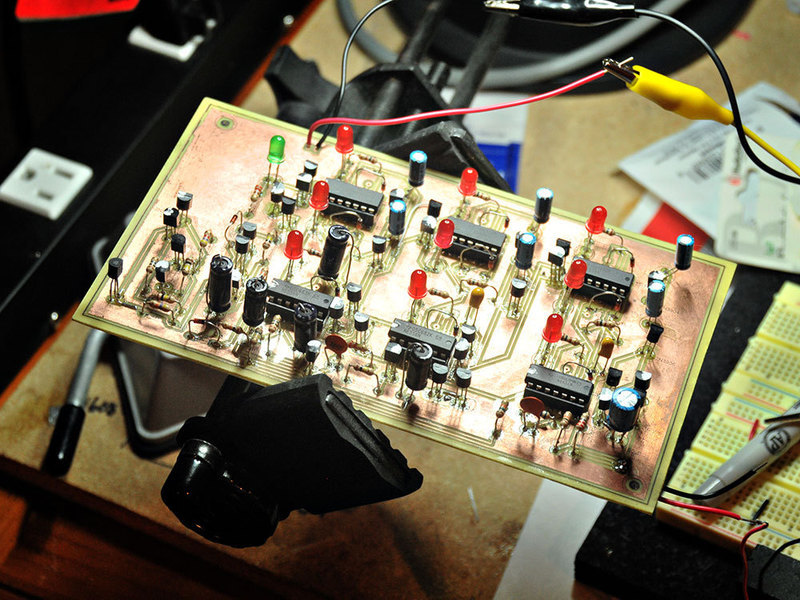

Launch EagleCAD and open the project design files, linked above. Print each PCB layout layer onto a transparency sheet. The CAD files are the best guide to component placement and orientation, so you will also refer to them later.

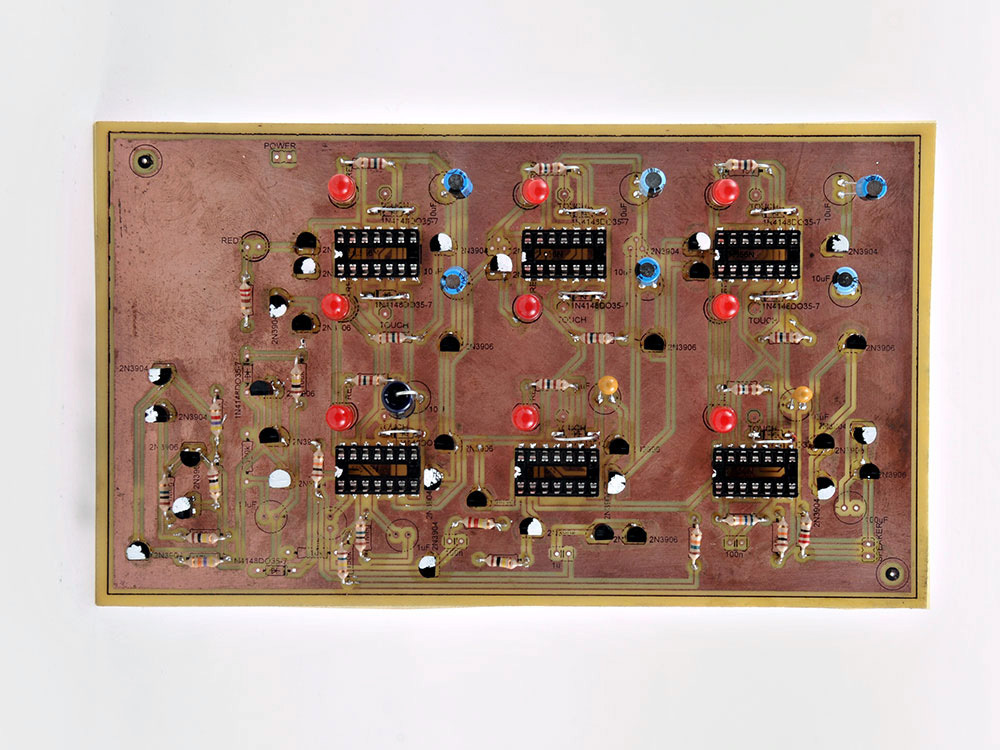

For each of the two layers, use the toner transfer method to transfer the etching mask to the copper cladding with an electric iron. Here’s a good page on the technique.

With the laser toner mask stuck tight onto the copper, etch the rest of the copper away with etching solution. Follow this guide: Cheap, Friendly, and Precise PCB Etching as a quick circuit board etching method, substituting etching solution for the peroxide, vinegar, and salt mixture described.

To make your circuit board double-sided, glue the two single-sided boards together back to back, using the two drill holes as an alignment reference. I used 3M #77 spray adhesive to bond the boards and left them in a press overnight.

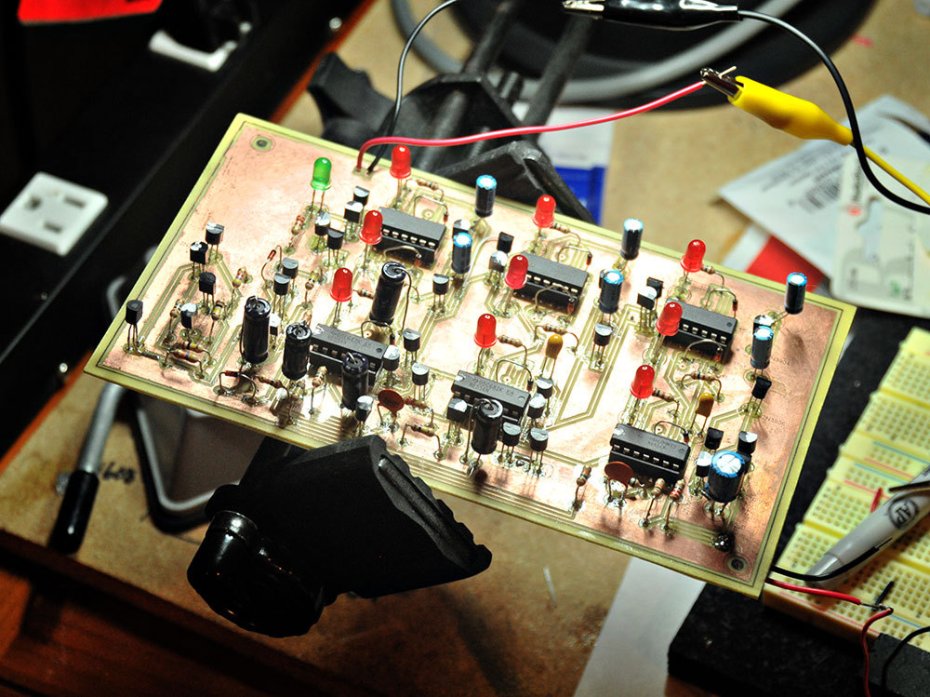

Print out and iron the label layer onto the top of the board, using the toner transfer method. Finally, drill out all the board’s through-holes using a 0.75mm drill bit.