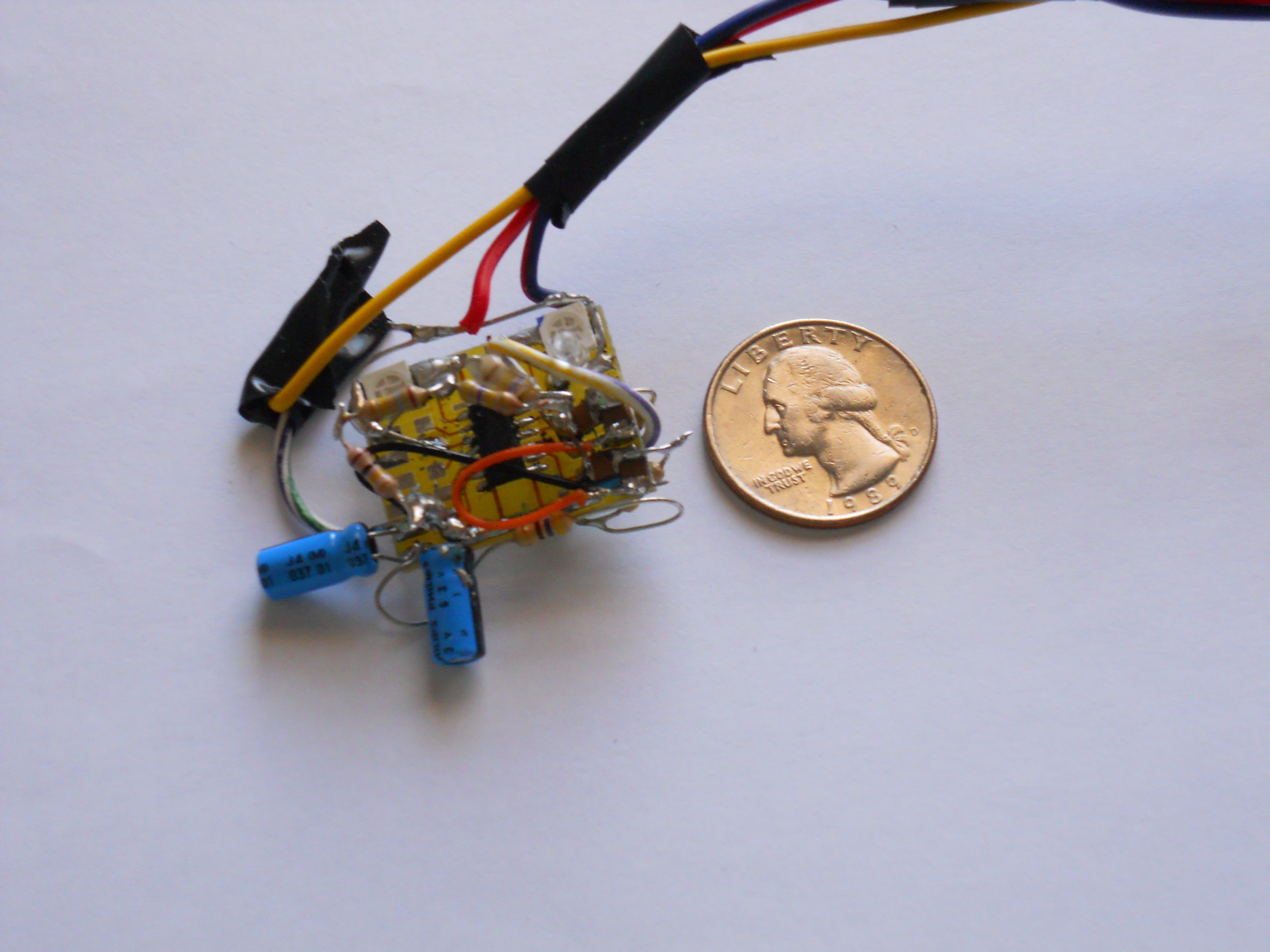

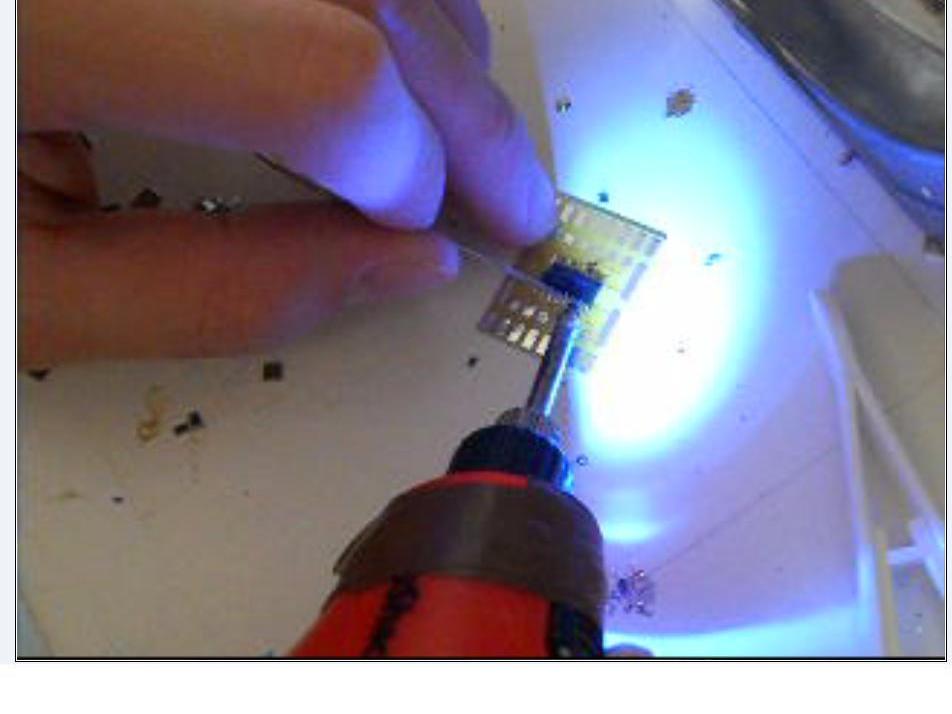

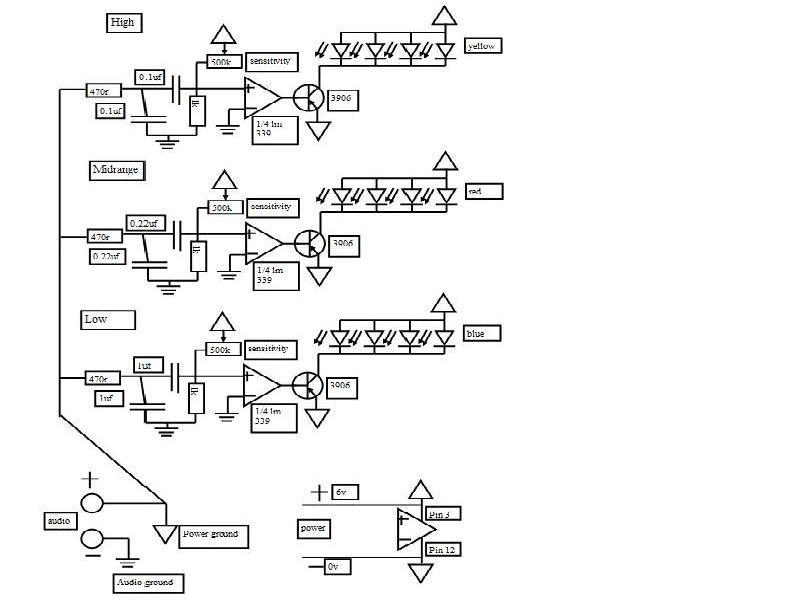

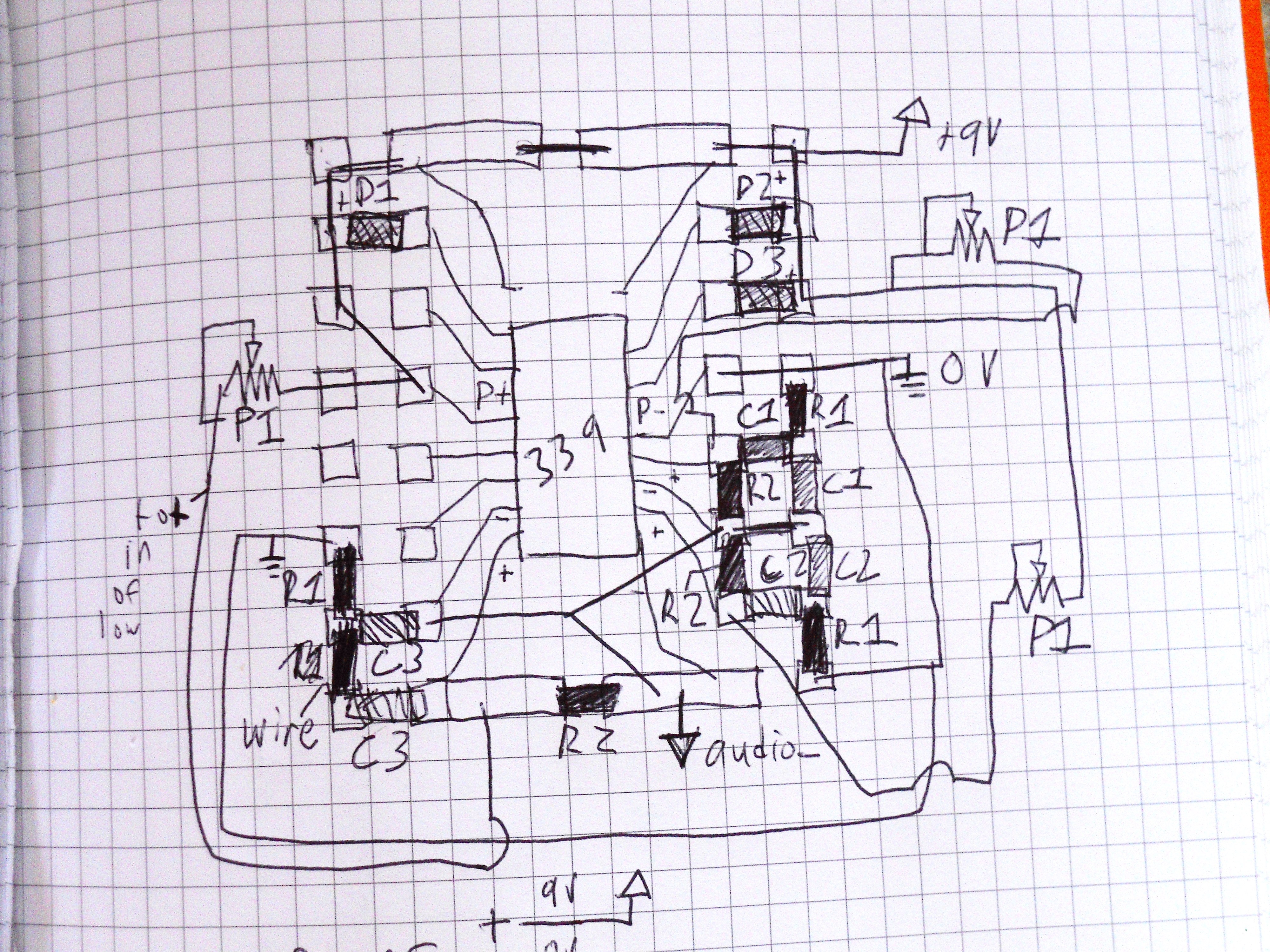

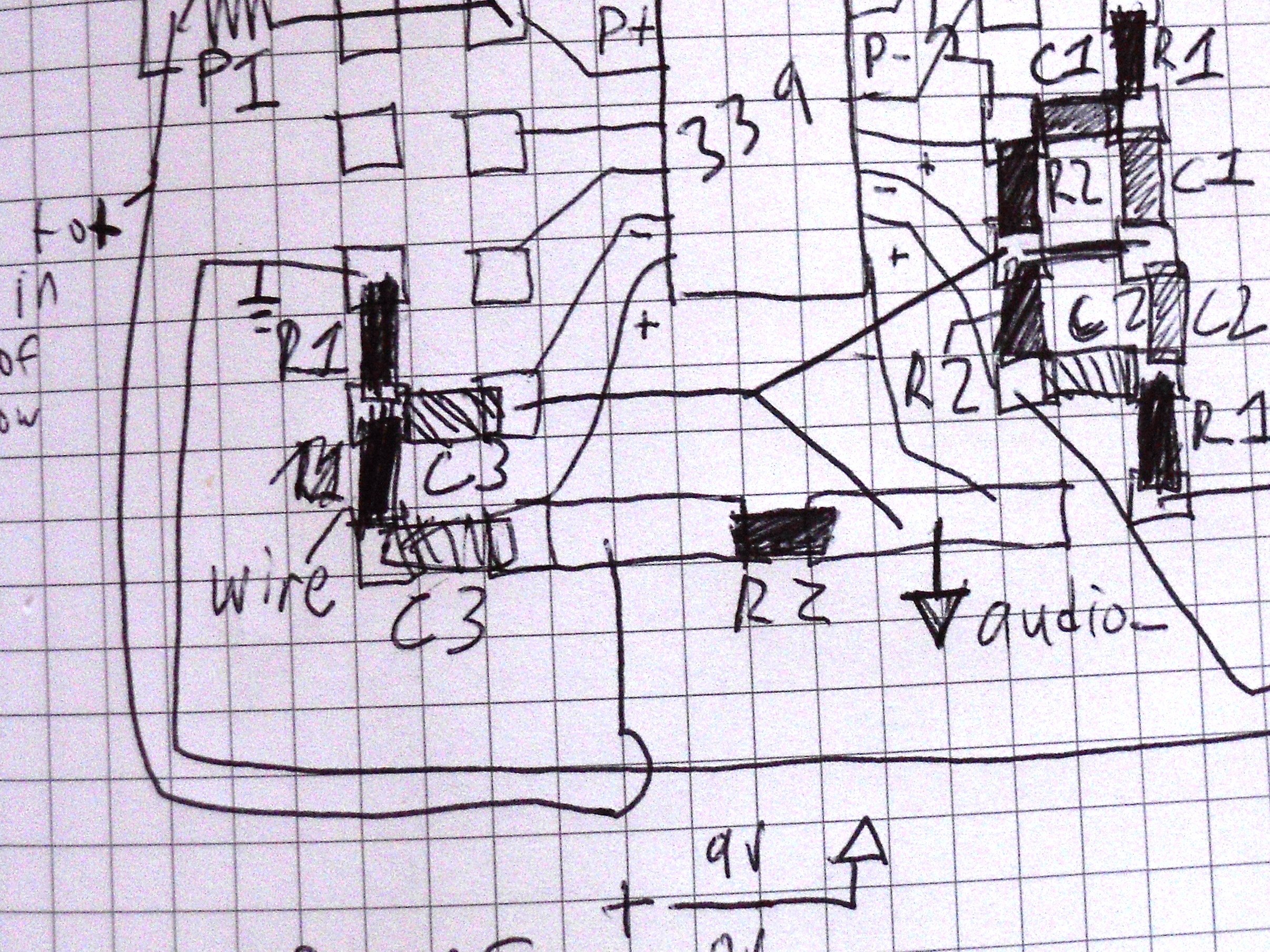

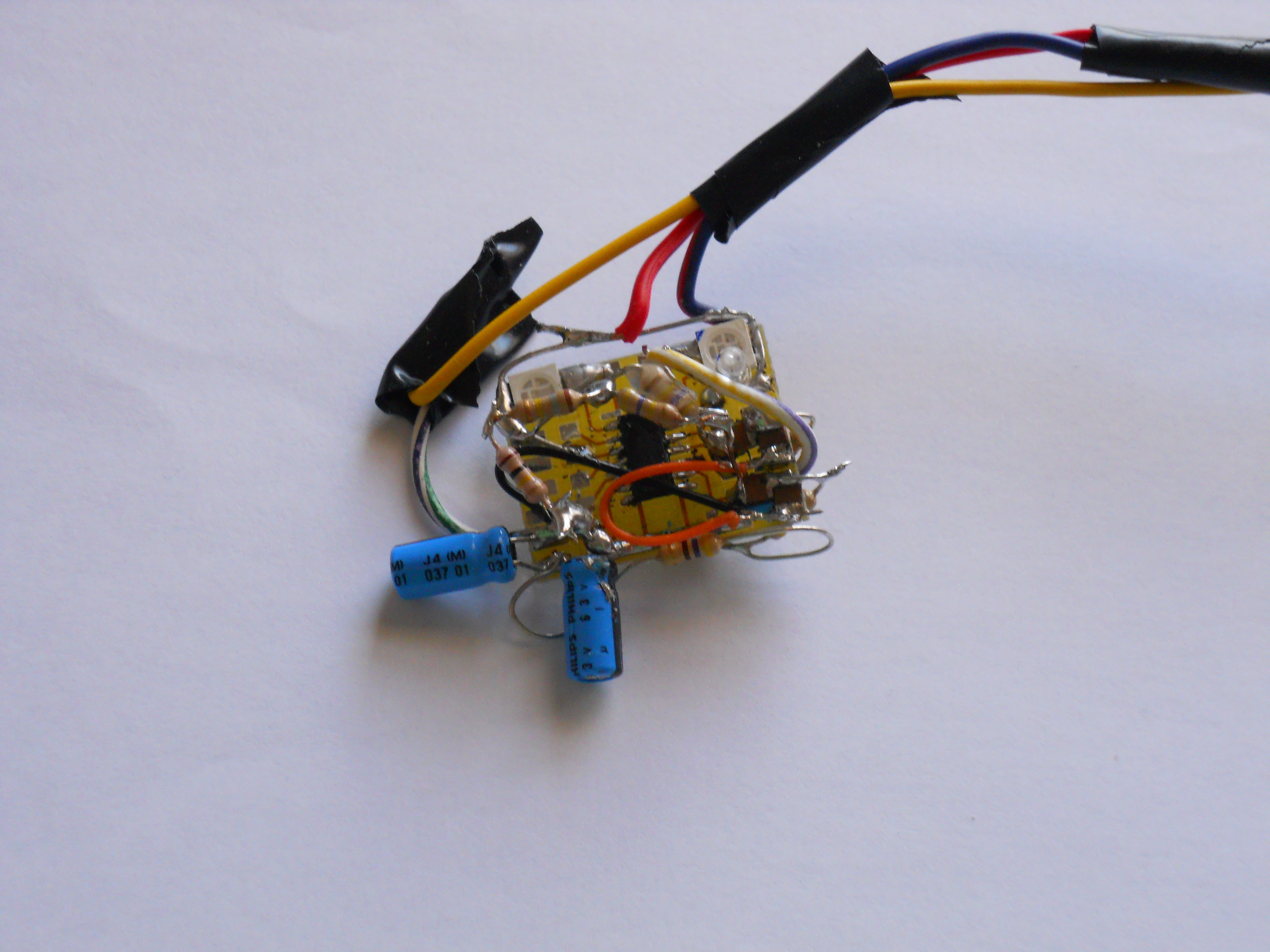

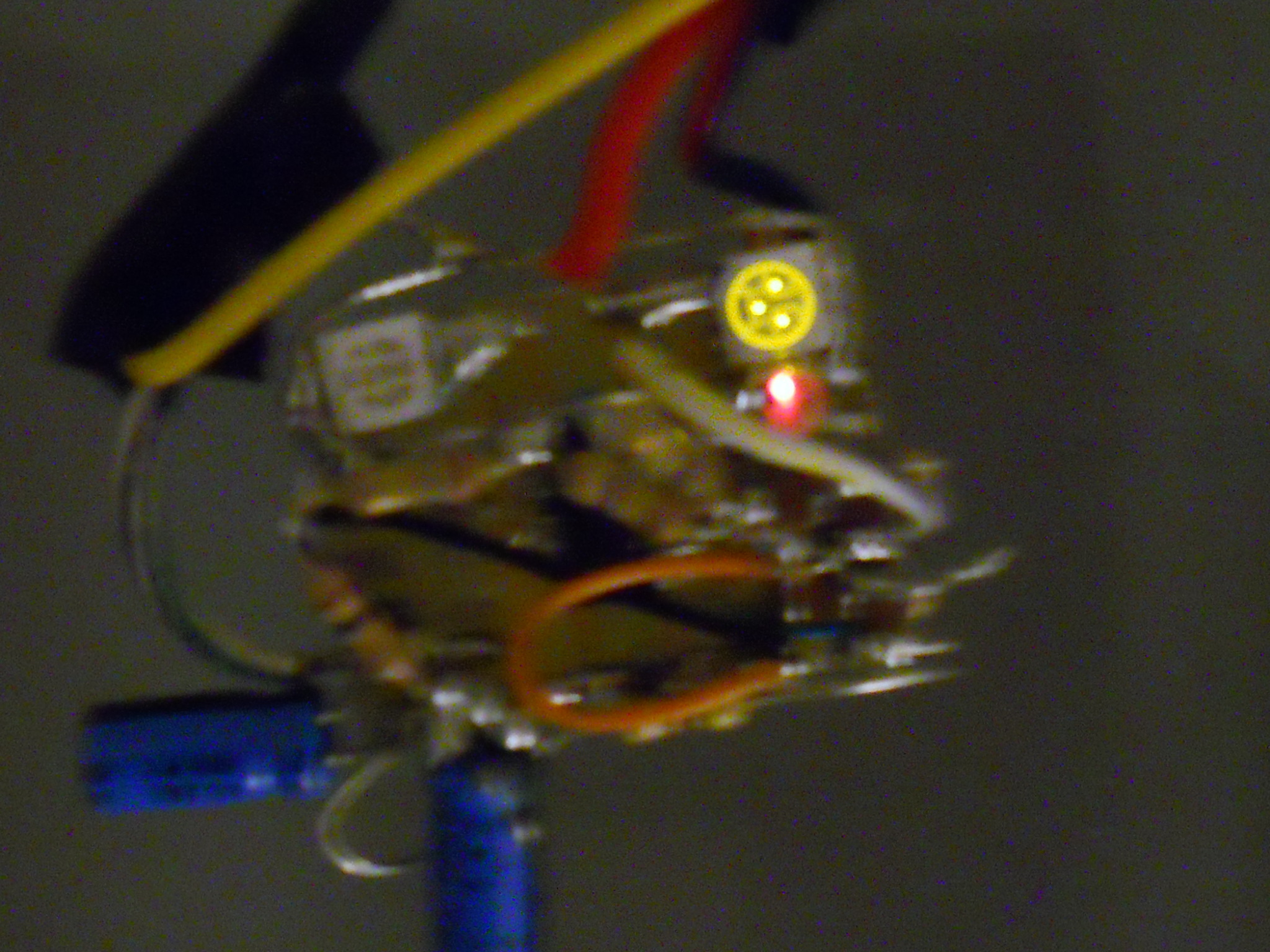

This project details the build of a simple SMD LED color organ. A color organ takes audio input from a line source, such as an iPod, splits up the audio into frequency bands, and pulses colored lights in time with each band. For a more detailed explanation, watch Collin Cunningham’s “circuit skills” video on color organs. I was inspired to build my own from his video, but since I did not have access to all the components he did I had to design my own version.

I suggest buying the components from Jameco. If you buy 100-packs, you can find the components, except the board and IC, for just 1 cent each. At that price, the whole unit only costs about $10 for the first, then just $3.50 for additional units.