Biotechnology is powerful, but only for those with the tools to experiment with and utilize it. The DIYbio movement seeks to put the tools and techniques used in well-funded laboratories around the world into the hands of ordinary people who have an interest but not the means to investigate biology.

One of these tools is the centrifuge. Centrifuges come in many shapes and sizes to fit a wide variety of laboratory needs. There are large machines with precise controls for RPMs, G-force, timers of all kinds, and even ones with temperature control. Then there are mini-centrifuges used for simple DNA extraction and quick-spins for mixing the contents of test tubes.

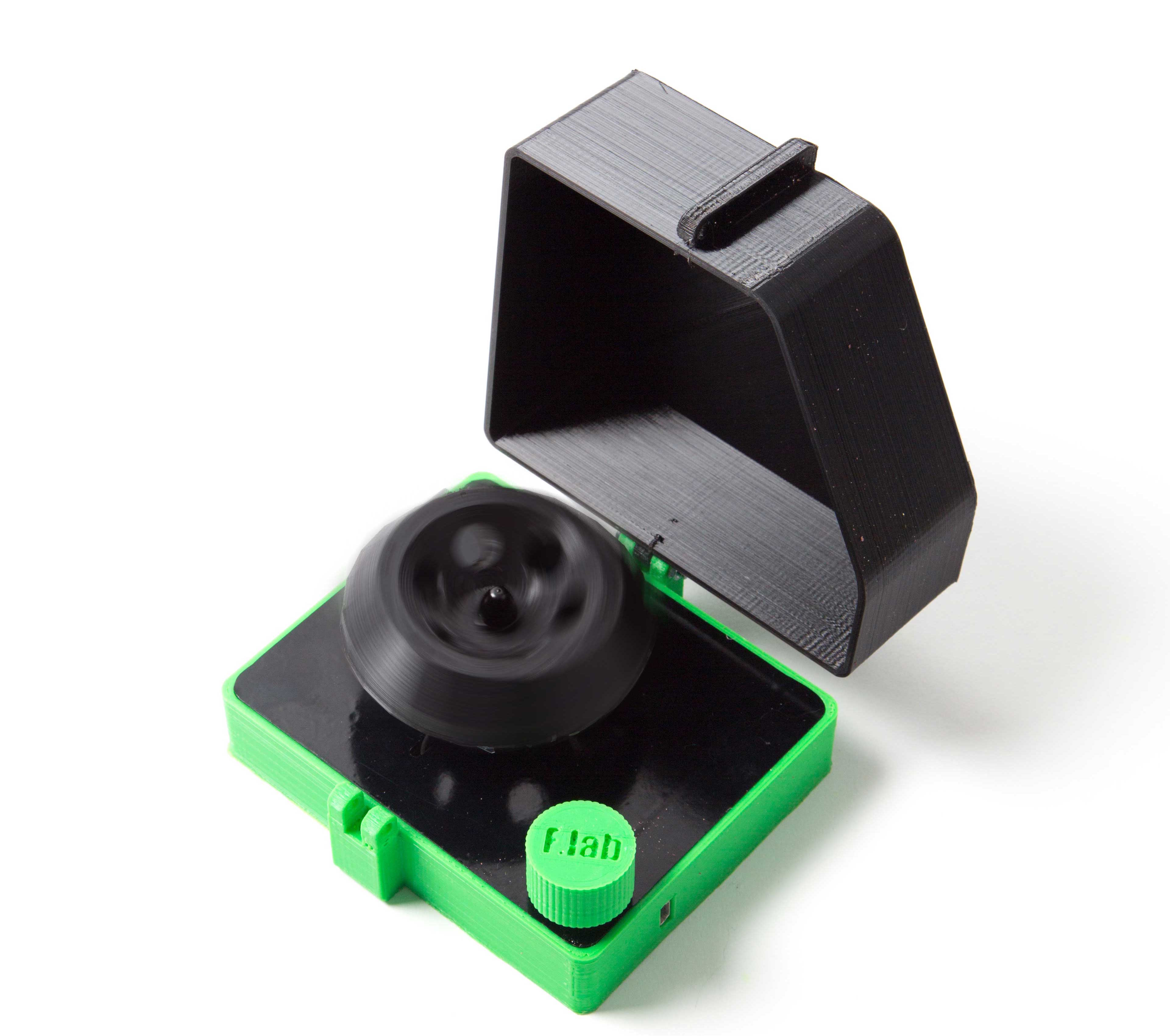

This 3D-printed DIYbio mini-centrifuge was designed to do the latter and has actually been used in a real university biology lab doing real protocols. Building one is easy, and hopefully after you’re done reading this, you will have ideas of how to improve on this one, or maybe the inspiration to tackle other types of otherwise inaccessible and expensive pieces of equipment with 3D printing.