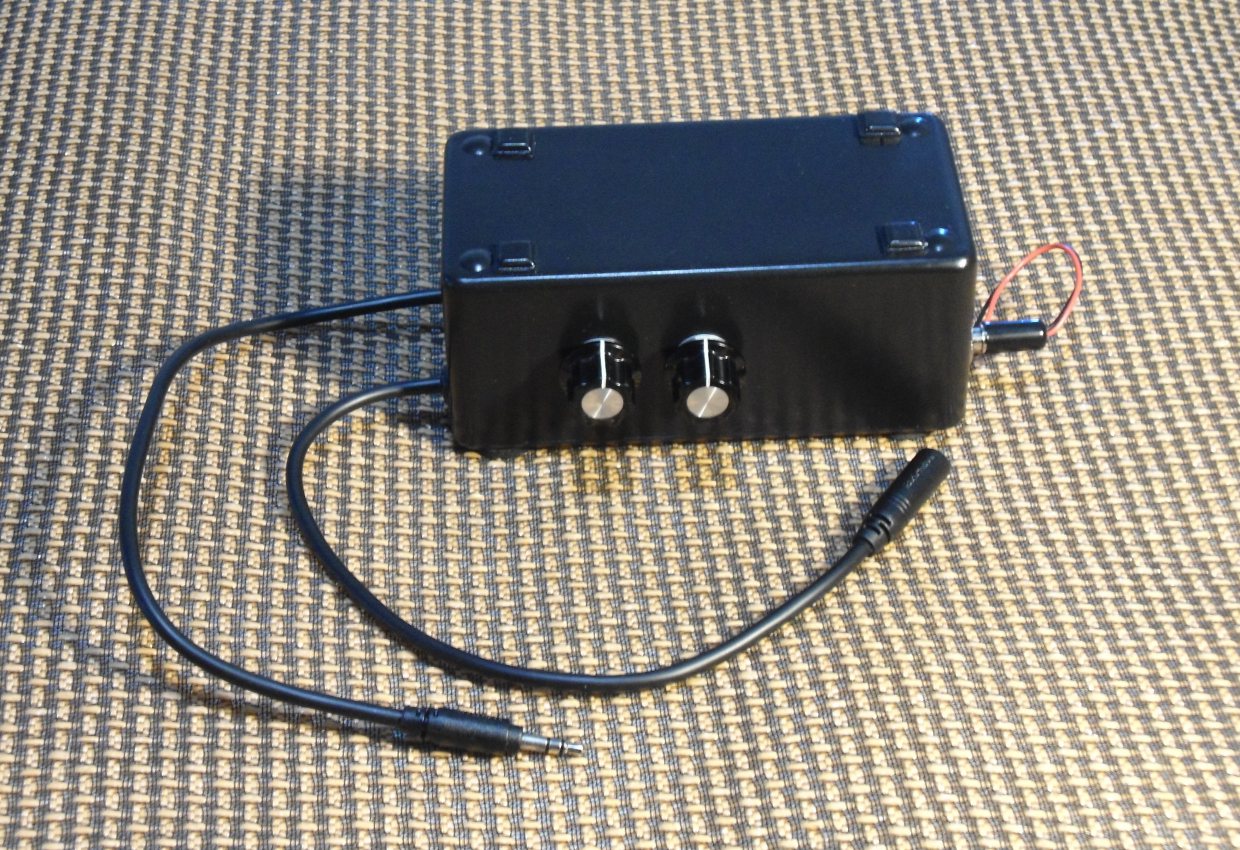

The Bass Bump Headphone Amp is an audio accessory you can build to improve all of your private music listening. It has enough power to give clear sound and punchy dynamics through most any pair of headphones, or even a set of small speakers. The custom bass enhancement circuit lets you boost the music’s critical low-frequency spectrum to your taste. It sounds better than the headphone driver circuits in most smartphones and MP3 players because it has a lower source impedance and much higher drive current. This means the sound from your headphones is unaffected by factors like long cables or impedance mismatches. All of the parts come from RadioShack, right down to the rechargeable battery and external charger. Build one and you’ll hear the difference right away.

I chose the LM386 amplifier chip because it’s easy to build with — it’s widely available, will run on a single power supply as low as 5V, and requires few external components. There are higher-performance chips on the market that are often used in portable headphone amps, but a dual power supply would be required for a fancier op-amp circuit, which makes the power and charging electronics much more complex. The LM386 performs well and keeps things simple.

The Bass Bump Headphone Amp has no power switch — you turn it on by inserting the coaxial power plug from the battery clip into the coax jack wired to the amp circuit. In this way two parts perform 3 functions: power switching (jack and plug), battery recharging (battery plug), and external power for the device (power jack). The plug and jack are very rugged. For stationary use, you can also power your Bass Bump from a USB port, using a custom cable we’ll also show you how to make.

How It Works

Resistor R8 provides a load for the source device, reducing noise. The input signal splits into two branches. The separation between frequencies happens at about 100Hz, between conventional bass- and mid-ranges. High-frequency sounds pass through the junction of C6/R3, and low-frequency sounds through R7/C5. Series resistors R4, R5, and R6 connect the high-pass and low-pass filter outputs, recombining the frequencies together. Since R5 is a potentiometer, it can be used to control the extent to which high- and low-pass outputs are mixed in the recombined signal. Resistor R4 limits the maximum bass “cut” to about 3dB, and resistor R6 limits the maximum “boost” to about 13dB. Note that R4 and R6 are different values because we’re more likely to want “boost” than “cut.”

The signal from the filter enters the LM386 amplifier chip U1 through pin 3. Resistor R1 provides a ground reference level for the chip input. Capacitor C1 is a filter to ground any high-frequency noise from the source device that makes it this far. The chip is powered by a 9V battery or external power with the supply connected to pin 6. Pin 4 is ground. Capacitor C4 filters noise from the power supply.

Pin 5 is the amp’s audio output. This pin adds a DC voltage equal to one-half the supply voltage (4.5V in the case of battery power, 2.5 in the case of USB) to the audio signal. Capacitor C3 blocks this additional DC voltage from reaching the audio output and passes only the AC audio signal. R2 and C2 form a so-called “Zobel” network to ensure a low-impedance load at high frequencies and to damp oscillations. Resistor R9 acts as a ground reference to keep C3 from charging up and “thumping” when the headphones are plugged in.

Let’s build it!