If you dig around in your camera’s settings long enough, you’re almost assured to find that it has a mode to create time-lapse videos — those magical, time compressing movies that can turn any hillside or street corner into a lightning-paced dreamscape.

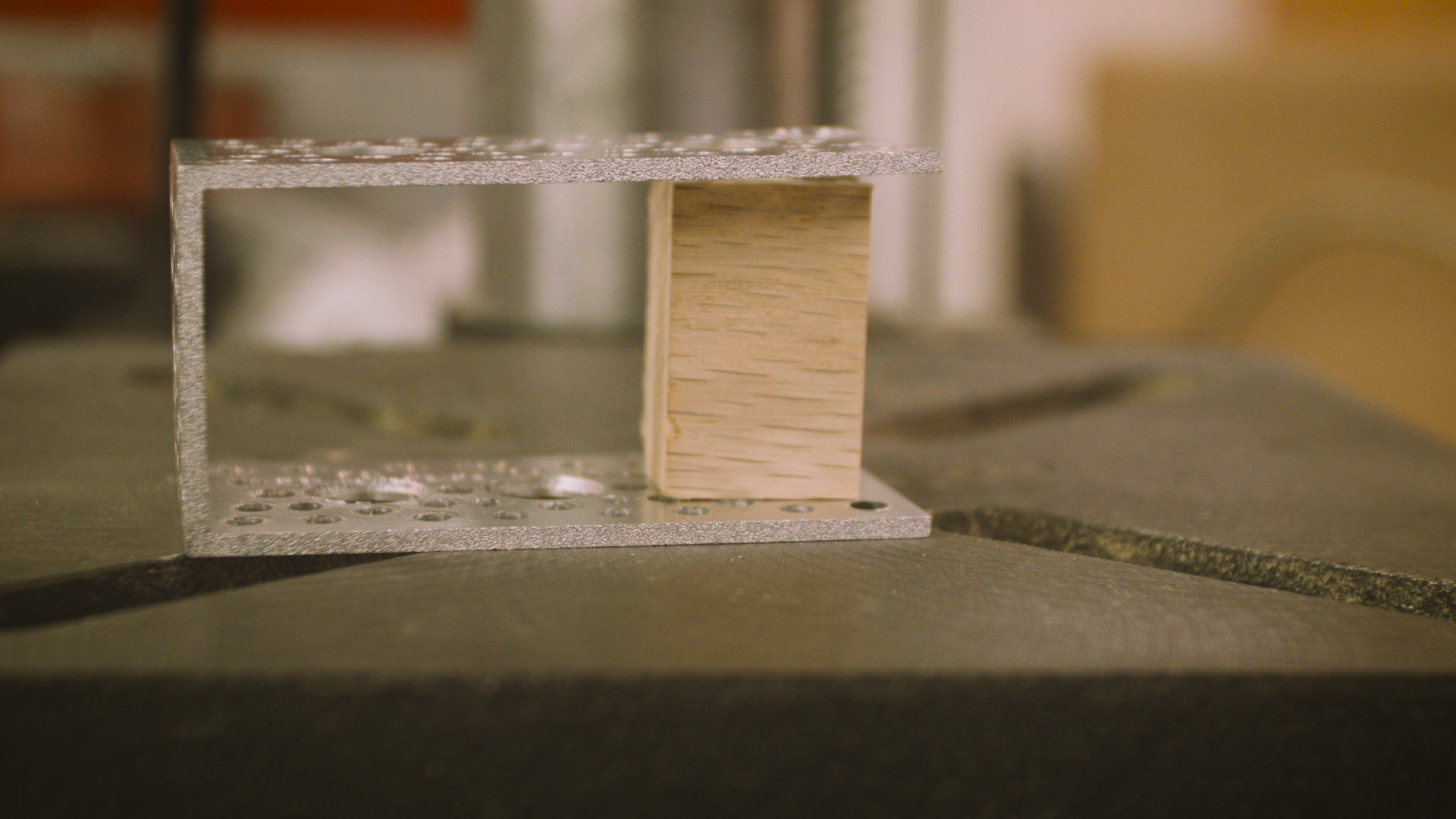

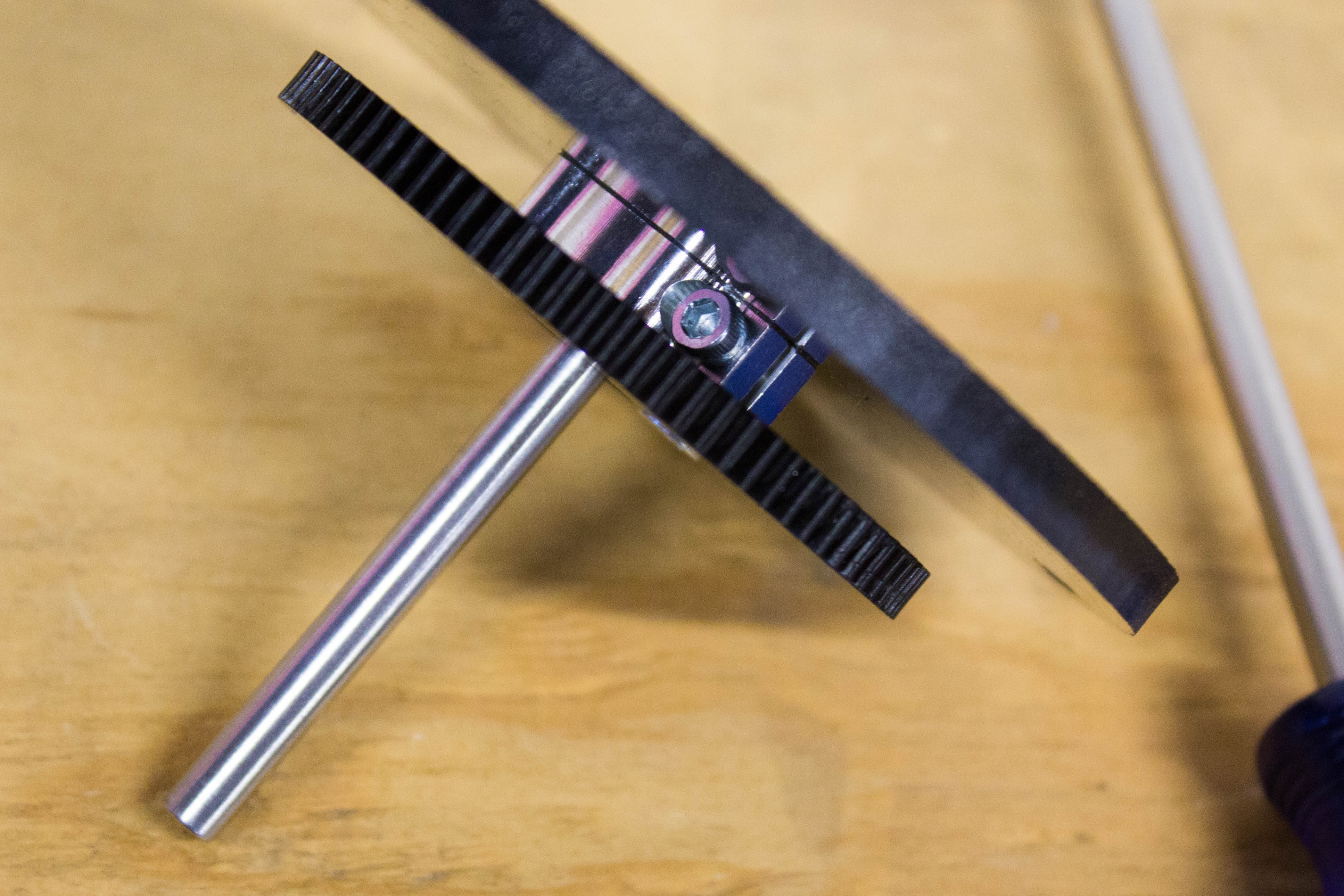

Time-lapse videos by themselves are easy enough to make, but if you do enough of them, you’re likely to get bored with the motionless camera framing. But what can you do here? Having a moving time lapse means moving a camera very predictably, and very, very slowly. You can build a simple panning rig out of a mechanical kitchen timer, but that’s only good if your time lapse is an hour or less, plus, the camera will rotate the full 360 degrees in that hour, further limiting your control.

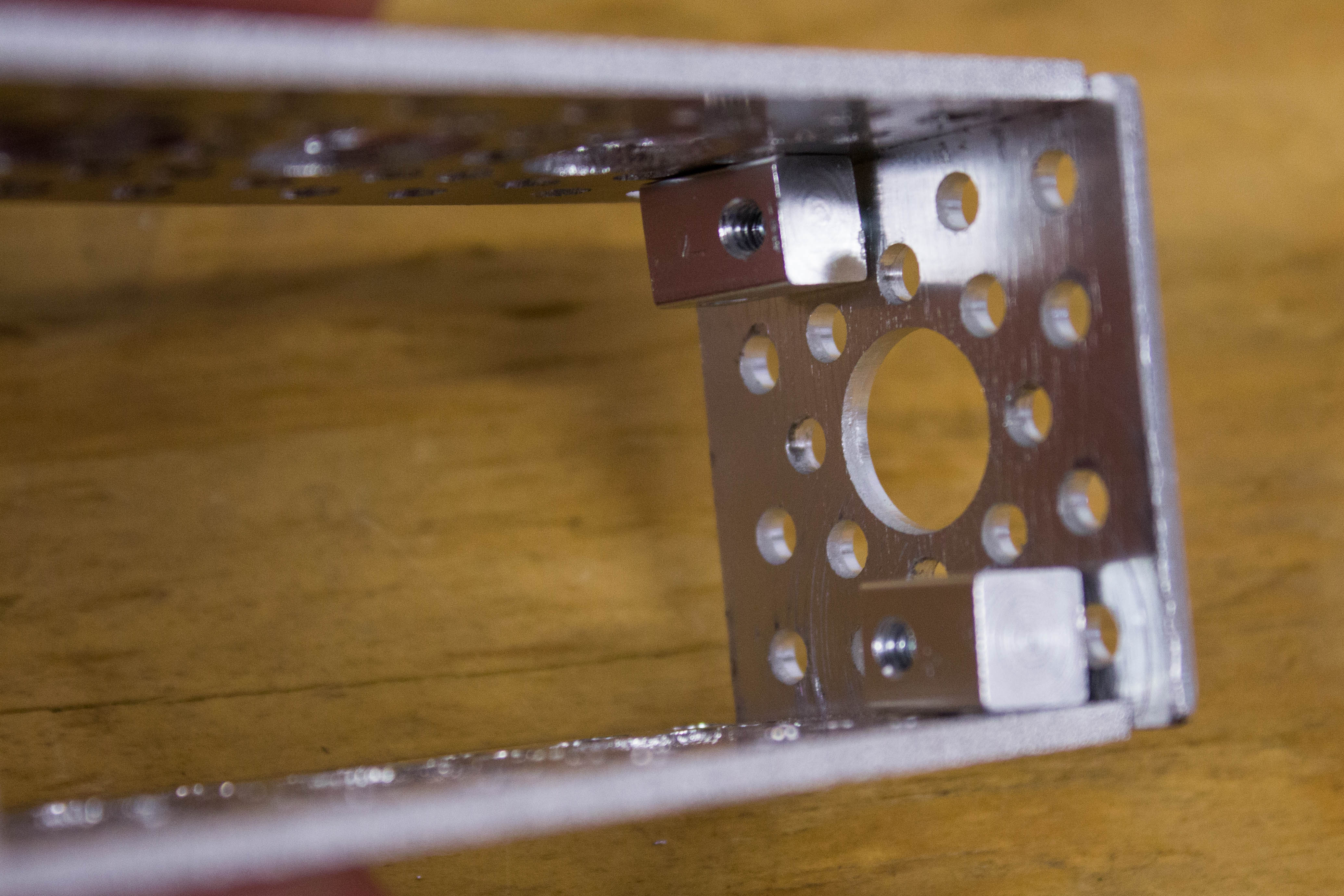

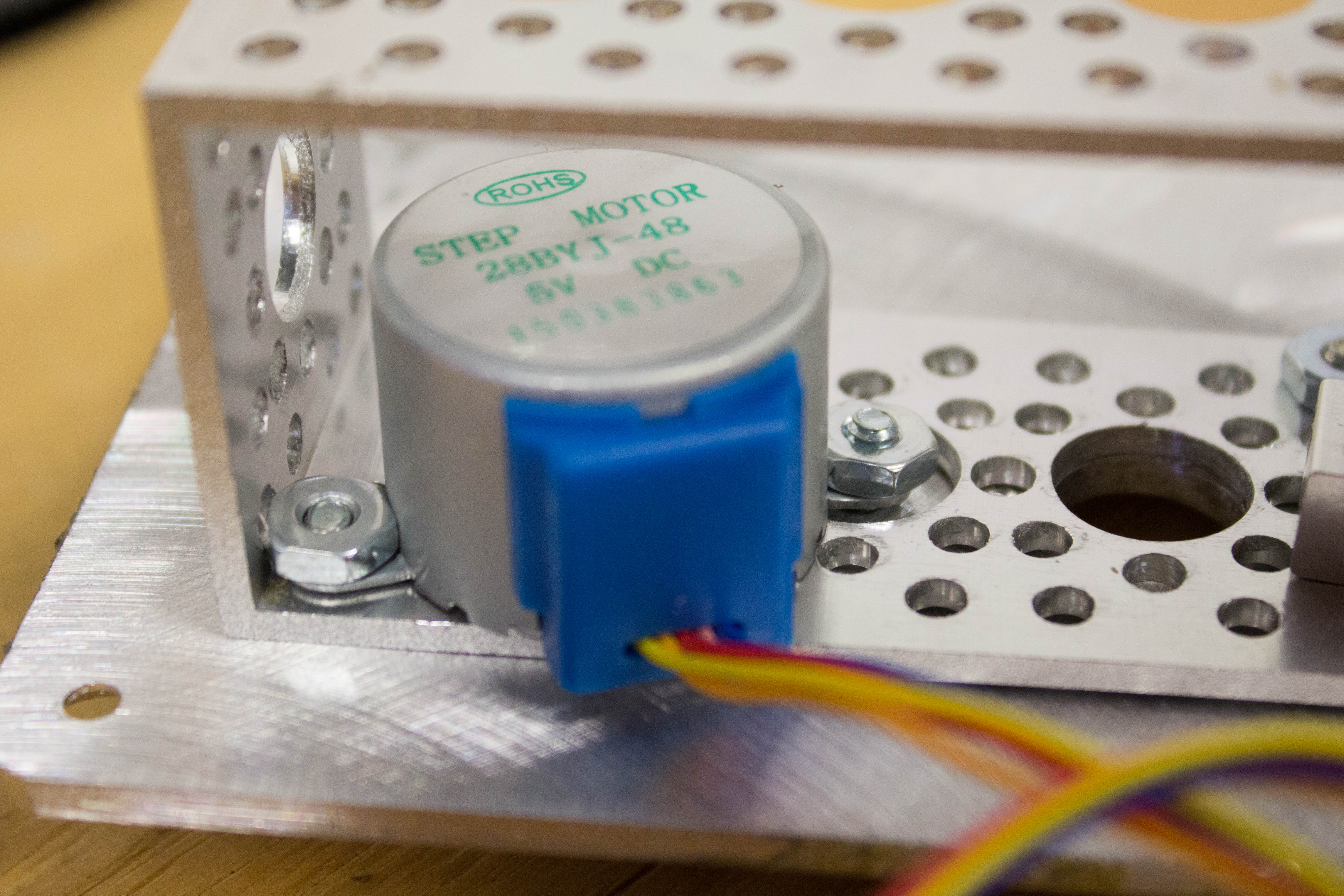

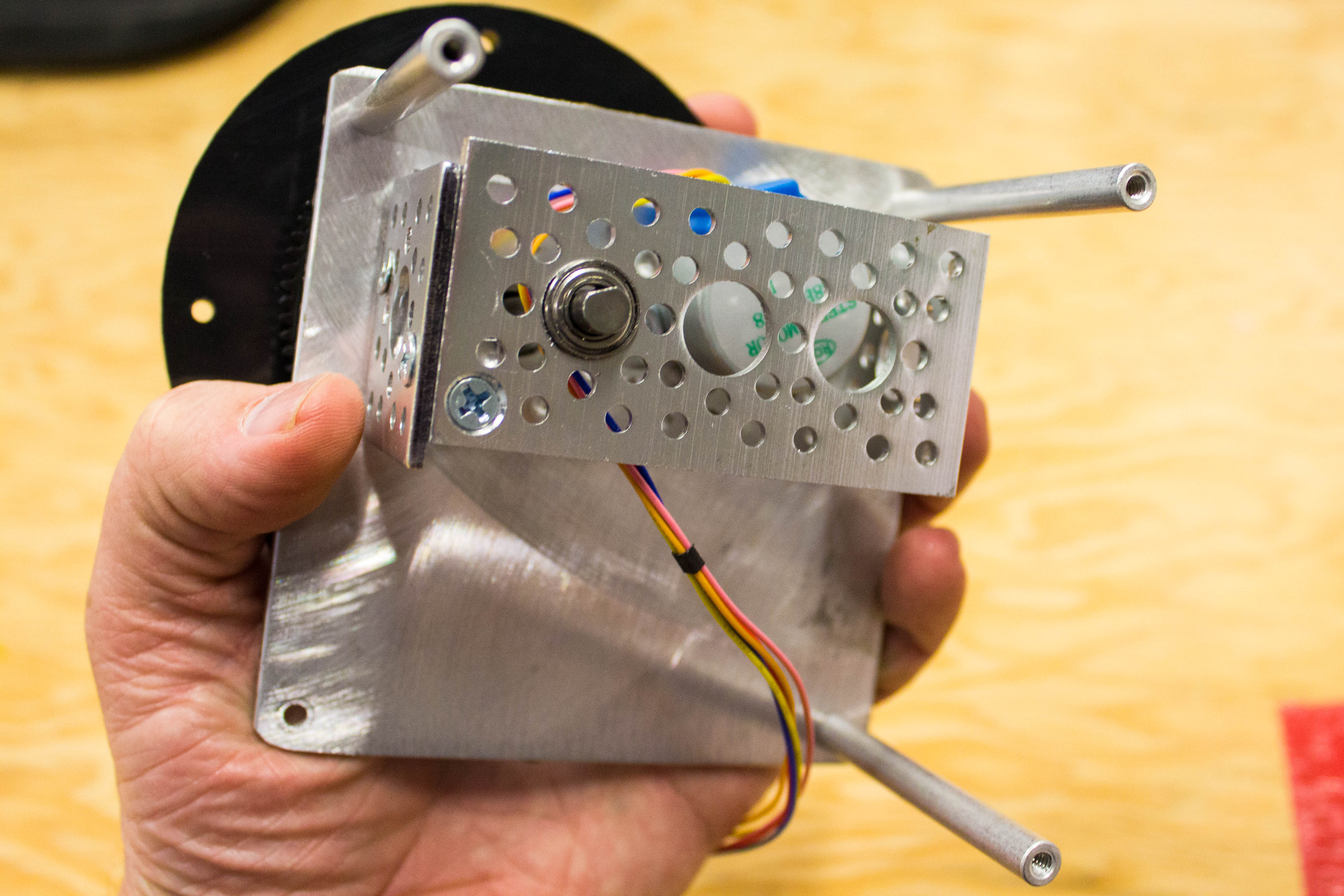

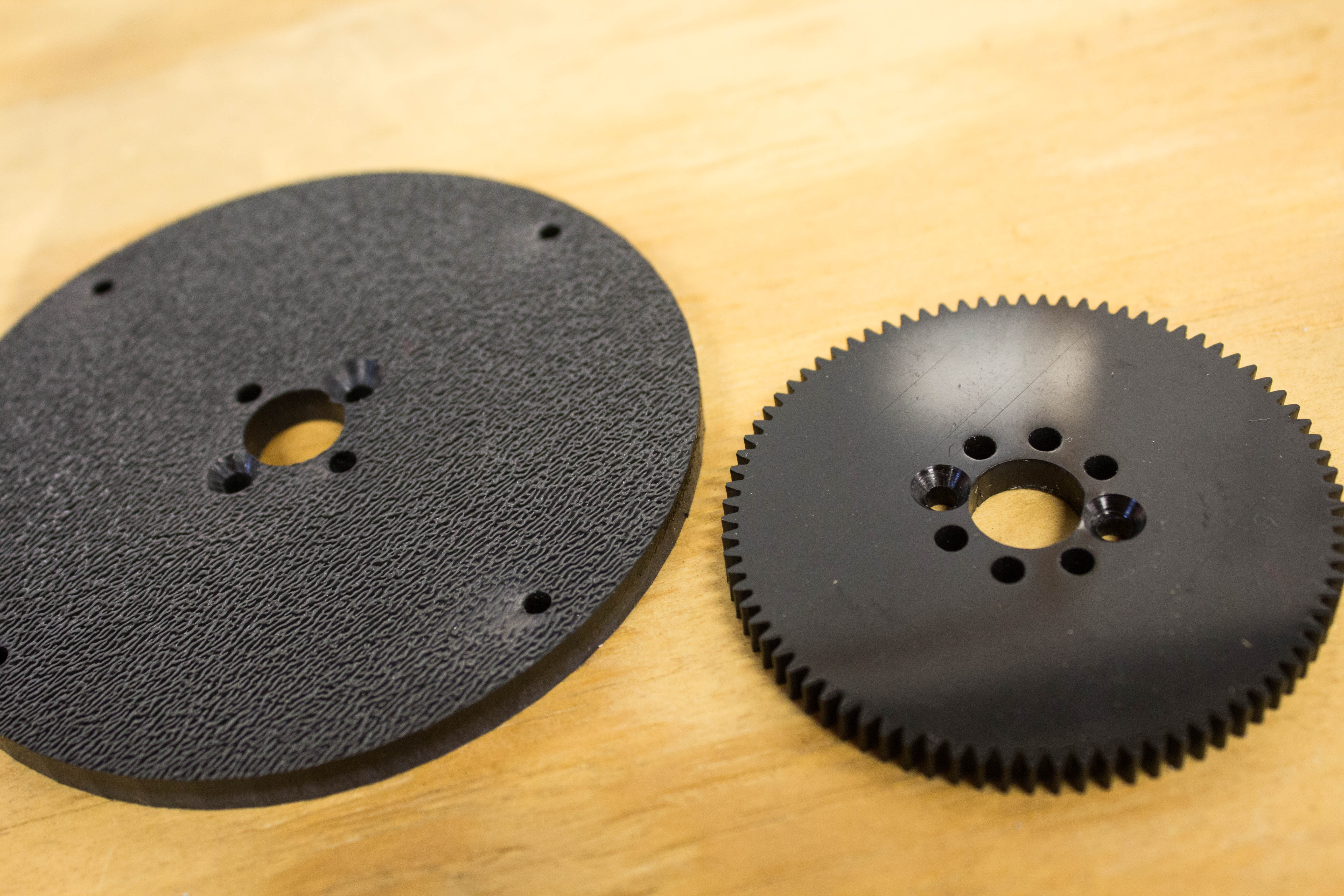

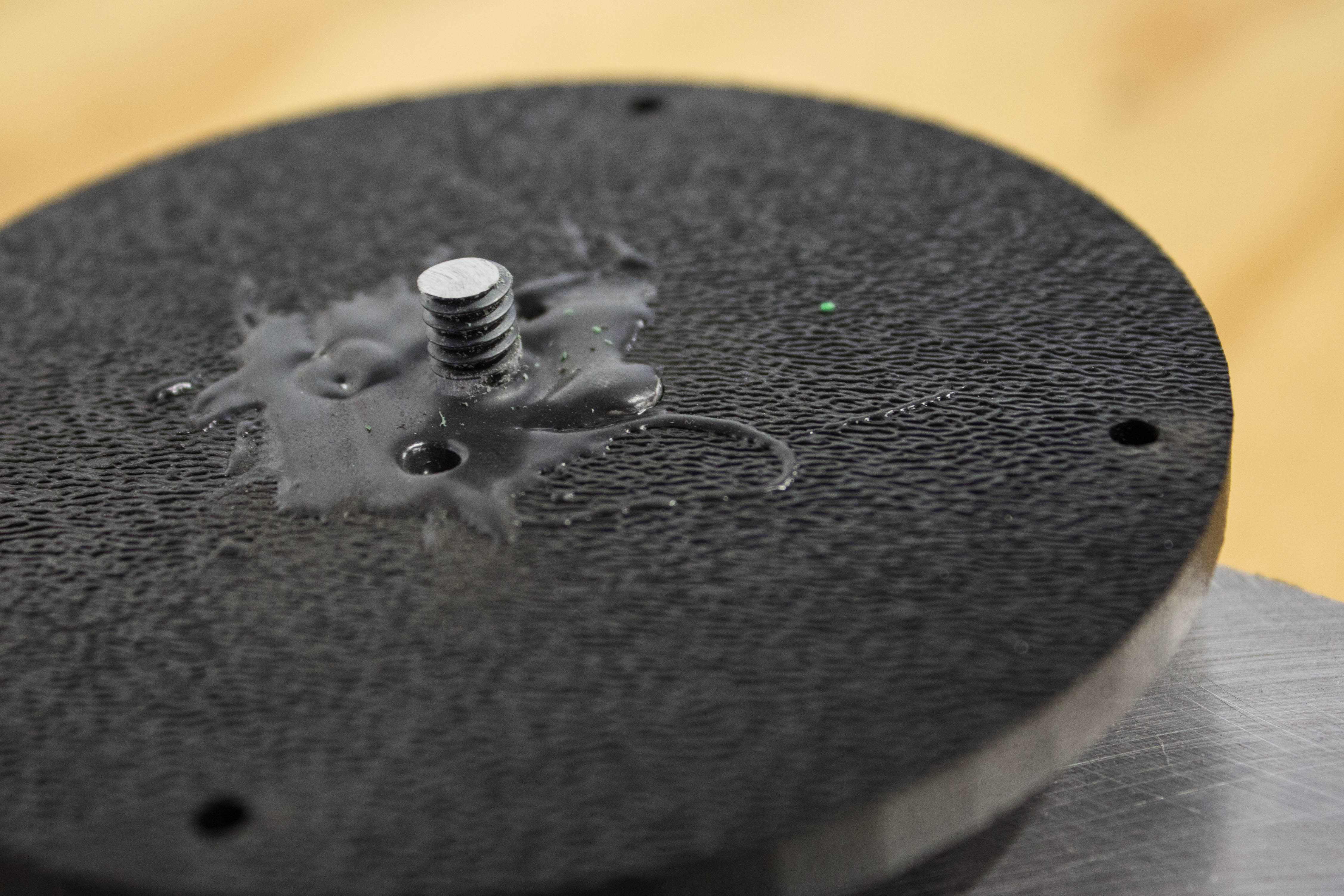

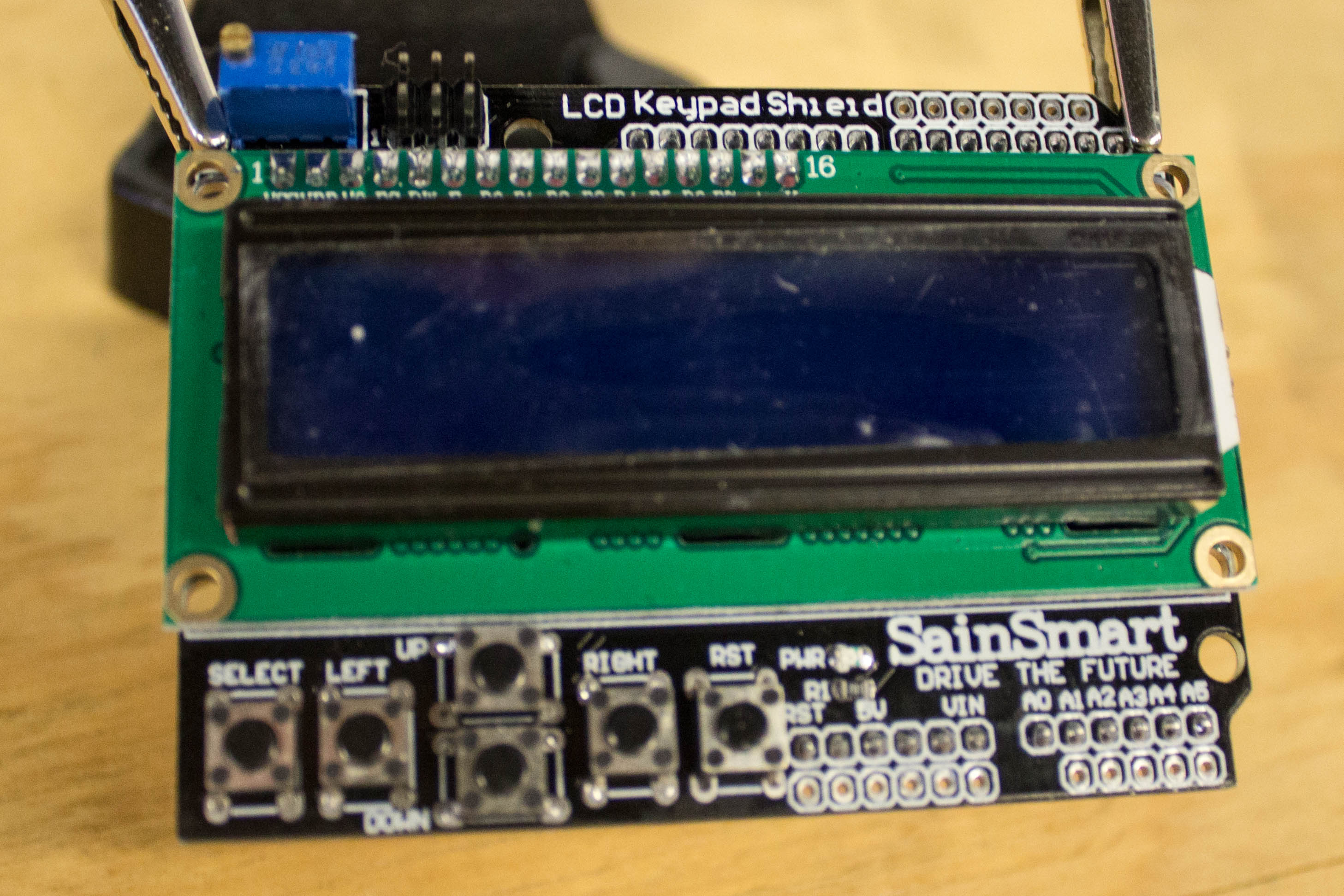

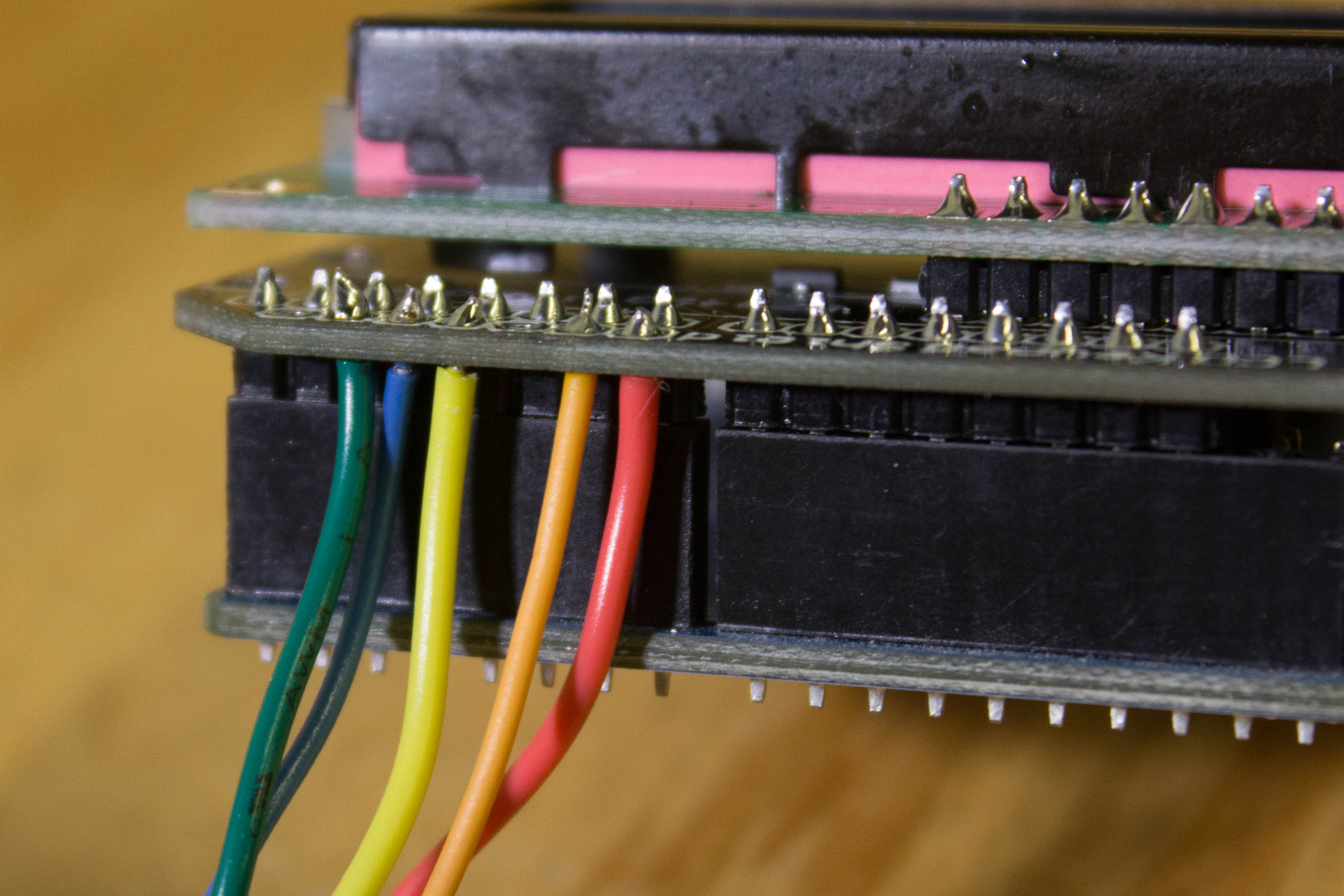

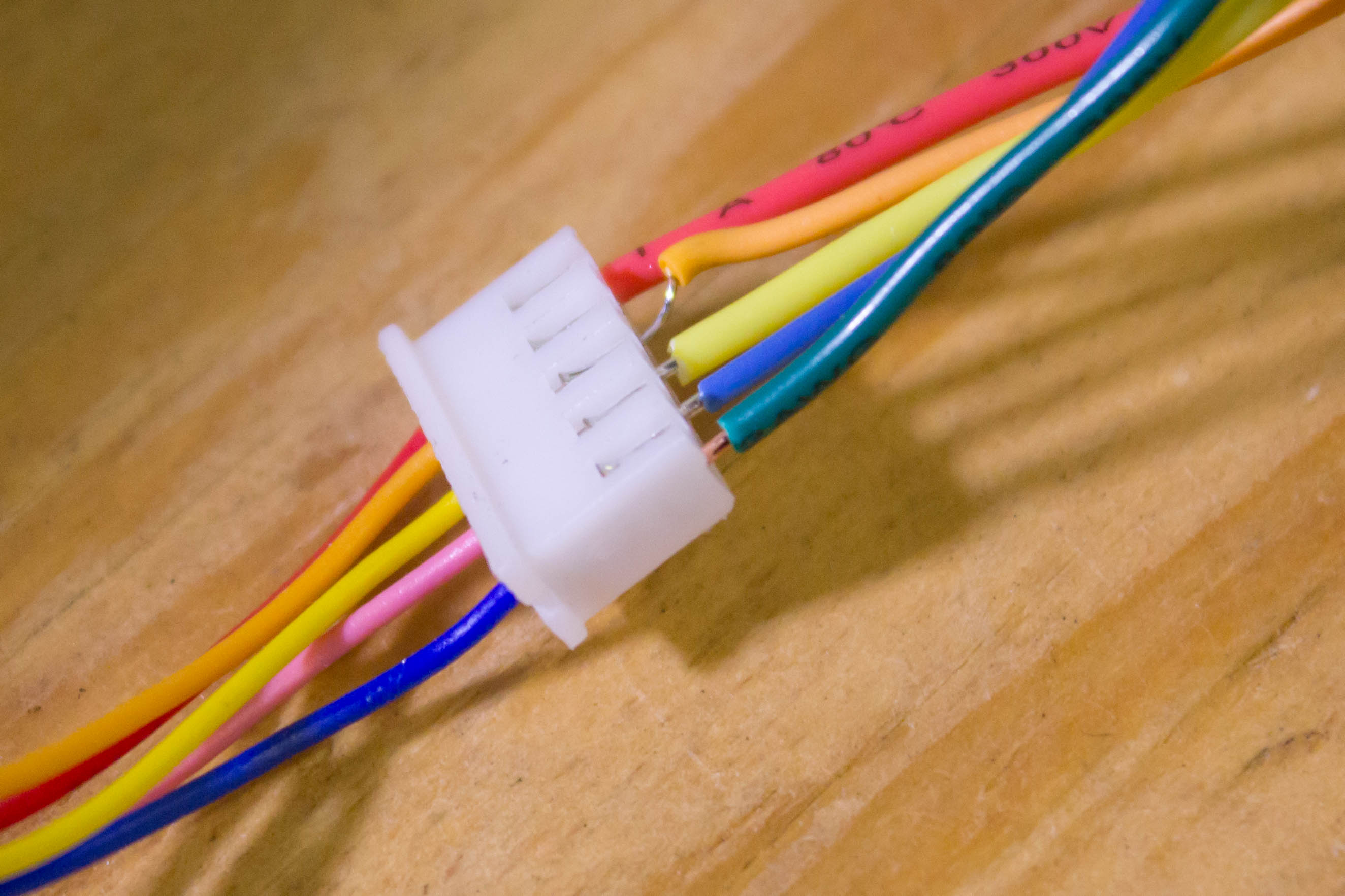

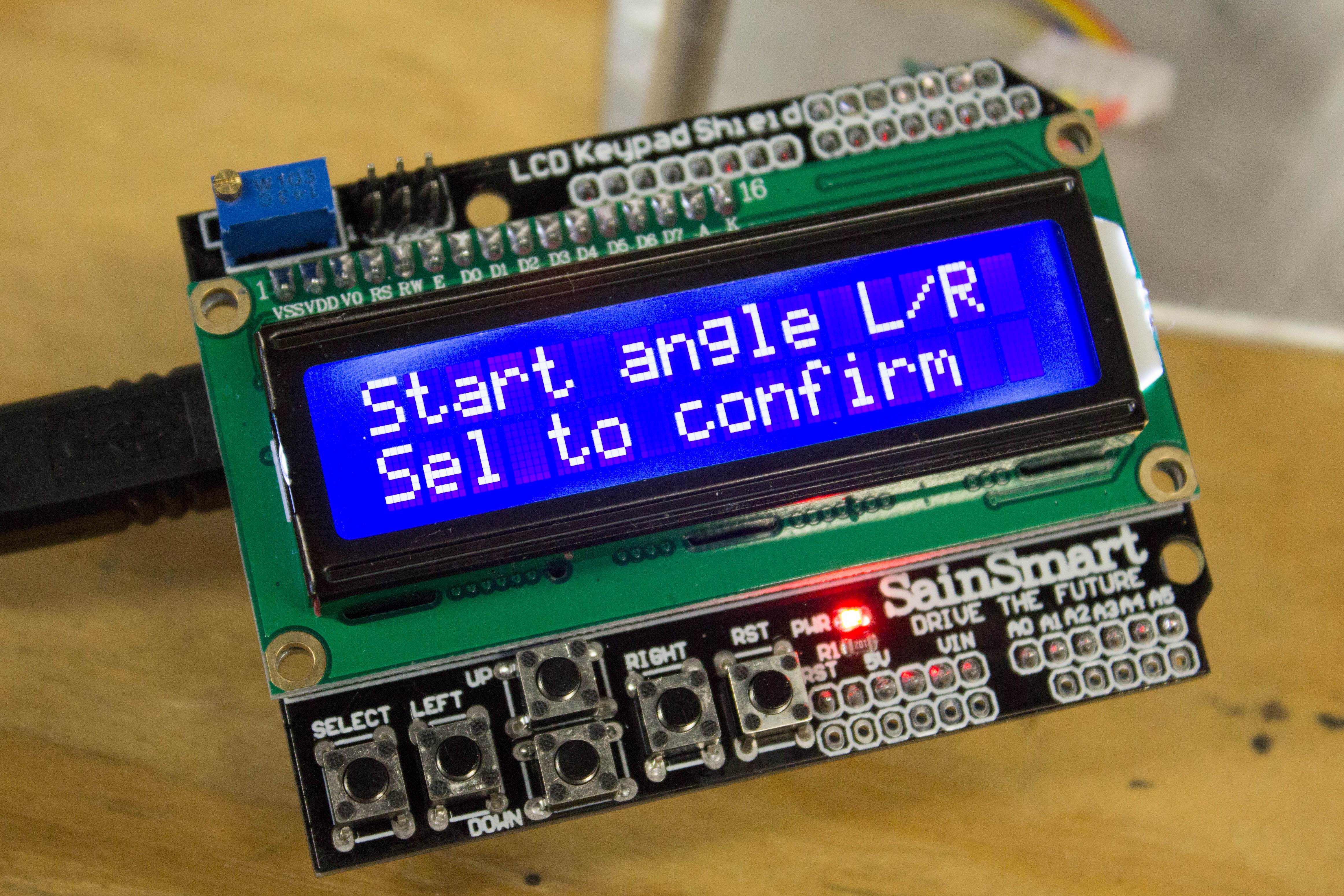

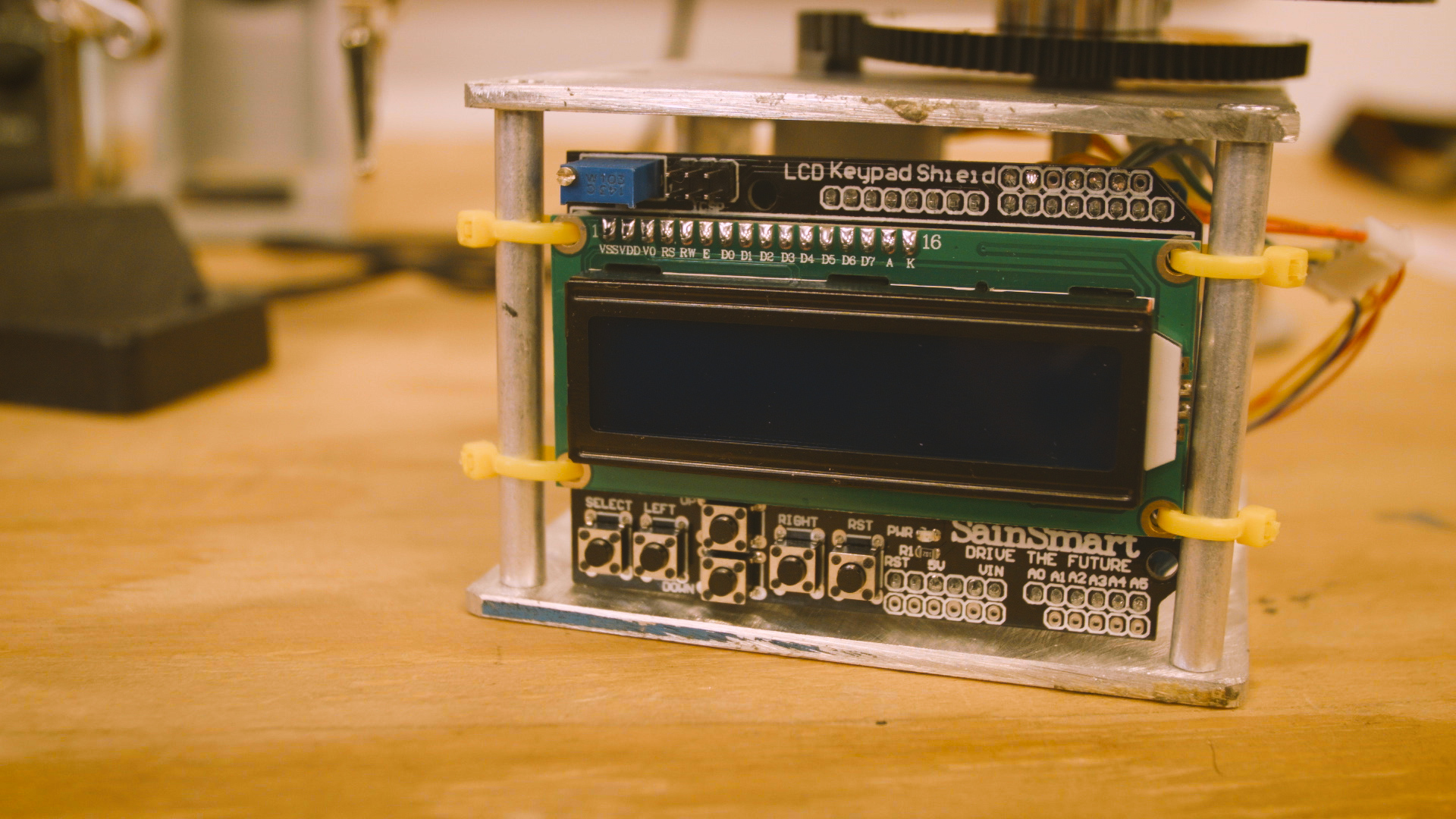

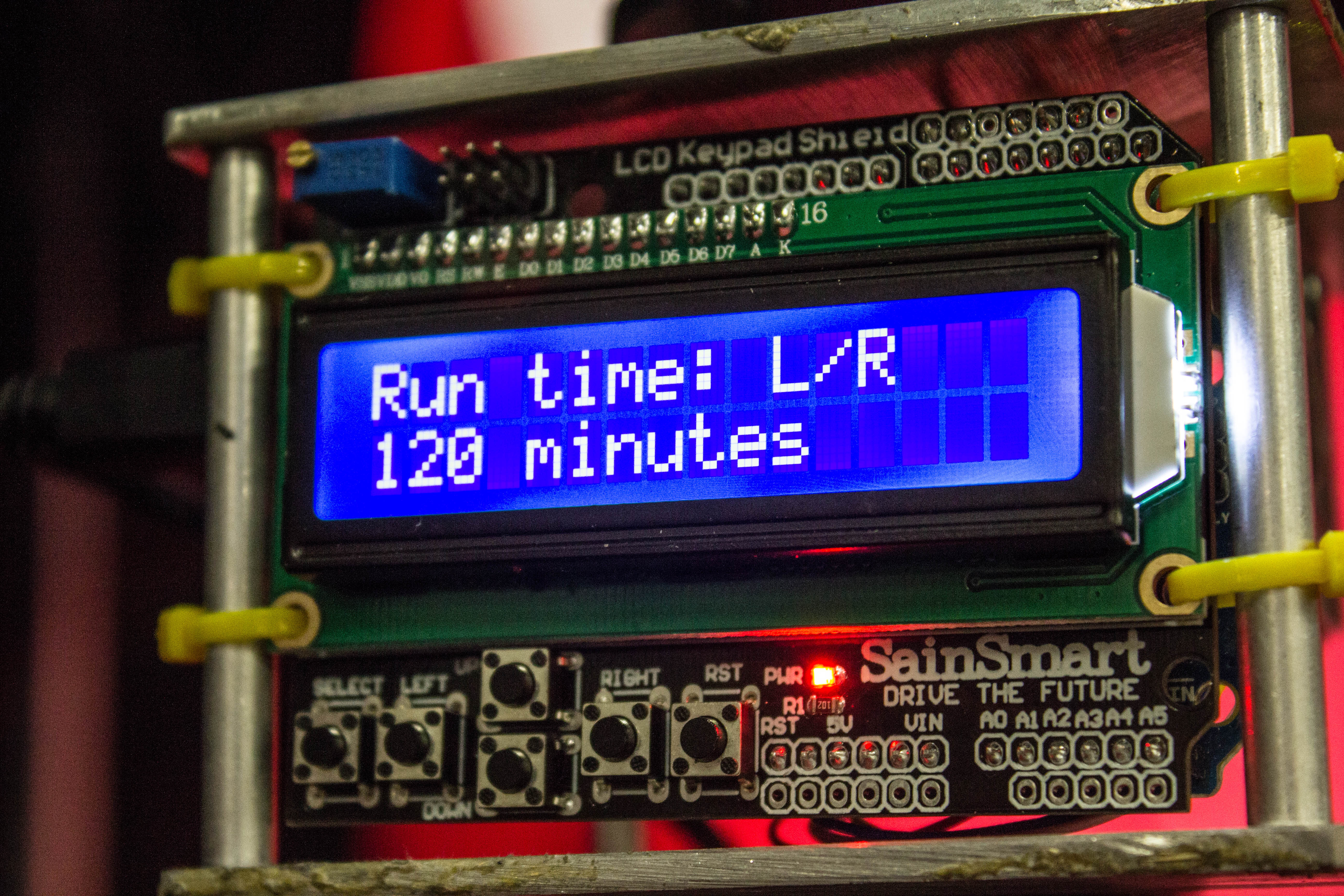

In this project, we’ll be using an Arduino microcontroller and a stepper motor to precisely control the panning of a camera during a time lapse. Using this LCD keypad shield as an interface, we can precisely set our starting and stopping positions, as well as setting the duration of our time lapse — anywhere between five minutes and 12 hours. The device can be powered via any USB power source, and those portable USB bricks used to keep your smartphone alive during long days will work perfectly, and can power the device for up to 12 hours.