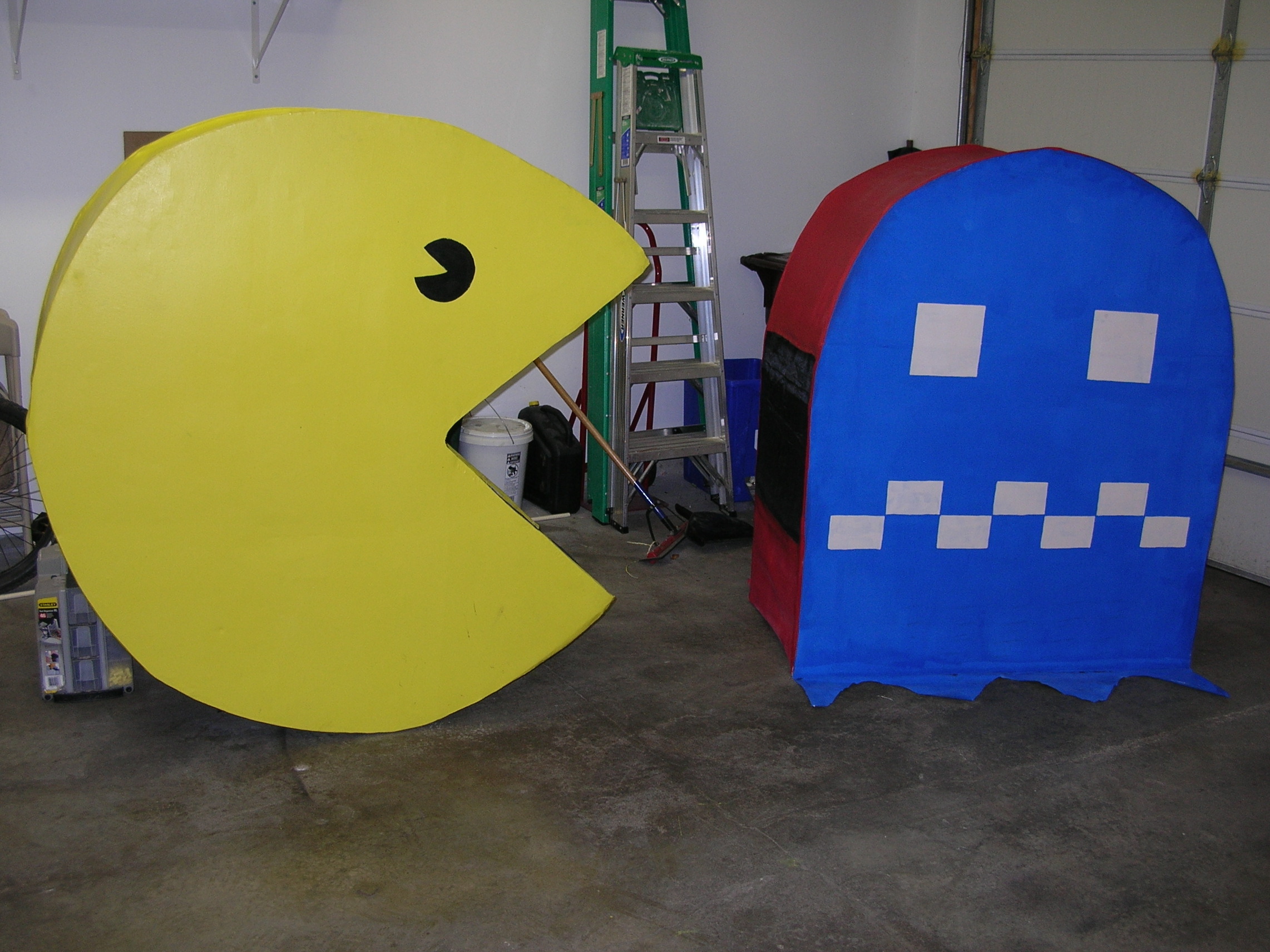

A few years back I built a giant Pac-Man costume at the last minute, but it wasn’t good enough for a tinkerer, so I figured that there had to be a way to make it better. What better than to add a functioning mouth to the costume! Thus started the six-week saga of making a giant working Pac-Man costume and matching ghost. These are not projects for the faint-hearted as they take a lot of hard work, and are very large (5 feet tall, 2 feet wide).

Here’s a video of the final product

The shape didn’t turn out the way I had hoped, mostly because I lacked a few tools. A ring roller would have allowed me to add a bend the the CPVC, but I had to rely on tension alone, which created some interesting and unintended shapes.

Project Steps

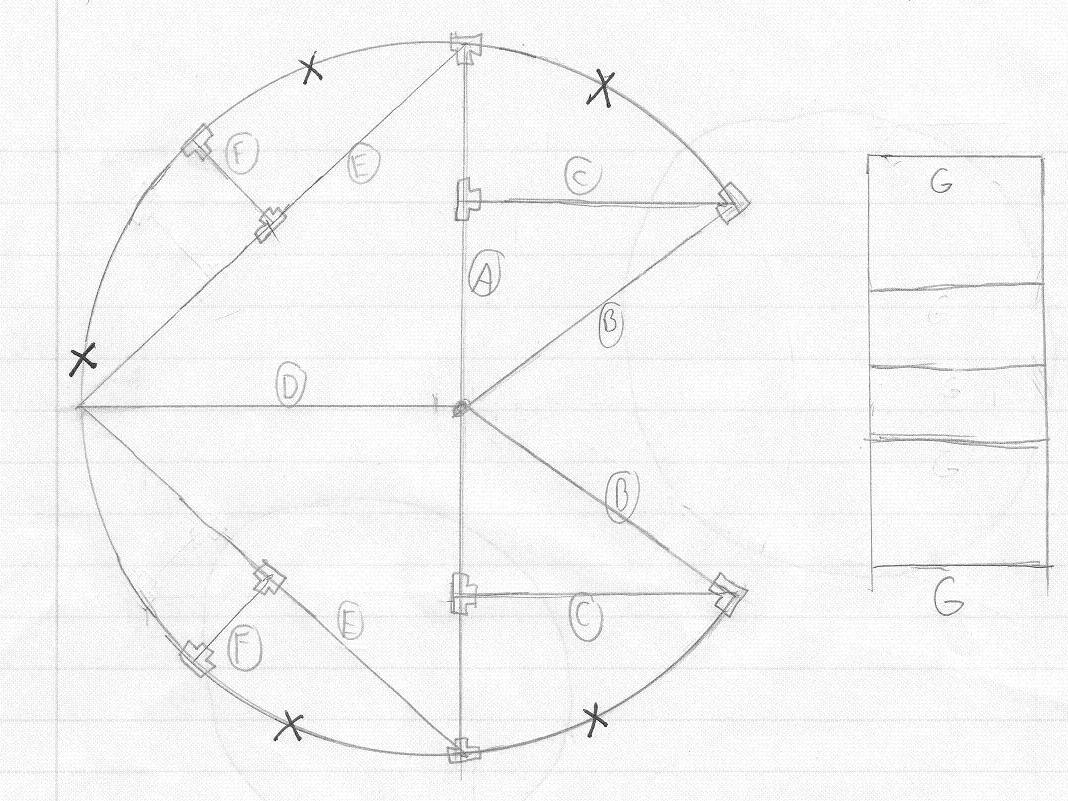

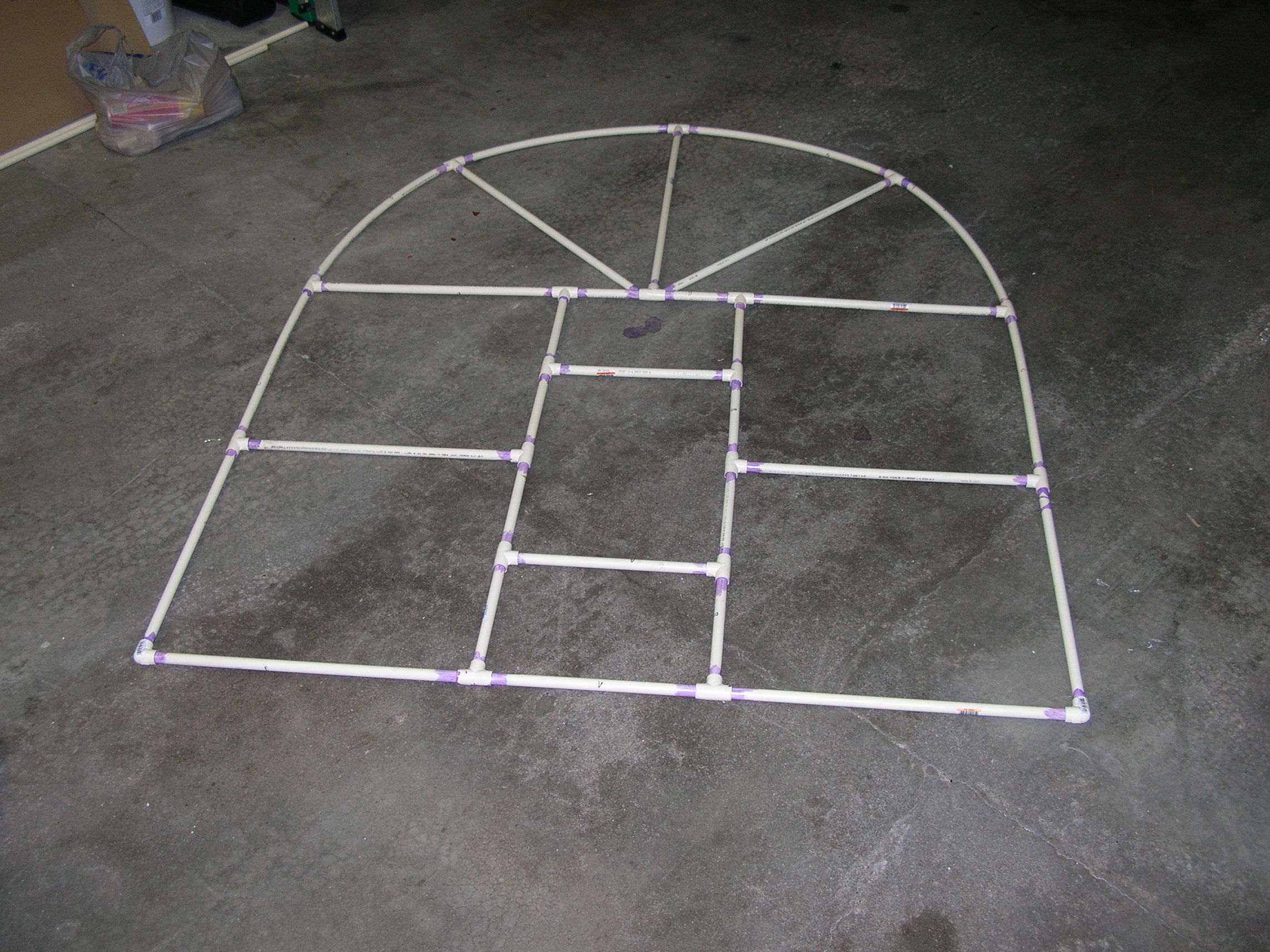

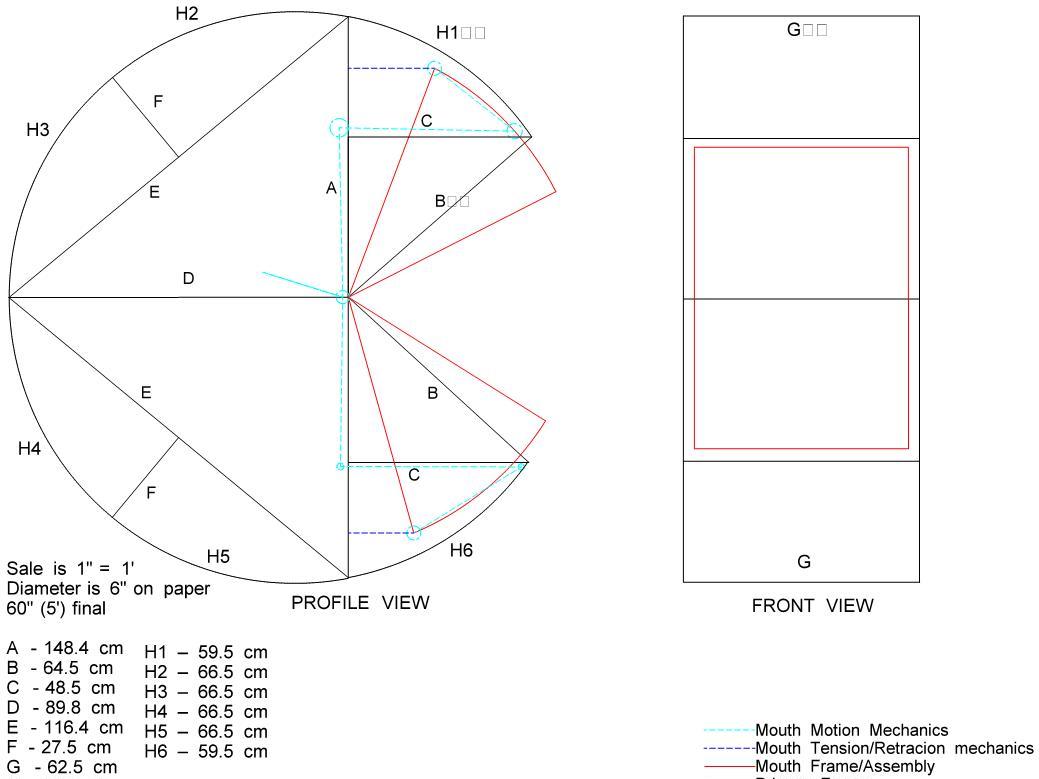

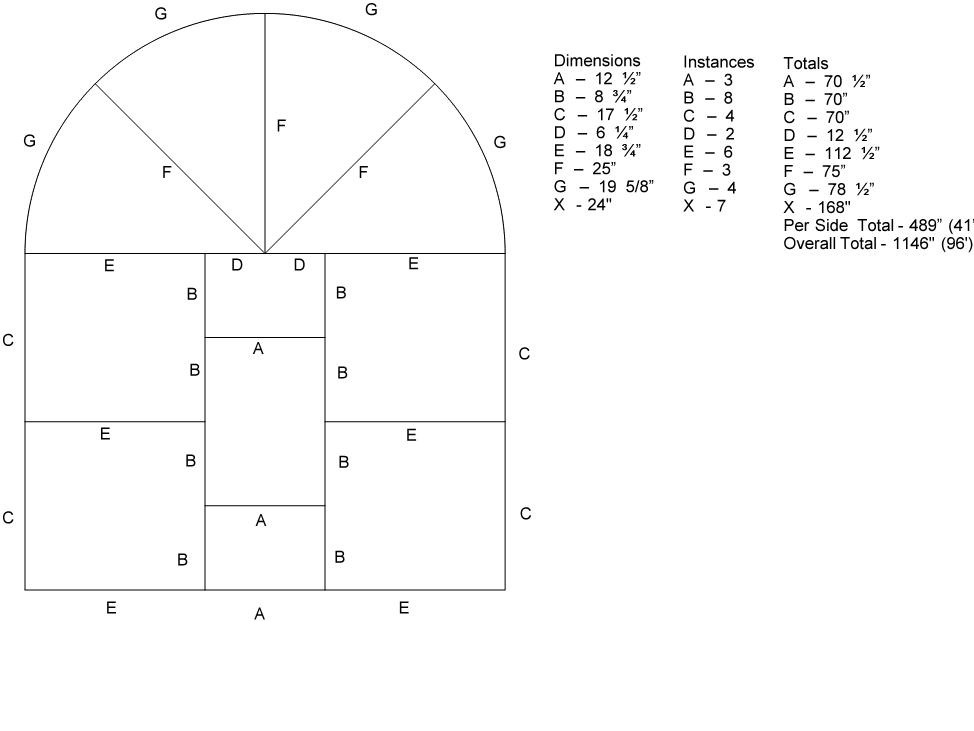

I spent a while planning this project, but not quite long enough. I did initial sketches on paper and then did some very simple CAD work.

Unfortunately in the Pac-Man costume I forgot to plan for the extra length that the PVC joints would create, so it caused some deformation of the frame shape. If you plan to make one of these, do not use the lengths listed; you’ll need to adjust them to account for the size of the PVC Joints.

The CAD Drawings are bad because I have absolutely no CAD experience. I just sort of stumbled my way through until I got what you see in the picture.

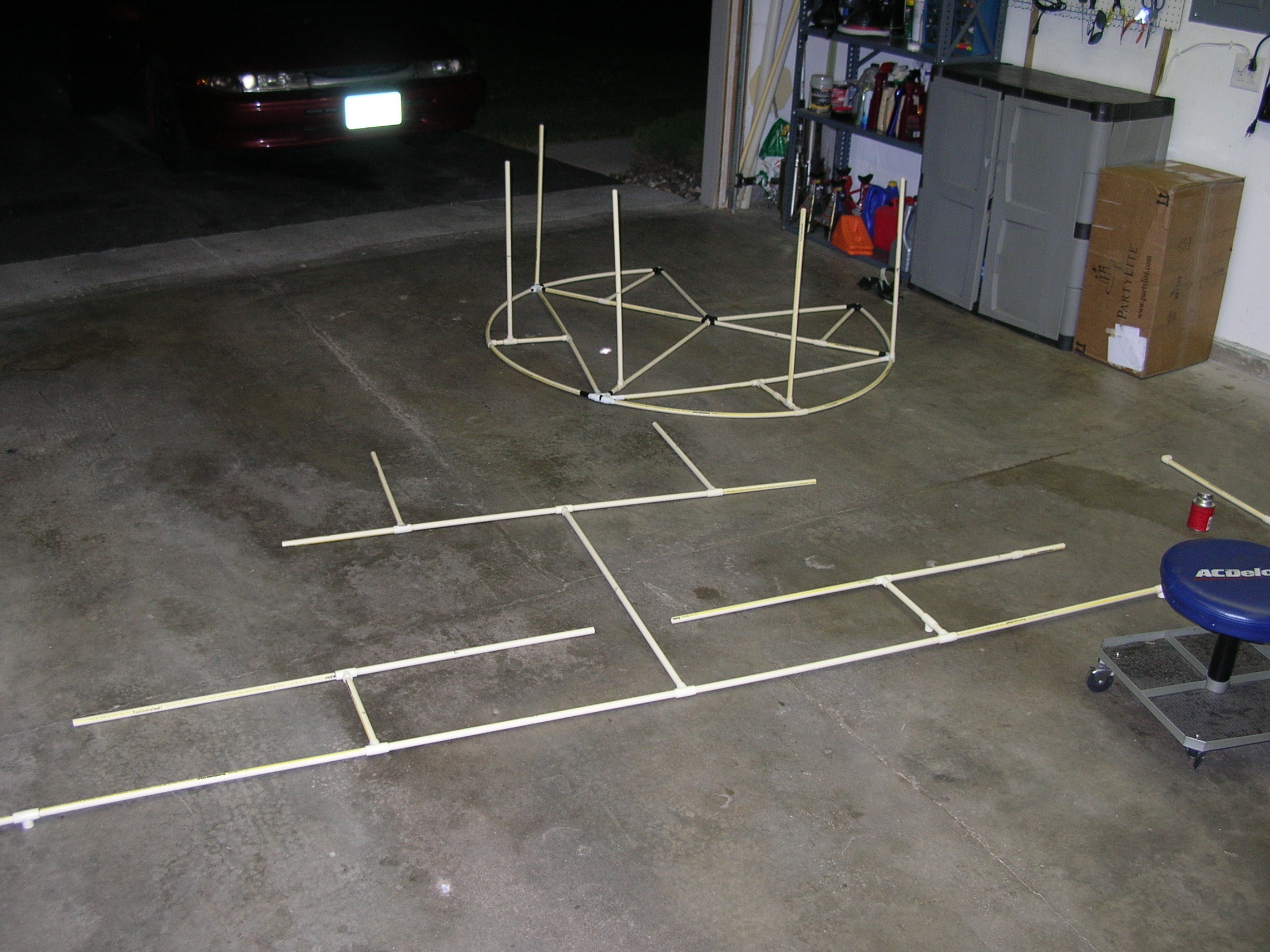

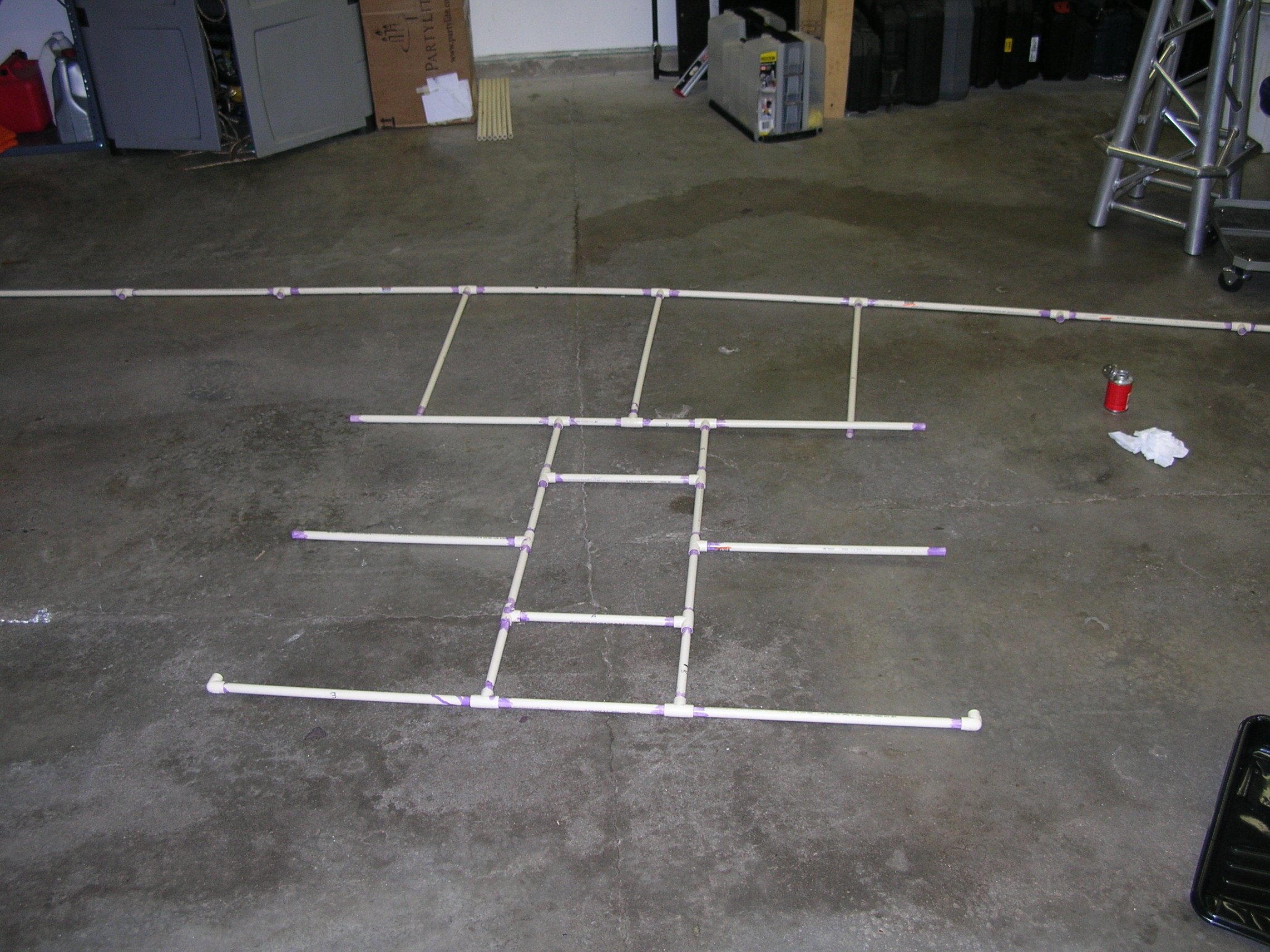

There isn’t too much to say here; it is simply a matter of cutting/labeling the sections of PVC pipe and beginning assembly. One note: Make sure that you let the PVC cement dry completely before doing any kind of bend. Also, while you are building the sides you should install T-joints for the crossbars. At any area where there is no joint to assemble things I just used lots of electrical tape to hold things together.

Putting the outer frame together

I started out with very short crossbars to make sure that both sides o the frame lined up correctly and then moved on to the lager ones.

This will depend somewhat on a person’s size, but to give enough room I made my crossbars 24″ in length. This gave me room to work inside the suit as well as leaving it narrow enough (just barely) to fit through doors.

The third picture is me standing with the frame for size comparison.

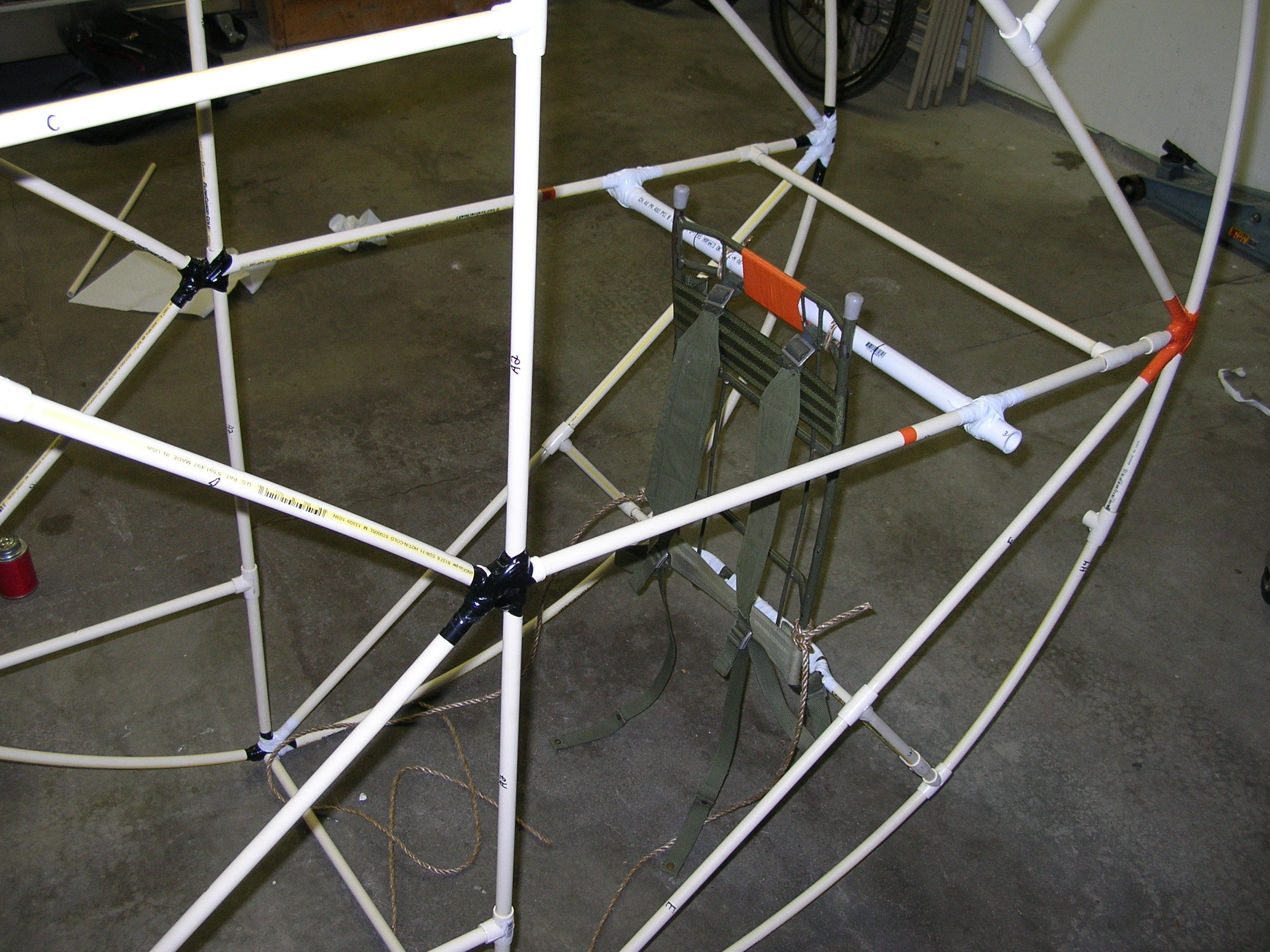

Here I attached the harness to the frame. The harness is just an old external-frame backpack from a surplus military pack. I discarded the backpack portion (it was disgusting) and just kept the steel frame.

To attach the harness I used one piece of CPVC and one piece of 1″ PVC as crossbars, and wrapped them in tons of electrical tape. It turned out that the CPVC crossbar wasn’t strong enough and snapped after some use, so I had to replace it. You should just use two pieces of 1″ PVC; it’s much stronger.

I also cut out one of the cardboard sides, which was silly since I didn’t end up using it for quite a while. I just used the frame as a template and cut the cardboard.

In retrospect I wish I had waited to install the harness until the mouth was completely finished since I didn’t realize just how front-heavy the suit would be.

Building the mouth

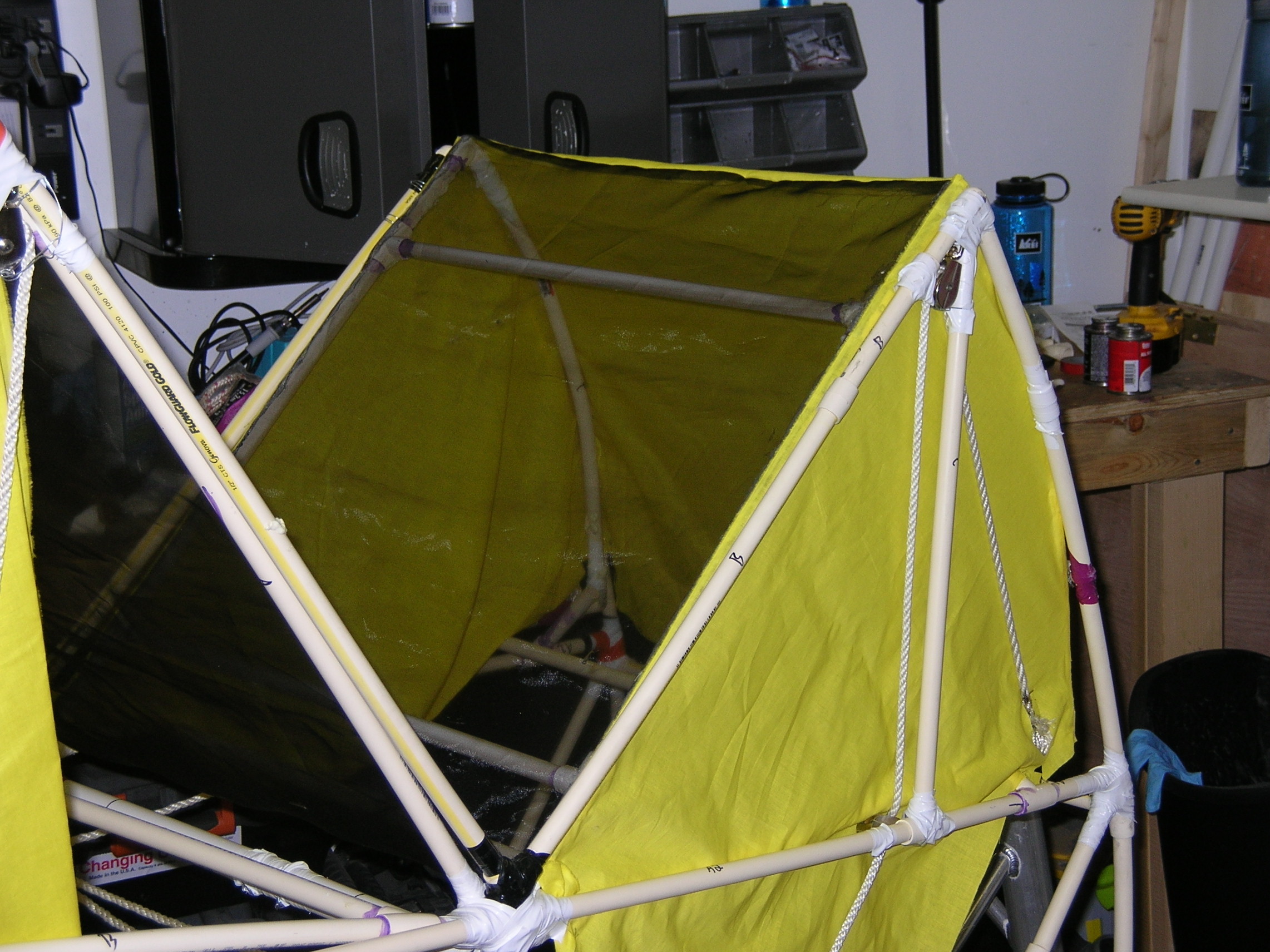

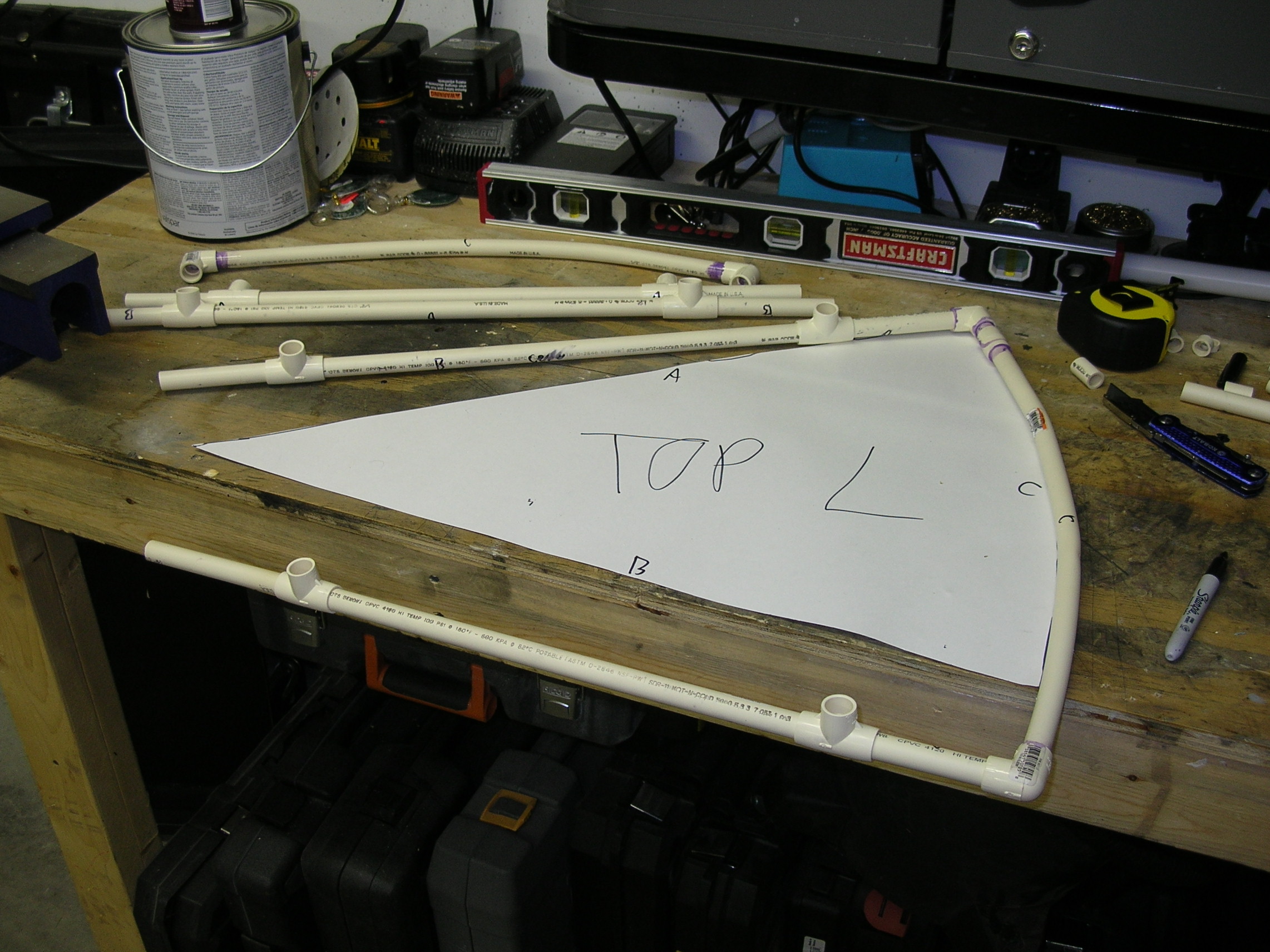

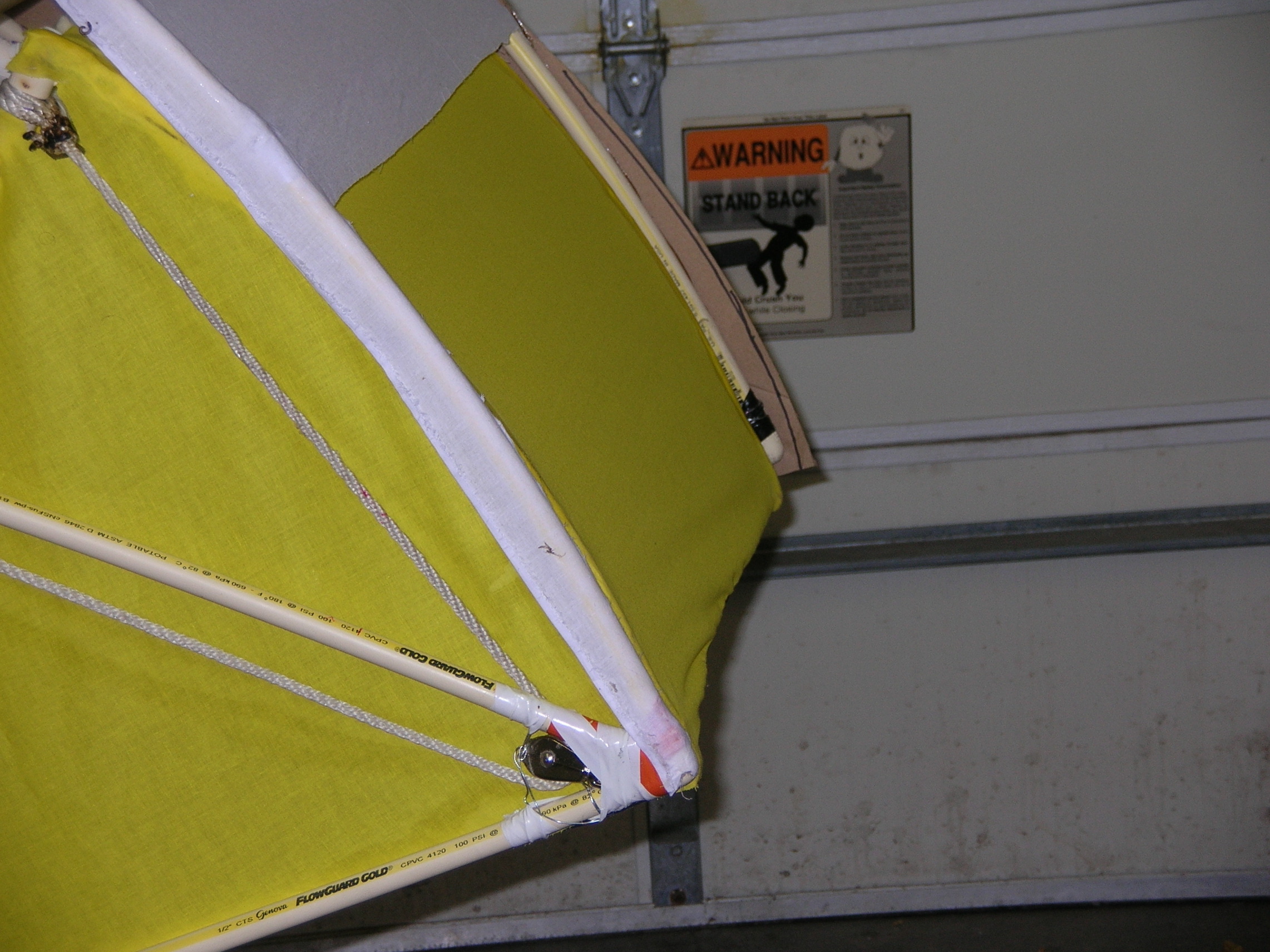

The mouth was the bane of my existence for this project. I built two smaller pizza-slice-shaped frames that sat just inside of the main outer frame. I built a jig out of screws on my work bench to bend the CPVC in and then used a heat gun to make them hold the shape.

If I were to do it again, I would make the jig out of scrap wood and use my oven to heat the CPVC. The heat gun was inconsistent and did a sloppy job.

Once the two “jaws” were built, I installed them with steel wire and electrical tape at the back corner. This allowed them to be flexible while holding them in place.

Mouth Continued

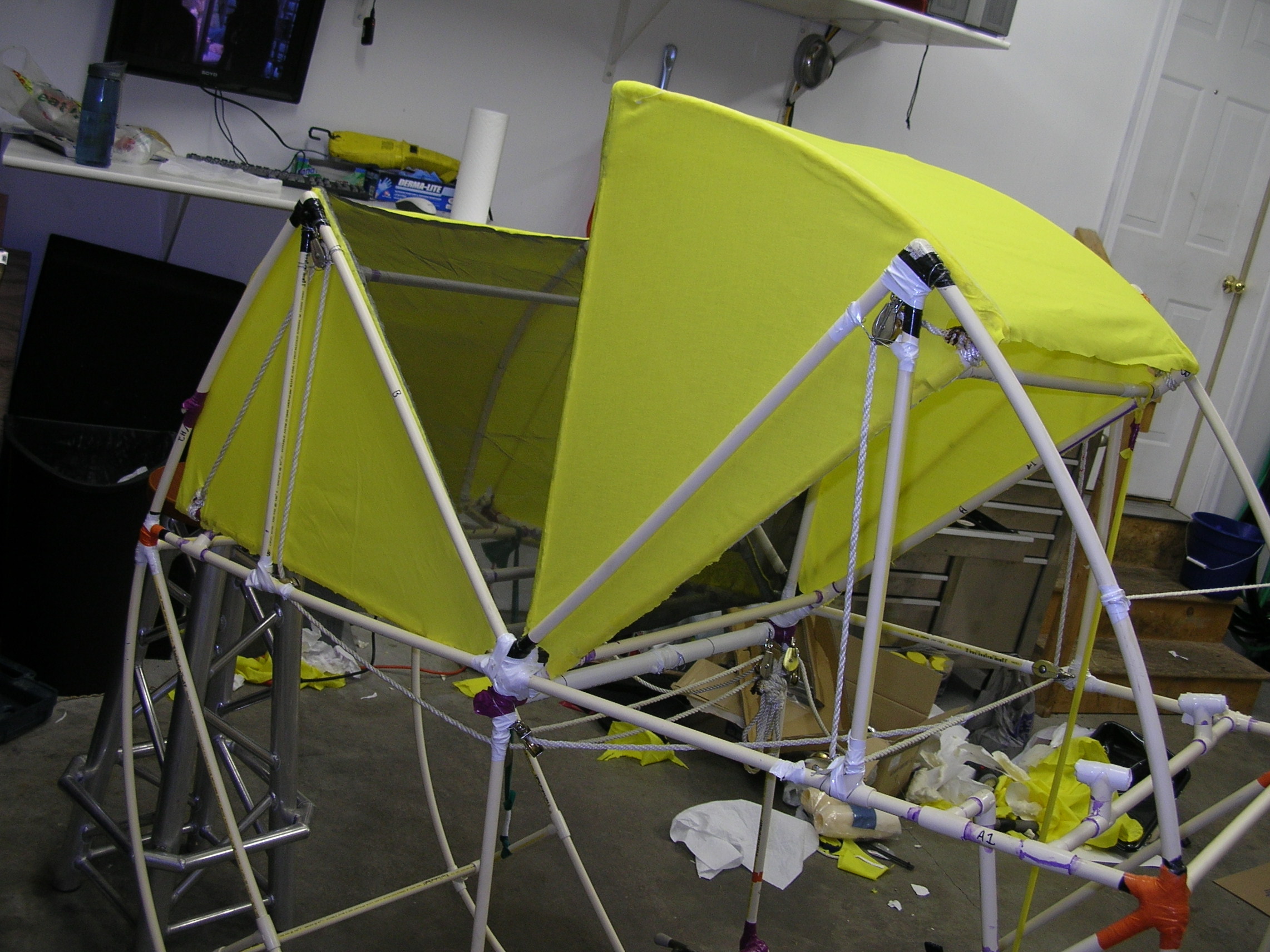

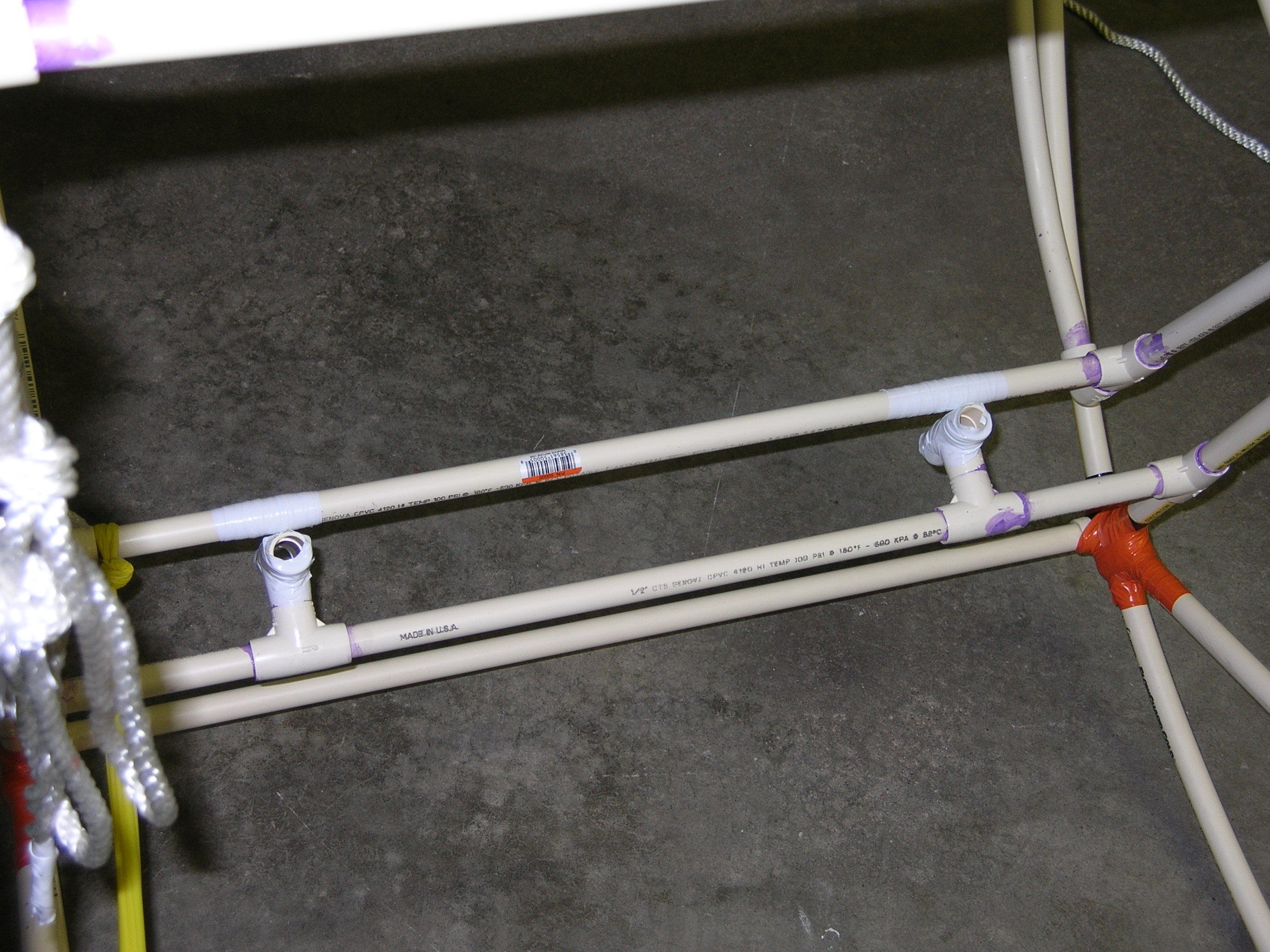

For the movement I installed pulleys using steel wire and electrical tape, and fed the rope though them. This took the better part of a week to get working properly, so patience is a virtue.

I started out just having ropes on one side of the costume, and this worked great when the whole thing was just CPVC. Unfortunately once I got it dressed the mouth started to bind because the CPVC lacks rigidity and I ended up adding a second set of pulleys/ropes to the other side of the costume.

To make the jaws retract into the frame on their own, I tied thera-bands from the jaw to the main costume frame. These are just the latex exercise bands you can get at a place that sells exercise equipment.

Mouth Continued

The jaws did have a problem with recessing too far into the suit, so I added “stops” for them.

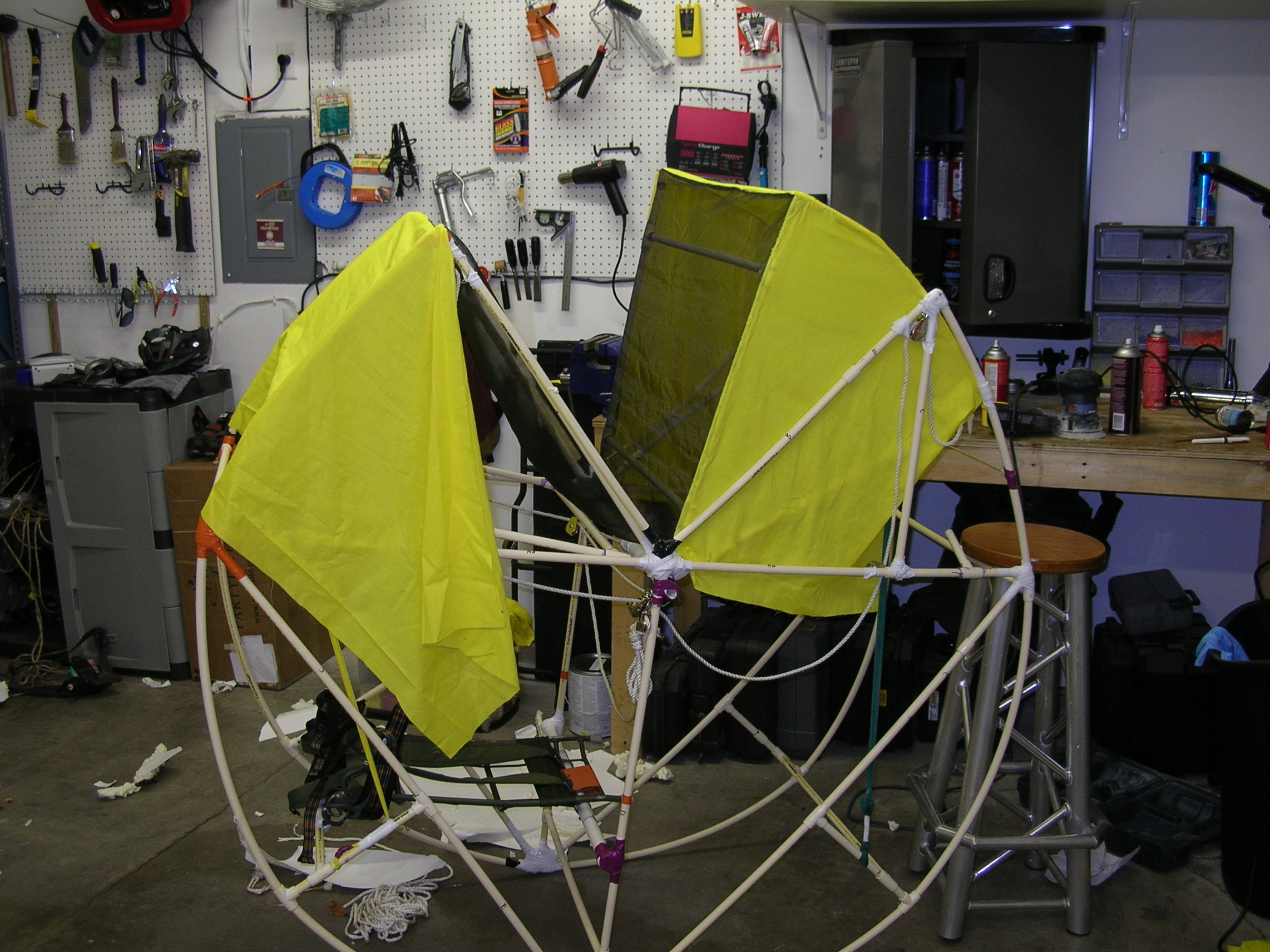

Dressing The Mouth

I took the time to sew the black sheer and yellow fabrics together in a giant “I” shape. This I was then able to just lay over the jaws and glue on. It worked beautifully.

Later on in the process I decided to paint the inside of the suit black. I wish I had sprayed the PVC just prior to this point, and that I had sewn black fabric onto the inside of the yellow. There was lots of frustration trying to glue black fabric into that area once the whole thing was put together.

More pictures of dressing the mouth

These were taken after I trimmed the excess yellow fabric off and glued everything in place.

Attaching the center section

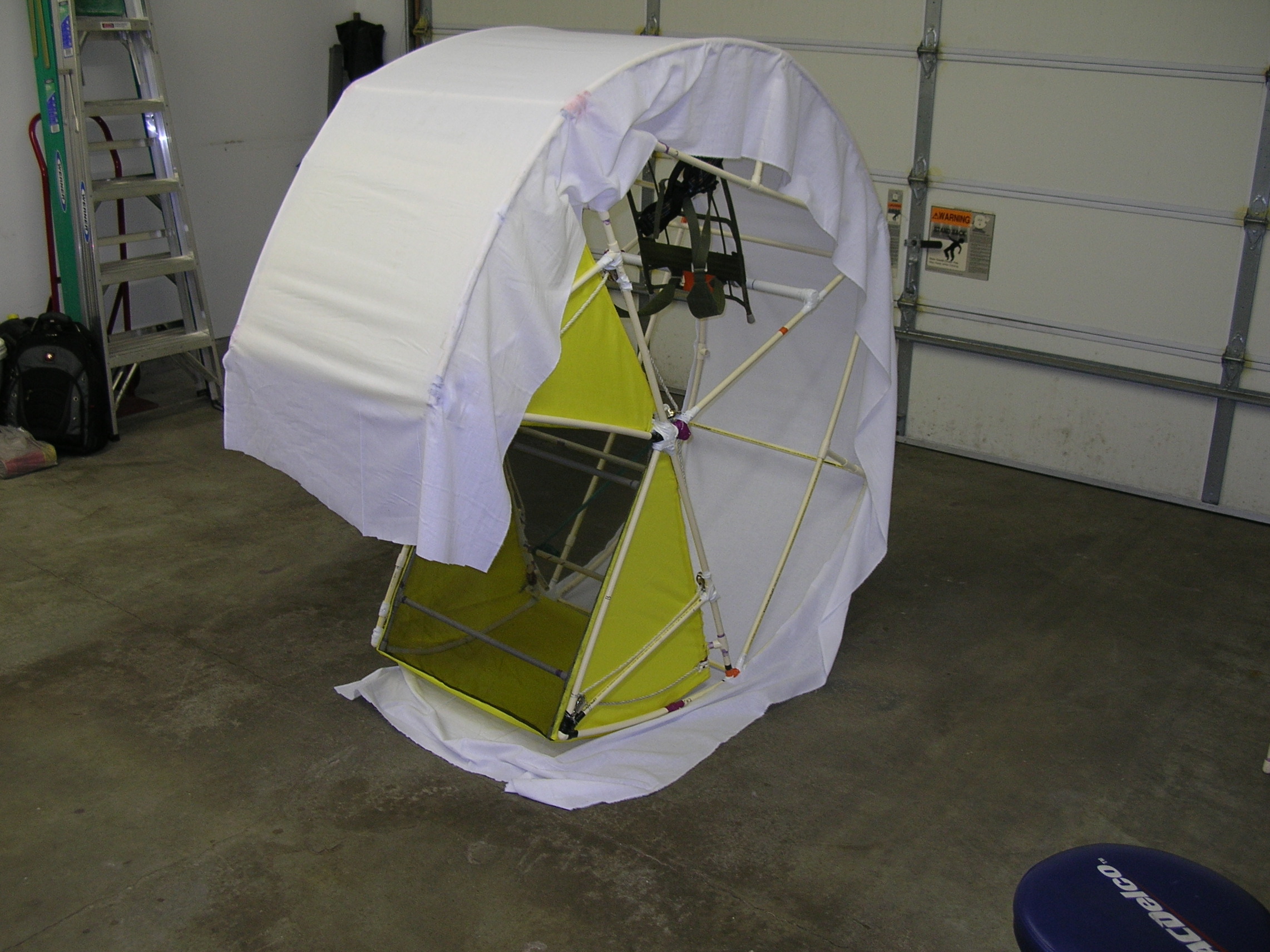

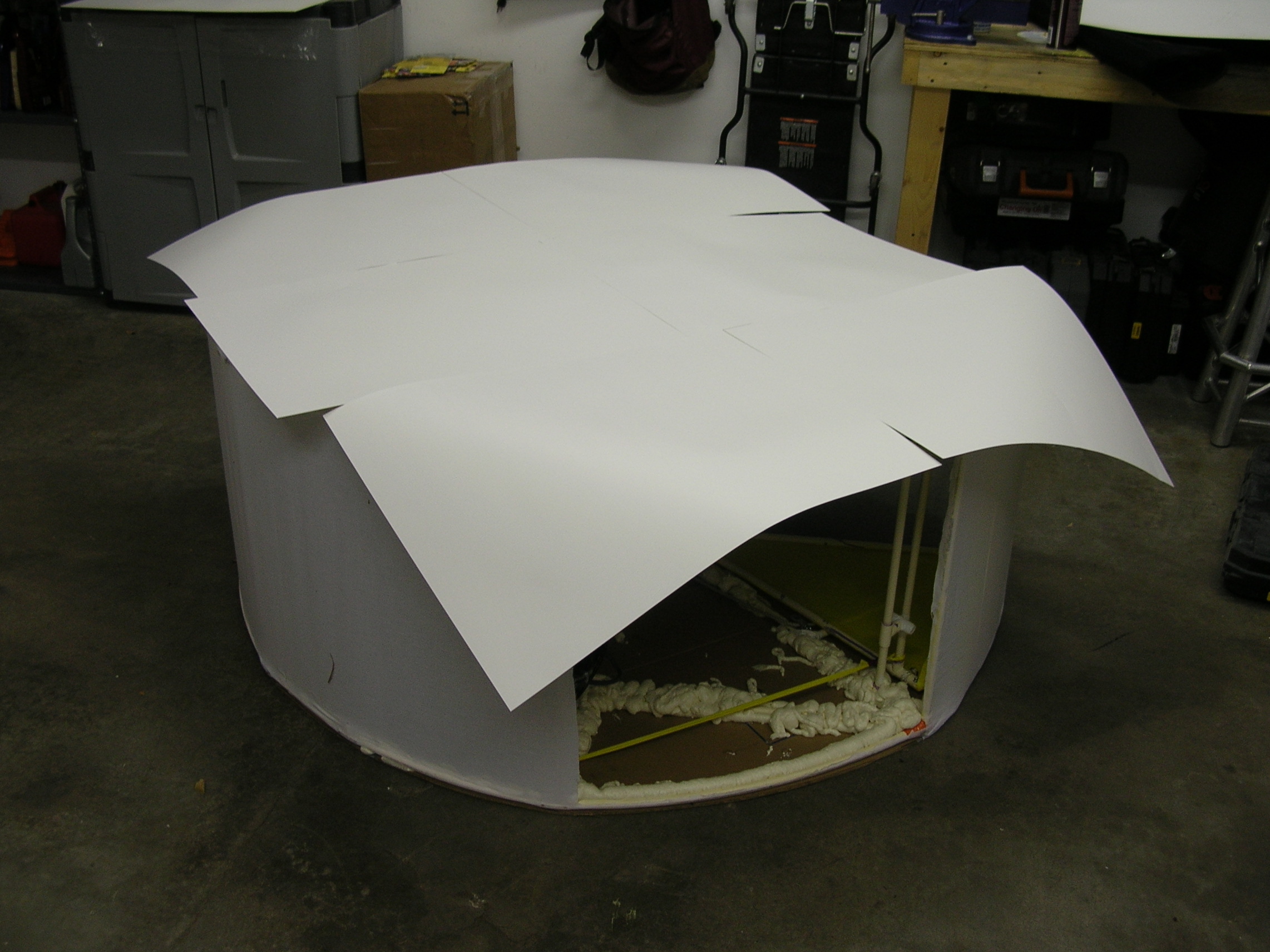

Now that the mouth has been dressed it was time to attach the muslin. Patience and a good respirator are all that this required. I also recommend wearing gloves since the Amazing Goop glue doesn’t come off of skin easily.

Once the glue is dry just cut off the excess muslin.

I chose to use muslin for this part because it would offer flexibility and would make a nice smooth curve. Cardboard wouldn’t have looked nice as it wrapped around.

Mouth Problems

Since my mouth pieces weren’t built just right they stuck out of the primary frame at some point in their movement. Both were at different points. Because of this I had to cut a section of muslin out and re-attach it later once the cardboard sides were on. I left extra cardboard sticking out past the frame in the offending areas and just glued the patches of muslin to that.

Also, don’t forget to cut a hole for yourself.

Attaching the sides

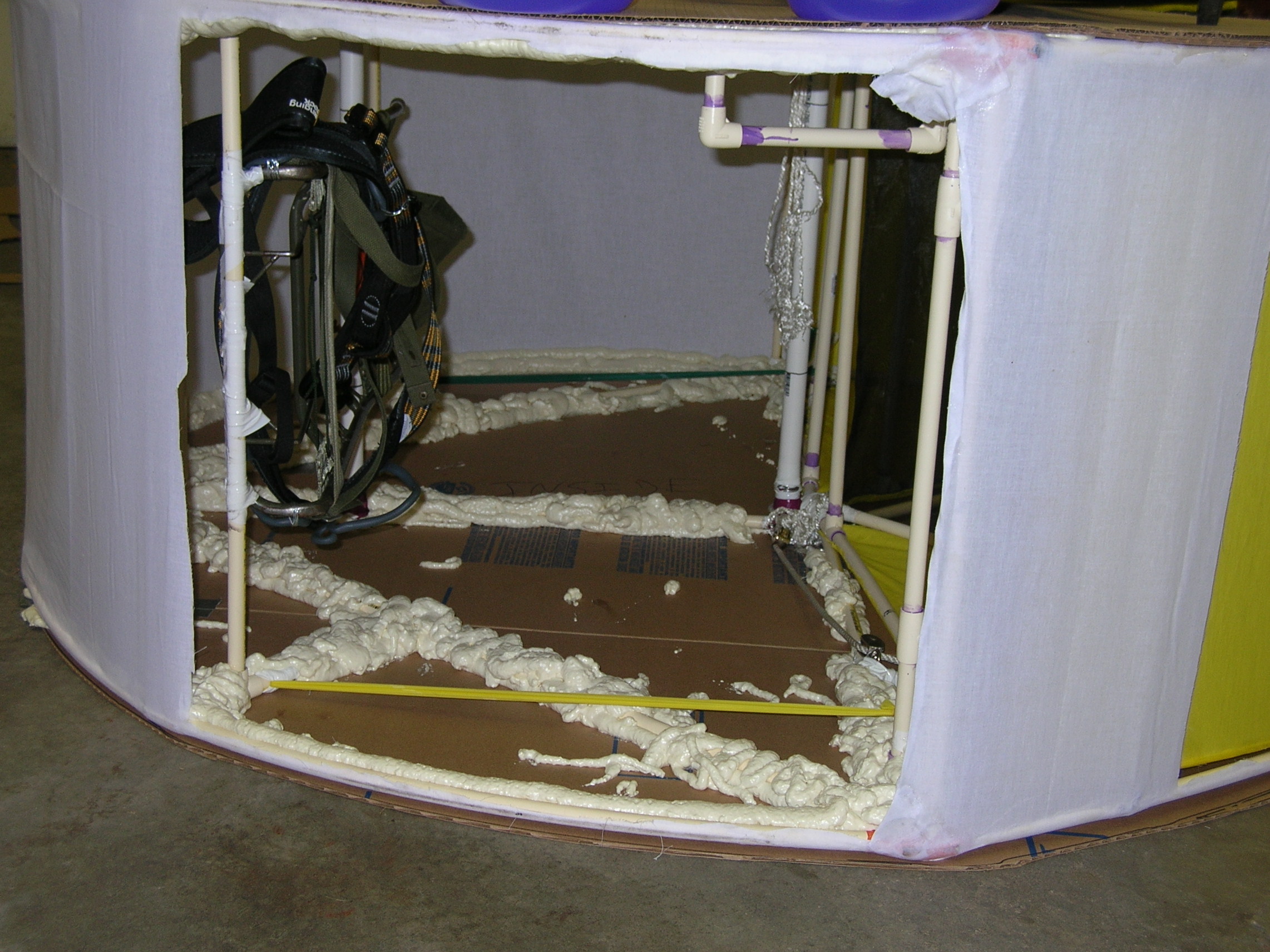

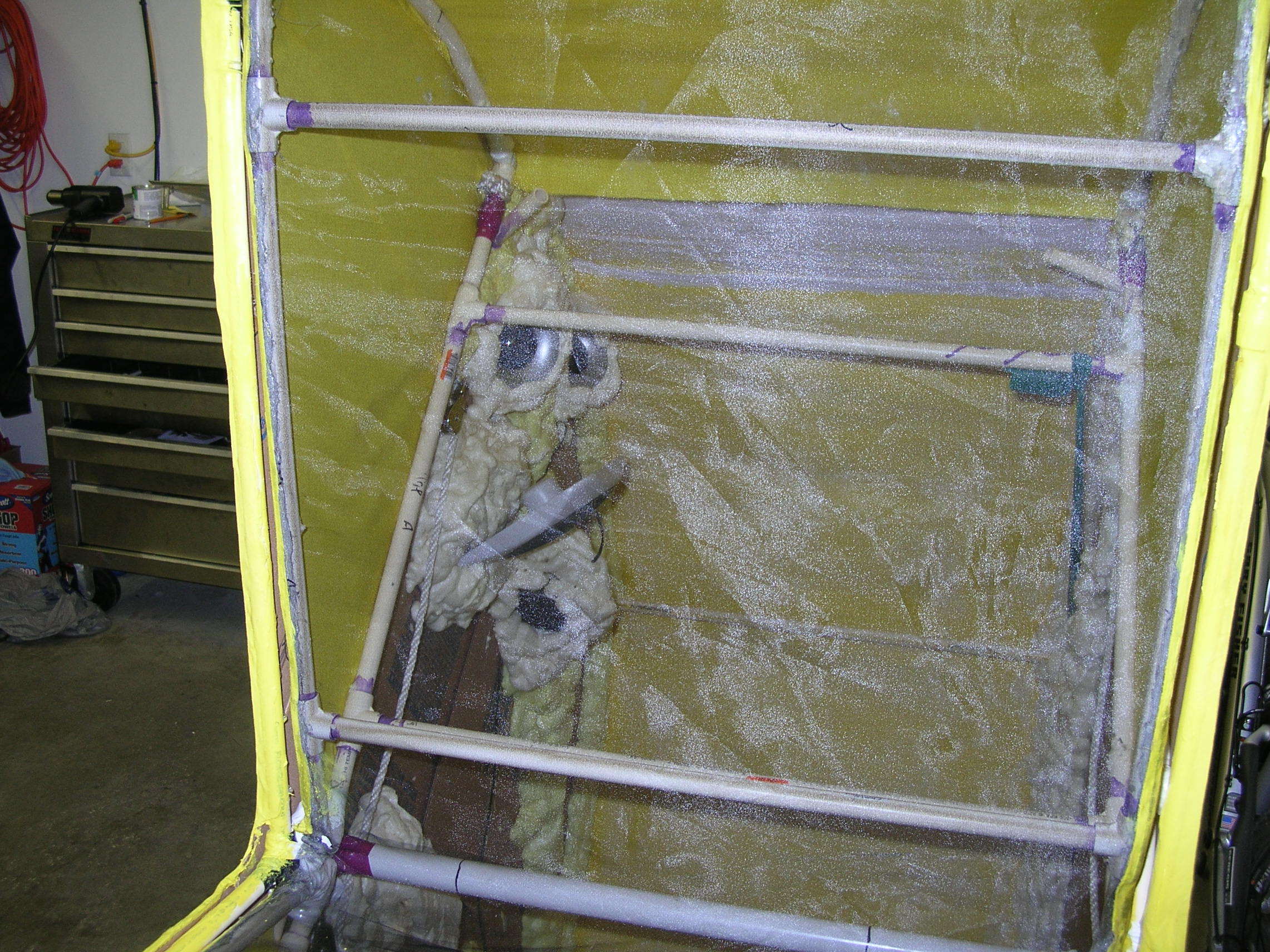

The sides of the suit are pretty simple. They’re just big cardboard boxes cut to fit. I had trouble attaching cardboard to PVC, so the final solution was just to use expanding foam. It sticks to both materials and I was able to encase the PVC in the foam.

I went overboard with the expanding foam. I could have done with half as much as I actually used.

Also, once the sides are on I would recommend painting them with a primer. I had issues with paint soaking in and causing bubbling.

Finishing the sides

I reattached the sections of muslin that I had cut out by gluing them onto the cardboard and got painting.

I had used spray-glue to attach posterboard to the surface of the cardboard so that it would look cleaner. It worked, but when I painted it the posterboard swelled up badly and looked terrible. The fix for this was to stretch bleached muslin over the whole side and glue it on. This was very time-consuming and required lots of straight pins. The end result looked very nice, so I would say to just go this route in the first place.

Finishing the sides continued

Here are some more pictures of attaching the muslin to the sides.

Painting

Once the sides are ready, simply paint the whole darn thing. Remember to lay something down underneath wherever you are working so that the paint doesn’t get all scuffed up. I also painted Pacman-shaped eyes on with black paint.

Finishing the inside

Like I said previously, I would take care of painting the inside black before you get to this point, but I didn’t.

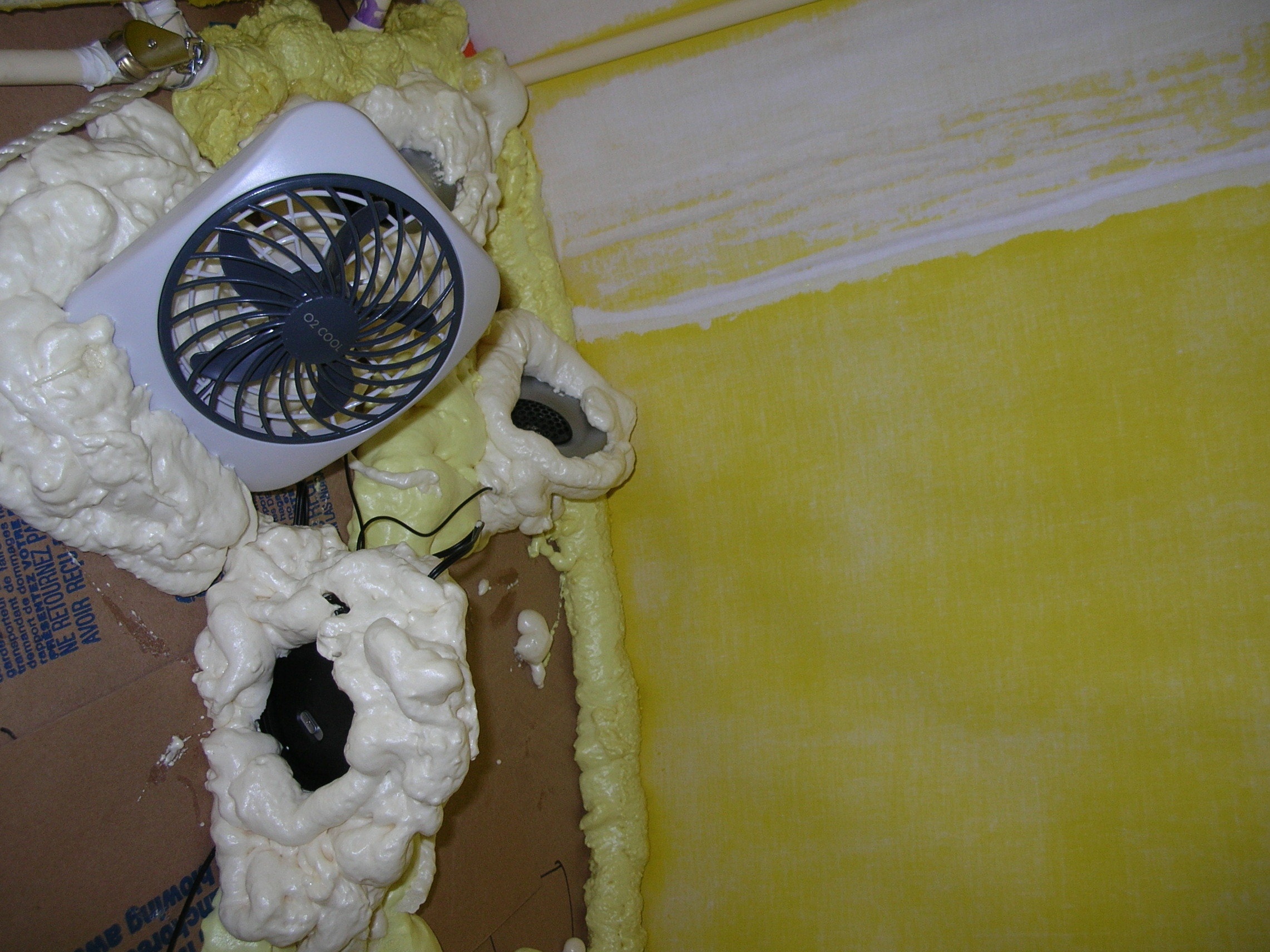

So here I took the time to foam in a pair of battery-powered speakers (along with their battery module) and a battery-operated fan. Using latex paint makes this thing very hot to wear even when it is in the high 30’s outside.

Finish up any other interior work that needs to be done, like attaching the hip-belt if you haven’t already.

Finishing the interior

I decided to paint the interior of the costume flat black to make it harder to see into the costume from the outside through the mouth. It worked very well, but was difficult at this late stage.

I also glued black fabric onto the inside of the mouth frames to hide the yellow because it stuck out like a sore thumb from the outside.

Finishing the Mouth

I had problems keeping the mouth operating properly. It kept sticking on things; this required a lot of troubleshooting, but even after clearing things out I had to resort to greasing everything. Anywhere that the mouth rubbed on the outer frame I applied a liberal amount of wheel-bearing grease. I also used a dry Teflon bicycle lube on the pulleys and rope.

Now it’s time to build the ghost

The ghost was built in the same way that Pac-Man was, but didn’t take near as much work because of things I learned on Pac-Man and because there are no moving parts.

I did the same thing, using short crossbars to make sure everything lined up properly and adjust if necessary.

Then I installed the full size crossbars.

Once the frame was together I installed the harness the same way as in Pac-Man, then wrapped muslin around the center section again.

I originally tried using red see-through fabric for the opening, but it proved to be way too fragile, so I cut it out and replaced it with the same black that I used for Pac-Man’s mouth.

I don’t really have pictures of finishing the ghost, but it was put together the same way as Pac-Man.

I cut out cardboard sides, attached them with expanding foam, stretched/glued muslin over the cardboard and painted it.

The center section and one side of the ghost are red (with the eyes) and the other side is blue. This way you can chase each other around properly just like in the game when Pac-Man eats a power pellet.

The ghost has the wavy lines at the bottom, but they’re just fabric so they fold up under the costume which is why you can’t see them in some pictures.

Conclusion

While this isn't a terribly difficult project, it is very time-consuming and required a lot of troubleshooting.