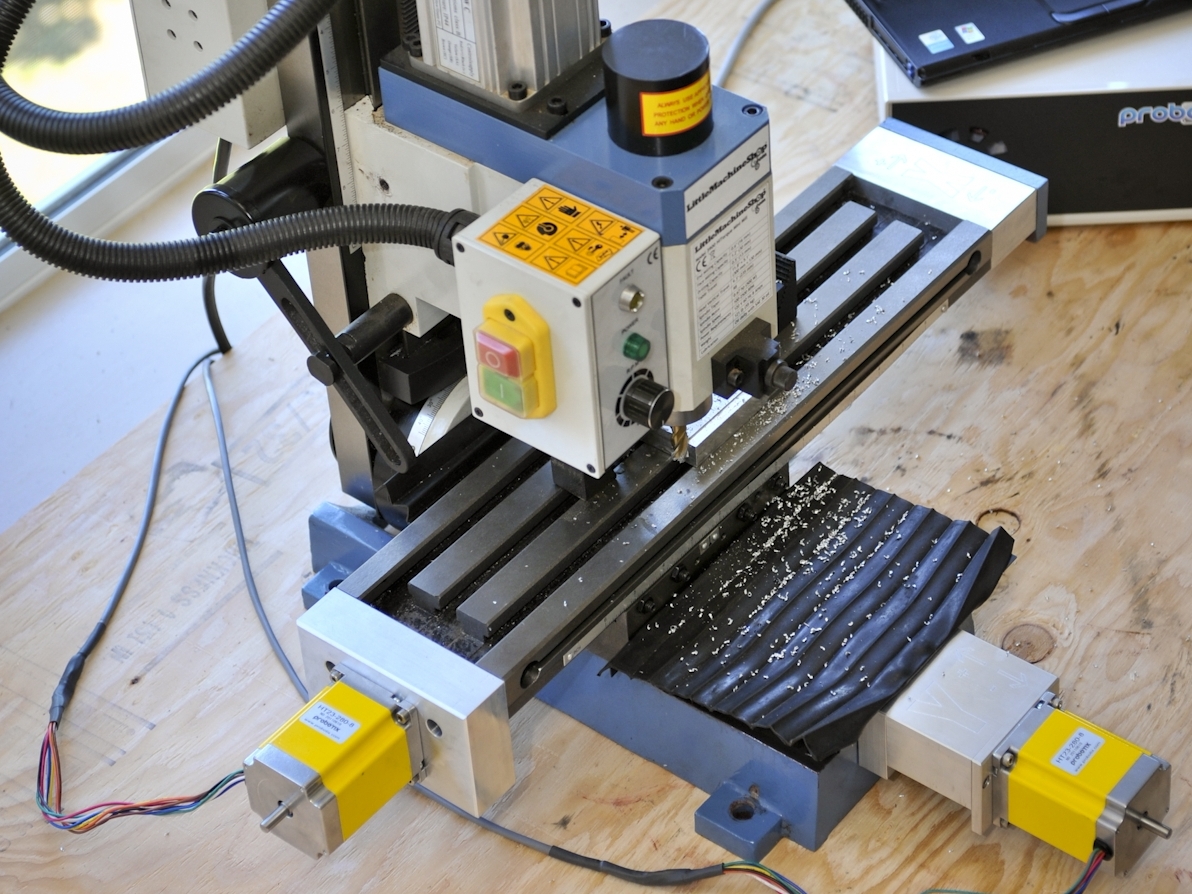

What do you do when you want a CNC machine, but don’t have the room or the funds for a massive professional machine to build your custom parts? I found myself in the same dilemma, so I chose to scale down my purchase and invest in a manual mill that I could eventually convert to a CNC machine.

Before purchasing my X2 Mini Mill from LittleMachineShop.com I did some research to investigate what it would take to make the switch from a manual mill to a complete 3-axis computer numerically controlled milling machine. These small hobbyist mills are manufactured in China and Taiwan, and then shipped to companies like Harbor Freight, Grizzly and Micro-Mark who paint them various colors and sell them under different names. Since the basic foundation is all the same, a small community has formed around this popular mini mill platform to share ideas and hacks. When opting to convert to CNC, there are numerous kits and conversion designs to choose from. These options range from simple PDFs with diagrams and schematics to high-precision hardware and electronics bundles.

CNC Fusion is a small company that machines high quality conversion parts made from 6061 aluminium stock. The company started in 2004 when Michael Rodgers, a machinist by trade, wanted to build a CNC machine but realized that he could not build the parts he designed without first owning a CNC machine.

That initial desire has led Michael to design and fabricate CNC conversion kits for small manual mills and lathes, and now his kits are sold around the globe (40% of CNC Fusion production is shipped to overseas customers). The household garage has been converted into a machine shop where Michael machines the majority of the kit components using a huge five axis CNC mill while wife Sharron runs the massive CNC lathe to machine the ends of the ball screw threads sold with their kits.

The X2 Mini Mill kit is the most popular from CNC Fusion, primarily because the mini mill platform is considered a great tool at a modest price for hobbyists. With the X2 Mini-Mill CNC kit #2 all the new upgrade parts bolt to existing features and you replace the factory lead screw with high-precision ball screws and new motor mount adapters to accept NEMA 23 stepper motors. The hardware installation is very straightforward and requires the disassembly of the X and Y axes before reinstalling the ball screws. You will also need to drill two holes into the central column of the mill to install the Z-axis ball screw hardware. Besides this step, the entire process is completely reversible in case you ever decide to switch back to manual machining (but honestly, why would you?).

I will provide steps for setting up the electrical components and required software in a separate tutorial. This project will only cover the physical hardware conversion.