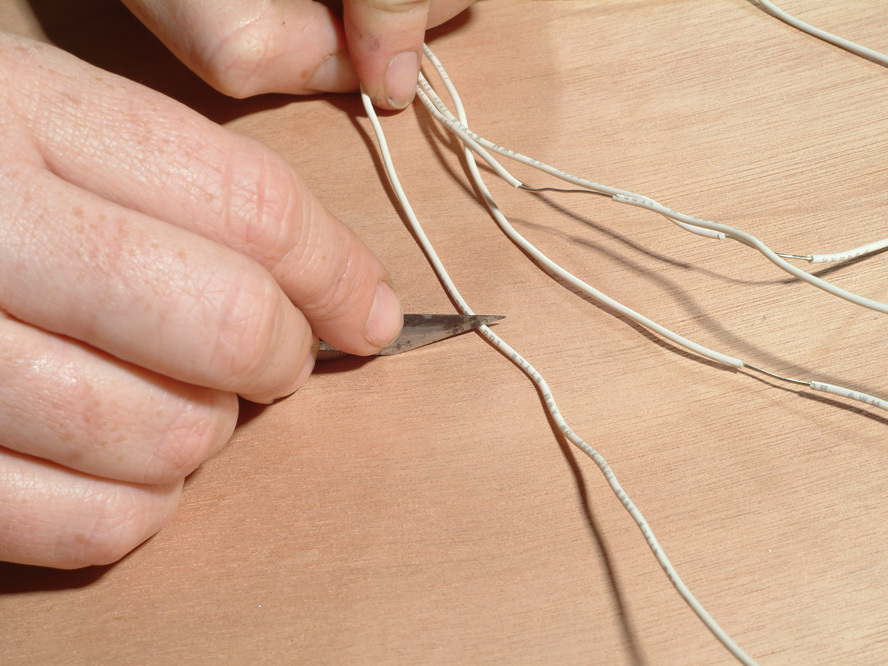

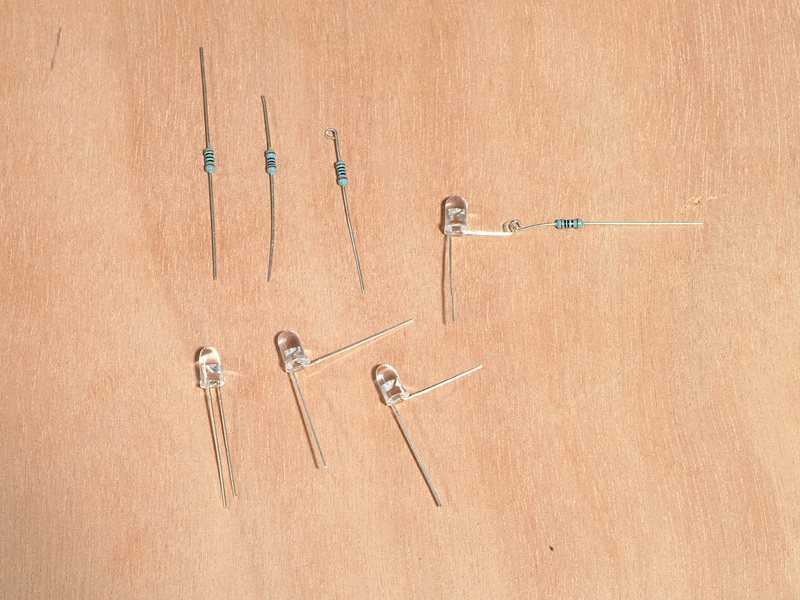

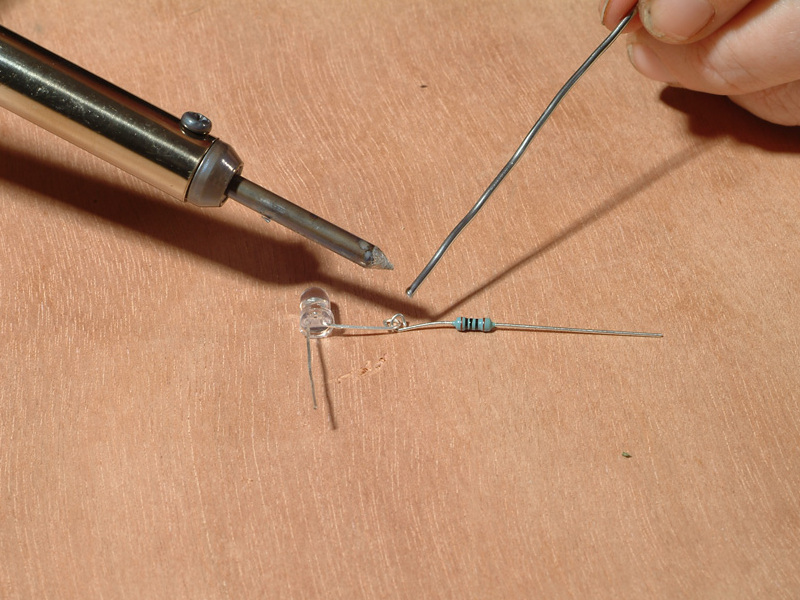

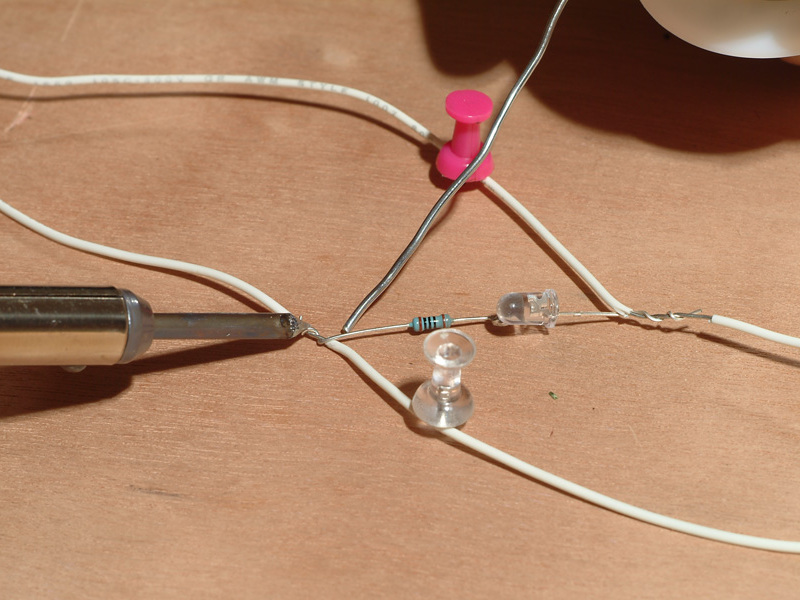

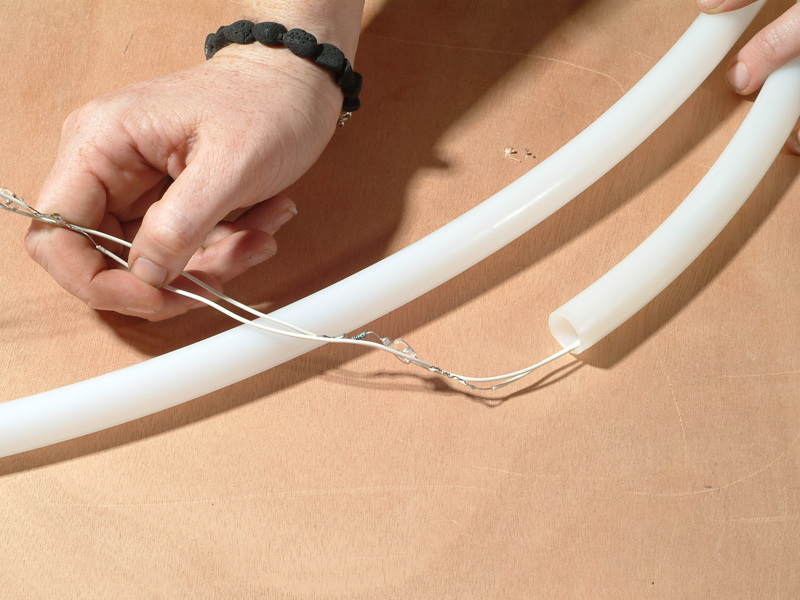

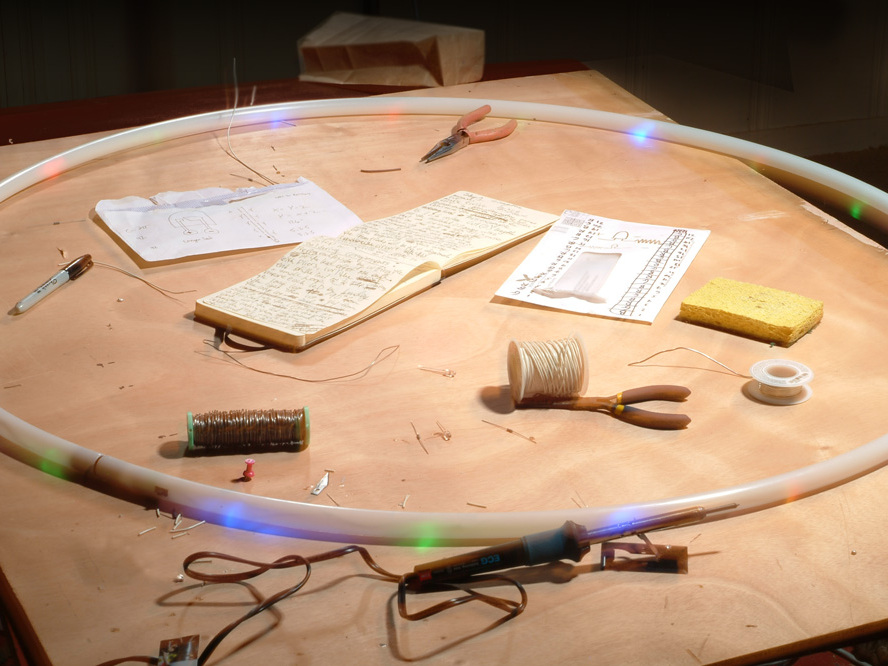

LED hula hoops are so beautiful to watch, and creating a custom hoop is a satisfying challenge. Twenty-one LEDs are used in this hoop; 6 are flashing LEDs that cycle through the colors of the rainbow. Each light is combined with a resistor and then wired together in a classic and simple parallel circuit.

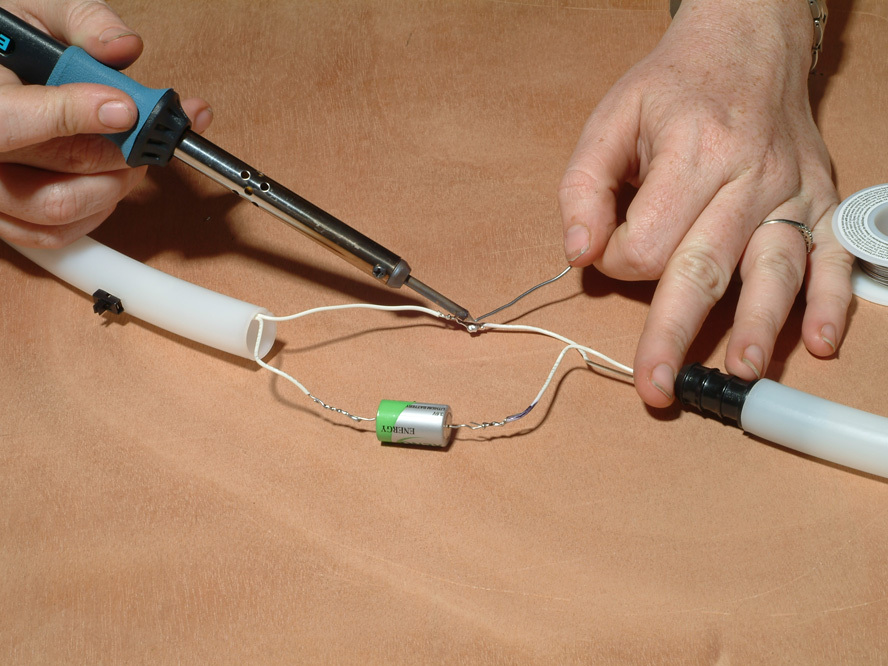

Be sure to research each part and its specs when creating the circuit design. Each LED for this project was chosen for its similar voltage drop, making things simpler by requiring only one value of resistor.

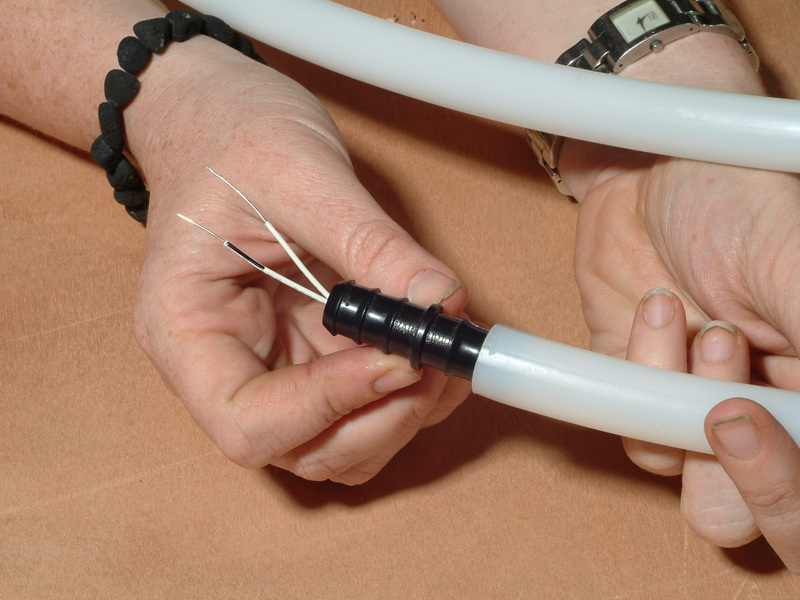

The battery for this project can be a laptop battery like the one used here, or a few AAA batteries taped into series. Either way, the tube can be taken apart for the battery to be easily changed. Experimentation and thoughtful research will make this project successful.