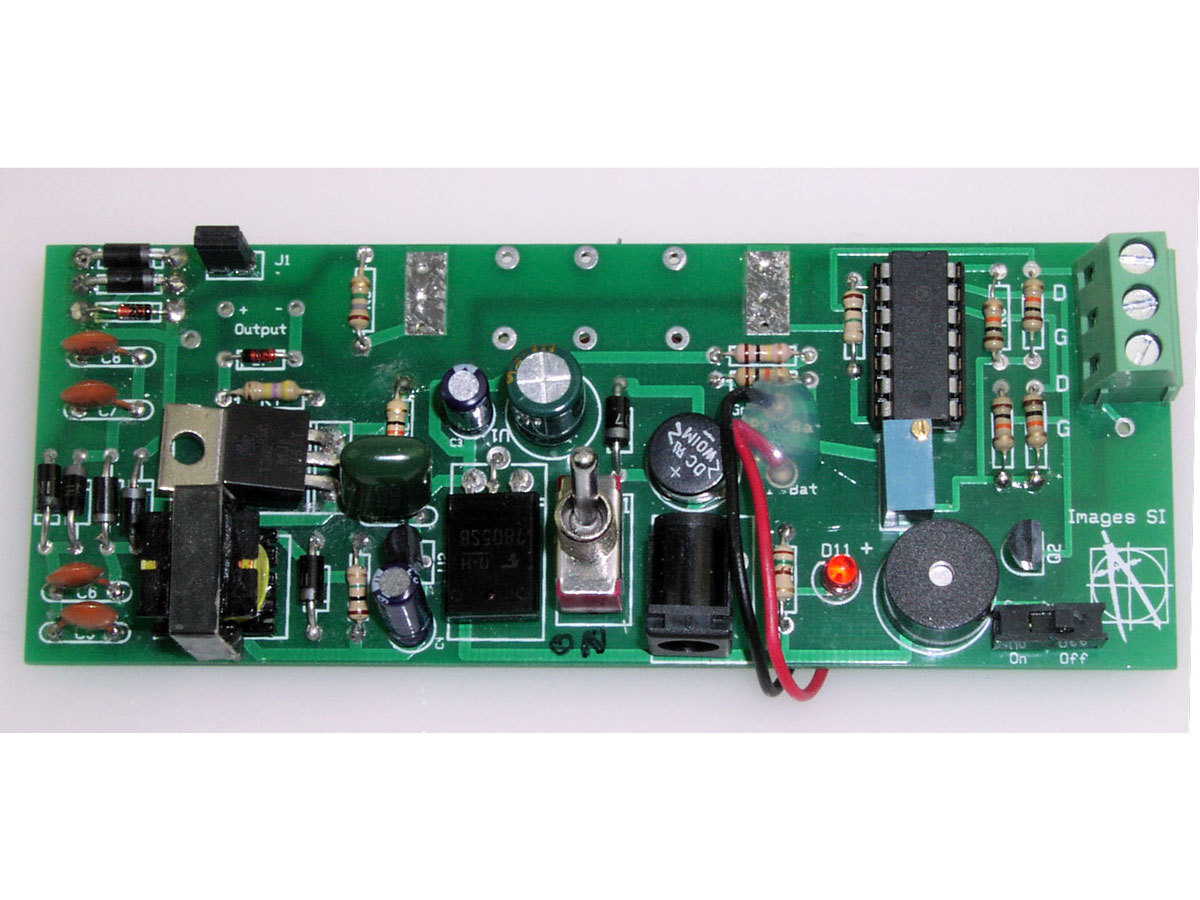

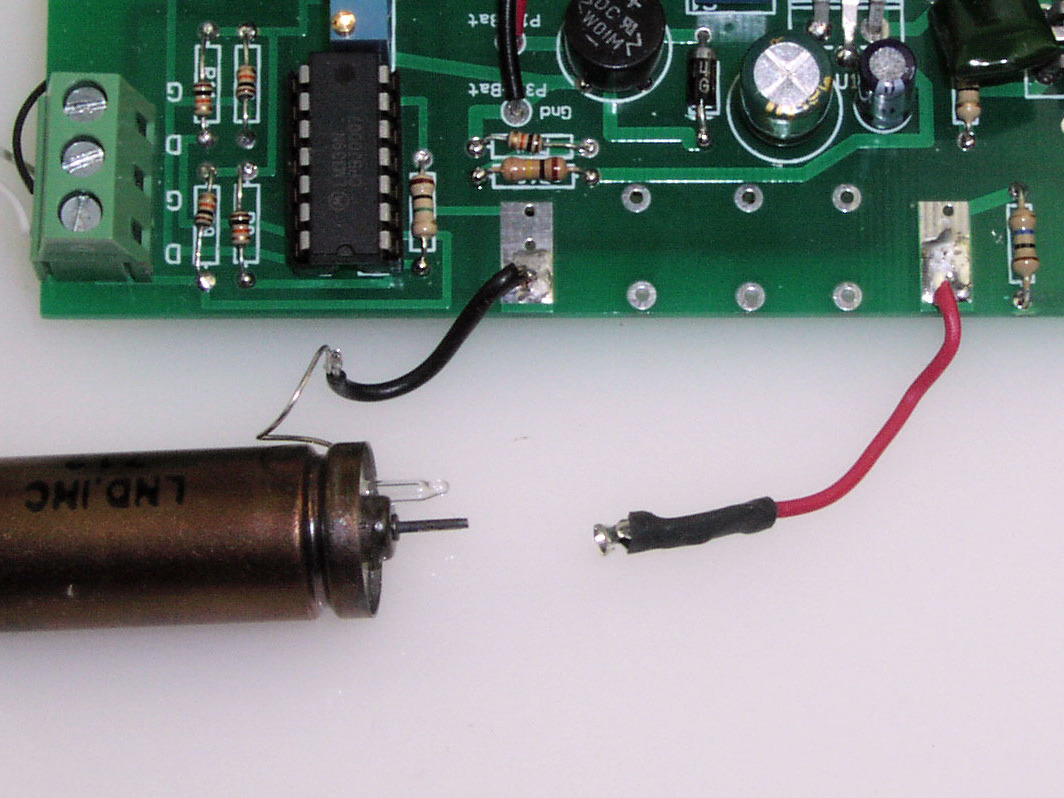

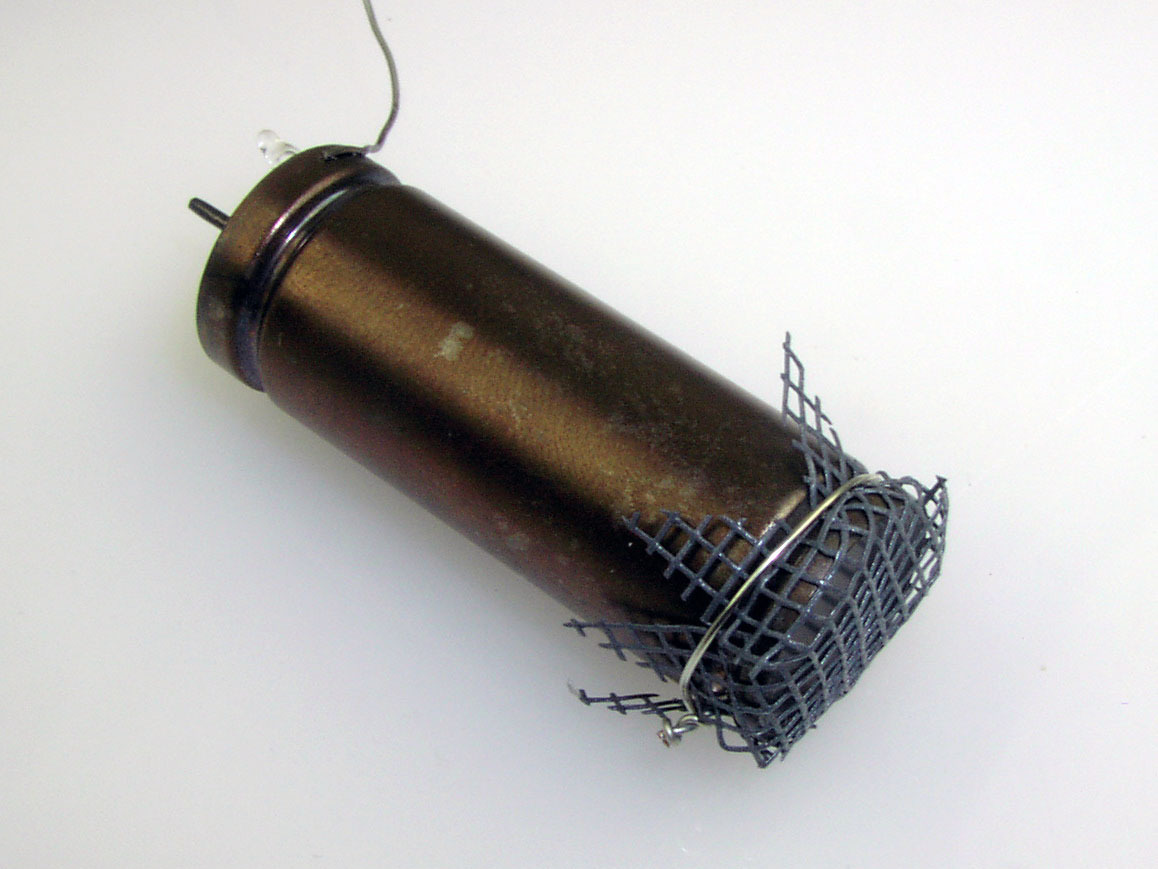

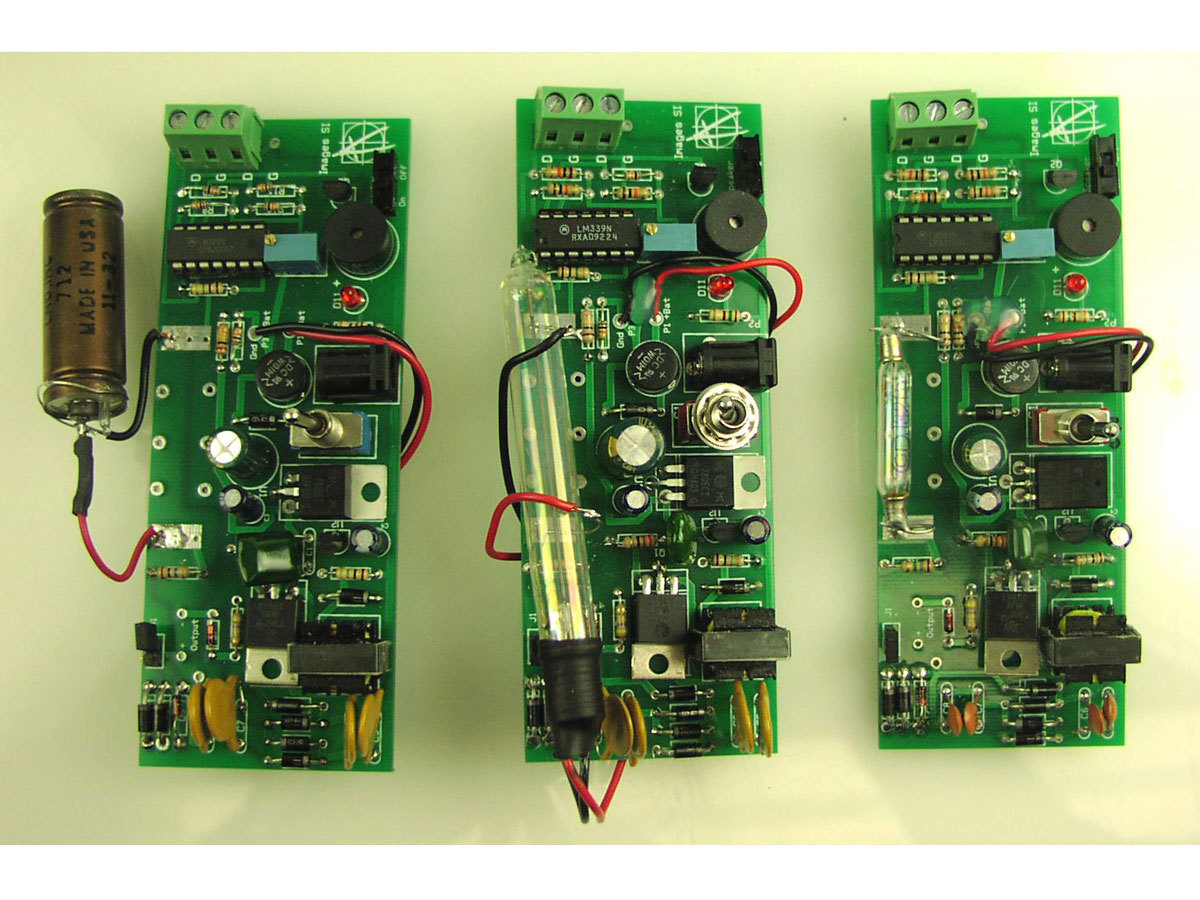

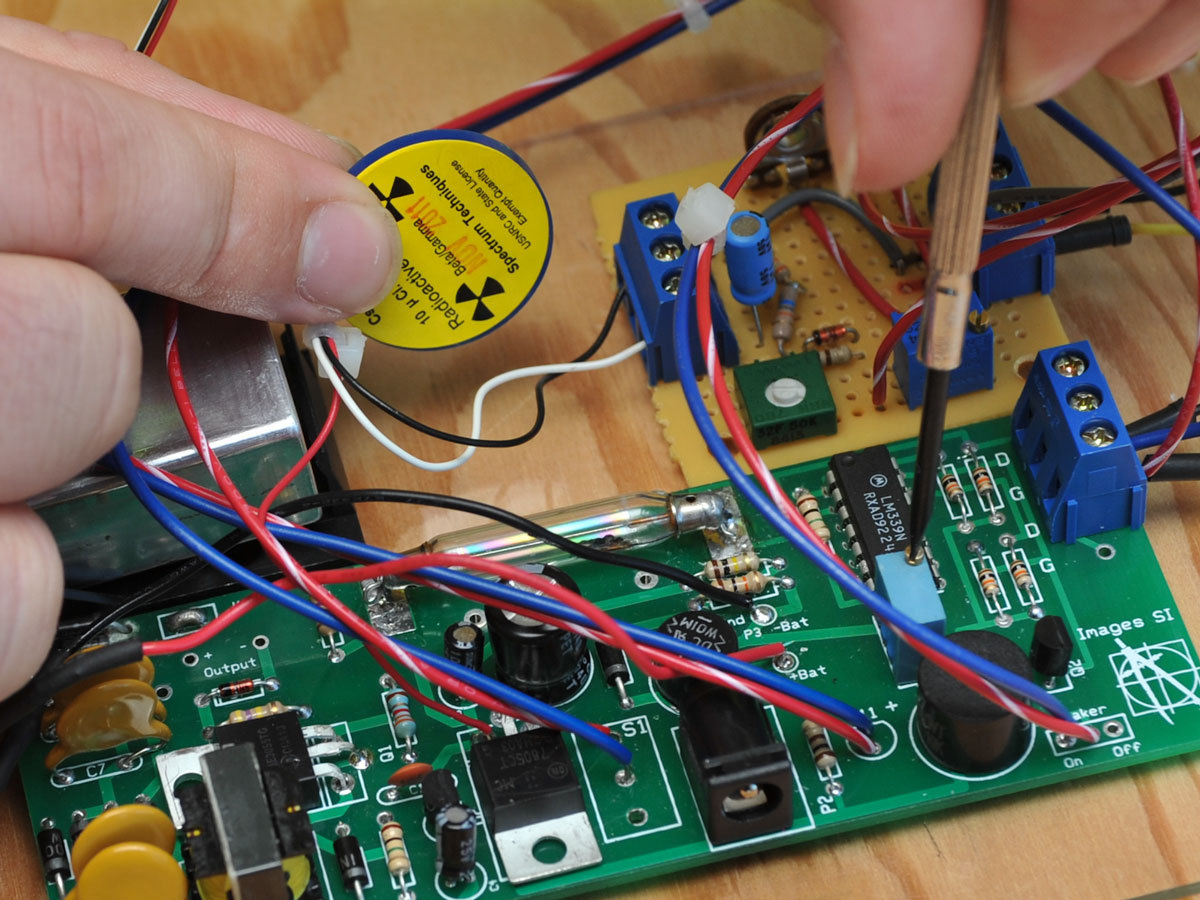

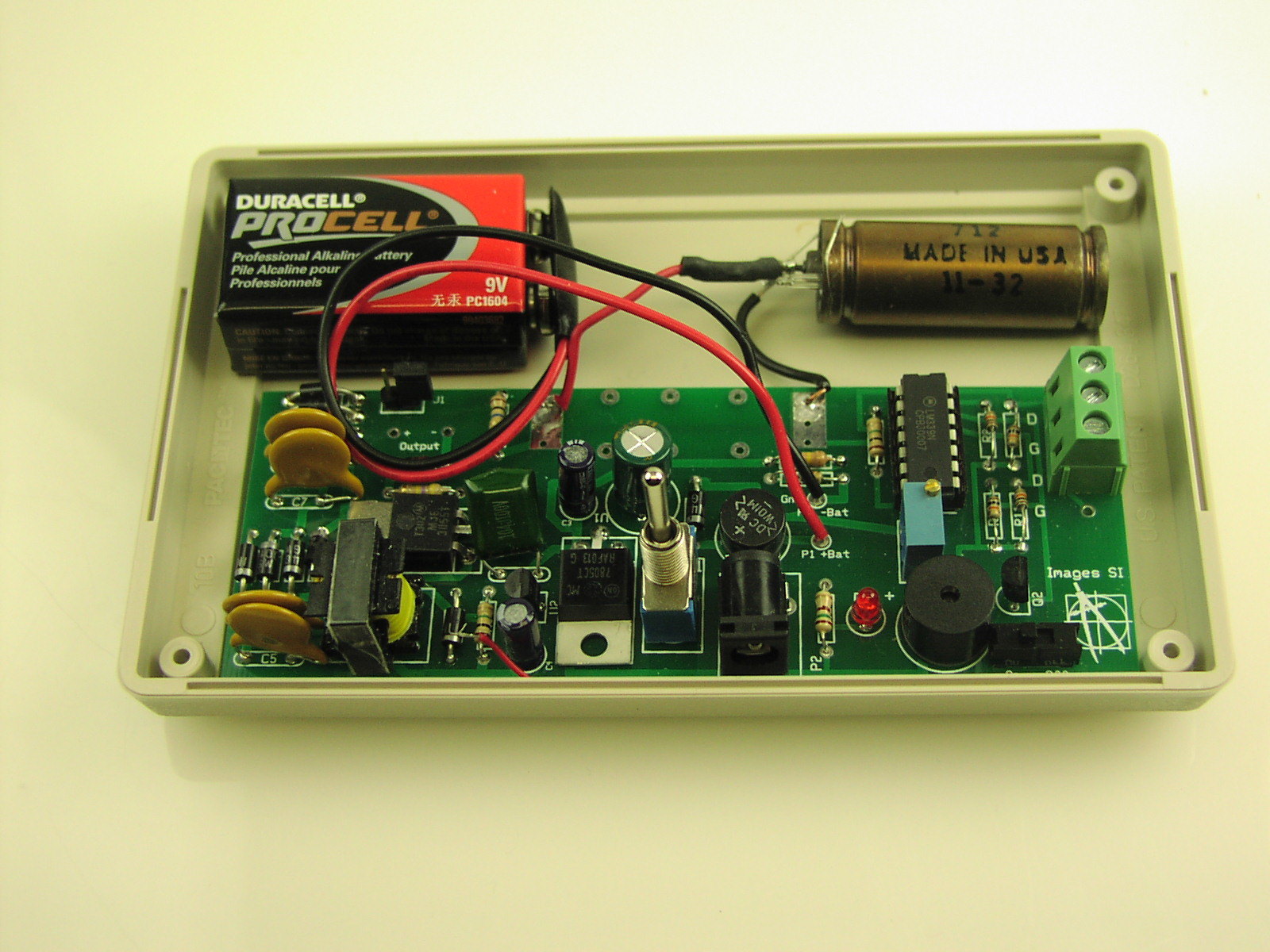

I’ve been designing, making, and selling Geiger counters for 15 years through my company, Images Scientific Instruments. They’re fundamentally simple devices; you just need voltage high enough to run the Geiger-Müller (GM) tube. Anyone can design a counter that will work somewhat, but it’s hard to make one that’s reliable and long-lasting, because the electronics are so touchy.

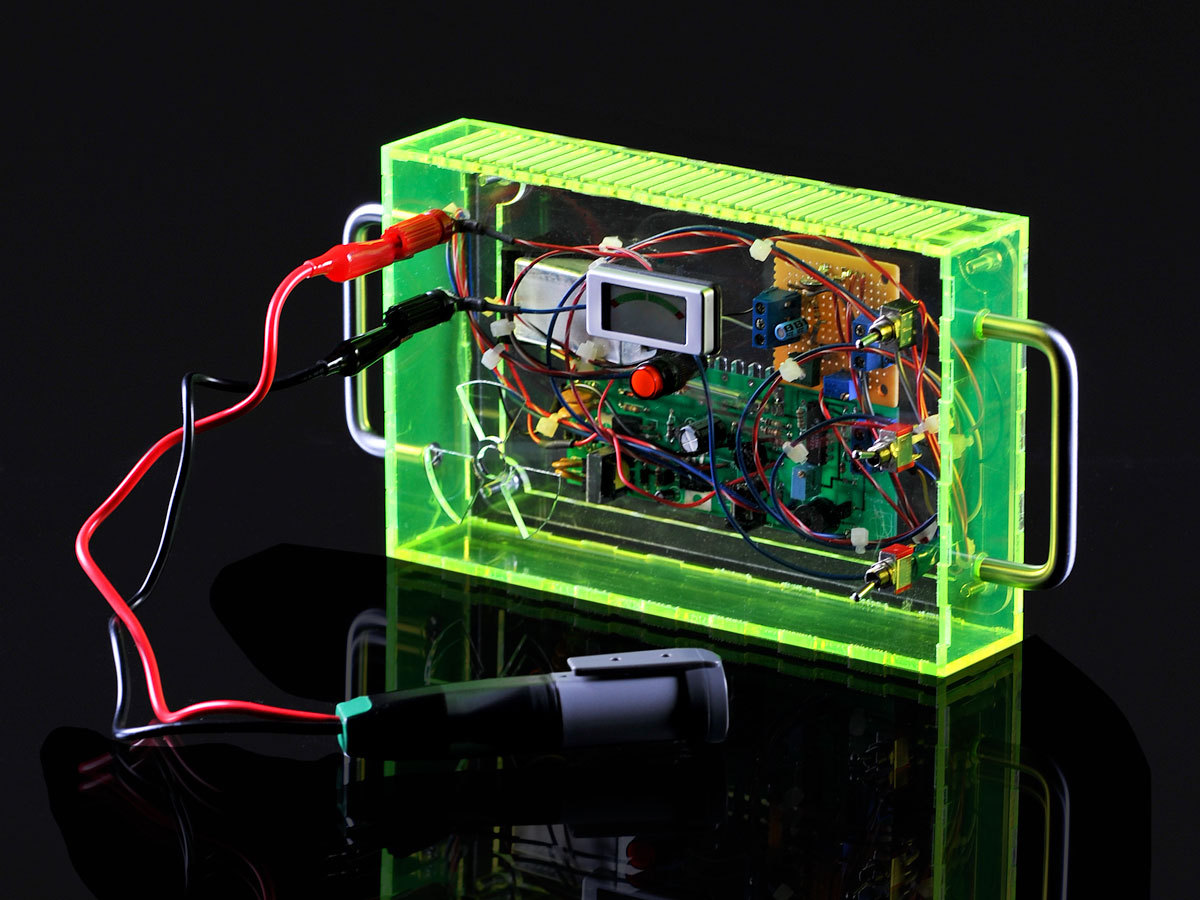

Last year I was redesigning my basic Geiger counter circuit when the earthquake, tsunami, and nuclear crisis hit Japan. We sold out immediately, and I was so swamped with orders that I had to put my improved design on hold. But I finally finished, and here it is.

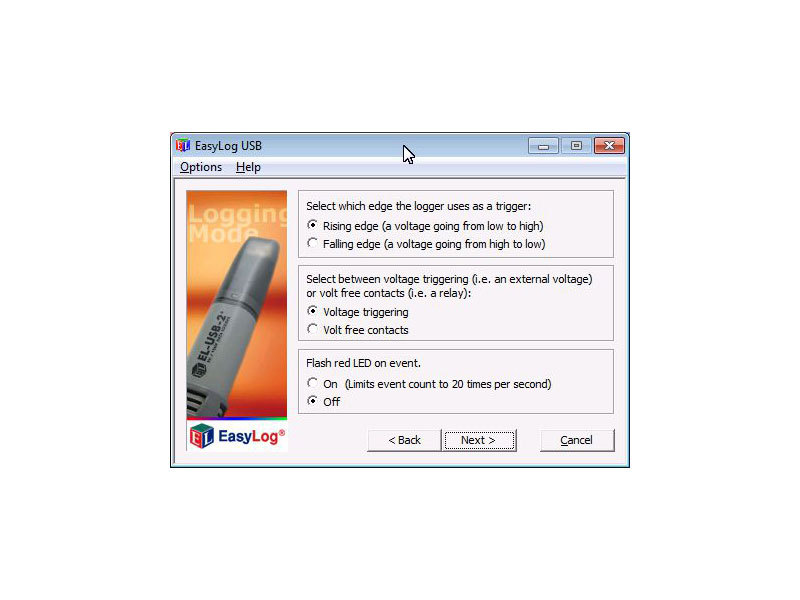

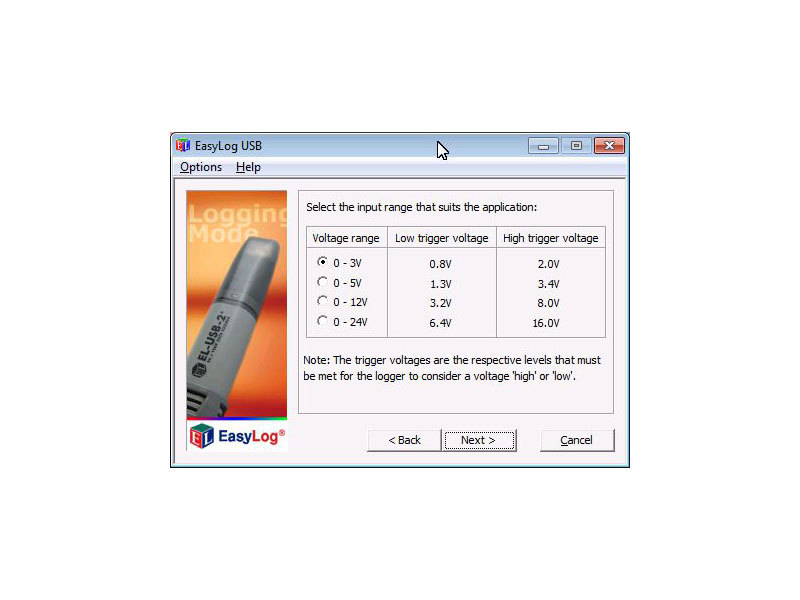

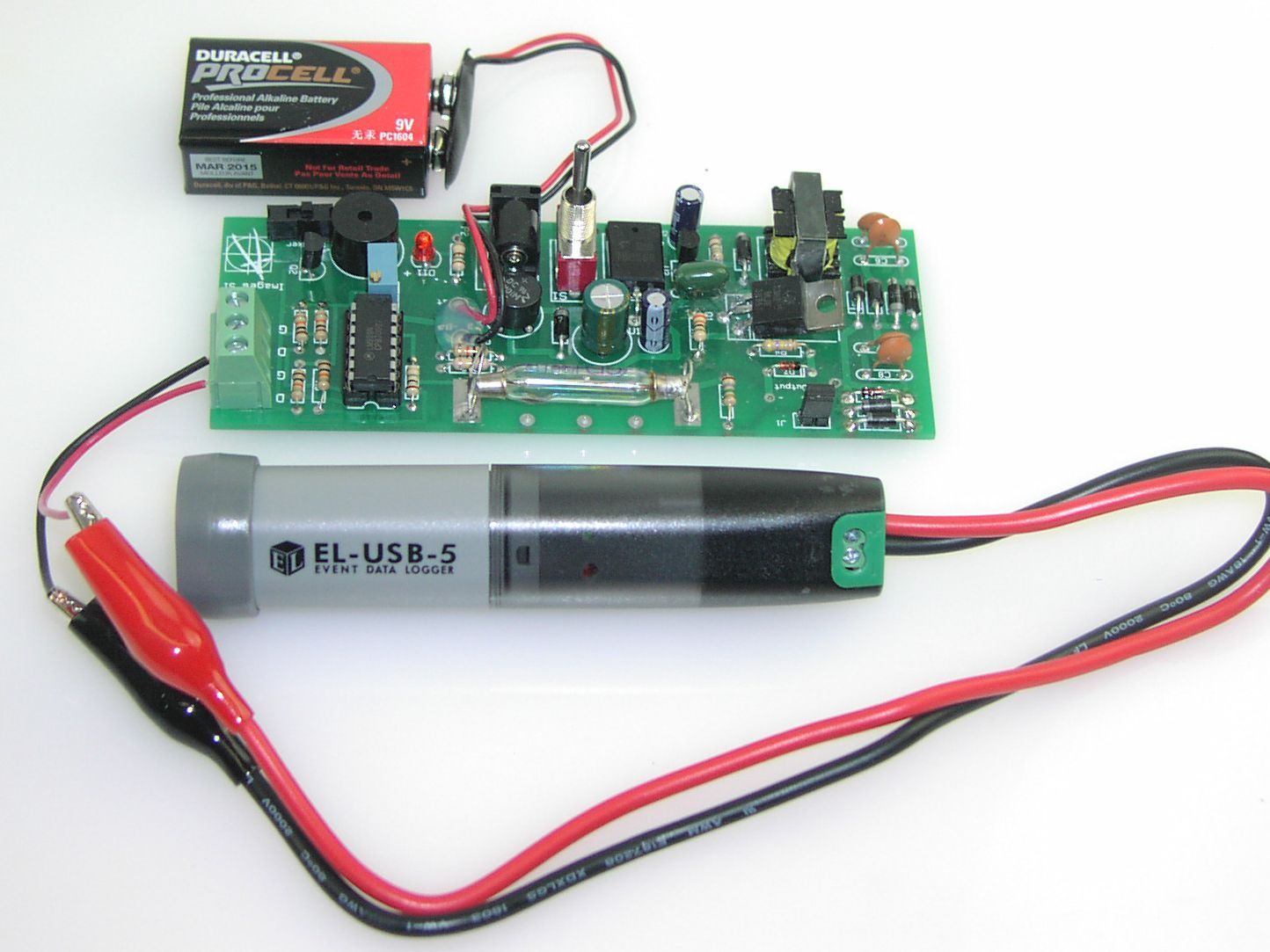

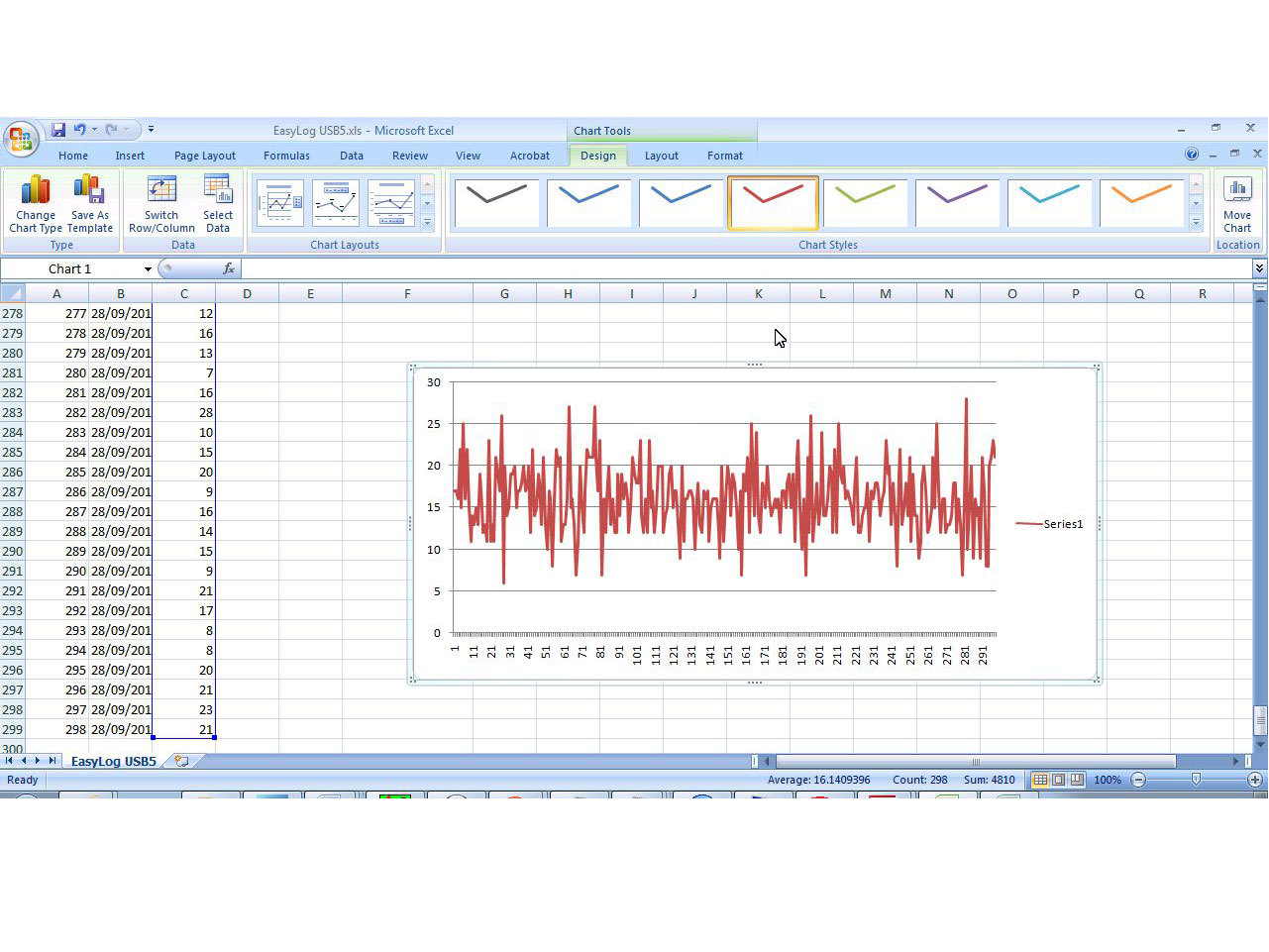

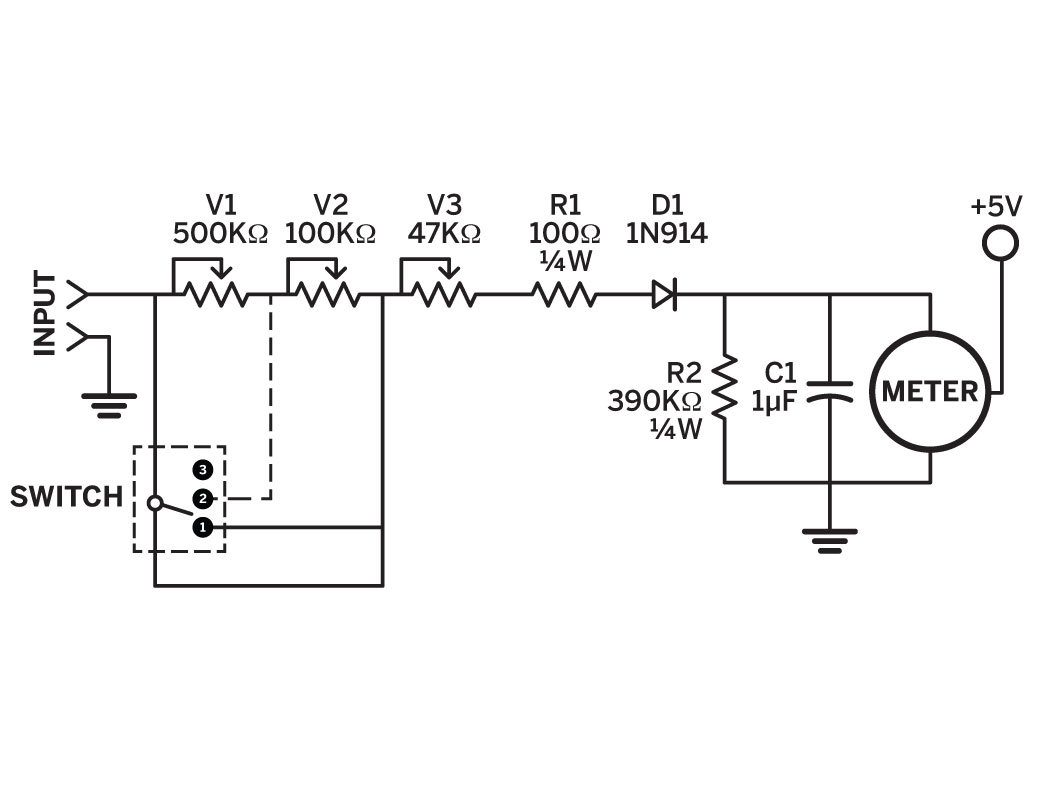

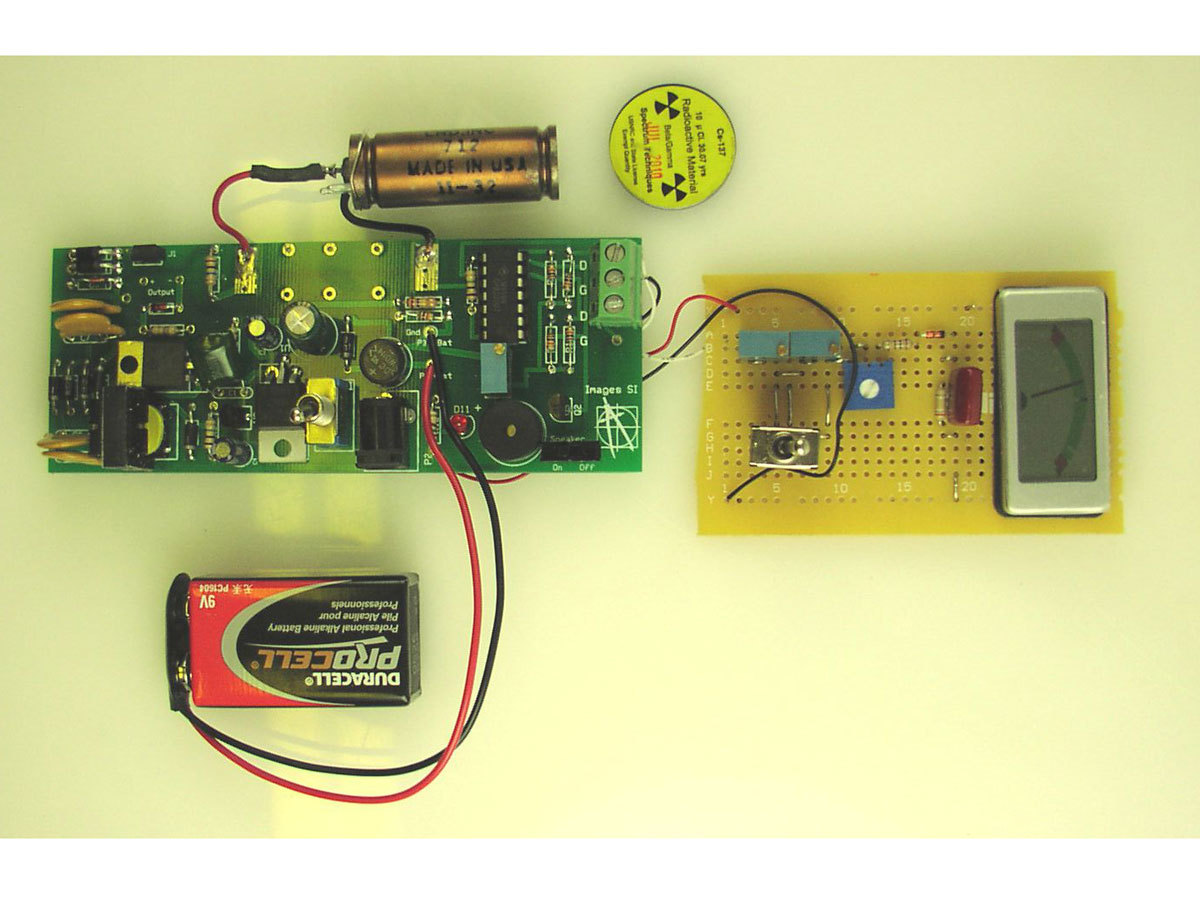

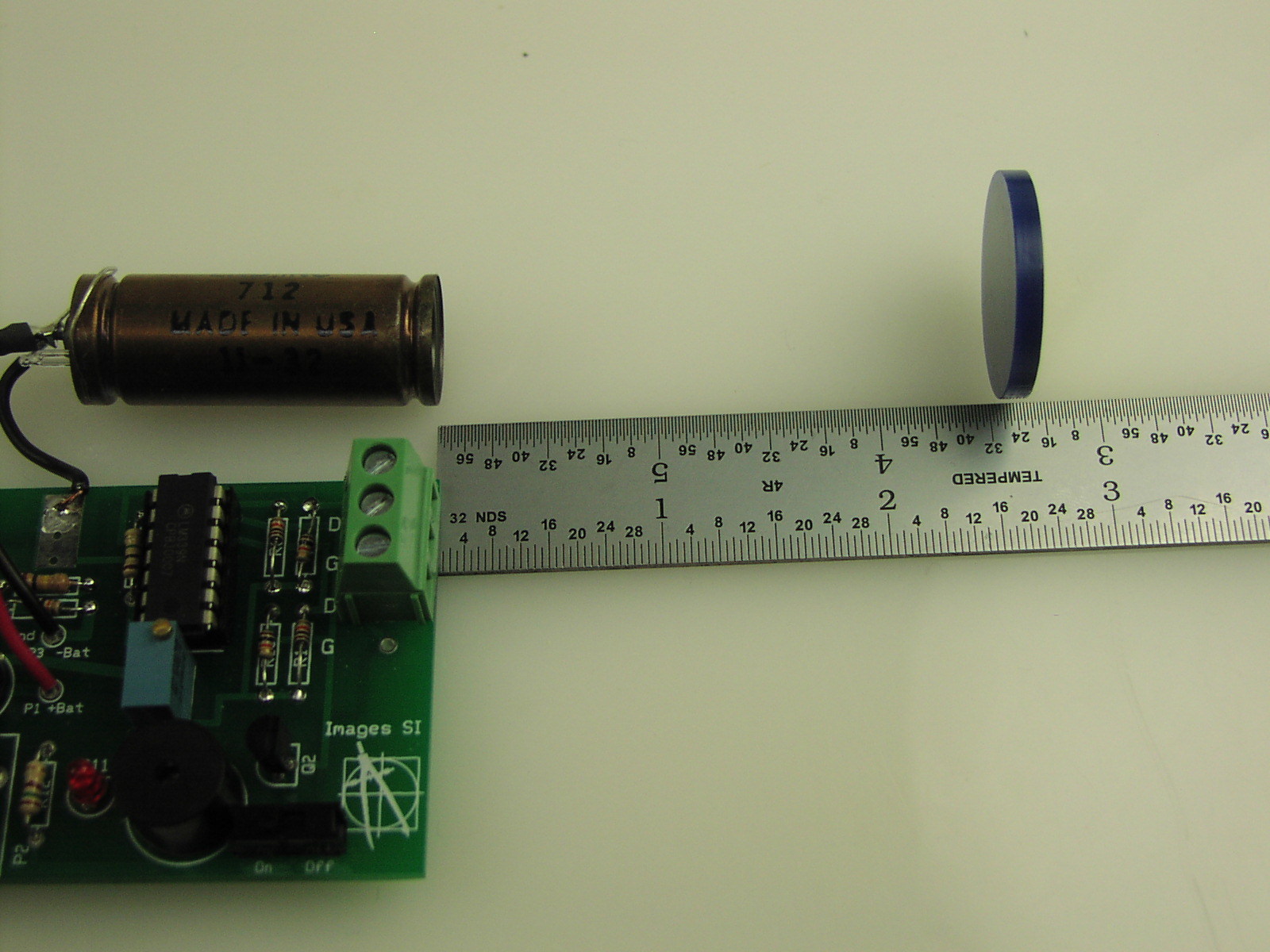

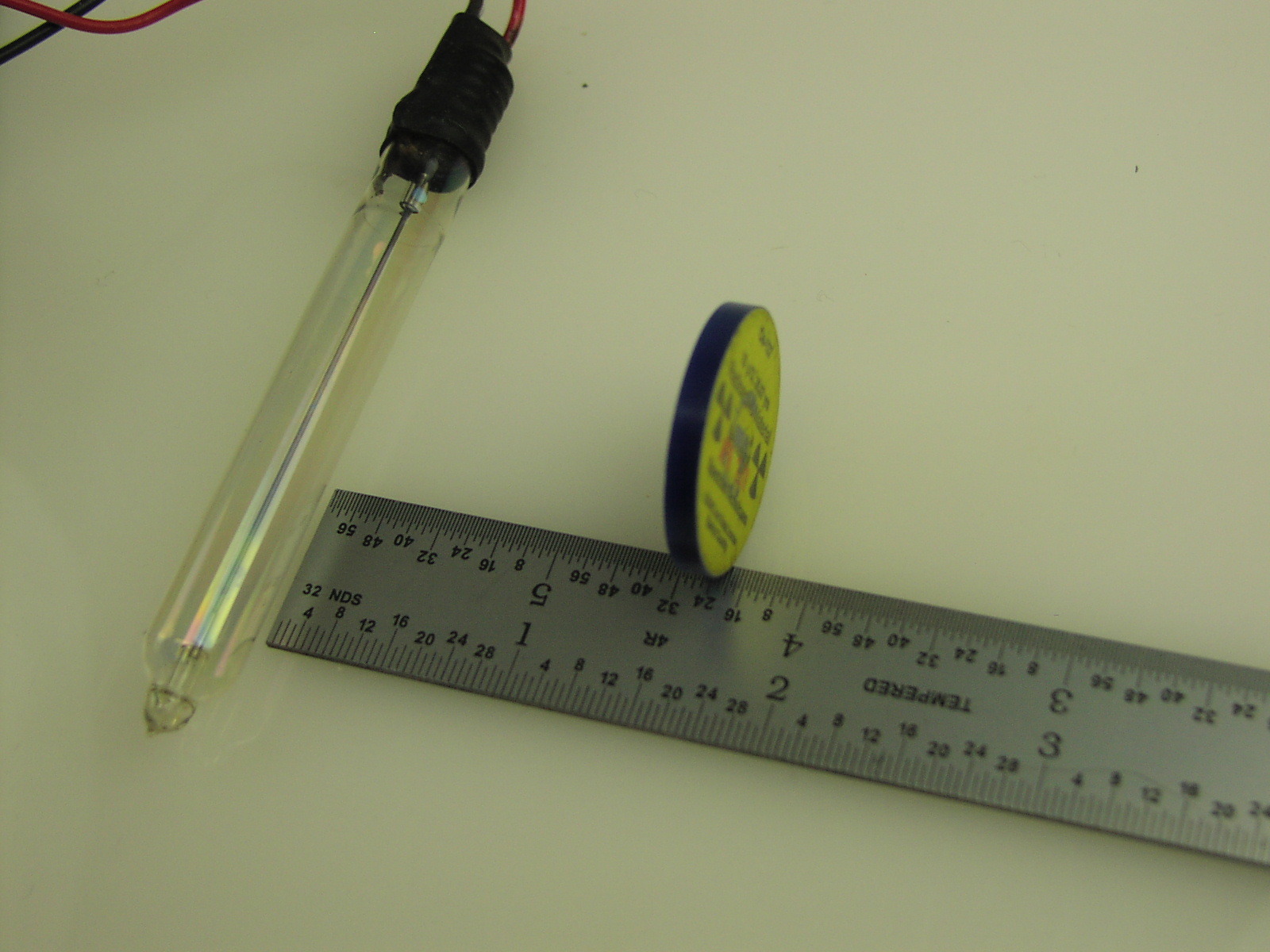

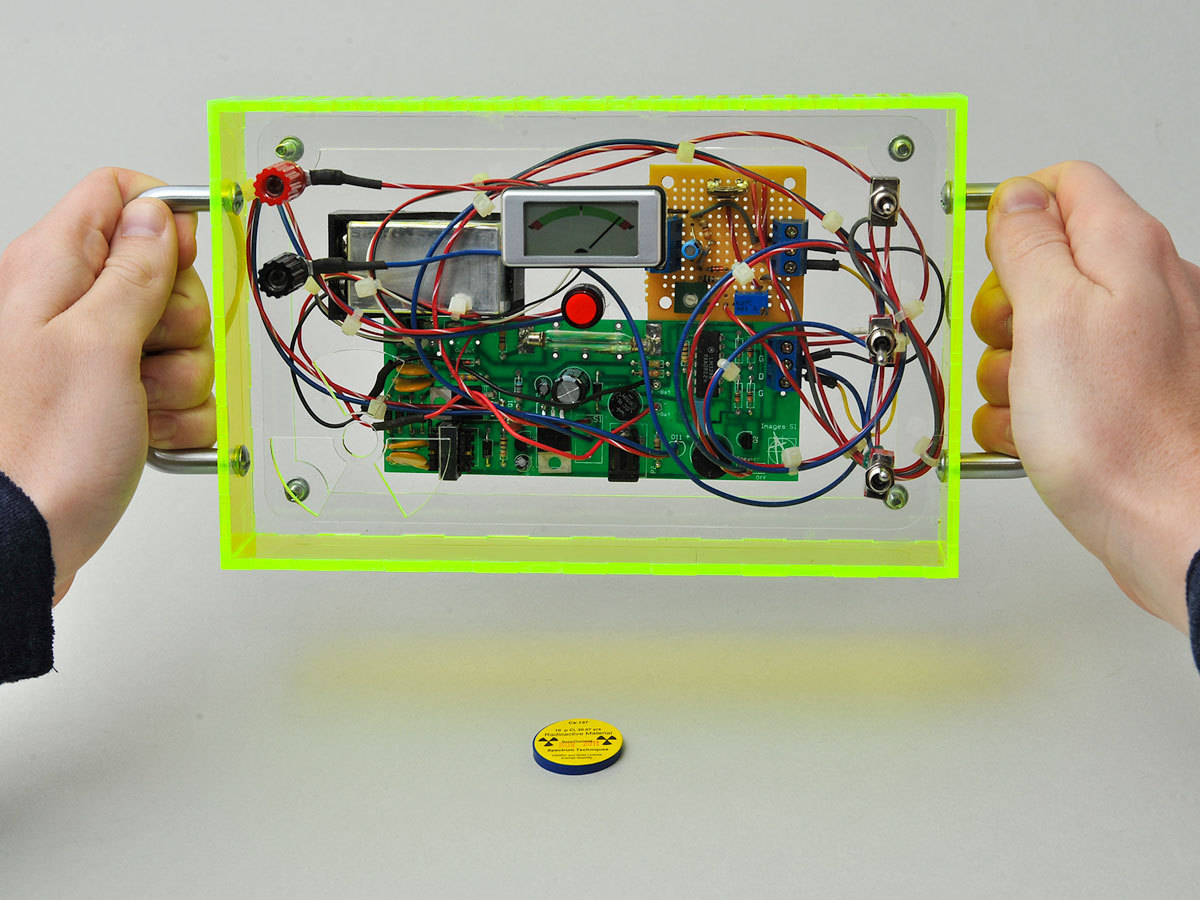

You can easily configure this counter to use a variety of GM tubes. Not only will it output a click and an LED flash with each radioactive particle detected, you can also connect it to analog or digital radiation-level meters, a PC for plotting data, a portable SD-card data logger for placing somewhere without a computer, and a true random number generator. It’s also compatible with the Radiation Network (http://radiationnetwork.com), so you can share your readings with others worldwide.