Nuclear fusion is the process of squeezing two atoms together so tightly that their nuclei fuse, creating a heavier atom and releasing a blast of energy. Fusion creates the inferno inside the sun — and the hydrogen bomb — but no one has yet harnessed its enormous power for peaceful uses.

They’ve tried, of course, with experiments ranging from massive tokamak reactors to modest laboratory setups. In 1989, physicists Martin Fleischmann and Stanley Pons announced they’d achieved “cold fusion” of hydrogen into helium at room temperature, only to face withering scorn when others failed to replicate their results.

Luckily, DIY nuclear engineers can achieve honest-to-goodness “hot fusion” right at home by making a Farnsworth-Hirsch fusion reactor, or fusor for short.

This mini fusor is a demonstration version — while it generates only insignificant quantities of fusion products, it does show how inertial electrostatic confinement (IEC) reactors use kinetic energy to cause fusion. It’s also a good introduction to high-voltage power supplies and vacuum systems. The skills the project imparts will help you tackle bigger fusors and other projects involving plasma and high-energy physics.

Plus, the fusor just looks totally cool. An eerie purple-blue glow emanates from the reactor, and a really well-made fusor can produce a mesmerizing phenomenon called a “star in a jar.”

Curious? Read on…

Warning

This project uses high voltages at potentially lethal currents. A high-vacuum apparatus may implode if improperly handled. This device may produce ultraviolet and x-ray radiation. Do not attempt to build or operate it unless you are capable of safely using high voltage and vacuum equipment.

How It Works

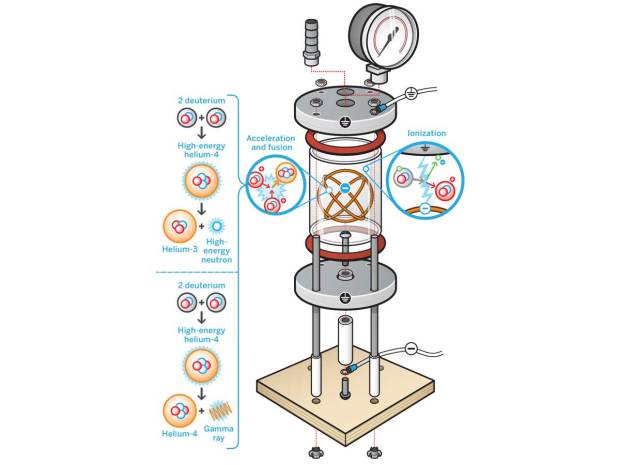

The typical Farnsworth-Hirsch fusor has two concentric electrical grids inside a vacuum chamber: an inner grid charged to a high negative potential, and an outer grid held at ground potential. Our benchtop version has a stainless steel wire inner grid, and uses the aluminum chamber walls as the outer grid.

A variac controls the AC mains voltage input to a neon sign transformer, which steps up standard 110V AC to the 10kV range. A homemade rectifier converts AC to DC power to charge the grid.

A vacuum pump evacuates the chamber to a pressure of about 0.025mm of mercury, clearing the playing field so the few remaining gas molecules can accelerate without premature low-energy collisions. A vacuum gauge indicates the pressure inside.

High voltage across the grids causes gas molecules to ionize; that is, they lose an electron and become positively charged. Electrostatic forces then accelerate the ions — mainly O2+, N2+, Ar+, and H2O+ — toward the high negative charge at the center. Some ions collide; those that miss the first time are arrested by the electric field and re-accelerated toward the center for another go.

Low-power fusors produce a beautiful purple ion plasma “glow discharge” similar to plasma globes and neon signs. In high-power fusors, the inertia of the ion collisions squeezes hydrogen atoms tight enough to fuse, hence the term inertial confinement.

High-power fusors typically fuse deuterium (D or 2H) into helium and tritium. Deuterium is a hydrogen isotope whose nucleus contains a neutron in addition to the usual single proton. It occurs naturally in very low concentrations, primarily as hydrogen deuteride (HD) but also as “heavy water” (D2O), “semiheavy water” (HDO), and deuterium gas (D2). Only 1 in 6,000 hydrogen atoms is deuterium. Tritium (a hydrogen atom with two neutrons and one proton) is even rarer.

When two deuterium atoms fuse they create a high-energy helium-4 atom, which stabilizes itself by releasing a proton, a neutron, or a gamma ray. This release leaves behind a tritium atom, helium-3 atom, or helium-4 atom, respectively.

Fusor Nation

The fusor was developed in the 1960s by Philo T. Farnsworth, who also invented television. It’s popular with DIY experi-menters because it’s easy to build and can reliably produce fusion reactions.

Fusors have yet to produce useful power, but they can be dangerous. They require high voltages and can produce harmful ultraviolet, x-ray, gamma, and free neutron radiation.

IEC reactors are currently being studied at MIT, the University of Wisconsin-Madison, University of Illinois, Los Alamos National Laboratory, and EMC Corporation, among other labs.