There are billions of triacs in the world. In almost every lamp dimmer, every electric stove, and many motor controllers, power is moderated by a triac clipping a portion of each positive and negative AC pulse.

When I started writing about this ubiquitous semiconductor for the second volume of my Encyclopedia of Electronic Components, I didn’t expect to find much new to say. After all, the triac was invented more than 50 years ago. Imagine my surprise when I realized that it could have some low-voltage DC applications. Why, it could even be controlled by an Arduino! That was when I decided that a triac and myself should get personally acquainted.

Testing, Testing …

By combining five segments of silicon, the triac achieves some unexpected capabilities. Like a transistor, it switches current. Unlike a transistor, it doesn’t discriminate between positive and negative. You can run electrons through it in either direction, and it won’t mind at all. Likewise, it will respond to either forward or negative bias on its gate terminal. It’s also “regenerative,” continuing to pass current even after the gate bias is removed.

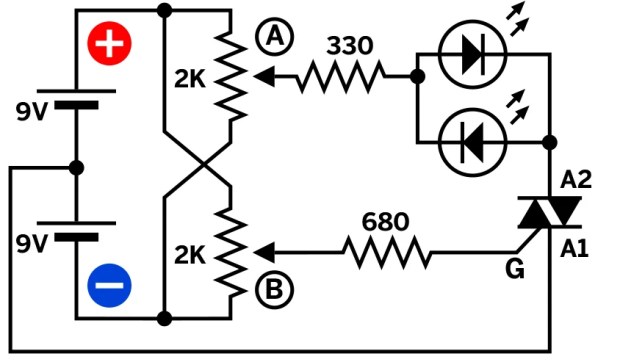

Sometimes the triangles in the symbol have open centers, and the symbol may be flipped or rotated. These variations make no difference. The gate is labeled G, while the main input/output terminals are labeled A1 and A2 (or sometimes T1 and T2, or MT1 and MT2). If the terminals are not identified in a schematic, A1 is always the one nearest to the gate, and gate voltage is always measured relative to A1.

So long as the gate has the same potential as A1, the triac blocks current in both directions. When the gate voltage swings higher or lower than A1, the triac will conduct current either way. Above a level known as the latching current, the flow will continue even if the gate voltage drops to zero. The flow continues till it falls below a level known as the holding current. These parameters are listed as IL and IH in triac datasheets.

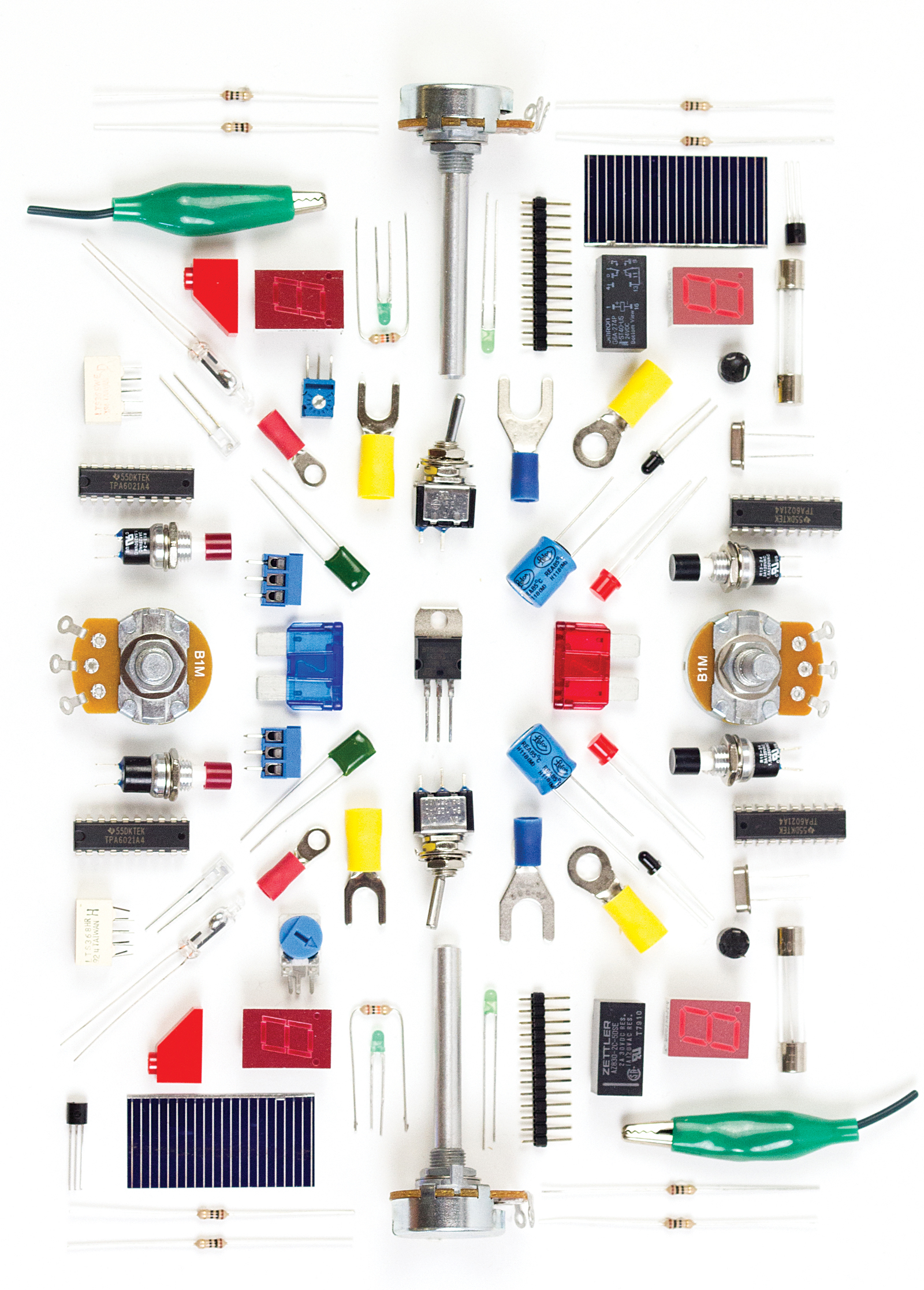

A test circuit can be safely breadboarded, because although triacs are intended to work with 110VAC or higher, many will function with 12VDC or less, and can switch LEDs instead of light bulbs. I chose the BTB04-600SL because it will pass up to 4A of AC but can be triggered by as little as 10mA at 2VDC. Many triacs have similar specifications.

To provide positive and negative current, I used a pair of 9V batteries. You can substitute a split power supply if you have one. A 2K trimmer labeled “A” in the schematic applies a voltage ranging between +9V to –9V through a 330Ω resistor and a pair of LEDs to terminal A2 of the triac. Your LEDs should be rated for at least 20mA forward current. They are oriented with opposite polarities, to show which way current is flowing.

A second 2K trimmer, labeled “B,” applies +9V to –9V through a 680Ω resistor to the gate terminal. The resistor values were chosen to provide just enough gate current and latching current without burning out the LEDs.

Set both trimmers midway through their ranges, and connect the power. Turn trimmer “A” all the way toward the positive end of its range, and nothing happens yet, because trimmer “B” is applying neutral voltage to the gate. Now turn “B” either way, to apply positive or negative gate bias, and the triac will start passing current, lighting the top LED.

Things get interesting when you turn trimmer “B” back to its neutral position. This deprives the triac of gate voltage, but it still keeps conducting, because the 20mA passing through it is just above its latching current. You can even unplug trimmer “B,” and it makes no difference.

If the triac remains conductive with no gate voltage at all — how can we stop it? Simply turn trimmer “A” slowly back toward its neutral position, and when the current into terminal A2 drops below 10mA, the LED goes out.

If you repeat this test with trimmer “A” supplying –9VDC instead of +9VDC, the other LED will light up. It may not behave in exactly the same way as the first LED, because the triac’s response is not completely symmetrical.

What Next?

The triac is a latching device, which makes it ideal for pushbutton activation. Send a pulse to the gate, and a motor powered through the triac will start running, and keep running. You can stop it by interrupting the power supply, or by bypassing the triac briefly to zero-out the potential between its main terminals. Add an appropriately wired DPDT switch, and your start button can make a 12VDC motor run forward or in reverse.

Try it yourself using the circuit above. It runs a motor, stops it automatically, and reverses it, all from a single button-press.

Pushbutton S2 energizes the triac, which starts the motor turning. At the end of its arc of rotation, a cam closes a limit switch (S3 or S4), which flips a latching relay (S1) to reverse the power. Most relays break one contact an instant before making the other. That hiatus without current will be sufficient to switch off the triac, which cuts power to the motor. The motor will stop a little way past the limit switch, so that the switch does not waste power continuing to energize the relay coil. When the triac is triggered again by S2, the motor now turns in the opposite direction. S5 will stop the triac at any point by bypassing it briefly, while S2 will restart it.

Some people like to trick out their cars with motors that open the hood or the trunk or do similar stunts. This circuit would be well suited to that application. Similarly, linear actuators, such as those sold by Firgelli, can operate gadgets in the home like drapes that open or close or an entertainment center that emerges from inside a cabinet. Often these motors require 12VDC, which can be provided by cheap AC adapters designed for laptop computers. Here again a triac could be used for motor control.

Another possible application would be a “panic button” to stop a motor by interrupting power through a triac, in a battery-powered device such as a robot.

Lastly, because the gate of a triac only requires a few mA, it can be activated by a microcontroller. Check your triac’s datasheet; it’s probably Arduino-compatible.

For too many years, this quirky semiconductor has been ignored. What other applications could it have? Let your imagination be the limit switch.