Five years ago we built our first book scanner from salvage and scrap. Book digitization was the domain of giants — Microsoft and Google. Commercial book scanners cost as much as a small car. Unless you chose to destroy your books in sheet-feed or flatbed scanners, there was no safe and affordable way to preserve the contents of your bookshelf on your e-reader.

Collectively, we tried to fix that. Over 2,000 people contributed more than 350 designs and thousands of lines of code at diybookscanner.org.

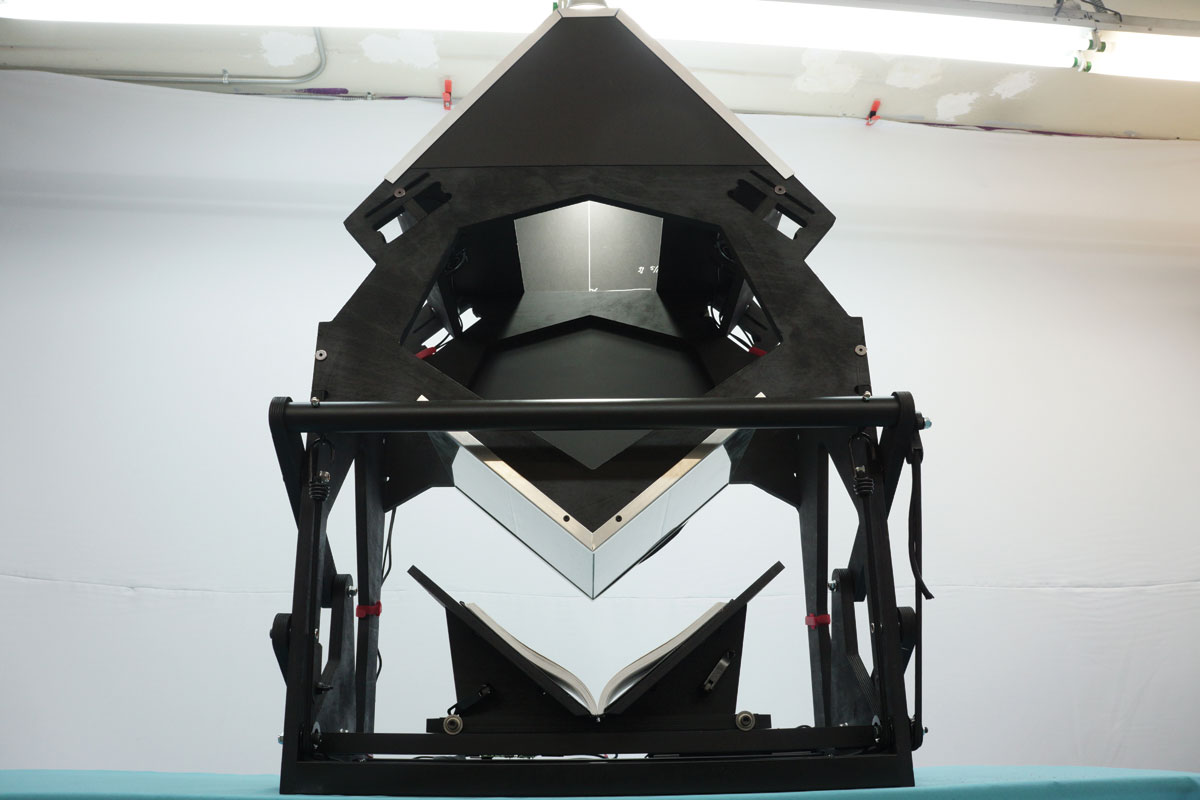

The result is the Archivist — the VW Beetle of book scanners — cheap, durable, and tremendously effective. It’s open source and made with the simplest materials possible, like plywood, bungees, and skateboard bearings. As fast as you can turn the pages, the Archivist photographs them automatically and creates a zip file of the entire book, for conversion to the e-book format of your choice.

Here’s how you can make your own. We want to see one in every community, starting with hackerspaces. This document shows you how to put together the Archivist kit, which has some nice features that are a little tough to DIY; where appropriate, we’ll fill in DIY approaches.

How DIY book scanning works:

- Lighting — Cheap cameras need a lot of light, and post-processing is easier if the light is bright and uniform.

- Camera support — Cameras need to be placed opposite the page. Post-processing is vastly easier if the cameras don’t move.

- Platen — The “page flattener.” It’s a V-shaped construction of glass or acrylic. Flat pages are easier to process — in fact they’re usable with no post-processing. (Good input equals good output!)

- Cradle — Holds the book, gently, and accommodates the spine of the book.

- Base — Holds all the other stuff together.

- Electronics — Many of us build a simple system to trigger our cameras electronically using Stereo Data Maker software. The new Archivist system has an onboard Raspberry Pi running software called Spreads to operate two Canon point-and-shoot cameras (updated with Canon Hacks Development Kit firmware) and then sends the zipped images to your computer. Spreads even has a web interface so you can control your book scanning from any smartphone or tablet.