When the Star Wars: The Force Awakens trailer was released, the internet was buzzing about this new round droid.

With a renewed interest in practical effects, our curiosity was piqued. “Are they going to actually make one?” This question was answered at the Star Wars Celebration. Our curiosity became an obsession as we watched BB-8 roll around and size up R2-D2. The ball droid was real, and hackers and Makers around the world thought they had the answer as to how it worked. Concept art, 3D prints, and prototypes started popping up on YouTube and we knew we had to throw our hat into the ring.

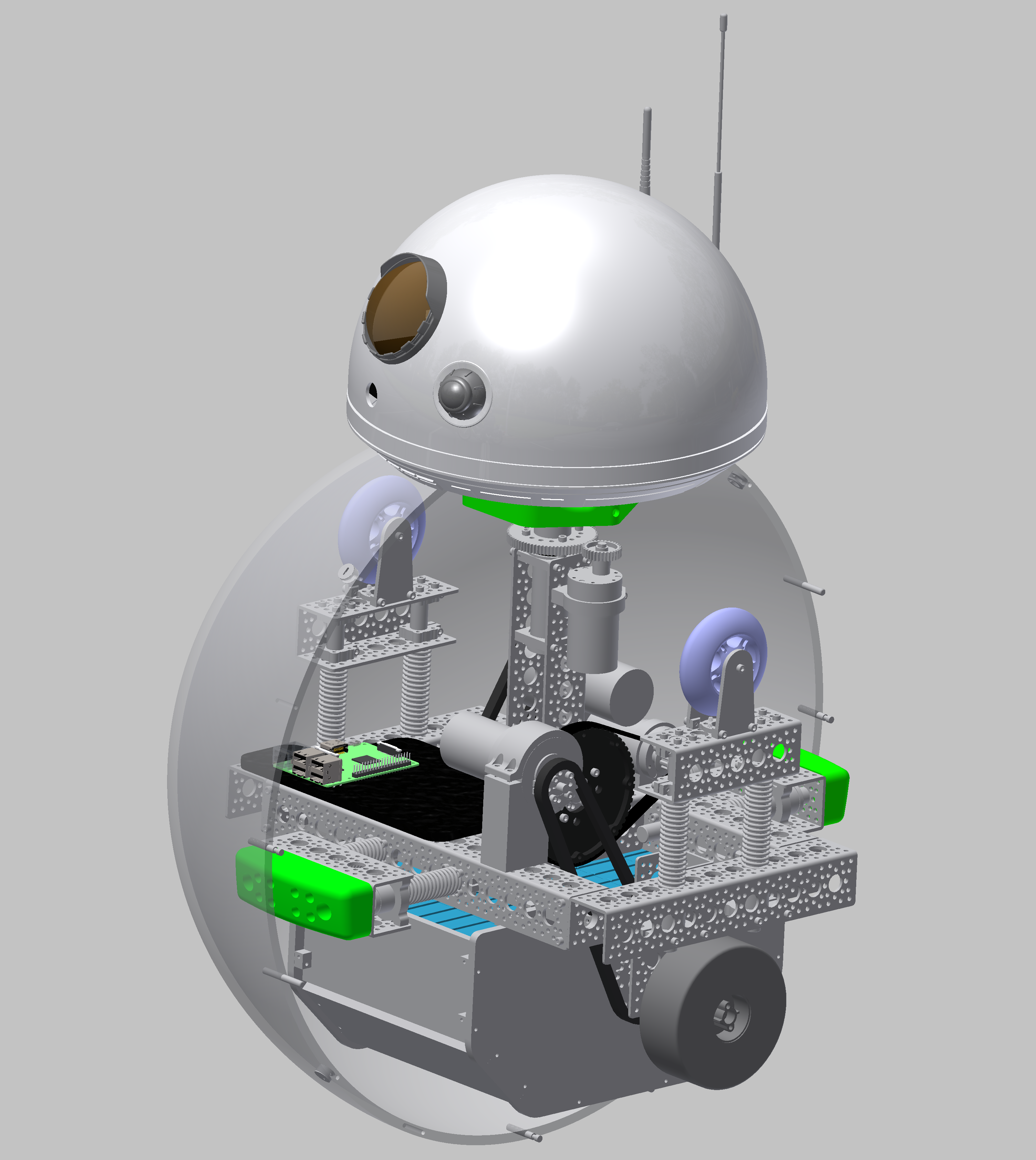

Since there are others trying to crack the BB-8 we wanted to work quickly on our proposed solution. With the help of ServoCity and their online CAD models, we quickly leveraged the Actobotics line to build the inner structure. For some of the detail pieces and internal components, we turned to 3D printing to give us quick results. The Loveland CreatorSpace provided us a base camp and excellent resources to complete this build.

The inspiration for our mechanical build was the Sphero. We had a hunch when the first videos were released that Sphero was involved somehow. We popped one open and began to replicate the mechanism. To add the head and motion we took cues from an older Sphero model. The original Sphero has a singular upper support, whereas Sphero 2.0 has two passive upper wheels to main-tain support. Our design combines aspects of both, using upper wheels for stability and a central support to attach the head via magnets.

The shell is 2 custom-molded ⅜”-thick polycarbonate hemispheres. We decided to go this route to ensure roundness, strength, and enough thickness to mount LEDs in the moving shell.

The team behind our build consists of four Makers with a shared passion for robotics and Star Wars alike, and their obligatory dog companion. I was responsible for the mechanism that brings the BB-8 to life. Pamela Cortez, another SparkFun engineer, developed the brains of the droid, which consist of Raspberry Pi and Sphero. She also focused on giving our BB-8 a voice, which includes some Easter egg sounds from your other favorite droids! The aesthetics of the robot, including the floating head and movie-worthy details, were applied by Allison Cavis and Maurice Woods, two artists-turned-engineers whose sculpting and casting experience make the droid’s appearance unmistakable.