Last year my 13-year-old daughter asked for a skateboard, so I gave her my 20-year-old board (which wasn’t seeing much use). She liked to ride it along the bank of the Los Angeles River, and I would ride with her on a Razor scooter. But after a while, I started to miss having a skateboard, and I thought it would be fun to make one.

I put it off for a few months, until I saw a video of Lloyd Kahn, the well-known maker and former geodesic dome guru, cruising down a gently sloped street (makezine.com/go/kahn). He’s 75 years old, and his skating skills are top-notch. This was the inspiration I needed to get off my butt and make my own longboard.

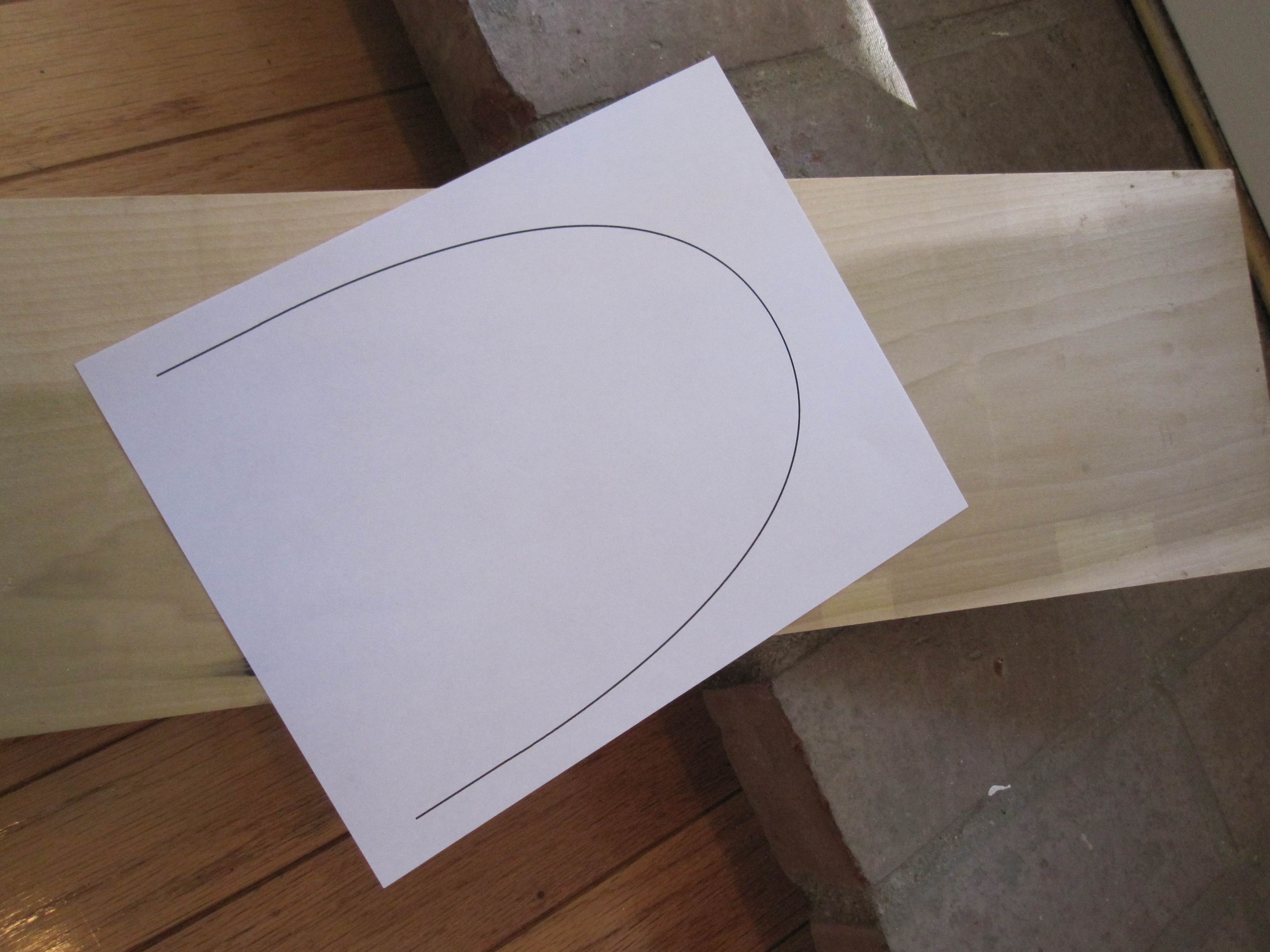

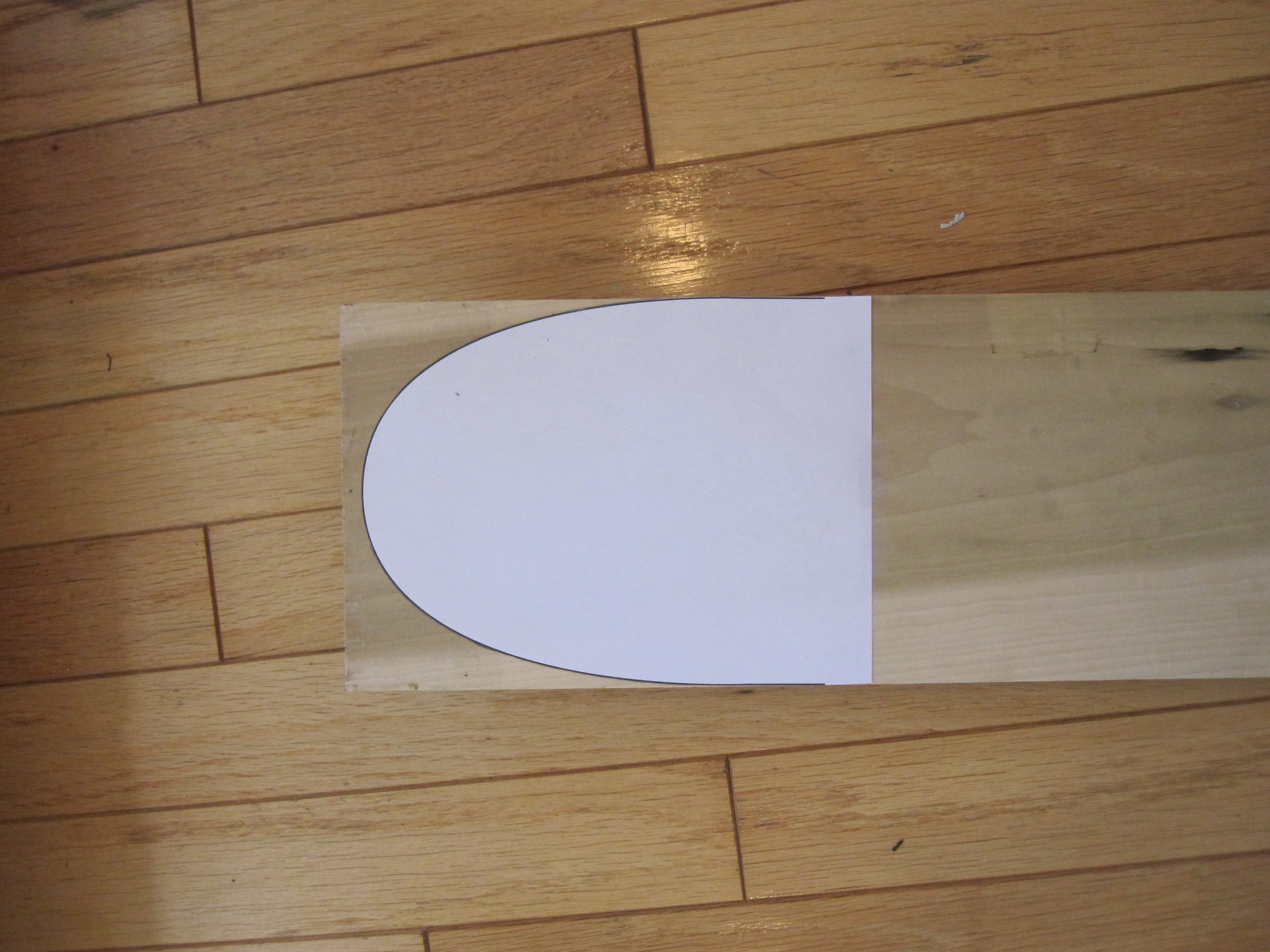

I went online to look for plans. There are many plans and kits available, but they seemed overly complex for what I was setting out to do. I simply wanted a 4-foot-long board that wouldn’t sag too much when I stood in the middle of it. My solution was to make a board with a hump in it.

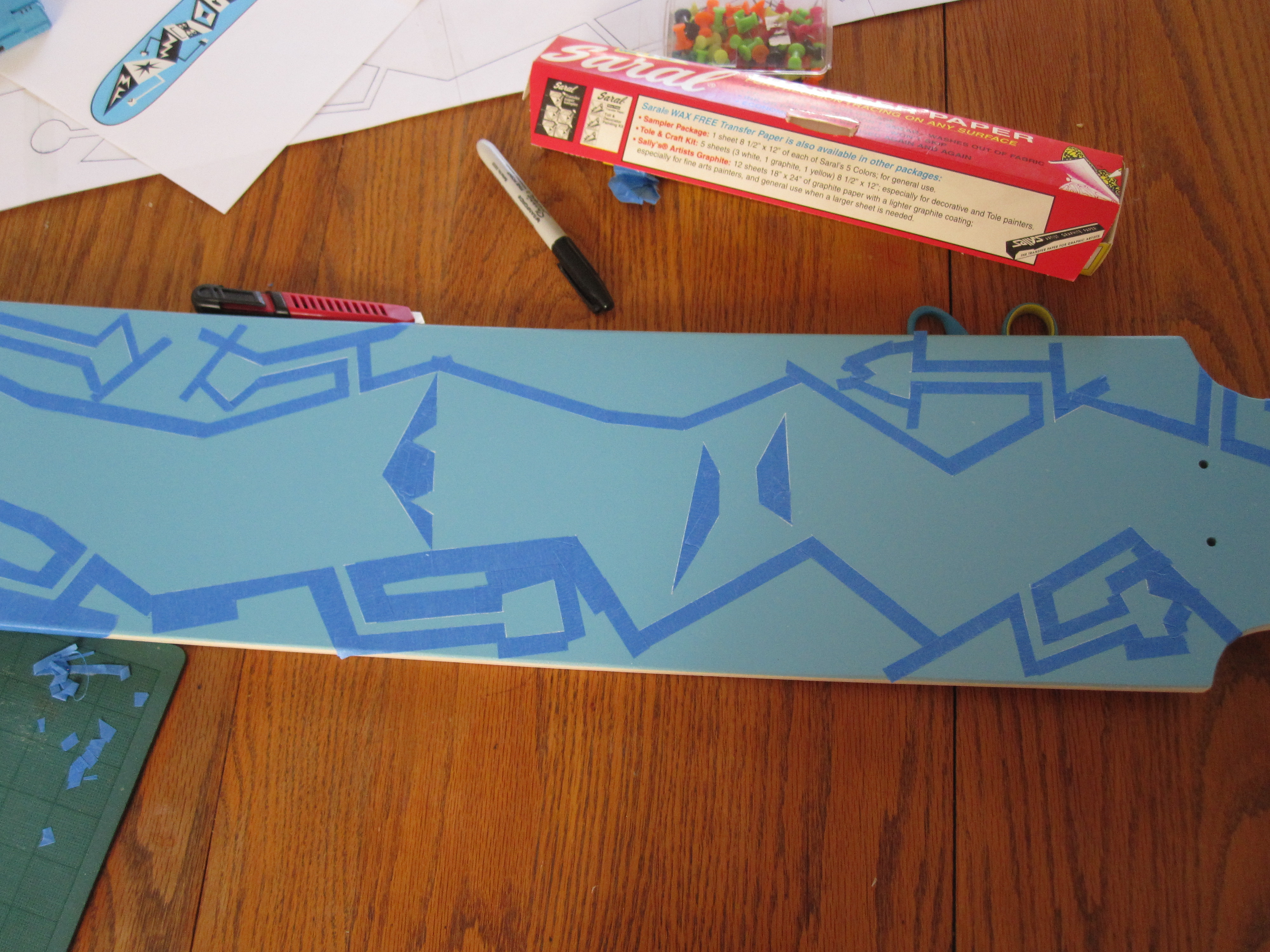

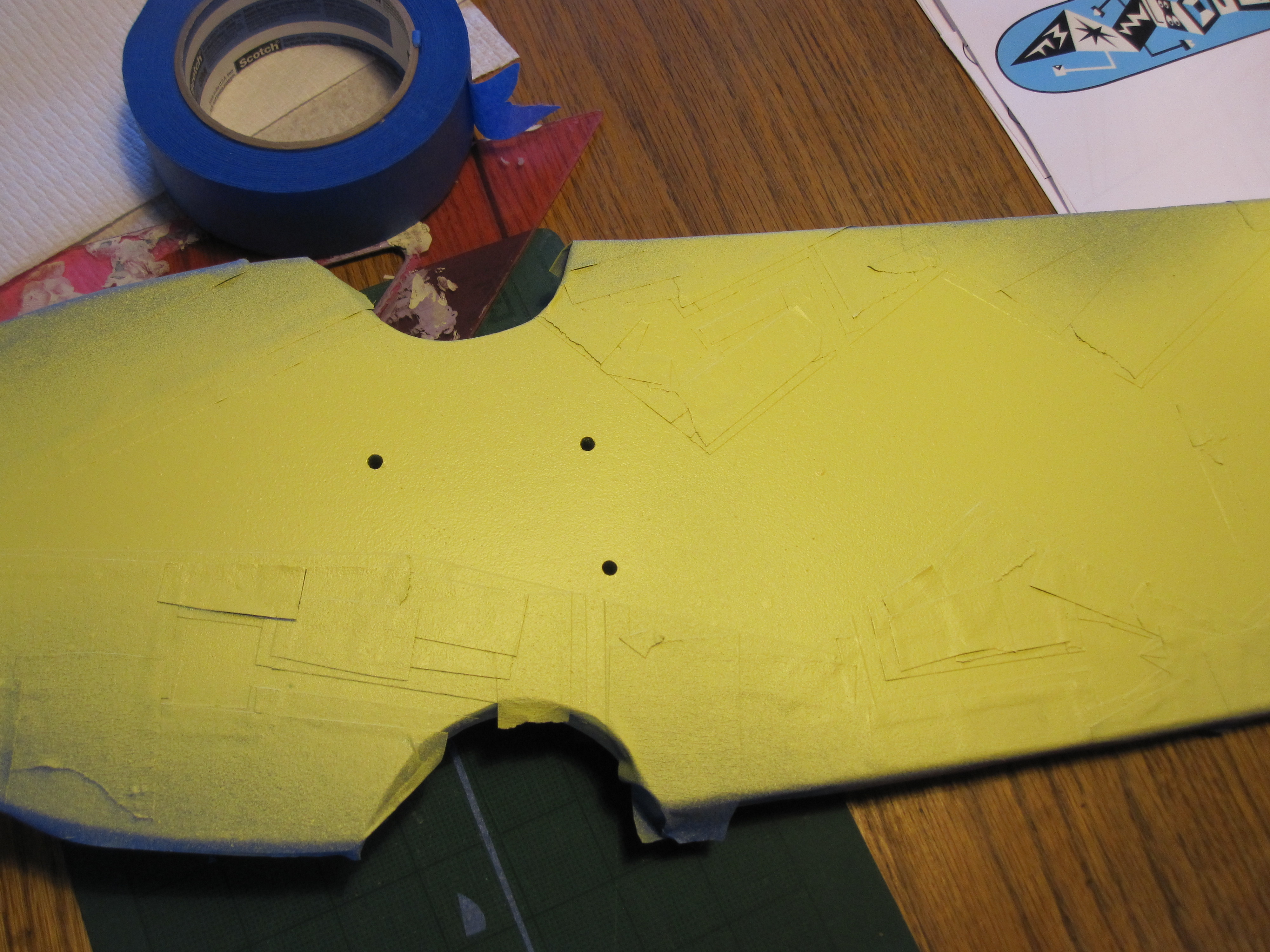

Here’s how I did it.