A step up from that design is the “treadle” wheel, which adds a crank and reciprocating pedal for greater mechanical advantage and smoother operation. And among designs for treadle wheels, the “Leach” type stands out as a popular favorite. In the embedded video, potter David Berg demonstrates the action of a Leach-type treadle wheel and gives a bit of background on its history.

Named for famed English studio potter Bernard Leach (Wikipedia), the Leach treadle wheel was in fact designed by his sons. Bernard’s grandson Simon Leach is a renowned studio potter and teacher of pottery, and still uses and actively promotes the Leach treadle wheel design in his work. They are expensive to buy, but the plans and design details are widely known and shared:

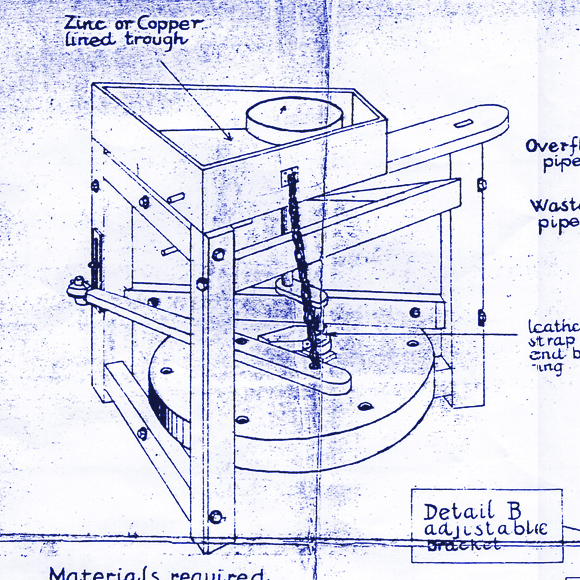

- This set of scanned, hand-drawn plans hosted on a Duke University server is of unknown provenance, as far as I can tell, but is mentioned favorably in DIY wheel threads on several online pottery forums.

- Potter Lloyd Cledwyn hosts a site dedicated to the Leach treadle wheel, including photos of an original wheel, a high resolution scan of some early blueprints, and some nice original assembly illustrations.

- Simon Leach himself has published a large photo gallery meticulously documenting the construction of his newly-commissioned treadle wheels. Simon’s YouTube channel is also a great source of information, and features several clips detailing the assembly, history, and operation of the Leach wheel.

Though I haven’t seen any detailed step-by-step tutorials, plenty of information is available, between and among the various other online resources, for potters who want to build a Leach wheel for themselves. This one, from Pittsburgh artist Dan Matuschek, is a nice example. [Thanks, Barry!]

ADVERTISEMENT