Innovation happens anywhere, anytime, with anything. Sometimes, you don’t need a bunch of expensive tools or multi-syllable equipment to engineer the ultimate mixture of art and science. Sometimes, you only need imagination and a few Legos … Well, those and one highly accomplished Lego builder.

Last spring I commissioned 3D Systems’ Brian Cooper to create a masterpiece made completely of Legos. An MIT graduate and software engineer, Brian (aka “Klaupacius”) is known in the Lego community for building uniquely large, gear-articulated robot models, and his instructional e-book, “Teknomeka,” has helped people build big all over the world. You can see his handiwork in Lego shows as well as in TV and movies.

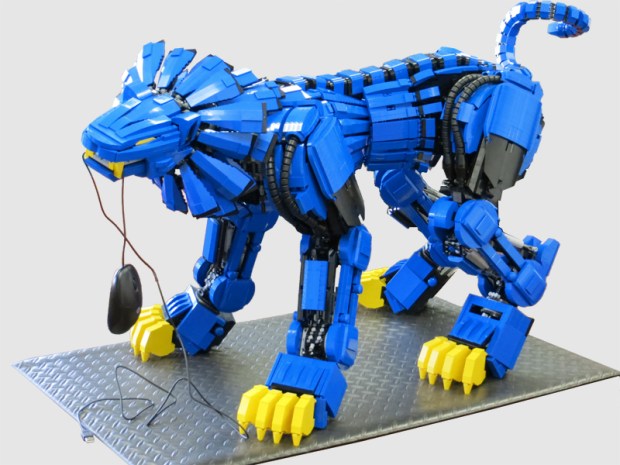

After a year, he produced an amazing blue cat named Geo. It’s a testament to how far imagination can take you. I’d like to turn it over to Brian to give us the scoop on how he made this incredible creation.

Geo – DAC

I build two types of Lego robots: “real” robots (motorized and controlled via on-board computer or remote control) and “fantasy” robots (poseable with manually operated mechanisms). My real robots are more utilitarian, since stylistic bits tend to get broken when a robot runs amok. My fantasy robots are meant to be posed and displayed at conventions (www.BrickCon.org), so I invest as much time in their appearance as their inner mechanisms. The fantasy robots also mandate a back story to explain their existence. With this in mind, I give you Geo’s story:

Geo is a Durable Animoid Companion (DAC) from a future time where robot pets have mostly replaced animal pets. They mimic all desirable pet behaviors, in addition to providing security and maintenance functions in the home. They have simulated neural networks and can develop a unique interactive bond with their owner that lasts a lifetime.

Reference Material

I built a Lego bee once, and in doing so I realized that the two rear legs needed to be longer and point backwards to balance the body. You have to learn as you go, because you don’t realize how vague your mental image of an animal’s mechanical structure is until you try to build one. Making Geo was no exception. I had to ask questions, like what does a cat’s hind leg really look like under the fur? What are the body proportions? What’s a natural posture?

At the same time, I took mechanical inspiration from a line of Japanese animal robot toys, Zoids, but diverged from this when I started studying real feline joint structure. Still, it was natural for a future robot pet to share a bit of the style of these futuristic toys.

The Skeleton

Over the last 30 years I developed my building technique as a means of making larger, stronger models with fewer parts. Rather than sculpting a solid mass of bricks, I engineer an interlocked Lego Technic beam skeleton, which is then covered with a plated skin. I call it the “skyscraper technique.”

For a robot, the skeletal sections are connected by joints, and these are the focus of intensive design iteration to satisfy three critical needs: 1) range of motion 2) force resistance 3) an accessible user interface. (Attempting to satisfy all three of these requirements usually results in a bin of rejected joint prototypes, which I keep assembled for future use.) For the knee joint, I thought I had a perfect joint package using a worm gear drive, and I was so delighted that I called it a “fun pack,” but testing showed that the plastic gears could slip and wear out, and would be difficult to replace in the finished structure. In addition, it takes a lot of strength to support a two-foot-tall, three-foot-long model. So this went into the reject bin and I switched to linear actuators, making the joint like a triangle with one adjustable length edge, which is very strong.

The complete skeleton has 15 articulation axes driven by these actuators, six axes driven by the worm gears, and six axes with no drive mechanism since they are perpendicular to gravity and friction suffices to control the angle.

The reject bin is also filled to the brim with failed neck and shoulder joint designs.

The Skin

I wanted to use highly reflective, curved parts so the model would have a luxurious shine. While Lego comes in many colors, they don’t produce all parts in all colors. As it turned out, the most appealing color with the largest variety of curved parts was blue. Yellow is a great accent color, and I wanted to use all yellow teeth. But there was an issue: Amazingly I could only find the small teeth in Europe, via www.bricklink.com, for a sum that offended my sensibilities. (As a side note, pro builders don’t buy entire Lego sets. Other people buy full sets and sell the individual pieces on BrickLink. I couldn’t build on the scale I do without it.)

Other design notes:

- I had the idea of making the skin adjustable via articulation, so the overlapped plating from the neck to the waist is attached with dozens of ball-and-socket joints.

- I wanted the model to have a sinuous flow from nose to tail and accentuated this with a pronounced spine, also linked with ball-and-socket joints.

- There are two deliberately skinless patches on the underside between the front and back legs to serve as safe lift points when moving the model.

- The tail looks very lively and invites being played with, though this is not recommended as it is held in place with less robust “click” hinges. Ping grabbed for the tail when she saw Geo for the first time, but she can do that. This is her pet from the future.

The Project

Overall, Ping’s Geo project took one year to complete with as much time spent on engineering as artistic styling.

Public exhibition is always a great way to conclude a long-term project, energizing you for the next year’s epic build! Geo will be displayed at BrickCon 2013 in Seattle, Saturday Oct. 5 and Sunday Oct. 6.

ADVERTISEMENT