For decades, humans have imagined, even come to expect, life-size humanoid robots in their future. The sober truth is that such robots are extraordinarily complex mechanically, the intelligence to reliably bring them to life is still outside our grasp, and the cost of building such thinking machines is prohibitively expensive. But while we’ve been dreaming of our own C-3POs to clean up our crap and serve us dinner, something significant has been happening.

The technical communities of the internet have been growing, the Maker Movement has been rapidly expanding, the price of high-tech hardware needed for such sophisticated machines has been rapidly falling, and technologies like 3D printing and CNC have moved towards the mainstream. All of this has created something of a perfect storm for a new kind of crowdsourced robotic development.

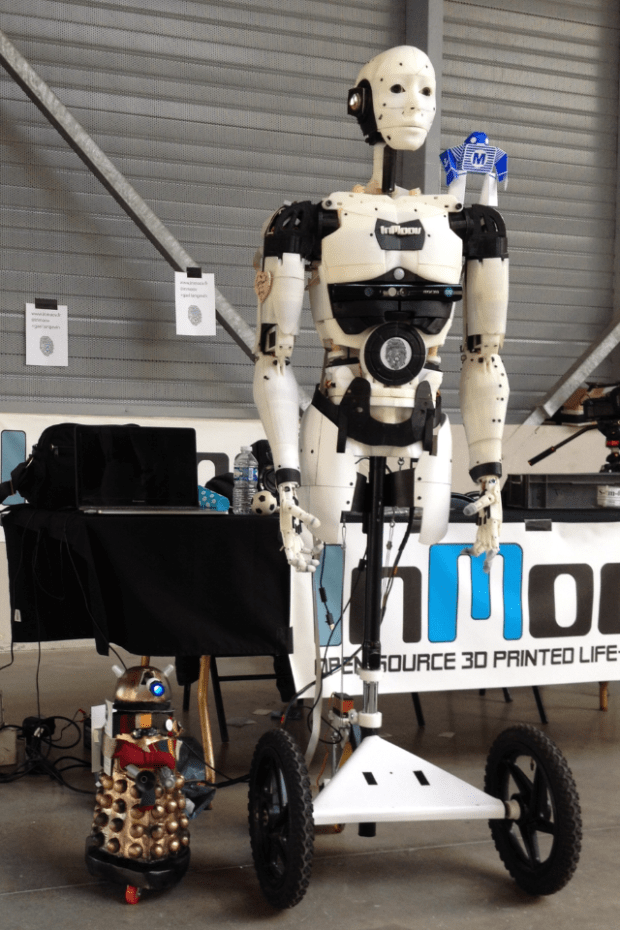

One of the most exciting projects currently using this crowd-based development model, with impressive results, is Gaël Langevin’s InMoov. Gaël’s open source, 3D printed humanoid has become a regular on the Maker Faire circuit and has even landed him on the cover of the current issue of Make: (well, his robot, anyway). Langevin and the InMoov robot just recently wow’d another crowd at Maker Faire Paris last week and now he and his robot are on their way to the Bay Area for next week’s MakerCon and Maker Faire. We thought this might be a good time to take a deeper look at the InMoov project and the Maker behind it.

Langevin was born into a family of creatives. His father is an artist and his mother is a decorator who also built the furniture that adorned his childhood home. At the age of 9, Langevin built his own pinball machine out of cannibalized record players and lights. At 12, he convinced his brother to pool their Christmas money to buy a welder. He wanted the tool so that they could build their own go-kart. Soon, Langevin was also making his own props for the 8mm movies that he began shooting at the family’s country home in France. He went on to study fine art and sculpture, eventually landing a job as sculptor, mainly doing commercial work.

Langevin sort of stumbled into the InMoov project. He had gotten a 3D printer for fabricating parts for some of his commercial jobs (he already had a CNC machine for the same purpose). A client asked him to bid on a job to 3D print and build a prosthetic hand. The deal fell through, but it had already gotten his creative gears turning, so he decided to design and build the hand anyway, in his spare time, just for the challenge and the fun. He’d been fascinated with the mechanics of the human hand ever since he was that precocious boy, who’d made plaster casts of his own hands. In October of 2011, Langevin created his first 3D printed hand, and in January of the following year, he posted the design files for the hand online and the InMoov project was born.

Going open source was only natural for Langevin. “Sharing the parts with the open source community was a logical route for me,” he says. “I have been using Linux for years, the open source Blender program as my 3D graphics software, and my first 3D printer was the product of an open source project.”

“The InMoov hand sparked the early pioneers of the 3D printed open source prosthetics movement,” says Matt Griffin, formerly of Makerbot, now at Adafruit. “It provided evidence to what would become the RoboHand and eNABLE project communities that 3D printed limbs were mechanically possible on a low budget.” In turn, Langevin himself would become part of this movement he helped inspire. “I circled back around to actively participate in the open prosthetics movement, particularly in the Bionico project,” he tells Make:.

From the modest beginnings of that hand, the InMoov robot has grown, up the arm, into a neck, head, second arm and hand, and a torso. Legs are not designed yet, but Langevin has recently given InMoov a temporary wheeled base. This allows the robot to move around and more casually interact with people. For hardware the InMoov, as it stands to date, employs 28 servomotors and 2 Arduino Unos. The number of people currently building InMoov bots and feeding their development efforts back into the project is impressive.

So far, the robot has been reproduced in more than 55 countries, in at least 50 universities, and in Fab labs, hackerspaces, and in individual garages, basement workshops, and kitchens. Langevin estimates that the number of InMoov clones currently stands at around 180-200. The files for the hand have been downloaded more than 70,000 times.

Langevin’s InMoov robot is quite the globetrotter. He’s been to six Maker Faires, from San Mateo and New York to Paris and St. Petersburg, and his clone brethren have made an additional 16 other Faire appearances, including the White House Mini Maker Faire last June. Langevin will be one of the presenters at MakerCon next week, May 12-13. And he and his robot will be at Maker Faire Bay Area 2015. Something unique happened at the Paris Faire. It was the first meet up of InMoov robots from around the world. “It was the first time I gathered five InMoov robots,” says Langevin. “And they all came from different countries, Italy, Sweden, Netherlands, and France.” He adds: “It was very interesting to see and hear stories from the builders and to see the affection they all had for their clones, due to the fact that they had built the robots themselves.”

For the Bay Area Faire, Gaël is looking forward to getting his robot back among the people. “In Paris, we were on a stage for the first time, he says. This created a distance and many people felt too uncomfortable to come onstage. “For Make Faire Bay Area, I asked to be without a stage,” says Langevin. “InMoov needs to be among the people to be understood. Humans are social creatures and need physical contact to lessen their apprehensions.”

The InMoov project has come a long way since the first round of plans was released, only 2½ years ago. But there is still a lot to do. “Building the legs remains a big challenge,” says Langevin. “I’ve designed two iterations already. But since I use my personal income to buy components, I have to be careful with my choices and can’t do all of the tests I’d like.” And he has the design constraint of needing to build something that others can easily replicate. “Creating legs within a very low budget, legs which require speed, precision, and to build with parts that are available throughout the world, is a real challenge,” he adds. Langevin has gone to great pains to keep the entire project affordable. The top half of the bot costs around $1,500 to build. He wants the bottom half to cost around the same.

The other big challenge is, not surprisingly, InMoov’s “intelligence.” Langevin and the InMoov community are currently working on improving MyRobotLab (a project headed up by Greg Perry), the open source program that brings InMoov to life. “We are currently focusing on two major improvements to the robot. First, a calibration solution so that all of the InMoov clones will be able to share their new features, gestures, and knowledge with each other. And second, to begin programming a basic system of Artificial Intelligence. AI is, of course, a very large concept and I should be careful with what this means. At this stage, we’re looking at a basic Siri model. But we can get great results with that. And the fact that we can have a robot decently interact (and in a sense converse) with someone is pretty amazing!”

Langevin sees the InMoov project as a great way for those curious about robotics, computer programming, 3D printing, and mechanical engineering to take on a project that is scalable. Just as he did, you can start by building the finger, then the hand, and then keep going as long as you’re interested. There’s a whole community of enthusiasts waiting to help you and to have your help. “I believe that having a worldwide community building a robot is a much smarter and safer way for humanity to approach the robotic future,” he says. “Start with a finger,” he adds. “And one day, when your robot is reading your kids a bedtime story, it might just say, “Why, when I was a little finger….”

Somehow, it seemed fitting to give the last word to one of InMoov’s clones, Robyn, built by Markus Örngren, a contributor to the InMoov project. Here, Robyn says hello and answers some commonly asked questions. And if you think Langevin’s fantasy of your future robot reading bedtime stories is farfetched, Örngren has a video on his YouTube channel of Robyn doing just that.

You can learn much more about the InMoov project on its website and Langevin’s YouTube channel. And, if you decide to get involved with InMoov, we’d love to hear about your efforts.

ADVERTISEMENT